Archive

Quantity vs Quality

Quantity vs Quality

3 months into my placement, I have learnt a number of lessons. However, the most prolific, which seems to define the difference between success and failure, is that quantity (or at least payment thereof) is irrelevant without quality. Whilst this should evoke confidence that the final product is ‘defect free’, rigid insistence that the final product is 100% compliant with the original specification, can cause costly and at times unnecessary delays. A couple of examples are as follows:

Re-profiling

Re-profiling works are almost complete….well, according to the Contractor?! With only 60m left to go, Vinci are understandably looking to the Client to sign the Substantial Completion Certificate in order to receive payment for the works. The key problem is agreeing the methodology for checking levels, agreeing what substantial completion actually means and trying to interject a level of common sense into the process. Approximately 80% of the re-profiled area is within the -45mm tolerance, inevitably however, there are a few spots which are outside this tolerance. It has been deemed that a laser level will be most suitable for checking the entire 6.6km2 area, by dividing the slab into sections of even gradient. The Client is proposing that all points outside the tolerance be raised in a Non-Conformance Report, and a Substantial Completion Certificate will not be issued until the works are 100% compliant with the original Project Managers Instruction (PMI) (i.e. lowered or ‘raised’ to be within tolerance). The Vinci stance, (well at least at Section Engineer level) is that the slab will be covered by a minimum of 80mm of blinding before the final rail slab is placed, therefore what is driving this degree of accuracy? A decision is yet to be made but at £800 per day to hire the Rockwheel, Vinci are understandably keen to reach an agreement soon.

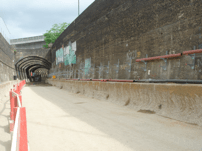

Western Approach Ramp re-profiled to SSL (note constant seepage).

Western Approach Ramp re-profiled to SSL (note constant seepage).

Eastern Approach Ramp re-profiled to SSL (note drying out of ramp following initial seepage).

Eastern Approach Ramp re-profiled to SSL (note drying out of ramp following initial seepage).

Piling

Piling is now progressing well and the Continuous Flight Auger Piles (CFA) and Controlled Modulus Columns (CMC) are finally complete on the West Surface Site, and have since moved to the East Surface Site. The piling works are considerably over budget and more than 8 weeks delayed. 6 changes of sub-contractor team would suggest there were some internal problems, however, a substantial percentage of delays were attributed to stringent Client quality control procedures. Whilst there is no arguing that the Client has every right to check contractor and sub-contractor works, a team based approach to problem solving, and a spirit of ‘mutual co-operation’ was often replaced with inflexible procedures and unpredictable responses at inspection points.

The last of the CMC piles on the West Surface Site, from the site boundary to the top of the Approach Ramp

The last of the CMC piles on the West Surface Site, from the site boundary to the top of the Approach Ramp

Whilst the examples given demonstrate how a degree of Client flexibility could facilitate the construction and handover process, the bottom line remains that the contractor proposes and agrees the Inspection & Test Plan (ITP) before works start. The difficulty I have experienced when writing ITPs, is knowing how much detail is required to effectively monitor work and control quality, without impacting too much on production (i.e. ‘quantity’). The key is including sufficient Witness Points, whilst ensuring that the parameters for Hold Points are fully understood, agreed, and can be met.

In my opinion, a consequence of convoluted Client ‘Acceptance’ procedures, is that not enough time and consideration (by both Client and Contractor) is dedicated to devising suitable ITPs. The focus is gaining Client ‘Acceptance’ by the quickest possible means in order to start production. Inevitably, the problem then comes at the first Hold Point, where ‘quantity’, if it is not of the agreed ‘quality’ rapidly becomes wasted effort.

The risk for a contractor or sub-contractor of not providing the predicted ‘quantity’ within an agreed time is mitigated by an elevated tender price, and the ‘unforeseeable/exceptional circumstances’ clause. However, the impact of not fully understanding, or being 100% compliant with the pre-agreed ITP can have far wider reaching consequences; and there are no clauses for damages!

An exception to the rule….

Dewatering The Chalk and Thannet dewatering wells were turned on 3 weeks ago and the ground water is now being pumped into the docks. Piezometer readings are being used to gauge progress, and a Chalk well pump was replaced with a smaller one, after results showed that the well was actively (as opposed to passively) drawing down the water level thus risking differential settlement in surrounding strata. In this example, the ‘quantity’ of water, is inextricably linked to the success of the works, and unlike the examples above, is ultimately a measure of the ‘quality’ of the scheme. Interestingly however, if the dewatering is unsuccessful the risk sits with the Vinci. The sub-contractor carries no responsibility, despite the dewatering scheme being their design. And presumably, if the proposed scheme is not effective (i.e. the ‘quantity’ of water draw down not achieved), the sub-contractor will revise it – for a price!