Archive

Its been a while, but things are ticking along fine in the design office

Hmmmmm, been a while since I’ve written one of these, anyone would think that a thesis, several reports, a day job and moose-dodging in the Alaskan wilderness might use up one’s blog-writing time…..!

For the serious stuff (if like me you read the funny stuff first, scroll down to the bottom):

I’ve now been working the Mechanical section of the USACE design office for a couple of months, and am enjoying the work greatly, the 3 hours each day wasted in the Baltimore commute not so much, thankfully though no car accidents yet.

The largest single piece of work I’ve been working on has been progressing the design of a renovation of some military accommodation in Boston. As handed to me, this was at a very early stage of development and so I have been able to take responsibility for the advancement of the mechanical design. This has been considerably slower than I would have liked due to the necessity of learning several of USACE’s software programs that I am unfamiliar with (I long for HEVAComp!) It does seem that every individual step requires a new piece of software, so whilst I am broadening my horizons dramatically, I am getting a little frustrated with it all.

I am currently evaluating which technology to employ for the updated HVAC system, thus exploring many HVAC options, ruling out the truly ludicrous, and conducting an annual energy analysis of the most likely. The most feasible few, I have explored in more detail; 2-Pipe, 4-Pipe and Water Source Heat Pump in order to cost the initial retro-fit installation. I produced a whole-of-life costing for each option and this is leading me towards the WSHP. The next stage of this will be a more detailed design of the WSHP, although this depends on future funding approval (see below – sequestration). One other frustration is that I have had to work entirely from poor quality pdf As-Builts, given that the opportunity for a recce (jolly) to Boston is not on the cards. It certainly hammers home the importance of good quality As-Builts.

Other responsibilities within the section include inspection of completed drawings for adherence to fire regulations, which gets considerably easier once you understand the basics of US regulations and can anticipate common problems. It was slightly embarrassing to have to point out an error made by one of my mentoring co-workers in a drawing already released to the contractors, which seems to have now highlighted a serious and complex problem that I am now required to help him fix (whoop!). The problem was that he had implemented a system that would easily end up using the main through corridor as a duct, never a good idea! Clearly this is difficult to solve, but much better to have caught it early.

Problems at the SSP continue to roll on.

I am still maintaining a link with the construction work happening at the SSP and USAMRIID. The USAMRIID is moving into the fully fledged commissioning of all the diverse systems, and also getting closer to the point where the contractor ceases to be able to argue that his schedule is true to life. The communication within the SSP project appears good on the surface yet very little work is actually happening and almost inevitably it will move to litigation in due course. I am hoping to be able to observe this.

One of the problems that may critically affect the entire future use of the SSP is the poor concrete quality in the basement, which leaks ground water, not ideal for a bio-containment facility….. If this cannot be solved it may force extensive rework.

New projects on the burner.

I have a couple of new projects on the go, both of which are basically writing specification documents. One is for the plumbing of the renovation of a military building, and yep, you guessed it, it requires me to learn yet another piece of software (and liaise with the IT department for installation, which in itself is a mighty challenge!). The other is editing an Request For Proposal (RFP) for the fire suppression systems of some US Airforce installations in Abu Dabai. This is an interesting insight into the requirements of the fire suppression system and the USACE standardisation (or lack of) of specification documents.

Sequestration concerns.

I’m sure the media has adequately relayed that the US Government’s inner workings are about as cooperative as a box of coathangers, so they have rolled from one near financial miss to another, and the current solution appears to be implementing a four day week for Government workers. This is yet to be finalised within USACE as many people are employed as part of the project funding and thus making the situation more complicated. The lack of clarity is generating lots of rumour control, with people trying to work out what they will do with an extra day off a week (and 20% pay cut). This may affect project budgets but no one is sure yet.

In other news.

Close but no venison steaks for the Hancock family after a hunting season where something called a thesis was getting in the way of a good hunt! I’ve heard that there is to be a deer cull in the UK, hopefully I can help!!

We had a brilliant delayed honeymoon to Alaska, where oddly enough it was quite cold! We stayed in a wilderness hut at -30C on Valentines Day – I really know how to treat a wife on a special occasion….. We did see the Northern Lights, learnt how to husky sled and snow shoed up a mountain until we almost caused an avalanche (we snow shoed down pretty quick!)

I also managed to convince a co-worker to go on sabbatical last month – which management was pleased about, not because she was bad at her job but rather that she had been planning to quit outright, this way they get to hang on to her for a while.

Sarah is looking forward to quitting her job – having recently had to fire a temp for sleeping on the job, mainly bad because he was the site nailgun operator and was standing up with his finger on the trigger.

I hope that everyone is getting on well with their theseseses, it seems very close to hand in date and to us all getting back to the UK. Aaaaaaaah, proper Cadbury’s………

There can be only one!

As if in preparation for the move North, the snow in Gillingham began the night before the movers arrived. It hasn’t stopped for more than a few hours since, although the vagaries of the Aberdeen weather system has ensured that it hasn’t accumulated more than a few centimetres. Certainly not enough to discourage cycling to work, but it’s good to see it is not confined to us Northerners.

New Start

BP appear somewhat bemused to have another Sapper in the office and are at present deciding which team I am to work in, HR are scurrying around trying to find out how to register my employment, but despite this I ( under supervision) have managed to get an ID and so my foot is firmly in the door. I’ve been assured that I will have a laptop and a staff number soon and, much like Chris before me, the work will ramp up. Unsurprisingly I’m working in the same office as Chris at present, namely Projects and Mods, and so far I’ve mainly been referred to as Ish MKIII or Chris MKII proving there can be only one.

In the meantime I have started wading through the BP best practice doctrine such as “The Way We Work” an outline of the process by which projects and modifications are brought to the platforms and some guidance on the electronic system for managing change. I’ve booked myself on several of the courses required for onward integration, including the old heli dunker and survival at sea training which, by all accounts, is not as hard as in the good old days. No suprises there.

Bruce P60 Bridge Bearing Changeout

This is by no means on my plate at present, but I had the opportunity to sit in on Chris’ meeting with the Asset Programme Lead for Bruce, Kerry Scott. There is a distinct possibility that this project will come my way, which is mildly amusing in that it has been something of a PET project since Ish’s time with Chris writing the SOR for the Appraise phase and pushing it through to what is arguably the select phase. Either way, I’ve been reading up on it and will have my view on the situation next week.

Re-location

Corine and Hugo survived the move and are settling in well. The boxes are mostly unpacked and I have plenty of new furniture to un-flat-pack. Deep joy (love it really). Hugo was most entertained during the unpacking process and it just goes to show that you don’t always need expensive toys!

Time to enjoy this momentary lull!

Adding value!

By the end of the week I finally felt like I was adding value to what I was doing and not just being a newbie asking lots of questions. I am still asking lots of questions which I can only see increasing in the next few weeks as things get a little more complicated but after 3 weeks I am now producing product that contributes to delivery! With a large amount of handrailing from previous AMS’s I have now completed the AMS for the Dickson Road piling which starts on tue morning. It has taken a full week to get everyone to sign off the method statement and there has been a lot of red pen learning throughout the week. The biggest hurdle was of course health and safety and to understand the various management plans and JH procedures that I need to understand and quote. It has turned out to be a 39 page document for 3 days work! Luckily Australia have recently updated their H&S act from the Occupational Health & Safety Act to the Work Health & Safety Act from Jan 2012, which my ‘white card’ instructor told me was practiaclly copied from the UK so it is fairly familiar. Environmental issues are also a large consideration with the main issue seeming to be ‘dirty water’ run off into the various creeks that the alignment passes through. Any water that leaves the site must be treated before being discharged into a natural water course by digging a holding pond and adding floculant. It has been very dry here and recent excavtions down to 10m did not encounter any water nor did the boreholes which were done 3 years ago so we are not expecting a wet bore. However, we are planning for the worse as you do so we are using a tremie and as the hopper will be at ground level we will pour directly from the agitator truck. We will also excavate a trench to channel any water to a sump or pond but as long as it doesn’t leave the site we will leave it aone or use it as dust suppression. The top of pile will be about 3m below the current ground level so we will be drilling about 9m deep. As there is a 1m projection and due to RTA (Road Traffic Authority) spec we have to overpour by 400mm (dirty/unpure concrete top to be trimmed) so we ended up ordering 8m cages incase we have to drill further to achieve the required 5m socket depth within the rock. We also ordered additional L bars which we will weld onto the top of the cages at the required length so that they will sit flush with ground level to making unhooking the load easier for the rigger.

I have started to spend JHG’s money this week ordering 44m3 of concrete with a message (I hadn’t got a clue what he was on about initially but a message just seems to mean ‘there abouts’ so that you can tailor your last truck to the exactish quantity you require + or – your original order). I have planned for 3 days to complete all 10 piles (5 for each abutment) which would have meant we could have wrapped it up by easter but apparently thu is a RDO (Rostered Day Off) for all in the construction industry – apart from those on a salary – so we will have a 5 day break before competing the last 3-4 piles.

Having generated worklots for the two abutment pile groups and having produced a concrete pour plan you are also required to send out notifications based on the relevent HOLD and WITNESS points prescribed by the spec. Quality control on this project requires that both the client (Transport for NSW) and the RTA/RMS (Road Transport Authority – recently rebranded to the Road and Marine Service). The client has its own ‘surveillance officers’ that work along the alignment that need to be informed about what you are doing so that they can view the work with some points being HOLD points in which we can not proceed until they are happy. As we are working on the roads and rail we effectively have two sets of parents and the RMS have employed Halcrow to carry out Project Verification on their behalf so they also need to be notified about what and when we carry out specific work and it is these characters who take a keener engineering interest to make sure the RMS spec is being adhered to.

Overall this week has been a little too desk bound for my liking but unfortunately neccessary and I feel like I am now contributing and getting to grips with the project/company specific procedures. Having the power to spend alot of money and being aware/conscious of what you are spending is an experience I have rarely worried about in the army but here it is at the forefront of my mind. This mornning I spent $7000 on stainless steel dowels!

Next/this week as I am writing this on a mon, I will be mainly site bound as we install the piles and I also intend to focus on understanding the contract a little more. It is a Design & Construct contract and I have managed to grab a copy of it for some evening reading tonight before meeting up with Terry Stroud the commercial manger by the end of the week.

The weather remains rediculously hot – I hear there is a little snow in the UK – but I’m glad the Ute has aircon. Although the fact that everyone has a white Toyota Hilux with a flashing amber light has meant it takes me a lot longer than it really should for an educated man to try to remember where I parked!

On the Rise(r)

At the end of the 2nd week I am gradually settling in on site. The pace is furious but that is probably because the project is nearing a milestone that is worth about $20m and without a big push it may be missed. To couple with that the next 2 weeks are short due to Easter so I don’t expect the pace to slacken much.

There has been a restructure of the project team since last post which has seen a split into North and South project teams. This has meant a move of offices but probably only for a while before we move again when the growing hospital superstructure expands into the space we are currently sitting.

It turns out that I have picked up responsibility for a stricken riser in the Central block that appears to have been passed from pillar to post by both management and contractors alike. I have inherited the task after its initial lift from pile caps to RL 6.2m but quality control seems to have been an issue. On first inspection it was clearly evident that not only was the reinforcement completely different to the schedule, but its placement within the walls was pretty poor. The cover ranges from 10-60mm and the surface finish (Australian Standard (AS) Class 3) is debatable, but due to continuation prior to resolution it would appear that a precedent has been set and parties agree to disagree.

I was due to monitor the 2nd pour by shadowing one of the lead project engineers but ended up managing it myself. I was quite reliant upon the contractors for information but very wary that they were only telling me what they wanted. The reinforcement continued to be an issue for the 2nd pour as it turned out it had been incorrectly scheduled by the reinforcement provider and due to time pressures the design was amended to use what was available. This actually increased the overall strength of the wall, but threw up issues with header beams above and below wall penetrations. Because the header beams were designed to fail in bending it meant that the shear reinforcement was greater. However by increasing the bending reinforcement meant increasing the shear reinforcement further which led to crowding of steel around the beams and a lot of awkward fixing to ensure room for the vibe which increased time delays. Due to the rush to complete this task I was left feeling like a young Troop Commander with a clearance certificate again cutting about site to get the required contractor signatures to certify their work before the concrete could be called forward.

The pour appeared to go well from my amateur perspective, but after the shuttering was removed it looks pretty poor. There are a couple of small areas where the concrete hasn’t quite reached on the underside of voids and a couple of corners that appear to have honeycombed somewhat (potentially a leak in the formwork).

One thing I should definitely picked up on was the starter bars to the next level. Although this lift will be capped by a slab and the subsequent lift will then tie in after it has been cast, there are sections of the next lift where door voids are designed. By dealing with the lower lift in isolation I didn’t check the reinforcement plan for the upper lift and should have noticed that the reinforcement should have been closed off. As it stands now there is only a very short length of reinforcement at the top that will be enclosed by the slab. This is not a huge issue as the slab reinforcement can be amended to accommodate this oversight, however it does highlight to me how looking at the bigger picture will save time in the future. I should have ownership of the next lift from the start and will be able to manage it to completion with the correct Reo, and correct starts for the next lift.

I am now looking at column and wall pours in the South Block from the upper car park level to ground level. In an attempt to make up some time it was suggested that the columns and ramp walls should be poured as one unit. I agree that this would save time in pouring, but after the issues with reinforcement fixing that I experienced with Riser 1, think that the additional effort of getting the whole thing formed and fixed could take longer than expected. The other option is to use couplers embedded into the columns and pour a more simple, un-structural flat wall at a later date. I will be looking into this next week.

My objective for this week is to get my head fully into the contracts. I have booked a meeting with the project commercial director to do this

Peaks and Troughs

This week has been particularly variable in the level of activity. The project has very definitely been split into 3 separate blocks now with 3 distinct teams, I have found myself on Block B which is the largest at 17 storeys. Being the highest pretty much puts my block on the critical path, and rather critically we are running about 4 – 5 weeks behind depending on who you talk to, the high level of liquidated damages on this job £500 000 per week brings the delay into sharp focus, the week commenced with my project manager under considerable pressure, I think I was one of the few people who started this week with a guarantee of employment by Friday.

- Last Friday the sub-contractor stated that the first slab pour on my block would happen on Wed 20 Mar 13, even my inexperienced eyes knew this to be a complete work of fiction from the outset, hitting that timeline required the laying of all the drainage on the basement level, pouring of a further 4 pile caps, installation (once receipt of the finalised design and materials) of a pump chamber that will raised the foul water into the main sewer on the road outside, the steel fixing of the slab (thank God for the industrious Eastern Europeans, although not when I’m the one locking up as they always leave last) and the fixing of the internal walls and slab step up. Funnily enough the slab pour didn’t happen until today (Fri 22 Mar 13). The problems encountered along the way have been interesting, some of which I’m kicking myself as I feel I should have seen them coming.

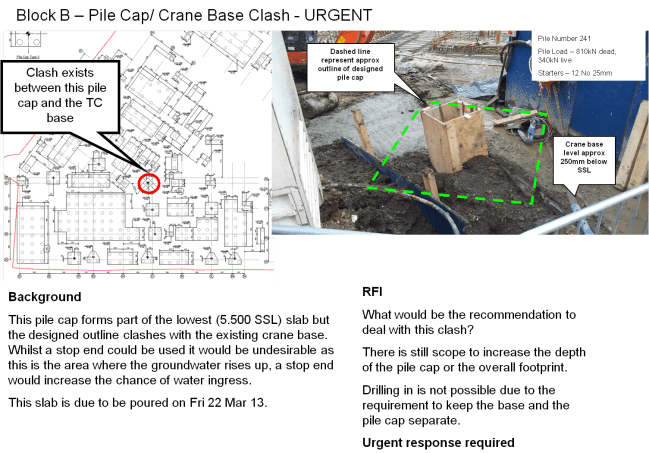

- Crane Base and Pile Cap. The crane base for my block sits just below the finished slab level of the basement, inside the basement itself but outside of the final structural walls. Somewhere along the line, either in design or tolerances during construction the base was constructed very close to one of the structural piles and overlapped quite severely with the pile cap as designed. Due to the artesian water conditions on the site we wish to minimise the number of joints in the concrete and therefore wished to include the pile cap in question. I was brought to my attention by the sub-contractor’s foreman. The design engineers have been somewhat overwhelmed with RFIs on this job and as such a response is not guaranteed in a timely fashion, I decided on a new approach. The world of construction doesn’t seem to have seen a quad slide before, it works. The response was received in good time to implement the solution although in the end time simply got the better of the pour and that particular slab pour didn’t include that pile cap.

- Mistaken Pile Cut Off. Those of you that know me know that diplomacy isn’t a strength of mine and it took all my effort to remain as neutral as possible during this incident. In the rush to get the slab poured on my block, the sub-contractors normal MO of banging in RFIs constantly about the most minor of items fell by the wayside, they assumed that a pile cap drawing was wrong, not just a bit wrong but wrong by 3 metres. They believed that a pile cap with a top of concrete level of 8.000m was wrongly detailed and so have read 5.500m and commenced pile trimming, right up to the point where there was no reinforcement left in the pile and so on the final pile crunch they lifted a 1.5m lump of concrete out of the ground. The problems that this has brought to light are:

- What to do with the broken pile? How to tie any remedial work to the pile as there is no steel left in it.

- Who pays for the solution to be implemented? A couple of issues here as it seems the steel should still be present in the pile at the break off level which raise QA concerns about the piling contractor, we are now looking at the possibility of having to try to use a cover-meter on piles that are exposed to check the length of reinforcing.

- Pour Day Panic. This is the one that I absolutely know I should have picked up sooner, I had been doing the checks to ensure the drainage was in place under the slab, but I had been guilty of assuming the sub-contractors knew what they were doing and of not thinking it all through. With the concrete deliveries 45mins off I realised that the drainage that was in wasn’t as it had been previously the soil and vent pipes for the foul system and therefore a pipe that continues up throughout the floors but in fact an open top gully that needed to sit flush with the top of slab. Thinking I must be wrong I asked the question about the absence of the gully pots and saw a foreman’s face drop. So disc cutters out, panic ensures and ground workers installing gullies as the concrete is poured no more than 5 or 6 metres away. Rich earns himself a breakfast.

A bridge two far!

Having spent most of my time last week getting stuck into the 47 drawings of Dickson Rd Overbridge I Have no switched my attention to another bridge. Kemps Creek bridge is an Underbridge which is the last structure that takes the rail line into the stabling yard. It is a 72m span which is about 80% complete but has sat idle for about 2 months as what I understand to be a ‘spartacus’ bicker occured as to who had the priority. The stabling yard won and so it is now time to crack on and complete the bridge by constructing the parapit walls. This is a view looking from the stabling yard end towards Glenfield with Eastwood Rd Overbridge in the distance. Both end appraoch slabs were cast on Thu and we ended up pouring to about 1755 where all works need to be complete by 1800 so we were cutting it fine – looks a little cloundy but it was still 25 oC. There are 46 precast parapit sections each weighing about 5T to be placed on the edges using angle brackets which bolt into the deck. Once these sections are secured then the walk ways will be poured which will cover the anchor brackets and tie in the parapit sections to the bridge deck. This has also been done on Eastwwod Rd bridge but as the brackets are effectively only temporary they didn’t seem to be strong enough, when the crash barriers were poured we had about 20mm movement on one section due to the weight of the concrete so that the bolts for the traffic barrier railing are now out of alignment.

West approach slab the day after being poured – the gantry’s in the background are the start of the stabling yard.

A view looking E from the stabling yard down the alignment – you can see Eastwood Rd in the distance which i near completion and beyond that Dickson Rd is yet to be started.

I have finished the AMS (Activity Method Statement) for the piling which now has a week to be passed around Safety, Enviro the superintendent, senior Project Engineer and Construction Manager for sign off so that the piling contractor can start next monday. The plan is that the piling will be complete within 3 days although we have a 1 day float before the easter weekend to complete. I managed to get hold of the borehole logs which were drilled back in mid april 2011 so fortunately around the same time the piling will take place. They drilled to a depth of 15m but the piling will only go to a depth of 8m and they are 900mm dia. The top of the pile cap will be a metre into the shale and then below there is a siltstone/sandstone mix. No groundwater was encountered which is understandable considering the dry summers here although the supervisor is convinced it will be a wet bore due to flooding they had in the area a few months ago. The rig is a Mait HR 130 which is tracked and due to the existing road providing a firm foundation it all seems to be straight forward with no issues perceived. Once the piles have been placed the civil team takes over for a few weeks to rip out the road and CSR (Combined Services Route) are placed so we will have a min of 2 weeks away from site I believe before we can finally trim the piles.

Dickson Rd Overbridge site (and my Ute!) – the bridge deck will be about 7m higher than current road level.

Eastwood Rd still has an opening date of 25 Mar which seems to be ontrack as the asphalt is now laid and they were finishing the walk ways on fri with line marking scheduled for mon. The final issue

that might scupper this date is due to the supplier of the throe screens that need to be erected. We still need to have a closed road in order to fit them but there is currently no work on when they will

be delivered. The supplier is from England and we are not sure if they are even in the country yet. If Eastwood is not complete this pushes back the piling of Dickson as we can not close Dickson as well

as Eastwood.

A big lesson learnt this week is site housekeeping and stores/material areas. We in the army have this drilled into us but by know means get it right all the time but it seems on this site if you you see

some reinforcement lying about and if you don’t get caught in the act you can help your self to a bit of it. I spent a good afternoon counting metal brackets and checking reinforcement deliveries which

we were all short and then learning we were the last in a chain of an organised pilfering scandal which means we are left with re-ordering half of what was ordered last month.

Better late than never

Finally I have reached site. It has taken a fair degree of admin to move countries and a brief period of R&R in the wine region to pacify Nicky; apparently 36 bottles will last until next visit (24 Mar).

I attended a corporate induction at head office Western Australia which was a good welcome to the company but lacked any of the detail that I really wanted for AER 1 and mainly consisted of powerpoint presentations given by people who would rather be doing other things. A fairly standard induction I think. The following day was spent in an isolated cell on the top floor of the building frantically clicking my way through online learning packages that I was assured were essential for site. I was told on arrival at site that 2 of the 3 were not necessary immediately so although I will not have time to do them when required at least I will have done them in order to forget them later.

The site induction was interesting. It actually gave a pretty good background to the project and was pitched at all levels. The team building activity of completing a 21 piece puzzle was my favourite part, though some struggled more than others. I had the corner piece so nailed it early and decided to project manage from the back.

The project is huge and has advanced rapidly since Steve left, as such has been split into North, Centre and South Blocks, with the superstructures well and truly out of the ground. The North is more advanced than the South with the main cores well into jump forming with the decks chasing the cores up rapidly. In the Centre and South the majority of the piles are now capped and columns cast with work well underway on the first slab for the upper car park level. The ground slab has been leapfrogged as the E&M plan was not completed on time and would have held up construction (Proof that E&M’s worldwide are slow and unwieldy). This will be completed once the backprops have been removed allowing work to commence beneath the first slab. (I may delve into this further for a TMR as I am sure it was not a lightly taken decision). I can’t really provide much more detail as yet, as after day 2 my head is pretty much still swimming.

The local schools entered a competition to name the cranes. The winners were:

- Koolangkas

- Kranasaurus

- Magnus

- Sir Lift a lot

- Tall Bert (My favourite)

I have been appointed as a Project Engineers though I am currently shadowing the Centre and South Engineer until I can take of the training wheels and fly free. Could be a while. Initial chat was that I may take over the as Project Engineer for the Centre block but I am meeting with my PM next week to discuss my objectives and set a plan to achieve them.

My time currently has been spent preparing works packs for column pours and I will soon be looking at preparation of a slab pour. I have been out and about on site whenever possible mainly to bring some of the masses of drawings to life, but also to ask the other Engineers how we have got to where we are and why things have been done as they have to understand the history of the project.

I have been impressed by the quality of engineer on the project. Even the youngest of site engineers is incredibly knowledgeable and luckily, all are quite willing to lend a hand to understanding the processes.

I have only met a few Australians on site so far. In similarity to Rich, everybody else appears to be Irish. It is no wonder the Irish economy is in turmoil, they are all working overseas! Looking forward to Paddy’s day this weekend.

A Building Is A By-Product

|

“The easiest and quickest path into the esteem of traditional military authorities is by the appeal to the eye, rather than to the mind. The `polish and pipeclay’ school is not yet extinct, and it is easier for the mediocre intelligence to become an authority on buttons, than on tactics”. |

|

| Captain Sir Basil Liddel Hart Thoughts on War 1944 | |

After a number of visits to our site this week I’m starting to feel that this quote applies equally to construction, it is far easier to attempt to win a Considerate Constructors award to make your bosses happy than it is to understand what exactly is going on on your site. I’ve said it to a couple of you over the phone, but for the wider audience; I am beginning to truly understand why construction isn’t really profitable.

We poured our first slab and put up the final tower crane this week, which has really changed the face of the site, the first of the core walls has been poured also. The remainder has been much the same as the previous few weeks, pile cap after pile cap, I estimate that we have poured about 25 pile caps so far, approximately 30% of the total.

The main core pile cap on the highest (17 storey) block was due to be poured on Friday however this was postponed due to in complete detailing by the structure designers. What I haven’t managed to find out yet is why we got to 18 hours from pouring before the issue became obvious to the site team of the main contractor. In short the groundwork and RC sub-contractor had done the take off for the core, found that some walls hadn’t been detailed and raised an RFI, this was transmitted via a complicated info management system that doesn’t seem to keep the site staff informed. An incomplete answer was received from the consultants, at this point I believe a notebook, a to-do list and a willingness to be engaged in actual engineering would have been useful. In short the sub-contractor was unwilling (and rightly so) to proceed with incomplete details and when we (I) managed to get the structural engineer who happened to be visiting that day to commit his answer to paper with a signature it was too late and the steel required wasn’t on site. My knee jerk reaction to this is that communication is the key problem I’m witnessing currently, there are plenty of meetings that go on but getting the information out of those meetings if you weren’t there originally is very difficult.

AER 1 is coming along and I think I have an option for TMR 1 but thoughts on a thesis are non-existent.

Tunnelling Medical Passed!!!!

Well its been another week in the office and things are looking good. After my initial medical, drugs and alcohol test BAMNuttal are getting their pound of flesh.

I started off being told I would be working at Farringdon station, then it was Bond St and now it is Holborn station. The good news is my commute has now increased to just over an hour, however it does allow me to get any extra work completed before getting home to a crying baby.

To my surprise the project site isn’t that different to being on tour.

- Crossrail have commandeered an old pub/flats that we are in the process of converting into usable office space. Much like taking over a FOB on tour.

I’ve already managed to acquire the old optics from the bar ready to install at home.

- Like on tour a number of the Engineers seem to have misplaced their razor blades and have been unable to get themselves to a barbers.

- There is just as much un-necessary paperwork here as there was on tour.

- The structure of the organisation is far more complex than initially realised.

The first thing I have been getting to grasps with is where I sit in the Project and the Company, no easy task.

Project

Crossrail are in the process of investing billions of pounds, approx. 18 billion, into the rail network system, in order to connect West and East rail services. As part of this investment, London is benefiting from a huge uplift in its rail network. The upgrades are broken down into 4 main sections, the Western tunnels, Eastern tunnels, Thames tunnels and the Connaught tunnels. Each section comprises of a number of smaller projects. For example the Western tunnel section consist of tunnelling between Old Oak Common and Farringdon. This one tunnel drive takes in Old Oak Common, Westbourne Park, Paddington, Bond St, Tottenham Court, Fisher St and Farringdon.

At each one of these sites a number of Works are required ie Enabling/Demolition Works, Piling/Diaghram Wall works, Tunnelling Works and Final fitout works.

BFK has won the contracts for the Tunnelling works on the Western Tunnel Section. These Works are incorporated into the C300 and C410 contracts.

As such, my role is as an Engineer for the Tunnelling Works at Fisher Street, one of 7 sites on the Western Tunnelling Section. Hence the Enabling/demolition works and the Piling works have already taken place, by different contractors, and BFK are due to start tunnelling works in 3 weeks time. In due coarse BFK will hand the site over to a new contractor in order for them to start the Final Fitout Works.

Company

Although BFK’s part in the entire project may appear small, only the Western tunnel section and only the actual Tunnelling Works, it is still such a large contract that one company alone was unable to cope with.

As such a number of construction companies have come together in a joint venture, in order to take on the task. BAMNuttall, Ferrovial and Kier have joined forces to win the Crossrail contract and are known as BFK joint venture.

I have been seconded to BAMNuttall , one of the companies within BFK, as one of 2 Engineers on the Fisher St site. However BAMNuttall is not a company in its own right and is part of the Royal BAM Group. The Royal BAM Group consists of a number of major operations:

- BAM Woningbouw – Residential construction

- BAM Civiel – Civil engineering

- BAM Infratechniek – Utilities

- BAM Wegen – Environmental engineering

- BAM Construct UK – Building in the UK

- BAM Nuttall – Civil engineering in the UK

- BAM Contractors – Building, Civil Engineering, Facilities Management, PPP, Property and Rail in Ireland

- BAM Utiliteitsbouw – Non-residential construction

Induction Fatigue!

G’Day,

My first week at work has come to an end and I feel very Health and Safety conscious! The Glenfield to Leppington Rail Line project at the moment contains no actual rail line and I am part of the structures team responsible for delivering all of the structures along the 11Km alignment. My part in this is working under the Section Engineer where together WE will (he already is) be responsible for the 4 bridges from Leppington station to the stabling yard at the end of the site. The bridges consist of 2 underbridges and 2 overbridges with 3 of these ranging from 70-80% complete. The remaining overbridge at Dickson road is yet to be started and this is what I will be giving most of my attention to over the next 6 months.

Despite the lack of tracks, signals, overhead lines and of course trains the site has kind of, but kind of not been designated a rail site – it depends on who you talk to and what day of the week it is! Despite this uncertainty I have attended RailCorp’s induction which is the ‘white card’ version of rail, along with doing my white card and the site specific induction all of which took a day to complete and all of which issued me with a seperate photo ID card to fill my wallet with. I also have another card to obtain called a Rail Worker Safety card which is again a card but has a chip that says I have the other 3 cards but because the rail safety supervisors don’t have chip reading machines they won’t have a clue what’s on it so we have to carry all 4 cards around with us anyway.

Getting back on point, the Dickson Rd overbridge is a fairly straight forward beast but the Section Engineer is looking at me as the focus for the construction and it seems I have come at a good time so that I will be involved from start to finish with an estimated 5 month build duration. The bridge is very similar to the other overbridge at Eastwood Rd but where that was a pad foundation the design has been made to change to piles in an attempt to reduce excavation works and the amount of concrete in order to speed up the construction and save in the region of $200,000. The project as a whole seems to be doing well and is 6 months ahead of schedule, but the pace is being pushed all the time in a hope to increase this further and receive the associated financial bonus. The bridge is an 18m single span pre-stressed concrete structure which is due to start at the beginning of April. Construction can’t start however until the Eastwood Rd bridge is complete which is on the critical path. We have an unmovebale deadline of 25 Mar to complete this bridge so that the road can open before easter and so we can close Dickson Rd to start on the final bridge.

Overall, this first week has been thoroughly enjoyable but blurry! We have settled into our apartment in the eastern suburbs (exactly 950m from front door to sand on Coogee beach – down from bondi!) and the commute is only 45mins each way or 90 mins if it’s footy night as I discovered last night! I have also found that the last 7 months at Chatham seems to have prepared me well despite feeling at the time I was being punished but I didn’t know why!