Archive

Madness…

28 March 2012

The Mechanicsburg project which is about to run out of cash due to unforeseen ground conditions opened my eyes again today. I asked whether or not it might be possible to get the contractor to agree to allow the Corps of Engineers to resolve the issue. The logic being – there is no budget here to allow contractor to to remove the rock, therefore project will come to a halt and become a big white elephant and contractor will not get the work / money he wanted. I suggested trying to get a ‘training exercise’ for the green skins to do it from one of their training budgets and get their kit dirty for a change, thus allowing the existing money to complete the job and thus the contractor gets a bigger lump of cash and we don’t end up with a big white elephant……..you’d think I just crapped in their swimming pool by the response I got. Enough said. It’s just as barking mad as it is in the UK.

Carson Roberts – Horizontal drilling promotional material

Not the video I wanted to show you – but shows the same company on another project doing the same thing but bigger.

Boring……

27 March 2012

Intro

Another day another site. Today it was a 3 hour…yes…3 hour drive one way to see a drilling site in Towanda, PA. In order to help their town prosper and grow / expand on the North bank of the Susquehanna river the town folk have dug into their pockets and joined forces with the federal government (part of Obama’s stimulus package) to install a water main under the river. This will connect fresh and foul water supply to the far side so they do not have to rely upon storm drains and septic tanks. Department of agriculture has stakes in this small $1M project. Project is currently 1 month behind schedule and this is the contractor’s first project with USACE. Total length of bore is 1600ft (480m)

Conditions

Loose silt by river sides – line of pipeline runs under 1 x railway and a road. Extensive ground investigation material available from PENNDOT (Pennsylvania Department of Transport) when the nearby road bridge was constructed.

Method

Large diameter steel sheaths hammered into the silty layers to prevent ‘frac out’ of the drilling fluids (bentonite) when drilling starts. Will try and attach a video of how it”s done. Once the sheath is in place a drill will be steered along the required path using electromagnetic positioning (all except in the middle of the river where they will be going ‘blind’.) The drill is extended out using flexible shafts.

Once the drill emerges at the far side of the river, an auger will be dragged back through the bore hole to widen it. The process will be repeated until it is the required diameter. At this point the plastic piping will be dragged through the hole to form the completed pipe line.

On site

Very few personnel required. Picked them up for not providing cover from view between the public and the welding operation. PE concurred and added to daily report accordingly. Witnessed a full rotation of positioning of steel sections, welding and driving before the 3 hour drive home……The process is likely to be repeated until the full depth is achieved at which point drilling will commence. I don’t think there will be much to see until the drill emerges at the far end and some more exciting engineering can begin.

Asside

The CEO of the company did not appreciate the fact that I found his video most entertaining. The fact that the word ‘boring’ appears repeatedly to a really intense soundtrack seemed incongruous to me.

It’s all about personalities….

21-23 Mar 12

Having had a chance to see the Ashley reservist centre site again there is some noticeable difference in the pace of work and there are actually more people on site, but still not what you would expect of a contractor who is working to try and recover delayed schedule. A few more things have become clear also – the main thing being that the contractor representative (CONREP) is adversarial with the contractor and this possibly also explains why there are communication breakdowns. We sat in a progress meeting where the CONREP hit them with deficiencies they had never been made aware of previously. Blind siding the contractor in a progress meeting with deficiencies does not promote good will or mutual understanding. The CONREP has told me now in private that he would like to shut down the contractor for failure to meet the quality control criteria and some health and safety issues. He takes photographs and sends them direct to head office to get their opinion (The equivalent of going 4 up to us!). The contractor was certainly using the right language that would engender at least the impression of mutual cooperation, but this was met with a stony silence from the CONREP. (I will stop talking about this individual now incase this ever gets leaked and I get sued!….but you can imagine I have clear opinions of whether this individual should have been retired a long time ago.)

Now pan out and scroll across to another reservist centre in Mechanicsburg. It is the same type of building and is also awarded on a design – bid – build contract. There is a similarly slow pace, not because of constantly changing staff but because of unforeseen ground conditions that have led to USACE having to go back to congress for additional funds. There is perhaps a month or so of funding left before the contractors will have to be told to down tools until additional cash is sourced. There is a team at work trying to figure out if the requirement can be adjusted to accommodate at least some finished structures that will add value to the existing facilities. The CONREP on this job greets the contractors with a huge slab of elk meat that has been shot by a co-worker and an impromptu afternoon bbq is arranged. All the workers take 20 minutes off to come eat burned meat and talk about women, beer and cars. Progress is discussed and the contractor confirms that the last punch list (snagging list) items have been addressed and offers the papers to prove it. Afterwards a brief walk around identifies more items for the punch list and the principal contractor immediately tackles the sub contractors involved. One of them is on a second warning for not having a non-return valve on an acetylene torch and is warned that a further infringement will result in him being removed from site, but nobody falls out because of the manner in which he is told…..clear…direct…factually…not personal. I found a strip of spent percussion caps from a nail gun and pointed it out to the CONREP (trying to be helpful). The strip is tossed to the ‘superintendent’ (the site manager) with a playful quip that it’s a $1000 fine for every cap (spent or not) according to the contract, meaning the guy is now holding a $10,000 fine in his hands. The superintendent disappears to find the offending subbie and the CONREP is happy that it won’t happen again.

So what is the main difference between the two projects that really ought to be the same? It’s the working relationship and how the rules of the contract are enforced. You can smash the contractor until he is in a position where he is underfunded, on the back foot, off guard and becomes more and more open to further criticism until the project grinds to a halt. Alternatively you can work together, cut him some slack when it’s appropriate and keep them all on side in a spirit of mutual cooperation. Both projects are failing for very different reasons, but the difference is that for one them it is not necessary!

Wanted to take some lovely pictures for you guys to see – but I fear I might just get arrested. No photos allowed on a military base I’m afraid. I need to get a media pass and show all pics to the guard staff on departure….but what they don’t know can’t harm me. Will endeavour to indulge in subterfuge for the cause.

26 Mar 12

Contractor on the Mechanicsburg site has been ‘blessing’ the concrete pour as high winds were making a lean mix difficult to finish. CONREP has informed them that if this develops tension cracks they will tear out and replace at their own expense, but again, no love lost. I am fascinated by the fact that the client’s representative on site is expected to be an engineer and a clerk of works at the same time. He carries a specification with him for the job and is expected to do all the tasks that would be expected of the clerk of works. (I for one would not have spotted the missing non-return valve on the acetylene tank). I think it works though because the contractor is responsible for the Quality Control issues with the CONREP and PE focusing on Quality Assurance so the checks should be for back up anyway.

Have completed the first of my compulsory training……drug abuse and suicide. I thought I’d be free of MATTS for at least a short while!! Apparently if you suspect someone may be having dark thoughts you have to just come right out and ask them. I have been asking the office repeatedly if they are thinking of killing or harming themselves as a precautionary measure.

Vehicle registration fail….doh. But on the plus side, child number one has been safely deposited state-side…..doh.

Tunnels, Rock Wheels, Water & More Water…!

Update

Temporary Sump. For those have been waited with baited breath about the outcome of temporary sump and drainage at the base of the Approach Ramps, I am afraid there are a few more sleepless nights ahead (sorry Ros!). The works are still on hold pending the Designer’s decision about the final design based on the CPT results. The CPT results confirmed the soil stratification, and confirmed the extremely poor nature of top 3 metres of soil, as well as the varying degrees of consolidation within the Terrace Gravels. The sumps remain installed and the contaminated water in the East is being diverted into a sewer, and the water in the West is overflowing onto the invert slab and into the tunnel. Silt migration is evident from the deposits being left on the invert slab. However, until a design decision is made, the sumps will remain.

CFA Piling on the surface continues however with only 1999 left to go!

Why a Plan Never Survives Contact with Commercial

Whilst, I remain slightly vexed by the lack of flexibility instilled in ‘can do’ teams, as a result of the commercial and contractual handling of works, I am coming to accept, (albeit a little begrudgingly) that in the current climate, that will not change. Three distinct but commercially linked examples:

Contract. Having spent considerable time and effort planning for the Temporary Services Sub-contractor (VVB) to start works on Monday (de-conflicting works, scheduling subsequent works which cannot start until power, lighting and ventilation and pumps are installed), I was then informed that certain parts of the contract had not yet been agreed. Despite the VVB Project Manager being able, and willing to start the work which had been agreed, and admitting that there were alternative methods to undertake the works currently under dispute, the ‘collaborative approach’ stipulated by NEC all too often falls victim to commercial risk aversion.

Release of Information. In a similar way, the Drilling & Grouting Sub-contractor (Bachy) arrived on site to co-ordinate his works, to find that his scope of works had changed, which had a significant impact on his programme. Whilst the Contractor knew about the change 3 weeks prior, they chose not to inform Bachy, not wanting to risk delaying the start date (due to Olympic closure restictions). Whilst, Bachy will obviously get paid for the additional work, the early release of the changed scope would have saved considerable time and planning effort, and may have avoided what will now be a later start date in any case, and subsequent time pressures. Whether or not releasing this information before Bachy had confirmed their project documentation would have further impacted on the start date I do not know. However, I have learnt that the military adage of ‘never sit on information’ is not always applicable where money and contracts are involved!

Consultant Advice. VINCI’s Geological consultant (Bob Allen from London Bridge Associates – he has a friend who knows you John!) was invited in to discuss Temporary Works Design with the Temporary Works Co-coordinator, the Project Manager also asked that I take him on site to assess and advise on existing and potential water issues. We spent 2 hours walking the site and tunnel, and his depth of knowledge, acute appreciation of the affect of history on the structures (e.g. the presence of original formwork and sumps beneath the retaining walls), and prediction of existing conditions was both intriguing and relevant. Equipped with this enlightenment, I could not understand the logic behind certain permanent and temporary works designs. Clearly having been paid for his time (which for my education as the Approach Ramps and Tunnels Section Engineer was invaluable), I was surprised at the relative lack of action resulting from his visit. I was soon educated, and it has since become apparent, that the only area of financial risk to VINCI is Temporary Works, and the Clients owns any damage as a result of construction in accordance with the Client’s Design. It is therefore not in the interest if VINCI to take (or suggest) any corrective action, or indeed make any changes to the agreed methodology unless instructed to do so, which normally results from something not going to plan, or a design risk factor becoming too high.

Permanent Works

Concrete Invert Slab Re-profiling. From the base of the approach ramps through to the twin tunnel interface at the centre of the tunnel, the base of the tunnel comprised the original concrete invert slab, a gravity brick drainage system, ballast, sleepers and track. All material has now been removed down to the invert slab. The next stage is the preparation of the invert slab for the installation of the final track slabs upon handover of the project. In order to achieve the correct design level and profile, two methods are being employed. One is the complete replacement of the concrete slab in 1.5m bays immediately adjacent to the twin tunnels (30m West, 140m East), and the other is the re-profiling of the slab. A sub-contractor will carry out the replacement, and (following Drilling & Grouting and Dewatering) the re-profiling is being carried out by the VINCI.

Stripping out of the existing ballast and drain

As the Approach Ramps & Tunnels Section Engineer I am responsible for planning, coordinating and enabling all of the works, and in the case of the re-profiling carrying it out. Two trials took place to establish the most effective, accurate and safe equipment and methodology. A Rock Wheel attachment to a 21t excavator was selected, and manual setting out and checking is currently deemed as the most suitable means to ensure levels are within the Designer’s stipulated tolerances. The works have started and are progressing well, although the setting out and monitoring is time consuming for my Site Engineer, as is the checking for me. We are looking into alternative monitoring systems – thought I may look up Margaret Beach in the Survey department to seek some advice (I know she was keen for a field trip for the survey students!).

The Rock Wheel carrying out re-profiling

Clearly no works on this project would be complete without water, and the re-profiling does not disappoint. As a result of excavating concrete away from the existing concrete retaining walls, the surface area for seepage has been increased, and the flow path, permeability (due to removal of a relatively sealed surface) and opposing pressure from the slab has been reduced, hence the volume of water flowing onto the re-profiled slab has increased significantly. The presence of water on the slab makes re-profiling more difficult, and a temporary pump is being used to clear the surface of water until a temporary sump and drainage system is installed in the single tunnels, at the end of the re-profiling section.

A pump is used to divert additional seepage away from re-profiling area

Temporary & Enabling Works

Sump and Drainage System (Part II) The aim of the temporary sump and drainage system within the single tunnels is to prevent any water flowing into the section where the concrete invert slab replacement is taking place. This will enable the construction of the Drilling & Grouting Rig Platform and subsequent grouting works, followed by the replacement of the invert slabs. It will also negate the requirement for the central sump and Pump House, in order that they can be de-commissioned and reconstructed. It also solves the environmental constraint that no construction water may be pumped into the Docks following installation of a temporary drainage system and requisite permits to divert the water into the sewer system.

The main constraints in design of the sump, is that it cannot be dug below the final slab design level, allowing only a shallow basin, well below the 700mm submersible pump originally ordered. Identifying the critical issue here (all this critical analysis is clearly paying off!) I requested that the VVB pump specialist come and scope a more appropriate pump. He has changed the order to a suction pump with a skirt, upon which I will base my design. I have also proposed the installation of weep holes in the existing slab (as per the final design slab) in order to relieve the water pressure under the slab and control seepage during construction (likely to sit in the wait until instructed category I suspect!). The construction of the sump will start immediately following re-profiling….which can take place as soon as the Rock Wheel can access the tunnel…which it will be able to do as soon as the Tally Huts (and generators) have been re-sited… which can happen as soon as the stagnant water by the generator has been disposed of……which can happen as soon as the sewage permit to discharge arrives…. not forgetting the permit to disconnect the generator….. the Crossrail submissions and acceptance procedures… the lead-time on the pumps…. and VVBs contractual hitch preventing them from laying any drainage pipe…..!

So What & What next?

A number of works packages that were neatly programmed during the tendering process, have gradually changed in scope as the full extent of the works and issues has emerged. Contractual arrangements and delays, as well as non-adherence to strict Crossrail procedures have had a significant impact on start dates. As a result a number of works packages are now due to overlap and critical path aspects are still yet to be confirmed, such as the installation of power. I also don’t believe that full consideration has taken place as to the impact of re-profiling on the existing structure, already reflected by the increasing scale of movement measured by the retaining wall monitors, and set to increase as works move further into the tunnel.

So what next? Continue with the re-profiling, (the risk of any adverse effects sit with the Client – am I becoming a contractor?!) and deal with the water in preparation for Drilling & Grouting. Generators and ‘Rent a Vent’ (yes it is actually called that) can substitute the installation of mains power and ventilation, but a fully functioning sump and water diversion system is critical.

Aside from that, keep the Rock Wheel within 45mm tolerance of the final design slab level, keep planning plans that never survive contact with commercial, remain flexible and prepare for change…and more water!

Maybe we could enlarge the tunnel enough for boats to pass through instead?!

Supervision, a spoon drain and SCAB!!

Period Covered 20 -23 Mar 12

Summary: Supervision, a spoon drain and SCAB!!

Work as a supervisor has begun in earnest with safety (monitoring on site, paperwork audits etc) and sub contractor co-ordination my top priority. I am understanding how the site operates, meeting the sub contractor supervisors and building a working relationship with them

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk excavation and pile cropping

- Risk Assessment and Hazard Inspection Audit

- Co-ordination/supervision of Union Rep

- Service tunnel spoon drain – liaison with design team and contractor (contract dispute)

- Reports and returns – Site Diary etc

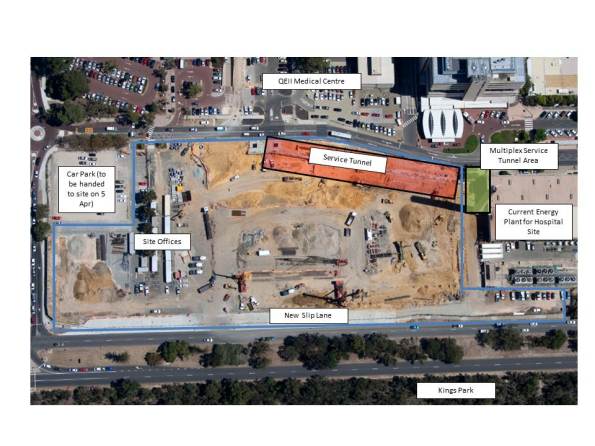

Aerial Photo

Work on site. No Change – less GMF (cropping pile team) and Crown (concrete capping beam team) contractors have been stood down until Wednesday as a result of safety concerns in order to allow adequate working space between piling and other contractors.

Issues. Considering the site has been going for only 10 weeks there seems to be a growing number of problems. The highlights are:

1. Congestion of Site/Possession of Northern Boundary by Multiplex. The first milestone on the project is to handover a new service tunnel to link the services to a new constructed energy building. This is driving the programme and the focus is to deliver the first stage of the tunnel to the client on 2nd May and the whole thing on 29th May.

However as a result of the client handing the most northerly section of the tunnel to another contractor work in this area by JHG sub contractors has been severely restricted. In an attempt to catch up time the piling, pile cropping and capping beam contractor were all compressed in the same area. This led to lots of co-ordination/in fighting with the sub contractors (good work for an army officer acting as a supervisor). This went on for 2 days until a call was made that it would be safer and more efficient to pull everyone less the pilers away from that area.

2. Spoon Drain. The service tunnel has a spoon drain at the bottom of it to collect and drain water running along the inside of the retaining piles. This was a detail which though pretty simple I spent a lot of my time this week dealing with. Until I got involved there were no dimensions or levels for this, and it took a lot of going between the Architect and the Structural engineer to determine who was responsible for this detail and to get the required dimensions.

Along with this the earthworks contractor initially refused to do the detailed excavation required for this work and it took the involvement of the Works Package Manager, the contracts administrator and myself to get to the bottom of it. It transpired that detailed excavation was not included in the Lump Sum part of the contract but was included 5 sections later under a schedule of rates section….problem solved after a bit of tension.

3. Trade union relations. Australia has a very different set up with powerful trade unions which are normally part of/affiliated with construction companies. John Holland has a different view and believes it can have a better relationship with its workers directly. This seems to work fine, less the relationship with John Holland and the Union Reps. Recently on site the Reps are coming on site to cause trouble and on one occasion the police have been called. As a supervisor I was responsible for babysitting the Rep during his last visit to site and ensuring he followed the rules. Interesting but a little weird!!

4. Oh Shit we hit something. Initially on site there were many services crisscrossing site and these have mostly been removed with a plan to remove the final few in the next 10 days. On Friday however whilst excavating the service tunnel a 150mm water pipe was struck and water released onto site. Emergency plumbing works will finish the diversion of this sewer over the weekend and the site was lucky as the water was “clean” (cooling tower condensation water) and will easily disperse in the Sand. Of more of a concern is that there is a High Pressure Gas main in the north of the site which we are still waiting permission from state to relocate….lets hope we don’t hit this!!

My Experience. I’ve been amazed at the speed of progress on site. The excavation progresses at 100 trucks a day as well as 10 CFA piles per day. My role has developed with me deputising as site manager on my third day, as the real site manager was on a training course and I have worked more with the engineers, trying to sort out the spoon drain detail – this has also given me some commercial experience and my initial naive thoughts of working as a team have been banished as commercial arguments have occurred this week.

I have observed the difficult role a managing contractor has. There is a balance bewtween a working relationship with the subcontractors and acting in clients and John Holland’s interests. This becomes evident with Safety v productivity issues. My view is that John Holland as an excellent paperwork system which should ensure safety on site and this understood by the Engineers and the Management but there is still a core of Supervisors who see safety as getting in the way – this will mean a constant battle to keep on top of this.

Finally, I have realised the importance of sketching. This is how I have been communicating with all of the subcontractors this week. Whether it be simple site plans or more complicated design detail being able to sketch quickly and clearly is obviously an art which I need more practice at!!

Week 2 – 19-24 March 12

This week I have mostly been finding my feet (try and say it like the fast show character). With the arrival of a mobile phone, a temporary laptop and having acquired a desk by buttering up the PMs PA, I have commenced working. At the start of the week it was a bit slow as we moved into our house and I had to deal with the removals arriving, but from Wednesday on it was all work, work, work. Well at least until 11am when the heavens opened and we had 120mm of rain in 2 hours. Oh how I love my scooter in the rain, particularly when water creeps into the engine and it keeps stalling!

Rain does not however stop the office which continues to be a hive of activity until about 2pm on a friday when people start to sly away for flights home if they’ve got Saturday off. This week I am not so lucky and am on the saturday shift but at least it’s an early finish with an 8 hour instead of 10 hour shift. It’s also giving me the opportunity to write this!

My roles and responsibilities are slowly taking shape and I’m running with the enabling works for the traveller to construct the jetty. We had our first meeting with a contractor this week and I will take the tender forward for revision of the scope of works before advising my package leader as to when to award the contract. This is only a measly $250,000 but it is something none the less and I am happy for it. I shall be looking to squeeze the contractors price in order to maximise profitability balanced against the fact that we still don’t know when the start date will be. We are waiting on Bechtel to issue permits for construction and from that point it will take about 8 weeks until the first boots on the ground.

I have also been tied up in classic Sqn 2IC business, proof-reading the work of junior personnel. The project plans (there are numerous including, traffic, safety, environment, etc) all need to be submitted for signature by the PM before being approved by Bechtel. I’ve been going through each of these in turn and conducting the proof reading, re-formatting, etc but it does give me a strong understanding of the project. I have also been amending accordingly, adding what engineer value I can where appropriate. Disappointingly they do not conform to JSP 101 but they will by the end of April when I’ve finished with these docs! The package leader is semi-impressed with my OCD and attention to detail but would probably prefer me to be a bit quicker.

In terms of engineering, I’ve not seen much as yet as the Jetty project will not be starting until May. However, the commercial side is ramping up and I’m going to be getting ticks in those boxes at least. I am going to be responsible for the test piles and their testing and to save money I am currently trying to use existing pile cut-offs that would otherwise be sent for scrap. The concept is to weld sections together in the hope of saving on the outlay for a 40m length of 1200mm diameter, 25mm pile. This might work but I need to do a bit of work on the strengths of welds, etc to ensure that they don’t fail in the testing. Watch this space.

I’m also designing (well on a fag packet as John would say) a concept pile cut off platform by bastardising (technical term on site here) a 3 pile group platform that was fabricated and not used on the MOF project. This is a work in progress and once I’ve done some calcs and with a bit of builders eye, I’ll hopefully be able to send my design off to the fabricators for said bastardisation!

Moving to off-site matters, I have spoken with John Reddie this week who was keen to learn from our transition from the UK to Gladstone. We certainly had a better one than the Marsh family but I suspect it was more to do with personality on my side and subtle/gentle persuasion as appropriate. That said, the PM won’t let me have international dialling on my phone! I’ve also been in contact with a communications executive (media man) from JHG who met me on a site visit. He’s going to run an internal JHG piece on me (us – I let him know of Steve, Ros and Dan’s existence) so there may be more to follow on that.

Family is all well. Lisa is now 35 weeks pregnant so the final push is getting ever closer. She is more relaxed now with us being in the house which is allowing me to focus on work. It’s long hours so we don’t see each other much in the week but any more and I might spoil things! Lisa has successfully filled the house with tat and I’m amazed at how much she sent without me knowing, particularly cushions, throws and bunting! Most importantly though is the fact that the kids mountains of toys are here, my dive kit (not that there’s any dive clubs in Gladstone as it’s only in the barrier reef national park) and of course, Austyn’s birthday presents!

All-in-all, life is good. More of the same is to follow and I’m still enjoying it (apart from the 4am wake up call). No photo’s as yet as I’m awaiting permission from Bechtel but this should be through soon. Otherwise I will set up a covert OP and they’ll never even know….

TTFN,

Roy

Progress…..

12 hours later – success – Common Access Card in hand and hopefully the paperwork is queued up for Ben Hancock now as well.

Vehicle fixed without requirement for payment or for state police to get involved.

Next up – compulsory computer training with USACE, medical registration for family, driving tests to be booked and then any other hoops they want me to jump through….come on USA – what other admin you got!?!?

The Fry Clan finally re-enters the 21st century…

Since arrival in the states the administrative machine has been quite impenetrable. I was keeping a mini diary on the ipad using a mobile connection but now that we have a proper full-fat connection I can consolidate the previous stuff as follows:

- Office call in Baltimore office. Met HoDs for design phase but am unlikely to meet any of them again for 8 months.

- Cel phone available – call 001 443 805 9636

- Cac card not ready. No ssn. No car. Many admin problems to resolve. (No CAC = no access to bases or access to IT facilities)

- Col Anderson is championing our cause and is very on Side. Understands our situation and is keen to ensure we get what we need out of theattachment.

- Have collected project docs for HQ project in Harrisburg.

- Light rail commute to Baltimore works well.

- Am repeatedly being asked if i am Australian…..

- Strongly recommend future US attachments come out early to avoid admin issues. Can not apply for social security number until have been in country for 10 days. Remaining 4 days insufficient to work outremaining admin. first week at work will be affected.

14 Mar

- Still chasing CAC(Common Access Card) and SSN (Social Security Number). Must identify a system of ensuring our future officers know what to ask for as the staff here do it so infrequently they do not process correctly.

- Had first experience of Maryland Vehicle Authority…….madness, but now have 1 set of wheels for travel up North to Harrisburg.

- Had initial orientation of Harrisburg office.

- Have volunteered to participate in the USACE outreach program to visit schools and promote science and engineering.

15 Mar

- 3 hour drive to deepest darkest Pennsylvania to visit a Reserve Centre. They are closing down smaller centres and consolidating them with larger, better equipped centres that cater for a larger area. The project is approx 25% complete.

- Contractors have changed personnel and so have USACE and the result is a birds nest of previous decisions / omissions with errors on both sides. I see a complete lack of communication, an overworked junior project engineer with little support from above or any ability to delegate. I believe the contractor is taking advantage of the ‘mess’ and is not pushing for resolution to submissions (as they get compensation after 30 days). I made a point of keeping quiet in the meeting as I clearly don’t know the procedures yet but chose to ask questions privately after the meeting. I also noticed a complete lethargy on site and very few workers were present. To me this site is not being recovered, considering it is behind schedule.

- Also visited levee systems to see how they work.

16 Mar

- Am now the proud owner of a SSN…..not that it helps with getting utilities to the house. They now want notarised copies of all my docs……

- Had further orientation of USACE Harrisburg office.

- Had orientation to New Cumberland Depot and specifically some new builds and a steam plant.

- Raised concerns reference Reserve centre problems with another engineer who is removed from the project. He confirms that the issues I raised are relevant but advises to wait a while before wading in. Will address diplomatically.

- Weather is gooood.

- Local radio is much better than uk. Have plumped for 98 rock! It’s the sound of Baltimore and helps make the 1hr 15min commute each way a little more tolerable!

19 Mar:

- Issues with new vehicle purchase. Chased though state police. Need to return to Virginia.

- CAC issue running in circles.

- Met with area officea manager.

- In depth discussions ref contracts used at usace.

- Discussions ref Ashley project. Reserve centre with many issues to resolve.

- Contact info with proposed home tel number etc passed up.

- Still no joy finding a Harley.

- Proposed HQ project on hold – will have to get involved in some levee projects that are being queued up.

20 Mar

- Conducted admin ref submissions. All logged in diary for area managers to see and help identify peak periods.

- Met Remi – another office manager who is in charge while Dawn Conniff is away playing soldiers.

- Have come up with alternative plan to acquire CAC via embassy. Will require trip to Washington which would also tie in nicely with vehicle admin required. Will have to go to Virginia to Fort Mead(?) for issue.

- Observed bottom of chain with reference to submittals* to see how they are processed.

- Still no utilities in the house (result of not having SSN until recently)

*Submittals:

USACE is structured and geared so that the project engineers work closely to a fixed set of rules and procedures. Their idiots guide to project management reeks of the APMP course that we did just before heading out here. Submittals are the formal way in which the contractor brings any information to the attention of the project manager. There is a computer system called RMS which tracks the progress of each submittal (which could be literally anything related to the projectr.) This system acts as an audit trail and enforces the role of USACE in the Quality Assurance role, leaving the contractor responsible for Quality Control. It seems to be odd that the contractor is self policing in terms of quality controil but I am assured that USACE makes it work…..

21 Mar

Re-visited Ashley (Reserve Centrre) project to see what progress has been made. Many issues with the submittal process were resolved betwene the PM, his supervisor and the Contractor. Contractor seemed very tuned in to the language that USACE wants / needs to hear. It is clear that there are still serious communication issues and in my mind it is crazy that the project manager on this particular site is not authorised to make decisions that will expedite the construction and allow progress to be made. 6 hours of driving today has left me lacking in horsepower.

All in all it has been a slow process of bedding in and there are still many administrative issues to overcome. Tomorrow will be spent at the embassy trying to resolve. I expect that next week will see some advancements (after I have completed the obligatory on-line training……[bangs head on table repeatedly])

Initial Start on Site

Period Covered 16 -20 Mar 12

Summary: Initial Start on Site

I have now started on site and my initial impression is that it is a great time to start. There are currently only 12 JHG personnel on site (Engineers, site manager, supervisor, H&S, Labourers) and approx. 60 sub contracting personnel. By October there will be 1000 people on site!

During this period I have completed the following:

- Meeting with Site Engineer and Manager

- On Site Induction (4hrs)

- Initial situational awareness, familiarity with site and subcontractors

- Right Of Entry/Union Training

- Meeting with QA

- Handover of duties as supervisor

Orientation to Site: (Server error on site, site plan and aerial photo to follow)

200m x 100m

Photos

1. Showing the congestion on site and the importance of co-oridnation and safety of subcontractors on site

2. Showing the start of the basement construction

3. Showing the problem of not using a debonding agent when breaking out the blinding layer

Work on site. The focus on site currently is five things:

- CFA piling to retain basement perimeter for basement excavation

- Excavation of basement level to RL 4.5

- Construction of New Service tunnel (150m) to link old services to new Energy Building)

- Final construction of Slip Lane (loading and offloading)

- Diversion of existing services

Issues. Considering the site has been going for only 10 weeks there seems to be a growing number of problems. The highlights are:

- High Pressure Gas Main under slip lane. The building of the slip lane next to Winthrope Ave (East) is key to the logistic plan and successful construction of the project. The slip lane provides the only onsite loading and unloading point once the basement has been excavated. A Just in Time logistics plan is being developed and tower cranes (5 eventually) will be used to unload the material. However the slip lane has not been finished as a High Pressure Gas Pipe runs across the proposed slip lane access. The State were approached 3 months ago to redirect this service but nothing has happened yet. If a solution is not created soon then this will delay the project.

- Historic Services/Asbestos Pipes. Even though a site survey was completed and each subcontractor scan the site before commencing any digging to get a permit to dig old services and pipes are still being found on site. This has included asbestos pipes. As a result a specialist contractor has been required to clear these when they are found.

- Rainwater “Urban” Drainage. At the northern end of the site is the old energy building, which will eventually be knocked down. At the moment however it’s rainwater drainage flows directly into the site. As a result 6 x soakwells have had to been installed which collect the rainwater and disperse it away from site into the sand.

- Removal of Excavated Sand. The ground work subcontractor GMF are falling behind schedule with the removal of excavated material from site. Due to the limitations of site space if they can not get the material away excavation work ceases. GMF do not have their own drivers and rely on a fleet of private drivers. JHG are being told that there is a lack of drivers in the city as they have all gone North to the mining site.

- Use of debonding agent. To assist in the construction of the capping beam above the CFA piles a blinding layer has been added to enable the works. This is then broken off as the excavation is dug. There have been issues with the capping beam being damaged when this has been done, so a debonding agent is now being used to minimise this damage.

- Shotcrete metal content and Z bars. The CFA piles are covered in Shotcrete. This has a metal content and has been designed to waterproof the piles and ensure water runs down them and into drains and the bottom. There have been issues with the metal/concrete mix and initial high ratio metal content mixes were unworkable, as a result a lower metal content and 2 meshes are being used instead. Though the engineer on site believes this is not structural, the design has required Z bars to be used to go around corners and pile caps. These are additional to the original design and not on site.

- Noise and Dust Control. The site’s proximity to the hospital site and residential areas means work can only commence from 7am to 7pm Sat – Fri. Along with this there are environmental controls and monitoring in place for noise and dust. Dust is being controlled by water spraying and the road is swept when required. As the work falls behind schedule then I believe an application to work Sundays will be submitted.

My Experience. Currently I have been given this week to get myself bedded into the site and work with the Engineer in charge of the excavation so my responsibilities are growing. I am expecting to move into supervising role later this week and then move onto more of an Engineer role once I have bedded in.

My Observations.

- Safety. I have a sense of disappointment that the safety message is not matching reality on site. Though paperwork is thorough and briefing continue there are many safety errors and the subcontractors seem to have a very relaxed attitude to safety. As I am likely to be in charge of the West of the site I will be considering some safety incentives and improvement schemes to implement. (And ask Rachel for UK Best practice and incentive schemes!)

- Co-ordination between Architect, Design, Construction. The detailed design really is only being signed of days if not hours before construction starts on site. This has already caused an issue with the Z bar/Shotcrete issue on site. With the Z bar on site and no on site “fixes” allowed by the designers the Z bar had to be ordered by the subcontractor = extra expense on site. Today I was told an extra 2000m of piling had been added to the plan once the piling had started as the design changed!

- Management Contracting in action/Partnering. I am finding this very odd. It will take me a while to find the balance between commercial and partnering relationships. In the short term there is limited commercial awareness on site and the refreshing overriding attitude is that whatever needs to be done to keep the project on track is to be done. (There is an unconfirmed value of liquidated damages of $140,000 per day the project is late)

- Co-ordination. There is a new team working on site from John Holland and the command structure is developing rather than being regimented. This ends up with information being lost and sub constractors beign told different things and confusion. Myself and the site manager are sorting this out, and as I move into the supervising role this will become clearer.

- Water Level – engineering rigour. More details to follow – but my initial reaction is there is a lack of engineering thought on site. For example no one is able to tell me the GWL on site and no seems to no where the bore hole logs are from the SI!!

Further Work

- Take on supervisor role, deputising for the site manager – co-ordination of sub contractors and monitoring logistics and health and safety on site.

- Continue to understand the site and the sub contractors.