Contracting, Sub-Contracting, Re-structure & Conflict Resolution!

Contracting

Re-profiling & Sump Installation. Re-profiling works has continued and the installation of temporary sumps within the tunnel, as well as localized temporary measures to divert the water have been sufficient to enable a -45mm tolerance, set by the Designer to be achieved. The profile of the existing tunnel allowed for 300mm (West) and 800mm (East) of slab and brickwork to be excavated to the final Structural Slab Level (SSL) at the sump locations. This step change was sufficient to create a natural shallow sump and negated the requirement to install addition temporary infrastructure that would impede access and have to be stripped out. Manual setting out and checking levels remains relatively time consuming but has proved the most flexible and effective method. The Client is remitted to check levels in accordance with the Inspection & Test Plan, which we invite them to witness following an EDM survey. The re-profiling has however uncovered significant longitudinal cracks which as well as severely increasing the flow of water into the tunnel, are of some concern to the Designer, who has been on site to carry out inspections.

Re-profiling at the entrance to the West Single Tunnel.

Re-profiling at the entrance to the West Single Tunnel.

Re-profiling at the base of the East Approach Ramps.

Re-profiling at the base of the East Approach Ramps.

Re-profiled section to create natural sump.

Re-profiled section to create natural sump.

Temporary ‘Temporary Services’. As a result of a 10 week delay in the Temporary Services Contractor commencing on site, it has fallen to Vinci to provide the requisite enabling services within the tunnel and approach ramps, including drainage, lighting, and ventilation. This has proved an extremely costly exercise, both in terms of manpower and resources. The drainage system, at any one time, comprises a minimum of 2 x 6” and 2 x 4” pumps operating constantly, pumping up to 1000m3 water a total of 1 km, over 15 m head every day. I estimated the size of pumps and pipe work based on the predicted seepage from re-profiling in the river terrace deposits (above the clay layer), and a contingency for rain. I also made the (in hind sight optimistic) assumption that the Temporary Services sub-contractors would gain Client ‘Acceptance’ to start within a couple of weeks from the Vinci installation. Upon reflection: despite the uncharacteristic hot weather in March, it is the UK – it rains A LOT; seepage is unpredictable and despite similar geology, the seepage encountered in the West side of the tunnel is considerably more than the East, and, Client ‘Acceptance’ is not a viable planning tool! Fortunately nothing that a simple change of pump and 300m of pipe work couldn’t solve – it pays to stay in with the site workforce!

Temporary sump and drainage in West Single Tunnel.

Temporary sump and drainage in West Single Tunnel.

Now that the central pump house has been turned off in preparation for shaft deepening and the Dock discharge consent has expired. All construction water within the tunnel must be diverted into sewers on the East and West surface sites. The Thames Water consultant carries out random checks in order to check that the quality and quantity of water being discharged is in compliance with the consent. Re-profiling is 70% complete on the West and the discharge is currently 676 m3 (176m3 over the consent) and 363 m3 (337 m3 under the consent) with 60% re-profiling remaining. To further compound the issue, the Temporary Services design allows for construction water to be provided by the fire main, which will generate additional construction water discharge. Potentially an extremely costly aspect of the project, not accounted for at tender. Whilst the foremen have ‘solutions’ for reducing the flow rate readings, the ‘legal’ alternative is to apply for an additional consent (which will take weeks if granted). Dependant on the outcome of the Thames Water consultants report, the Contractor may raise an Early Warning Notice, which the Client may accept or dispute as ‘foreseeable and/or within Vinci’s scope’.

Tunnel water discharge into Thames sewer.

Tunnel water discharge into Thames sewer.

Tunnel Health & Safety. In addition to the control of water, the progression of re-profiling into the tunnel required the implementation of several additional H&S measures such as control of dust, noise, fumes, and gas levels. Dust suppression, additional ventilation, and heightened levels of PPE were put in place. However, high levels of Nitrogen Monoxide, as well as the ignition of a methane flame as a result of excavating the tunnel floor, have since stopped works. We carried out a full monitoring investigation, and a tunnel gas consultant has been called into offer advice regarding intrusive works, before re-profiling works will continue. I am in the process of updating the ‘Tunnel Access, Egress and Emergency Procedure’ in order to improve it’s relevance and practical application given the changing nature of works and services within the tunnel. In fact, I thought ‘The Practical Application of H&S within Tunnels in the Construction Industry’ might make a relevant H&S TMR (and of course kill two birds with one stone, or at least kill one and make the other one ill through gas exposure?!)

Re-profiling within the Single Tunnel.

Re-profiling within the Single Tunnel.

Current temporary ventilation configuration: positive airflow in from the ventilation shaft and out the West portal.

Current temporary ventilation configuration: positive airflow in from the ventilation shaft and out the West portal.

Re-Structure

Commercial. Currently the Vinci bill for plant on site, of which 30% is providing temporary ‘Temporary Services’, is £35k per week. How much of that cost Vinci can recoup from the Client (for prolonged ‘Acceptance’ times or unreasonable rejections of submissions), or from the sub-contractor (for sub-standard submissions or delayed start times) now sits with the Commercial Team. A recent 50% increase in Quantity Surveyors, may be a reflection of the Contractors current predicament. For example, since the start of the Project Crossrail has raised 63 NCEs, and Vinci has responded to 30. Early Warning Notices are also a common occurrence.

Project Team. In addition to the uplift of QSs, several additional positions have been created across the Project Team. Namely, an additional Construction Manager (there is now one for Surface Rail and one for the Tunnel and Central Section), an Engineering Manager (to deal with design issues, which have thus far caused significant delays, and future interface management between sub-contractors and the Client), a Materials Compliance Engineer (to deal with the ‘Acceptance’ of materials, currently a disproportionately time consuming component of a Section Engineer role), a additional QA Advisor, and 3 more Section Engineers. The reasons for the sudden uplift were not disclosed, however I suspect the following are significant factors: the full scope of the Project was underestimated; insufficient contingency for problems encountered on site (although arguably the piling sub-contractors who are on their 5th iteration of site team have probably exceeded any reasonable assumption); and underestimating the strict procedural nature and commercial advantage of the Client. Whatever the reasons, the realization by Project Management that Vinci needs to meet the demands and standards on site, reduce Client ‘Acceptance’ timelines, but also have the capacity to achieve an equal commercial footing, is a positive and welcome move.

Sub-Contracting

VVB. Only 10 weeks on from their original start date, the Temporary Services sub-contractor has finally started on site! However, the site is still awaiting Mains Power (delayed by 3 weeks) to be turned on at the central compound in order to feed the tunnel via the ventilation shaft. The biggest contractual error: Vinci not delegating responsibility for access to VVB. In an attempt to provide mobile access within the tunnel, a ‘mobile’ platform was designed and procured by Vinci. Unfortunately, the mobility of the platform was subject to a lengthy re-configuration process each time a move was required. Since Vinci would inevitably be charged for the ‘standing time’ during this configuration, it was deemed unfit for purpose.

The proposed mobile access platform provided by Vinci

The proposed mobile access platform provided by Vinci

Vinci are now remitted to provide a MEWP to VVB for all access requirements, including fixing brackets at 3m intervals along the length of the tunnel. Access scaffolding through the ventilation shaft and into the tunnel, has now been subcontracted back to VVB and Vinci are awaiting a design, which will then require Client ‘Acceptance’ before work can proceed. Another additional plant hire cost, and significant delays incurred by the omission of one line from a sub-contract.

VVB installing LV cables from mains supply to distribution board in tunnel.

VVB installing LV cables from mains supply to distribution board in tunnel.

On a positive note, I attended the ‘Hilti’ Installation and Testing Course and am now qualified to test the installation of services brackets as part of the Inspection & Test Plan. On a not so positive note, if the Eastend residents don’t stop steeling VVB’s cable, there will be no power cables to install on the fully fledged and tested brackets! Another contractual debate: who is responsible for the security of sub-contractors equipment (in storage and once installed)? The VVB director is currently pushing for the installation to be handed over in sections in order to shift the risk to the contractor, which Vinci is resisting. The contractor is arguing that it is deemed a ‘secure site’ and that the security guard contacted the police, VVB have a lockable container, and that they could order materials to site in accordance with their programme and not stockpile. Police and insurance report are being generated, and I will disclose the results of the theft and sectional handover commercial battles in my next Blog!!

VVB installing LV and lighting brackets.

VVB installing LV and lighting brackets.

Bachy Soletranche. Only 1 week behind schedule, the Drilling & Grouting sub-contractors have mobilized and started on site today. Contractually, unlike VVB, they were tasked to provide all enabling equipment, and whilst initially I could not see the logic behind them bringing in generators, when there ‘would’ have been mains supply, I can now see why Contractors want to shift all possible responsibility for enabling works onto sub-contractors. The unforeseen delay in mains supply connection would have been billed as standing time to Vinci, or Vinci would have had to hire generators, (for which noise consent requires 4 weeks) resulting in further delays.

Extent of TaM grouting within the Twin & Single Tunnel (pink extent lines mark sump locations).

Extent of TaM grouting within the Twin & Single Tunnel (pink extent lines mark sump locations).

Vinci were however, responsible for providing a Working Platform for the Drilling Rig. The platform had to meet the requirements of the Bachy ‘Working Platform Certificate’ specification, as well as gain Client ‘Acceptance’ as a Temporary Works Design. By using the ‘arisings’ (I did question if this was actually a word, but was duly informed that it is an engineering term meaning material resulting from an operation) from the re-profiling, the requirement to ‘muck away’ the arisings was negated, as was the expense of procuring new material. By sending a sample away for a Particle Distribution Test, we were able to prove to the Client that it was of a suitably well-graded nature (characteristically akin to the Crossrail approved 6F2 fill material), to compact and use as the platform. The drainage diversion scheme correctly assumed no seepage (and thus flow of water) would occur between sump locations, and, that all water would be pumped out from the existing central drainage system prior to the pump house being closed. The later part of the assumption has however, not proved to be correct, and residual water from the existing drainage system is seeping back into the central section, thus slowly saturating fill in the centre of the twin tunnels. Whilst the steel lined central section does not form part of the platform, remediation works will be required to retain access.

Platform laid and compacted from re-profiling arisings to create Bachy Drilling Rig.

Platform laid and compacted from re-profiling arisings to create Bachy Drilling Rig.

A further consideration, which fortunately for Vinci was in the sub-contract, is that Bachy are responsible for recycling their own water, which will be fed down the ventilation shaft from the central compound. Both the contracts manager and the foreman came on a recce to the site and were made aware of the sump locations. However, it now transpires that no plans were put in place to divert water to these sumps. Bachy contingency planning is now taking place, which may involve guttering along the ledge or a trench within the platform.

Drilling and TaM Grouting control panel.

Drilling and TaM Grouting control panel.

The rig platform had to be extended in order to accommodate the fact the control panel is on the left hand side and thus the rig can only operate in one direction. Another example of additional work that could be avoided by attention to detail and early contractor – sub-contractor engagement and planning. Something that is often victim to disproportional resource allocation to gaining Client ‘Acceptance’.

The 10 week Drilling & Grouting operation will be a ‘Red Zone’ in accordance with the ‘Tunnel Access, Egress and Emergency Procedure’, requiring heightened H&S measures and alternative emergency procedures due the generation of noise, fumes, COSHH material and the restriction of access.

Subcontractor Delay. The delay in subcontractor start dates can be attributed to a number of reasons, however I believe the principal reason in both these cases is cross over between Temporary Works and Permanent Works. The contractor submits what is believed to be a design, which meets the scope and fulfills the submission requirements of a temporary design and installation. The Client on the other hand is concerned with, and focuses considerable attention on elements that will be handed over, or incorporated into the final design. In the case of the Drilling & Grouting, the issue if further compacted by the tunnel structural engineers wanting specific pressures for loading modeling and analysis, from a methodology based on a non-exact science. A Client, Contractor and Bachy Designer meeting was held which clarified most of the Clients concerns, and an agreement made that will see additional monitoring measures implemented in order to provide the Client with the requisite in-situ information during operations. A reasonable request, given the risk associated with grouting, but again not factored in at tender, thus affecting planned construction scheduling.

So What & What Next?

Future Planned (& Not So Planned Work). Just when things seem to be coming together, issues being resolved and subcontractors starting work. More sub-contractors come along….. and they all want to work in the tunnel! A result of delayed start dates, and lack of forward planning, communication or additional Project Manager’s Instructions has resulted in the following scheduled to take place within the Twin Tunnel during the next 8 weeks, starting on Thursday….. over to the Section Engineer!:

- Livis The Client has requested a number of additional cores to be taken throughout the structure, including the Approach Ramps, the Pump House and the Twin Tunnel Section in order to ascertain further information as to the structure composition for the final design.

Coring subcontractor Livis taking cores on the Approach Ramps.

Coring subcontractor Livis taking cores on the Approach Ramps.

Cores from the pump house required to confirm pump house reconstruction design.

Cores from the pump house required to confirm pump house reconstruction design.

Cores required through base slab within steel lined twin tunnels.

Cores required through base slab within steel lined twin tunnels.

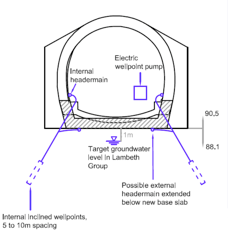

- WJ Groundwater. In addition to the global surface Thanet Sand and Chalk dewatering wells within the central compound, WJ are contracted to install localized inclined wells within the Twin Tunnel, in preparation for invert replacement (currently scheduled for June!), and the installation of the cofferdam in 2013.

Planned installation of dewatering wells within Twin Tunnel.

Planned installation of dewatering wells within Twin Tunnel.

Geology at the central section of Tunnel (clear purple represents the Docks and surrounding brickwork, and grey shafts the ventilation shafts, marking the extent of the Twin Tunnel).

Geology at the central section of Tunnel (clear purple represents the Docks and surrounding brickwork, and grey shafts the ventilation shafts, marking the extent of the Twin Tunnel).

Evolving Role of the Section Engineer. Already my responsibilities have shifted from focusing on gaining sub-contractor ‘Acceptance’ and mobilization, to monitoring, Quality Control and co-ordination on site. I remain responsible for Vinci works and enabling works, and after a few heated discussions with the Foreman and Works Manager, now appreciate that even if a project is driven by sub-contracts, the contactor (of the old school variety) will always resent someone else doing the work that the contractor used to do in the good ol’ days! However, I have also witnessed the sub-contractor take advantage of this situation, and winding the contractor up even more! I also appreciate the frustration on site at the apparent lack of planning (often resulting from inadvertent delays, other times they may have a point). All of which generally results in the Engineers getting stuck in the middle – something that the Project Director picked up on, (whilst standing in for the Project Manager) and called a conflict resolution meeting with our team and the Vinci site management team. It transpired that the Foreman and Works Managers were in fact frustrated with much bigger issues, aimed at higher management levels and mostly regarding surface works. A relief for our team, but from a personal perspective, I was reassured that a member of the management had acknowledged the fact that there were issues within the Project Team as a whole.

From a Section Engineer’s perspective, I can see both sides, and will continue to try and tip the balance between reactionary vs. planned operations. However, as you can see by the ‘Future Planned (& Not So Planned) Works’ above, this is not always possible, and hence the role of reactionary planner, politician, diplomat and ‘defender of the peace’ must also come into play!

Civify Tip:

Military words which do not exist in civvie street: ‘De-conflict’! I have felt the need to use this word a lot over the last few days, but was duly informed by my Production Manager that apparently it does not exist?! After explaining what it meant, the term ‘Interface Management’ was suggested as a more suitable alternative! Fortunately, I had not yet used the term in front of the Client, who instructed that the word ‘de-construct’ be removed from a Method Statement with regard the dismantling of the Pump House, for fear of destructive connotations!! (We did have to point out to them that this was the word used on the original instruction!).

Absolutely love the blog

A postcard from site …. Wish you were there

Some stuff:

You seem to be saying that your estimates of seepage were on the shy side ( I recall a low permeability figure assumed) but I must admit that I didn’t think about adding the construction water to flow estimates ( which is what I think you are pointing out) Also is there a settling tank between the pump discharge and the decant to the sewer?

Eastenders. I don’t know if I ever regaled you lot with my stories of life as a resident engineer ( when I were young) I was on schemes for the very early Docklands accommodation works- putting roads into the old canal systems..balh..blah…yawwwwn. Anyway the job I got chartered on was in the Docklands to the West and South of where you are – at Millwall . I had so much stuff nicked from my site (one week end the site offices were removed) and was subsequently in Deptford nick so often, that I joined the Deptford and Lewisham Police Sports and Social club and was a regular race-goer with them…. Plus ca change….and all that…..Pen up you experiences and offer the script to the BBC

Back to the blog…. Like the description of how the sub-contractor looked to the requirement behind the Spec and used the arisings

The drilling rigs are the same as the R.E. use for g.i.

I know some of the Cross Rail Client side. The modelling will be finite element models of the tunnel sequences. The grout operation implies point loads ( increased grouting pressure ). I very much doubt whether the client can do or say much about this other than to consider an equivalent load applied at the springing level of the tunnel. There is a delicate point at which the Client RfI sometimes require a response which begs the question – what can be done with this information. ? I’ll bet they come up with a ….’be sure that the grouting pressure doesn’t exceed what you told us it would be’……and the palliative will be ‘yes we’ll monitor that in real time’……eyeballs roll upwards and everyone gets on with it.

Coring: Did something similar a few years back… diamond drill cores through an existing lining …through masonry….through all sorts of backfill material!- varied on each coring then …clank clank clank of steel temporary works beyond the lining….no wiser after the event….good luck towith that!

WJ. … would like details of the dewatering scheme. Pumping from the Thanet Sands reducing the artesian head in the Chalk below?…… I’ve been involved in a number of schemes on this boundary and it is a treacherous boundary because the Thanet Sand on the boundary is very fine and there are often sink holes, dene holes, call them what you will … and I would guess the pore pressure varies a bit. Your beautiful yellow, followed by mauve diagram lets me know either:

The person who formed this section has a lot of boreholes to confirm the glorious straight line OR

Doesn’t really have a clue…… I think I’d have drawn a jaggedy line…at the very least………… once again …have fun!

In your para

and tip the balance between reactionary vs. planned operations. You mean ‘reactive’

I prefer de-conflict or clash resolution…. Interface management…..my arse.

Again love the blog….

Good stuff. JM and I have discussed at length! Trust you have seen this weeks NCE re grouting on Bakerloo line causing tunnel linings to deflect and strike trains. (I like the idea of reactionary operations but, as with deconfliction, I’m in with John)