Being a Civil(ian) Engineer….

THE PROJECT

Who?

Client: Crossrail

Designer: Arup & Atkins

Contractor: VINCI Construction UK – Taylor Woodrow (VINCI have recently allowed Taylor Woodrow to re-adopt their name following take over, after realising reputation wins tenders, not merely conglomeration).

Subcontractors: Menard (Piling), Gallagers (Central Tunnel Section), Lordon (Concrete Invert Slab), WJ (Dewatering and Piezometer Monitoring), Bachy (Grouting), VVB (Services), Sol Data (Monitoring, Survey), Cappel (Labour Supply).

Team: Tunnel & Central Compound Team – See picture below of my line manager: Production Manager, Nick Sammons and my glamorous Assistant Site Engineer, Alex Mitchell.

Role: Approach Ramps & Tunnel – Section Engineer.

What?

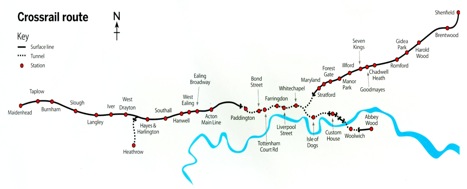

Connaught Tunnel is part of the Crossrail branch to Abbey Wood, part of the Crossrail route due to be opened in 2018.

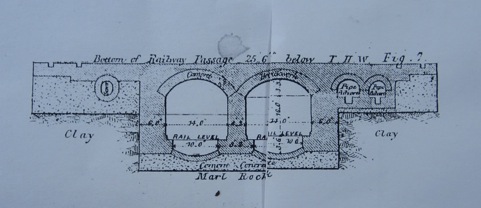

The history of the tunnel dates back to 1878. It allowed the railway to be diverted under the Connaught Passage, a water link which connected the Victoria and Albert Docks.

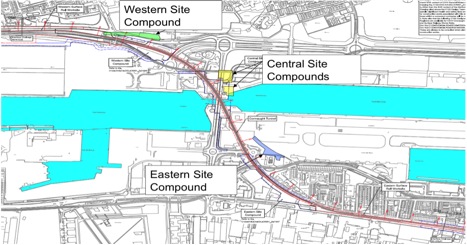

The Connaught Tunnel is 600m long and runs between the Royal Victoria Dock and Royal Albert Dock close to London City Airport. The project will see a series of repair, replacement, restoration, enlargement and new works, over the 1 km site, both on the surface and throughout the single and twin tunnels which pass under the Docks. The project has been termed both an Engineer’s nightmare and an Engineer’s paradise, due to the challenges it presents. The project is subdivided into ‘Groundworks’ (i.e. everything carried out East and West of the tunnel entrance including piling and reinforced concrete delivery), ‘Approach Ramps and Single Tunnels’ (which run from the Groundworks to the Twin Tunnel Section at the centre of the tunnel (from East and West side) and the ‘Central Section’ which includes the Groundworks, Dewatering and planning for the enlargement of the Twin Tunnels by use of a cofferdam in the docks.

Where?

I am based out of the Site Office in the East Compound, and am responsible for works on the West and East Approach Ramps and throughout the tunnel.

When?

The Connaught Tunnel is due to be completed in 2015. I will be with VINCI – Taylor Woodrow until December 2012 and expect to see the completion of all groundworks and piling, grouting, invert slab replacement, dewatering and the installation of a cofferdam in preparation for twin tunnel works.

Tasks

My team (i.e. Alex and I) are directly responsible for Tunnel & Ramp Earthworks, Invert Slab Reprofiling, Tunnel Services, Tunnel Grouting, Refurbishment & Bomb Damage Repair. I have attended the Tunnelling Course at the Tunnelling an Underground Construction Academy (TUCA) in order to gain access into the tunnel, and am booked on my Confined Spaces Course in order to supervise works in the shafts and tunnels.

THOUGHTS SO FAR…..

How?

The Team: The project teams were re-organised immediately prior to my arrival, I replaced an Engineer now responsible for the reinforced concrete slab (tunnel base) delivery (obviously disappointed not to be involved as you can imagine Richard! Although interestingly I did give some advice on Concrete Eurocodes to one of the BS-ified Designers last week!). My Programme Manager, Nick, arrived only a week before I did and was brought in to co-ordinate the Temporary Works, Approach Ramps & Tunnels and Central Section (currently dewatering). My Assistant Site Engineer Alex joined the company straight from University in Nov 11. Nick has 5 years rail and tunnel contracting experience, and Alex has a good insight into the Connaught project.

The Office: The biggest culture shock was initially entering the Office – I can now see how Ricky Gervais relates to so many people! The office is spread over 2 floors with the Designers, the Client, the Groundworks Team, the Reinforced Concrete Team, Works Management and Environment downstairs, and our team, the Project Director (an ex-US Army female helicopter pilot), the Project and Construction Managers, Quality Assurance, Planning, Commercial and H&S on the first floor. The first floor is considered to be the grown up floor, although I think our team may be the exception to the rule! It is interesting to be intimately involved in the construction process, sat across from Project Managers, Planners and Quantity Surveyors who are fixated on profit margin, planning time and estimating cost. I am responsible for submitting a weekly 4-week forecast to the Project Controls Manager, which has progressively moved to the right each week. I realise there is a bigger picture, and currently I am only exposed at relatively low level. Having experienced first hand the implications of commercial restraint on site, I am interested to gain direct commercial exposure later in my placement to see how the construction forecasts are processed in terms of managing time and cost.

Site : Site is definitely where I am currently most at home and fortunately, I spend the majority of my time on site, not least because the site is over a kilometer long! I can relate to ‘getting the job done’ and an array of personalities: Foreman East: Matty ‘the Rage’ Mayer (who speaks like the Irish Gypsy in Snatch played by Brad Pitt) vs Foreman West: Danny ‘I am always right, I always have to have the last word and I don’t understand why my workers don’t like me’ Lathia, to name but 2! I can also see how friction between the site and office rapidly builds if engineers, planners and managers direct operations without sufficient understanding of the realities of construction.

Why?

The Client: I have quickly established that Crossrail are a fairly unique Client, and their involvement in contractor affairs is unusually high. The Target-Cost contract gives Crossrail significant scope to achieve wider agendas, and upon initial impression, it appears to me that whilst the contract meets the high profile nature of their affairs, it is not necessarily fit for respective project purpose. For example, all trucks delivering to site must be Crossrail compliant (i.e. cyclist sensors, additional blind spot attachments etc.) and all material must be Crossrail apporved. Whilst for Crossrail, this is high on their ‘Ground Zero’ safety and sustainability agenda, it leaves little flexibility for the contractor to procure resources at short notice, or at a reduced cost.

The Commercial World: I recognise however, that I have a lot to learn in terms of the commercial world. Apparently, ‘Civvies’ don’t all work collaboratively to achieve a common goal, out of love and respect for Her Majesty, and a chance of an early knock off! Everything that takes place is commercially driven, and with that comes a bureaucratic process of establishing where that commercial pain or gain will occur. With that also comes stringent monitoring to ensure that that pain or gain is correctly attributed. After an extremely late night trying to solve a temporary drainage construction problem (see picture below), I found that nothing could be resolved until the contractor had been instructed. After initial frustration (also fuelled by the foreman and site workers who are not privy to the intricacies of the contract, and more akin to the military, simply wanting to get the job done), I was soon educated that “it is all about money!” Which, after my limited time in the commercial world I am now coming to understand, and can also see why there is a place for bureaucracy when defining and monitoring tasks and costs. I do feel however, that this process is sometimes enforced at the detriment of the final profit margin (i.e. use of time and resources attributing pain and gain at every stage, rather than focusing on minimising time and cost of the whole project).

“…I know it’s hard when you’re up to your armpits in alligators to remember you came here to drain the swamp” – Ronald Reagan, 1982

In the case of the temporary drainage installation, an unforeseen high influx of water (approx 20 l/s), and the requisite pumping caused settlement, migration of fines, piping and encroachment into the passive wedge of the existing retaining walls (see picture below). Additionally, the water tested positive for ammonia, which added a leaking sewer pipe to the equation! The high influx of water, as well as the saturated wall adjacent to the sump suggested that the problem, at least at that ground level may be limited to that section of ramp. Previous trial pits showed unpredictable and varied ground water levels throughout the site and along the ramp, due to its geographic location (on a soil strata interface), historical construction and existing structures and underground services. A limited degree of further investigation by the contractor, (i.e. digging investigative slits along the ramps to establish soil profile and ground water regime) could have given sufficient information to propose a solution, or at least confirm the extent of the problem. What actually happened was that the Client was informed by an Early Warning Notice and the works are now on hold whilst the contractor waits for an instruction to carry out an investigation. Whilst the time and resources for the contractor to carry out the investigative slits would have been above the initial scope of works, it would have negated the requirement for the imposed delay, and thus contributed to reducing the overall project time and cost. Admittedly, in this case, there may be wider implications for the final design which need to be fully explored, however, this case study has clearly highlighted to me the reality, and additional complexities of operating within a commercial environment.

SO WHAT & WHAT NEXT….

…Aside from backfilling the temporary drainage sump, stabilising the ground, removing the manhole box, diverting the contaminated water pipeline, obtaining a permit to dig, discharge, locating the sewerage leak, appeasing the environmental agency and coming up with a new temporary and permanent works plan…..! During my first 2 weeks as a ‘Civvie’ Civil Engineer, after 8 years in the comfort of the green institution, I have certainly learnt a great deal. Both in terms of how my strengths translate into an office and site environment, and what I have to learn about the reality of a commercially driven project.

Most Useful Attributes:

- Ability to effectively communicate

- Diplomacy – Whilst the project organization is not rigidly hierarchical, understanding the official and unofficial protocol is key.

- Authority on Site – Foremen are very similar to Sergeant Majors, only more complicated – plus I have 2!

- Co-ordination and planning

- Patience

To highlight the importance of mutually understood communication, whilst conversing with the PET Geotechnical Helpline, my advisor suggested that I could put one component of the ground water regime analysis ‘in the dock’. Given the highly sensitive nature of the existing contaminated water issue, I was extremely alarmed at this inference! Fortunately, upon further explanation, I realised it was simply another John Moran list of phrases not to take literally!

“…You can put that one in the Dock” – John Moran, 2012

Conversely, the infamous Army Officer assets which do not have quite the same affect on a commercially driven project are:

- Initiative in Isolation (i.e. on site or as the contractor) – Nothing will get done without Client approval.

- “A Sense of Urgency” – Speed is tempered by quality, cost, control and stakeholders (sometimes beneficially, sometimes in my view, with insufficient regard for long term project implications).

Cracking! What’s the form of contract, have you now moved the EWN to a compensation event, are you claiming float time on the delay, does the client/consultant have a deadline for responding to a compensation event, and would failure to do so permit you to implement your own solution at the client/consultants cost as an uncosted addition?

Nice piece

Here’s a take on it. Largely to clarify the sort of thinking that your formal assessments and CPR entries would benefit from.

Your first brush with contracting is representing the Contractor undertaking some accommodation works.

This is the construction of a temporary drainage sump to accept inflow from a slit drain along the centre-line of the approach ramp on the East side taking water from the surface of the new and existing ramp slab to be pumped (out into the dock?). In the final scheme this highway drainage will be routed to a pumping station (presumably located close to the soffit point of the highway in the tunnel section).

All-in-all it’s been a bit of a cock-up.

Technically:

1. It is an excavation close to the toe(s) of some old (mass concrete) retaining walls retaining the ground away from the existing ramp.

2. Because we are close to a dock basin we might guess at a GWL behind the walls to be close to the dock water levels. So there might be a hydraulic gradient above any point in the ramp.

3. Because it is an old gravity wall we know that there will be backfill behind and to the front of the wall. So the material properties might be a little ‘confused’.

4. One of the trail pits higher up the ramp suggests that there is a 1 metre thick layer of concrete at, or close to the retaining wall toe on the passive side.

OK – with this background what should the contractor do by way of ‘design’ of his works? OR what should he be calling for of the Client Design Team (see below).

Pretty well all of the (C’s) should be all be to tackle 1 to 4.

Managerially

1. It is a Target Cost Contract so the Contractor and Client have an on-going mutual aim of executing efficiently. I would expect there is pain-gain at the target cost?

2. The contract comprises a set of significant sub-contracts. Were these selected by the Main Contractor and approved through the Client? I would guess that the scope of these packages is well defined.

3. The scheme is designed by the Client Design Team. Where are the boundaries drawn between this design and designs that the Contractor might usually undertake?

4. Where does the responsibility for temporary works lie? Presumably with the Contractor with Client approval required?

5. At what point do temporary works attract Client approval requirements? If everything had to be Client approved, the Contractor would soon find that his ‘gain’ was being turned to ‘pain’ through the approvals process.

6. How does the Early Warning Notice work? Is it from Contractor to Client? Does it shift risk back to the Client and why would the Client accept if he thought that the issue was one that a reasonably competent Contractor should execute?

Managerially what preparation should a competent contractor undertake when executing the (now abandoned) temporary works?

Do the contractual arrangements prohibit the contractor from executing OR do you think that the contractor is condition to any risk back to the Client . How does this behavior affect overall outcomes?

Work this up and I’d say you’ve a pre-packed TMR