Archive

New Boy on the Blog

Pretending to be a real person is pretty easy, bluffing your case on a building site isn’t that hard (it helps if you’ve done it before) understanding an Irish Foreman who is as unintelligible as a Ghurka on a radio isn’t quite so easy.

I have been installed as an Assist Site Manager on the Mayflower Halls Site for Osborne in Southampton. As facebook followers will know I have discovered that this title is a little over-inflated; as such on a site that currently only has about 33 people on it there are 2 Assistant Managers (including me), a Site Manager, a Senior Site Manager, a Senior Project Manager, a Design Manager and a Construction Manager. So as an Assist Site Manager I started with less power than 2Lt ETS Officer. However, armed with nothing more sophisticated than a notebook, pencil and a 7 month crash course into how to pretend you know what you’re talking about I have already managed to avoid the other Assistant site Manager shedding the plant ticket checking folder onto my to do list and stopped a pile cap pour that was missing not only the drainage runs but the ground beams that tied into it. Being a real person isn’t that hard.

Things I have learned so far:

· Shaving is optional, even for quite senior managers.

· Civvies measure work in time not output.

· Bullshit still baffles brains. Signs, signs and more signs!

· Reinforcement drawings are nowhere near as simple as the ones they showed you in the lessons.

· Civvies find your use of ‘Roger’ quaint, look at you blankly when you say ‘Diffy’ and call you on the radio more than is really necessary because they like to laugh at your voice procedure.

· Contractors will wilfully do something that is wrong just so that they can be doing something.

· A ground worker who has done his SMSTS course suddenly becomes and expert on everything and the civilian equivalent of a barrack room lawyer.

Joking aside, there are a good many things that I just don’t ‘get’ yet, there has been a number of times I have found myself actually knowing more about stuff than those around me and fearing that I had a bit too much of the classroom about me. Osborne have so far been brilliant and very welcoming.

Stop Press – British Army Officer Barred from Salsa Club for Coke Related Incident!

Building 45 – Seismic Analysis:

Some really good progress was made on this one. We had an ’emergency’ meeting with the architects, fire safety guy (who fell asleep), electrical engineers and ‘the plumbing guy’. It turns out the scope of works has turned out to be way more costly than the Client anticipated. Gone are the heydays of bottomless Government coffers and it seems that people actually have to think long and hard about what they want nowadays…….still, completely undeterred by this the Client wants USACE to find the savings (of about $1M) whilst still hitting all of the criteria within the scope of works. I got the distinct impression that people have not been completely forthright with the Client as we appear to be continuing ‘at risk’ but with no defined boundaries. I am now very unpopular with the Architects from asking them to confirm exactly WHO is carrying this risk and what are the consequences of that risk. The vague response is that we’ll try and do what we can until the money runs out….well why wouldn’t we?

Some initial ideas for reducing the costs have been to re-use some old fridge doors instead of buying new ones as these will make an attractive ‘historical’ reference, a new boiler system has been canned and pipe dream of having a freight elevator to the basement has been dropped. As you might imagine – these amount to nowhere near the $1M target. Some more sensible ideas involve ‘packeting’ the works into discrete units that can be undertaken in individual chunks and funded separately. The whole of these packets make up the full scope of works, but will theoretically allow the client to undertake the work in stages, although I find it hard to believe given the complexity of Federal Acquisition.

From a structural perspective this really sucks because the building is so old – but still in use (thus limiting what I could actually get to see). It has been chopped and changed so many times and has suffered significant water damage in the past. Only partial areas have been uncovered for inspection and some significant defects are manifest. Therefore the full extent of the defects can not be fully ascertained – nay – will not be fully ascertained until the contract is in full swing, which will likely lead to additional costs….which the Client does not have. My report will have to contain strict caveats to that effect and I just hope they manage to iron out the colour of their money soon. On the plus side I will get a chance to go and work with the budgeting guys to learn how to make a million dollars disappear.

As for the seismic analysis itself – that was fairly straight forward but required a lot of interpretation and judgement. The only areas that it really falls short on (other than water damaged and rotting floor joists of unknown magnitude) is the fact that there are no ties for any diaphragm members to the masonry – which should theoretically be a fairly simple fix. I have a nice pile of calculations and codes to wade through which should keep me quiet for a while now.

Dam Structural Issues:

It seems the structures department is bracing itself for an inbound Request for Equitable Adjustment (REA) where a contractor tries to tell the evil government that they were diddled out of cash and that they want it back. I had some fairly extensive exposure to this side of life on Phase 2 and so I had a lots of suggestions for them based on this experience. The structures department tends not to get too heavily involved in these but this particular one involves a contractor specifically going against their recommendations – incurring extra costs and now they want to try and turn it around. Whilst I’m happy to get involved – I’d rather not as I’m kind of treading old ground and would rather seek pastures new for Phase 3.

On a related note – the REA I was involved in has been progressed using the tools I developed. The contractor is attempting to claim $3.2M – but the Government reckons only $500k is valid. I will try and get to sit in on the negotiations when they happen.

Happy C-Bomb Day

In Phase 2 I whinged about a particular member of staff in the Huntsville office who’s general attitude to work and responsibilities was stopping my team from being able to do their jobs effectively (and she earned the accolade of ‘C-Bomb’ from my guys). I was continually having to scour the USACE procedures and quote from the Federal Acquisition Regulations (FAR) to continually justify the roles and responsibilities of my staff (We don’t normally have to do this – but because the project was a joint effort – responsibilities became a bit blurred at the edges). Anyway – I singled the lady out as being the single biggest risk to the project and complained for ever to my line manager to get him to tackle the Huntsville office about it…..and he tactfully avoided the issue and left us to run the gauntlet. My parting comment was that if a cog in the machine is broken – then we need to fix it or replace it. Meaning we either need to train this person or move them on. My ConRep and Labour Rep both called me on the same day when they discovered that the C-Bomb has been sacked! Not that this had anything to do with me you see – she clearly upset everyone. The real surprise is actually that it has been proven statistically that here in the US you are more likely to die of natural causes whilst under Government employ than to ever be sacked – so this is kind of big…….although this news is not engineering-y in any way – it did cheer me up….I also know it wasn’t just me.

CPD:

A company called CINTEC (who also has a UK base) delivered CPD for our entire department on their masonry anchors and reinforcement systems. They have a ‘sock’ sheath around steel reinforcement that allows them to create custom anchors by pumping grout into the socks. Good simple stick and string engineering.

Structural Framing:

One of the junior engineers had produced some loading data for a new design which was to be sent out to a contractor to run computational modelling for new roof trusses on a building that I am not allowed to know about (for security reasons). The chief structural engineer was checking it over and was not happy with it and asked me to go through a last.minute.dot.com framing exercise with him to ensure we have sensible numbers. At first I thought ‘what would bat man do?’ but punching him in the face and diving out of the window didn’t seem the right option, so then I thought ‘what the the Farmer do?’ and a cunning scheme was developed on the whiteboard. The only thing that was missing was Steve Dollimore to sit at the back and nonchalantly inform us of any several mistakes….but i think it was sound. Our structures guy was complaining that many graduates do not have a good understanding of structural framing and thus – it drove home the importance of the exercise we did on the PET course…..even if I did curse it at the time.

Structural Canopy:

A design has been produced in house for a canopy above a series of guard booths at the (shhh don’t tell anyone) NSA at Fort Meade. In order to get some more money type questions buzzing in my head I asked if I could help with the take offs and subsequent costing etc. First phase is done – will go sit with the bean counters afterwards to see what they do. First observation is that there is an awful lot of assumption going on as to who is meant to be providing what information. I imagine that if the bean counter is not on top of his game then we may be missing big chunks out of our initial cost estimating process….which might explain why every single project we do seems to go over budget. Will report more next time.

….And in other news:

I have been interviewed by the Public Affairs Office so they can run an article about those dapper chaps that are floating around the office. (Conehead Jim – this refers to Ben and I before you hit me with bouts of sarcasm!). I kept telling the lady to ask Ben about his very British pass-time of ‘Dogging’, as this would make for interesting reading amongst our audience. Unfortunately she looked up the word dogging on google and has decided that this is not a suitable topic for USACE to promote – although she has offered some good advice on a park and ride near Westminster, Maryland.

And finally – if you were wondering about the heading of this week’s blog – the wife bought us Salsa lessons on Groupon for Christmas. We went back for our second of six lessons and whilst I went ahead to use the bathroom, Ulli took a swig from a bottle of coke (outside the establishment) before screwing on the lid and putting it in her handbag. The manager saw this and confronted her upon entering. After going through several variations of bull**it about it being illegal he physically went into her bag and confiscated the bottle (even the security staff in our Government building aren’t allowed to do this). By the time I returned from the bathroom Ulli had come to the conclusion (rightfully) that the manager was going to ‘get it’…….we were invited to leave and never return…… I know America is a big place, but we need to pace ourselves for fear of running out of drinking holes before July.

Update from Brisbane

G’day all,

Just dropping a line to update on progress in Brisbane – not sure I can compete with invitations to teh Shard or pictures of enormous plant moving stuff…but I have been involved with a number of projects both online and offline.

1- Design of a portal frame structure has been an interesting experience…supposed to be a small task which ahs now groen arms and legs. Wind loadings aaaaghhhh blooming frustrating but fortunately not dissimilar to our PEW teachings or our own code. Definitely not the most fun job in the world but it seems to be progressing well. Next job – sizing columns!

2- Enoggera Army barracks…ironically working with 2CER (combat engineer regiment) on their new barracks facilities, checking the design, andwering RFI’s, following variations and generally watching JHG mess up the construction. Its been good working with the contractor first so as to have some knowledge about what is likely to be asked for next…it seems we have a lot of power!

3- Design of bridges – I’ve been looking at some pile design, and redesign because the original designs didn’t take into a water pipe and various vibration issues…so it’s nice to get into some geotech as well as grillage analysis on the bridges.

4 – Offline I have been ‘doing a bit on the side’…. 😉 I’ve been assisting a friend on an enormous wharf job where a 300t silo has to be transferred from a heavy lift ship onto a barge in the harbour…the lashings, vehicle specs, additional stiffeners on the barge deck, connections and logistics are complex….it may warrant an appearance on Megalifts!!!

Once it’s on the barge, a vehicle drives under it, jacks it up on hydraulics and drives off…on a specially designed ramp. I’ll be popping to Gladstone in May on some leave to see the operation….

Attached are some screenshots – the first is an example of one of the vehicles used- these can be joined up like trains as they’re modular…our one will have 200 wheels!! I love it that the wheels can go in different directions.

These are just some images of the silo – 11m CofG is not funny!

I’ll try to attach some better photos – computer has just said no.

Back to the portal frame..remembering to use a UB for a column….

Best wishes,

R

Offshore on the Magnus platform

Offshore!!!

After three cancelled trips I finally got onto the Magnus platform to have a look at the jobs I’ve been working on for the last ten months – and now I’m stuck here!!! Having been delayed on Shetland on Saturday night we got in on Sunday morning and I was supposed to head back around noon today but alas, the fog stepped in once again and here I am, sat in a cabin at the top of Magnus (itself sat in 190m of water, 160 km NE of the Shetland Isles). Not a bad place, but having had family (younger siblings and spouses) up with Liz in Huntly since Saturday evening I’m feeling a little sorry for her!

So what’s it like? Well, in many ways it’s a 30 year-old rust-bucket! It’s quite strange wandering round actually, as all the photos I’ve looked at and plans I’ve studied are now there in front of me and some things seem very small and others a lot bigger. Inside the quarters there are nine floors up to the helideck and a broken lift, and “outside” in the process (working) areas there are 3-4 floors and an open piping deck, with an ALQ perched in the middle as well as the prominent cranes, drilling derrick and flare stack. It’s certainly impressive, and although its only 56 x 62m width-wise, getting anywhere takes a fair while due to the labyrinth of walkways and closed off areas, interspersed with stairwells and heavy, sealed doors. Geeks (you know who you are) – you will like this New Scientist article (from before Ben’s time!) that shows the scale of it: http://tinyurl.com/ayvb98l

Anyway, it’s been brilliant here, on a kind of treasure hunt looking at where the Piping and Instrument Diagrams (P&IDs) tie into the real thing. As most of my jobs are in the execute stage it has been a bit of a sightseeing tour since most of the engineering is done, other than looking at the Bunkering Lines job which is just going into Define…

Bunkering Lines

If I was to listen to our contractor, WG PSN, this job is bigger than Ben Hur. But going out to look at it, we are removing the existing fuel and water hoses (they’re replaced every 2-years anyway) and adding a semi-permanent fitting so they can be extended onto the flotel’s gantry when it pulls alongside in 12 months’ time. Which is all of 15 foot away. Difficult as it is to actually get a survey booked and done, the adage holds true: time on recce is seldom wasted!

Cold Boot

Two blogs ago I explained that the Cold Boot project had been delayed – but didn’t quite realise the implications of leaving it as it is. And this site is secure, right?

So… currently (and this has been the case for 4 years now), the boot drains “fluid” (mostly water and a few hydrocarbons) into the open drains. In doing this, the nearby gas monitor is switched off, but not the others (as this is judged to be too many). So, last week they drained it and the gas monitor picked up some hydrocarbon and caused a “yellow shutdown” which caused a partial but not complete shutdown. Without going into too much detail as this is now subject to a lot of investigations, this led to a build-up in pressure further down the system and kaboom! A 22” water pipe, specced at around 60 bar was subject to approximately 140 before it exploded and split wide open. Fortunately there was no one present as they would have been royally f*cked. Anyway, there’s lots of folk looking into it – predominantly because the pressure should not have built up like that and also because the platform’s been shut down since. So that’s nine days now that Magnus has not been pumping something like £1.5m worth of oil and gas. A day. Ouch.

Understandably, I’ve got a meeting lined up for when I’m back in to let people know how the project is progressing so it won’t happen again; they’ll love it when I tell them we’re looking at 1Q 2014 at the earliest!

Other jobs:

Bravo Crane has now finally been handed over, the last piece of which was a few days at Kenz in Zaandam, near Amsterdam last week. Finally, I thought, four of us going out for Amsterdam, what could possibly go wrong? Well ladies and gentlemen readers; never overestimate the power of civvies. After a good steak dinner, we retired to the hotel. I could not believe it, sat on my bed at 2130 hrs because the others were all tired/under the weather. Maybe I should have dragged them on my run (minus something in shorts and t-shirt in central Amsterdam, aah yeah) a few hours earlier to get some life into them. It just felt wrong (and I did check that they weren’t just going out without me…). I did consider having a night as the lone ranger but clearly hanging around civvies has made me weak too!

ETAP ALQ is nearly ready for handing over to the Renewals Team/ Cat B projects, as being £10-20m it’s outside of the “remit” for projects and mods. Shame really as it was interesting.

And design work (me doing some technical design) is due to start in March – better find that calculator of mine!

And in other news:

I’m doing a presentation to BP’s graduates (there could literally be a hundred but I’m expecting a few less) on leadership on Thursday as part of their “lunch and learn” series where they have a non-O&G developmental presentation. I think I’ve got a copy of MATT 6 somewhere…

Running on the Shetland Islands is windy and rainy; running on a running machine is just plain dull, but I’ve got to fight the pounds somehow!

Spare time offshore would be ideal for getting work done if the internet wasn’t as slow as it is (hence no sexy oil platform shot today folks). In all, this makes the “free time” all the more frustrating!

Liz and I haven’t entered any gnarly races this year (boo!!!!!), just the toughmudder, Edinburgh marathon and Balmoral trail race. Am considering running the Spey Way (60 something miles) at the end of June – can’t wait til the thesis is smashed and I can have my life back again!

And once again, Dougal is still getting bigger…

A consultant’s perspective……

Six weeks into my design office placement with WSP, I think I have come to understand why consultants are consultants, contractors are contractors and architects are architects….! I was also surprised to discover how quickly I switched allegiances and adopted a consultant’s perspective….nothing to do with the central location, swish office, great coffee machine and invitation to the opening of the Shard of course!

I was asked to contribute to the monthly ‘Knowledge Sharing Forum’, and conscious that I was highly unlikely to have discovered anything structurally ground breaking worthy of dissemination to the WSP Structures department, I went for a comparison of a design office and the military! Interestingly, I found the design office to be more comparable in many respects than site (summarised in the meeting minutes below):

Major Rachel Beszant is on secondment from the Royal Engineers. From her first month in WSP she has drawn five key similarities, and two differences to the military:

The similarities are:

- There is a strong teamwork aspect to our business – though we are each capable as individuals we can only deliver the projects we do working in teams.

- Within each team there is a structured hierarchy. This is necessary to ensure accountability and allocation of responsibility

- Goalposts change throughout the lifetime of a project. Whilst in the Army this may be due to a change of political leadership in our business we are faced with clients and architects changing their minds and on-site discoveries.

- Communication is vital to the success of our projects. This is particularly well done through the structures portal.

- People are the centre of the organisation and success is reliant on the skills and expertise they have.

The main differences being:

- As a private company WSP has to maintain commercial competitiveness. Money does unfortunately drive many of the decisions we make, though this does also ensure we are efficient.

- There are no Sergeant-Majors enforcing discipline on the second floor!

I fear if my turn comes around again before July I may have to work on a groundbreaking discovery!

Aside from organisational and people observations, I can confirm that geotechnical parameters and water levels are indeed as vague as John warned us… and London is sat on a lot of water! The British Standard generation hate the EuroCodes….. and software packages are almost as reluctant to change as the BS era! Software modelling is the way forward as long as you understand the programme and know how to fix the errors, and hand calculations are key for checking, but any longer than 2 pages are reserved for graduates (or RE attachment officers!!)

Verifying references (thesis)

Guys – don’t do this as it causes pain!

Joking aside, I just thought I’d confirm a study from Deloitt (Wauld, C, on fuel usage (it’s steadily increasing to 22 gallons/soldier/day on average) with some figures from their Government Accountability Office and Congressional Research Service (should be pretty solid). But oh no, whilst 68 million gallons of fuel, on average, were supplied by DOD each month to support U.S. military forces in Iraq and Afghanistan (Solis, 2009) there were 188,000 “boots on the ground” (Belasco, 2009). Which means a paltry 12 gallons/soldier/day.

My only thought is that Solis’ figures somehow don’t include airpower. In which case they are hugely misleading as the figure should be much more (124 million gallons a month). All the more confusing is that I imagined that there might be more fuel requried (because of air/avn) rather than less.

Any thoughts?

References:

Belasco, A. 2009. Troop Levels in the Afghan and Iraq Wars, FY2001-FY2012: Cost and Other Potential Issues. http://www.fas.org/sgp/crs/natsec/R40682.pdf accessed 9 Feb 2013

Solis, W. M, 2009. DEFENSE MANAGEMENT. Increased Attention on Fuel Demand Management at DOD’s Forward-Deployed Locations Could Reduce Operational Risks and Costs http://www.gao.gov/assets/130/121644.pdf accessed 9 Feb 2013

Wauld, C, 2009. Energy Security, America’s Best Defence. http://www.deloitte.com/assets/Dcom-UnitedStates/Local%20Assets/Documents/AD/us_ad_EnergySecurity052010.pdf Accessed 30 Jan 2013

All Change in the Aberdeen Office

All Change in the Aberdeen Office

Well, a month back and there’s a good amount of stuff going down in the Dyce office.

Staff changes

Promotions all round in my department which his good, as my Programme Lead (1-up), Eugene is keen to iron out those things that frustrated him when he was an SPA. (He’s replaced Hugh, who was a little bit “wet” at times). Similarly, Pete Neilson has taken over as Team Leader (2-up) and he’s pulling no punches in holding WG PSN to account. A few of their management have been “moved on” since his promotion and he’s bought in new staff to oversee their methods of working. Pete is taking a much keener look at the individual projects and our management and initiation of them. His predecessor, Paul Mullan, was good but never seemed to be around, basing himself in the main BP office rather than our separate office. This may have been good for him personally, but I think the leadership of the team suffered for it.

At my level, we have a new SPA who I am handing over the B Crane changeout to. While this is a shame as it was a good job to be running with, it will eventually give me time to get stuck into some discipline engineering. This is something that has been amiss on my placement but I’ve just came away from a chat with WG PSN’s engineering manager (a Fellow of the IMechE who sits on the interview panel) who is reading through my Personal Competence Statements in order to find the best projects to get me through Review.

It may transpire that I actually hand over all my jobs, which would be a big shame as they’re not due for offshore execution til July and I’d like to get them there! Still, no time for sentiments when I’ve got a thesis to write and A and B competencies to develop.

Contractor Changes

Such is the nature of this kind of work there’s been a good few chaps from the office move on over recent weeks. As well as being paid anywhere from £60-100+ an hour, contractors are on 1-weeks’ notice (either way). This means that if a new job comes along they are more than happy to move on within that length of time; regardless of a successor being lined up or not. With some drama, our lead process engineer was told to clear his desk then and there, whilst one of the construction planners sat next to me managed his full 5-days before moving on to better and brighter things. With one of the SPAs off at the end of March and the BP planner away at the end of February, there are more and more empty desks by the minute. This is causing some problems already; our cost estimator left in November and still hasn’t been replaced. The comment of there being far more jobs than “qualified” people in Aberdeen has never been truer.

My jobs

These are all progressing well with one notable omission, that of the Cold Boot upgrade…

This has massively stalled due to two main factors: the postponement of the Controls Improvement Project (CIP) and the realisation that there is no suitable pump to empty the boot (a vital part of the project). Being located at the bottom of the platform, already having a low NPSH, potentially having muds within the “fluid” and being at low temperature (JT effect kicking in there too) there really is nothing on the market that can cope. Separately, the postponement of the CIP means that any tie ins to the ESDVs will have to be through old-school “manual” logic gates cards – literally hardwired AND/OR gates that slot in to the old control panels (Ben would love it). So, while I can still get most of the TAR work completed, I am redefining the complete scope to use a N2 blow-down system instead; something that is so very different it will need a new HAZOP and LOPA to be done to ensure it is safe. Furthermore, when we re-connect the ESDVs we may need a gas outage to allow for them to be programmed; this is where it will get painful…

While this is a motherfudger of a change, I am thankfully not entirely responsible having inherited it midway through Define (plus, the CIP project only got postponed in December). Still, it is a bit of a nightmare and something I want to get back on the straight and narrow before handing it on. To be fair, having HAZOP’d the old (pump) system we are in a far better place for getting this N2 system right after a good Define.

On the plus side, it also looks like a much better solution that might be fully ETP compliant and so a permanent modification, rather than the pump system which was only a temporary solution until 2016.

Extracurricular Activities

How are you all getting on with CPD? The IMechE meetings here are at the opposite end of town, so I’ve only gone to one so far (it took 90 mins to get through the traffic and then it was really boring anyway). Still, BP are hosting one later this month so that will just be a trip to the other office. As for now, I’m just about to head into town so I can get stuck into some fun with the Young Members’ Panel; what better way to spend a Tuesday night?

Purple Monday

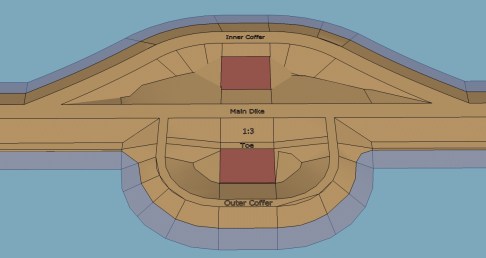

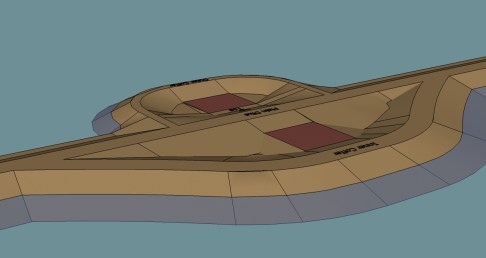

Poplar Island: Last time I blogged I had a conundrum on suitable temporary coffer dam configurations for the installation of the proposed dual purpose inlet / spillway structure. The proposed solution seems to make better use of equipment and resources and avoids re-mobilization of manpower and equipment. There are other potential benefits in so far as one of the temporary structures may be able to provide another dual purpose by acting as a ‘check dam’ for later stages of the project but I need to research this a little more first.

I have begun the stakeholder engagement to see if the proposed structure could have any wider benefits to the other users (such as the Ports Authority, University of Maryland or the Environmental Protection Agency) as I have seen testing stations precariously jerry-rigged to similar structures around the island. I basically want to see if we can incorporate something into the design that will make life easier for others. The initial response has been one of outright flabbergast. Apparently people don’t normally think outside of their bubble and the invitation to have input has so far been well received…..though I may live to regret it and start sticking to my own bubble as a result!

My current puzzle is to figure a way to make stop-log structures stop leaking without introducing bulk heads or spending any money…..this will be a fun one. [Richard – I’m sure you’ve puzzled over this in a previous life, perhaps during a long pause in a bell-ringing session – any thoughts or guidance will be gratefully received (bell ringing or otherwise)].

Building 45 Seismic analysis: Having been totally flummoxed by random circular references in the codes I have finally made some headway. The problem is that it’s not just the building codes that count, it is also subject to additional requirements because it is a federal building….which also references more design guides but in a way that only serves to complicate the issue. I have since discovered that because of this they have had to produce a ‘codemaster’ booklet just to help us poor mortals actually put pen to paper instead spending a lifetime reading in circles. I have undertaken a pretty extensive desk study and created the framework for the report to hang off of as well as generating a field check list for the survey itself to make sure we don’t miss anything. Thankfully the seismic analysis is based more on empirical data and observations of particular building types and their observed responses to seismic activity from previous events as opposed to having to come up with a super cone-head analysis and FEM….phew. Unfortunately the owners appear to want the moon on a stick included within their scope of works and now the whole renovation is in jeopardy unless they can trim it down somewhat.

Levee Screenings:…are long and tedious. Thankfully they spread the love on these so I won’t be stuck in damnation for too long. They are actually a really good way of learning from the experts, some of the knowledge they’ve spent a lifetime building up so I won’t complain.

Occupational Health and Safety Audit: Me and my big mouth. Having done my last TMR on H&S and asking lots of H&S questions of everyone, when the shit sandwich of dealing with the baseline info for the ARMY wide review came in – guess where it fell. I did a bit of questioning with the poor soul at the next level up who was eating an even bigger sandwich, it turned out the deadlines for this were tighter than PET student with a 75% thesis submission due. Ultimately I devised a questionnaire, gathered a sample set of folks, got the data and turned it around in quick time with a whole bunch of wider recommendations to push up the chain. It’s all gone quiet again for now but the next phase will be to revise the office H&S procedures, update the risk assessments and make sure everyone is processed….perhaps I will fake a heart attack that day.

Officer Professional Development: The most recent OPD was a trip to Washington DC with the other ‘green skins’ to have a look at the Federal Emergency Management Agency (FEMA) and the USACE HQ to see how they deal with emergencies, coordination of resources and command and control. Having comfortably making it through security to the briefing room FEMA decided that they still haven’t forgiven the Brits for that little misunderstanding in 1812 and ejected Ben and myself. Not to worry – we caught up with everyone for the USACE HQ brief where we got all the info anyway (go figure). Unfortunately I made a comparison of us being the foreign soldiers creating admin issues to the floppies at Sandhurst. I think Ben is now paranoid that the USACE lot think we’re the floppies….sorry Ben.

The OPD concluded with ‘Chem-Ops’ – the codename that was applied for us going to one of the officer’s houses and learning how to brew beer….all educational. Ben and I added to the educational theme by delivering a presentation on the history of the Corps, key achievements, current day and future……while they drank beer. I found that this makes an audience much more forgiving and would like to propose that this is how we should undertake the senior officer de-briefs in phase 4.

Other News:

I’m quietly confident that my long term light-rail stalker has moved to Canada – I feel safer already, but I appear to have picked up a stalker from the IT department now and am convinced he’s even more dangerous. I’m considering tracking down George in Canada to tell him all is forgiven….or better still – hook him up with IT stalker.

Ulli has progressed well with her horse riding and took part in her first fox hunt recently…..I didn’t ask what was for dinner that night.

…And the Baltimore Ravens have taken the Superbowl. What a game! They were…….running…..and hitting each other……and sometimes kicking the thing. I really have no idea what was going on, but if they had lost I am led to believe that Baltimore would be in flames about now. The parade is this Wednesday – so I will acquire a giant purple foam hand and show my support….and hope that nobody asks me anything about the game.