Archive

Big touble in little….town in the middle of nowhere.

Covers Period 30 April – May 4:

The best week so far at work! Plenty of variety and a chance to get the boots dirty, thus avoiding paper cuts in the office.

EDC SloarWall

At the end of the previous week the contractor had sent me a Risk Assessment (Called an Accident Hazard Analysis AHA over here). Essentially this was pipss poor and far too generic. I bounced it back to them with comments along the lines of ‘take this seriously or I’ll cancel your investigation’. This resulted in them sending ther H&S guy to supervise the task and conduct the relevant briefs and incorporating the issues that I had raised. Even so – our COn-Rep picked their guys up for lack of high-vis clothing, baseball caps under helmets, impropper ise of helmets, not using fall arestors when on the platform. Each of these issues were addressed on site before work continued but it was a constant bug-bear. The contractor has left with a much clearer perspective on the standards that the Corps requires. I have followed this up by sending the chapter and verse out to all parties who are expected to produce the AHA’s. In this respect we demand 100% commitment and complience – or they get 0% work completed at their expense…….I look forward to the inevitable repeat prescription on this.

Have been able to get the tech guys to be less vague about how they intend to deal with the roof ducting – as this overlaps two projects and had not been clearly defined as to where the responsibility on this project ended and the next one began. I was uncomfortable with the initial response as although everyone was happy to carry on working, it left contractual vagueries – and we all love those.

Ashley Reservist Centre.

Issues over defects on a loading ramp have come to a head and I have been giver catre-blanche to go and sort it out. This is going to be the basis for TMR 1 for me as there are opporetunities for technical analysis and research as well as contractual issues to solve. I booked the hotel etc and set off to spend 24 hoursd on site to investigate the defects, interview the contractors and gather evidence.

Breaking down the issues this is a historical birds nest of problems which will take a while to consider and provide appropriate solutions, but the best thing I was able to do was to apply the ‘big levers’ principle as preeched by the Moran and the Farmer. Cutting away all the chaff allows me to find the lever that allows the issue to be resolved and for work to continue. Bottom line solution is that the contractor will undertake spectrographic testing of the placed concrete to prove ifit was up to specification. This then triggers a decision point. If the concrete is up to standard, they recommend and submit remedial actions for us to authorise (at their cost). If it is sub-standard I will work with them to prove the extent of the sub-optimal concrete and the questionable areas will be removed and replaced (at their cost). Simples – but there are a plethora of other issues that also need to be resolved, some of them diplomatically, some of them bluntly. Other issues that need to be resolved are:

– Contractor’s Quality Control procedure has been historically lacking and is still not up to speed.

– USACE Quality assurance procedures are not being followed and need resolution.

– Materials testing documentation is not clear enough to give contractor the level of assurance he needs.

– USACE ConRep is not working cooperatively with the contractor…and vice-versa.

– Deficiency reporting procedure is not working or being applied appropriately.

– Communication on site is inadequate and will continue to cause further delays and disputes.

– Areas of the specification do not comply with the working drawings. Essentially we have 2 song sheets and each party is using whichever suits them best.

From here a quick and dirty report will be produced to get the ball rolling on the resolution. I will then drill into the detail and generate two versions of the findings. One for consumption within USACE and one for the contractor to see. Wrap all of this together and hopefully a TMR will fall out of the other end.

DDSP ECIP Buildings 732 / 760

Used our ninja APMP qualification and skills to review and comment on the proposed PMP for the energy efficiency projects for which I will be Project Engineer.

And in Other News

Enjoyed a site visit to the Mechanicsburg Reservist Centre project which appears to be running on fumes as far as funding goes……they said no blasting as well and look where that got them.

This week’s road kill includes deer, blackbird, hedgehog and possum…although the possum may have been pretending.

We enjoyed our first ever Cinco de Mayo celebrations / Kentucky Derby day. We attended a party where I now see that the theme was meant to be Kentucky Derby (i.e. posh hats and day at the races atire)……I went with the Mexican theme instead. And when we were in the fancy dress shop I saw the coolest Iron-man mask and simply had to have it. So to keep in the theme (or what I thought was the theme) I went as Iron-Man dressed as a mexican (with grigo moustache attached to the mask). In the group photos from the party there is one character that looks decidedly out of place.

Commercials on TV continue to horify me. Apparently your kids can get premature wrinkles. So if you really care about your kid’s future, you owe it to them to treat them with child friendly botox.

Weeks 4 and 5. 23rd April – 4th May 2012

Week 4. 23rd – 27th April 2012

MIST – Minimum Industry Safety Training. Two days of classroom health and safety training in the Oil & Gas Industry is very similar to H&S training in the RSME – lots of PowerPoint and a consultant charging megabucks to teach it! The teaching was actually very good, with the presenter’s experience being passed on through some good anecdotes (crushing injuries, falling injuries) and a video about the Piper Alpha disaster to make us pay attention! Lots of “as an employee, it’s your duty to…” made us realise that it really is up to individuals to make sure that things are being done correctly, and to report it otherwise. They take this very seriously.

BOSIET – Basic Offshore Safety Induction and Emergency Training. Following the MIST, we (my gang of ex-army mates from the MIST course comprising of an ex-sapper, ex-signaller and ex-South African Commando) had another three days of mandatory training before we were licenced to go offshore. This course was a bit more fun though; still lots of PowerPoint but the banter increased as the lead-instruction dropped in quality. Sadly, where we had the experience of an ex-rig worker turned consultant for the MIST training, we now had a little girl who used to volunteer for St John’s Ambulance, and whose experience came from her dad working offshore – and this was reflected in the standard of her lessons (and my Inval). However, the other instructors were great, and before we knew it we were fighting fires and practicing helicopter evacuation from an upside-down, submerged simulator – lots of fun, and great for giving us confidence by practicing what we may need to do in the offshore environment.

Figure 1 – Helicopter Escape Training

Having passed a medical I am now ready to go offshore for a project recce (or similar excuse); can’t wait!

Oh, and my attempts at looking like a civvy are still failing; maybe it’s my chinos, highly polished shoes and pressed shirt that give me away each time?

Week 5. 30th April – 4th May 2012

ETAP CPF ALQ

Well, the ETAP CPF ALQ (or Additional Living Quarters on the Central Processing Facility of the Eastern Trough Area Project platform) is going to Appraise, and I’ve got £150k to spend on appraising it. Easy enough, but tying down the right people to speak to is not so simple – I’ve been stood up once now by the APTL (Area Planning Team Leader, or SO1 ETAP Ops as I like to think of her) who is neither answering her calls, Outlook meeting requests or being at her desk when I pop round to visit; and I really need to speak to her about the business proposal and SOR! Still, no worries just yet, but I’m going to call out the big guns when I get back from The South so I can move forwards.

It’s pretty much as mentioned in the last blog, but with the installation looking to be around the £8-12m mark and the cost of an extra 30 POB being around £5m p.a. in wages alone, (plus increases in flights frequency, risk, evacuation procedures and all manner of other things) I have to get a good business case done to validate whether it’s financially viable or not.

But it’s a really good project to be moving forwards with and I’m genuinely excited about it!

Runcorn

Most of last week I was digging further into the spurious task from one of the Programme Managers, Peter Neilson of investigating where the issues lie (if there are any) between the PSN offices in Runcorn and here in Dyce. This is boiling down to being a question of “what works and what doesn’t?” So far I’ve interviewed a number of members of both BP and PSN staff here in Dyce: the BP members of staff find the engineers in Runcorn much better than the Dyce ones here, with the problems lying in PSN’s Cost Estimating and variation control mechanisms, that is, tying down the initial spec of a project at each stage before; the PSN Cost Engineer I spoke to says that everything is rosy. Funny that.

Tomorrow (Tues 8th May) I fly to The South (Manchester) to interview a number of Job Responsible Engineers (JREs – PSN’s title for Project Managers), Programme Managers and Delivery Focal Points to see what their views are in some closed-door interviews. Having spoken to a JRE on the phone already, I expect that they are all ‘in the dark’ on what the delays are from, and as frustrated as the BP staff are, but I guess we shall see… Then, on Wednesday (as I found out this morning), I get to present my findings! This will be in an open forum manner to those in Runcorn I’ve interviewed, plus Peter and a few other Programme managers from here. The aim of this will be to see if there is a ‘best way forward’ if anything does need to change.

So, here’s to hoping for some constructive criticism from the interviewees so that this can form the basis of a managerial TMR!

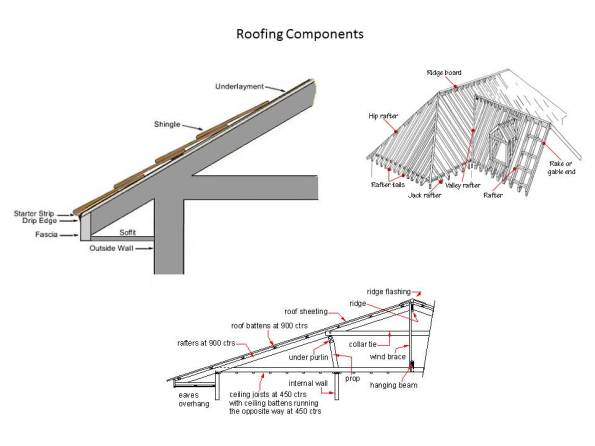

Roofing Components – Learning To Speak Builder

Have spent much of the day trying to understand what the hell my mech sub-contractor is on about. He has been telling me where he’s going to put his screws (not as funny as it sounds), but it seems all builders speak Klingon. I didn’t know half of these words so have made myself a translation slide – though you guys might find it useful if you ever need to sort a purlin from a rafter, or if, like me, you don’t believe that underlayment is really a word.

Arial Drainage – Anyone?

Has anyone ever come across ariel drainage? I haven’t been able to find anything on it from my own cursory research. I’d like to know a little about it because the hydraulic consultant on my site is telling me that it is because he has employed an ariel drainage strategy that the soil stacks and vents don’t line up. This is a man who I’ve caught out telling me porkies a few times already so I’d like to know my onions before I challenge him about it. I had understood that it was standard practice to have a soil stack that rose from the sewer in the ground slab through all floors to the roof where it vents, and that the drains at each floor run into it. I know that sometimes the stack has to make a slight detour, because drainage falls below mechanical services and structural elements in the priority of change, but thought that any deviations would be minimal and with a big radius. The deviations I’m talking about use 90deg bends and are across many meters on a single floor.

The job I am working on is a little unusual, in that there is no services riser. The section of the hospital that we are currently re-fitting was originally built as a single story, and then converted to a double, then a triple storey affair. Things seem almost to have been piled up on top of each other as the various re-fits and expansions have taken place over the years – even the structural columns have moved around (Mark, this probably answers your earlier question about the location of the med gas isolation valves – As is happening with this referb, they seem to be thrown in wherever they are needed to allow the next extension to be built). Here is a drawing of the new drainage system in my referb area, with my annotations of where the soil stacks are located on the floor below. The stacks and vents are linked by a vent header system in the ceiling above the floor shown.

Do you think that the use of air admittance valves on top of the stacks might be a more economical arrangement than using the vent headers?