Supervision, a spoon drain and SCAB!!

Period Covered 20 -23 Mar 12

Summary: Supervision, a spoon drain and SCAB!!

Work as a supervisor has begun in earnest with safety (monitoring on site, paperwork audits etc) and sub contractor co-ordination my top priority. I am understanding how the site operates, meeting the sub contractor supervisors and building a working relationship with them

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk excavation and pile cropping

- Risk Assessment and Hazard Inspection Audit

- Co-ordination/supervision of Union Rep

- Service tunnel spoon drain – liaison with design team and contractor (contract dispute)

- Reports and returns – Site Diary etc

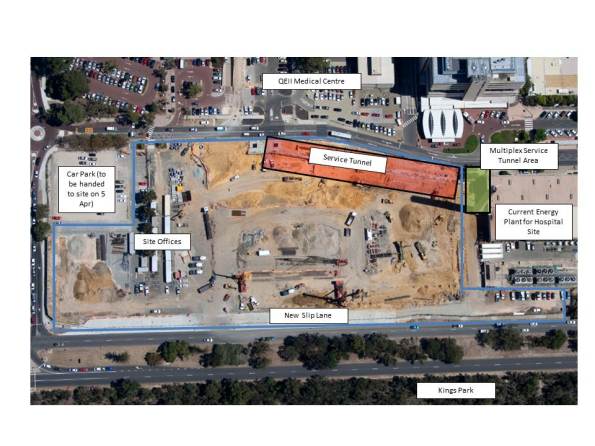

Aerial Photo

Work on site. No Change – less GMF (cropping pile team) and Crown (concrete capping beam team) contractors have been stood down until Wednesday as a result of safety concerns in order to allow adequate working space between piling and other contractors.

Issues. Considering the site has been going for only 10 weeks there seems to be a growing number of problems. The highlights are:

1. Congestion of Site/Possession of Northern Boundary by Multiplex. The first milestone on the project is to handover a new service tunnel to link the services to a new constructed energy building. This is driving the programme and the focus is to deliver the first stage of the tunnel to the client on 2nd May and the whole thing on 29th May.

However as a result of the client handing the most northerly section of the tunnel to another contractor work in this area by JHG sub contractors has been severely restricted. In an attempt to catch up time the piling, pile cropping and capping beam contractor were all compressed in the same area. This led to lots of co-ordination/in fighting with the sub contractors (good work for an army officer acting as a supervisor). This went on for 2 days until a call was made that it would be safer and more efficient to pull everyone less the pilers away from that area.

2. Spoon Drain. The service tunnel has a spoon drain at the bottom of it to collect and drain water running along the inside of the retaining piles. This was a detail which though pretty simple I spent a lot of my time this week dealing with. Until I got involved there were no dimensions or levels for this, and it took a lot of going between the Architect and the Structural engineer to determine who was responsible for this detail and to get the required dimensions.

Along with this the earthworks contractor initially refused to do the detailed excavation required for this work and it took the involvement of the Works Package Manager, the contracts administrator and myself to get to the bottom of it. It transpired that detailed excavation was not included in the Lump Sum part of the contract but was included 5 sections later under a schedule of rates section….problem solved after a bit of tension.

3. Trade union relations. Australia has a very different set up with powerful trade unions which are normally part of/affiliated with construction companies. John Holland has a different view and believes it can have a better relationship with its workers directly. This seems to work fine, less the relationship with John Holland and the Union Reps. Recently on site the Reps are coming on site to cause trouble and on one occasion the police have been called. As a supervisor I was responsible for babysitting the Rep during his last visit to site and ensuring he followed the rules. Interesting but a little weird!!

4. Oh Shit we hit something. Initially on site there were many services crisscrossing site and these have mostly been removed with a plan to remove the final few in the next 10 days. On Friday however whilst excavating the service tunnel a 150mm water pipe was struck and water released onto site. Emergency plumbing works will finish the diversion of this sewer over the weekend and the site was lucky as the water was “clean” (cooling tower condensation water) and will easily disperse in the Sand. Of more of a concern is that there is a High Pressure Gas main in the north of the site which we are still waiting permission from state to relocate….lets hope we don’t hit this!!

My Experience. I’ve been amazed at the speed of progress on site. The excavation progresses at 100 trucks a day as well as 10 CFA piles per day. My role has developed with me deputising as site manager on my third day, as the real site manager was on a training course and I have worked more with the engineers, trying to sort out the spoon drain detail – this has also given me some commercial experience and my initial naive thoughts of working as a team have been banished as commercial arguments have occurred this week.

I have observed the difficult role a managing contractor has. There is a balance bewtween a working relationship with the subcontractors and acting in clients and John Holland’s interests. This becomes evident with Safety v productivity issues. My view is that John Holland as an excellent paperwork system which should ensure safety on site and this understood by the Engineers and the Management but there is still a core of Supervisors who see safety as getting in the way – this will mean a constant battle to keep on top of this.

Finally, I have realised the importance of sketching. This is how I have been communicating with all of the subcontractors this week. Whether it be simple site plans or more complicated design detail being able to sketch quickly and clearly is obviously an art which I need more practice at!!

Steve, glad you caveated your last statement about sketching or else I would have jumped straight in there! Similar safety points again from my side and this is obviously a common thread having seen Jim’s previous comments. The JHG paperwork is a little tiresome and when I discussed with the supervisors it seem that it is a pure paperwork exercise to cover arse as they have no involvement or ever get invited to review/read them. I’m also discovering that they have a lack of trust of the engineers, particularly junior ones. They tend to spend a great deal of time (so they say) correcting the errors that the engineers have caused. I’d advise you to try and understand their concerns of junior engineers as well as some of the migrant workers…there are clear communication issues here, partly due to a lack of integration, that can be easily overcome with some gentle persuasion!

Steve, you’ve made my day – sketching is a vital skill that we all need to practice. Drawings and sketches are the primary means of communications with indigenous contractors as they don’t understand contract specs (mostly ’cause many can’t read!).

Roy, great to see the cross-pollination of themes between the two sites. There’s a TMR in there somewhere in you H&S observations. Jim – perhaps you could provide more guidance with your greater experience of this historic issue?