Archive

Moving dirt.

We completed all 10 piles on 3 Apr and for the past week and a half I have watched the civil team move a lot of dirt from one side to the other with no obvious plan. They have now taken possession of the site since we finished (they actually started ripping the road up while we were still on it!) to carry out the bulk excavation down to a sensible RL for us to carry out a more detailed excavation for the pile caps and embankment retaining walls. It has been a frustrating week trying to get a coherent answer or any information out of the civil team and I have picked up on a very strong sense of us and them between the civil and structures team throughout the project. The issue lies with the lack of work available to the civil team who are being pushed to close their worklots as soon as possible and move to other projects before coming back later in the year to proceed with the landscape works. There has been over million cubic metres of earth to move on this project and the Dickson Rd bridge is the final structure to start so they have been keen to get in and for us to progress so they can complete their work. Their impatience shows and results in less dialogue rather than more but by the end of this week we were all on a more even keel and the help of a few simple powerpoint sketches seems to have impressed and helped visualise the work required for all involved. We also have the Combined Services Route (CSR) digging away in the same patch of ground with one route adjacent to abutment B which we have successfully de-conflicted with but another route passes through abutment A and which at the moment looks like it travels directly through our excavation works. I am sure there will be more on this in next weeks blog but we first need to raise this issue with the designer.

As the civil team work to raise the ground on either appraches to the bridge we have manged to gain access to the abutments a day earlier than planned to start the detailed excavation at abutment B which we continued on saturday and hope to finish on Monday. We have now excavated about 2.5 metres below the existing road level and once we have cleaned out the excavation we can start the FRP works. Once complete the excavations will be blinded and the piles trimmed next week.

The pressure has been on at the other end of my section of works at Kemps Creek bridge which is at the entrance to the Stabling Yard. The stabling yard becomes a rail site as of Monday which seems to mean security gets beefed up to that of an army barracks (minus the armed guards) and the rail team works at a more relaxed pace. What this means for the rest of us is that we all work to the rail timelines. Track is starting to be installed at the stabling yard and so the civil team need to be laying the capping layer which the ballast sits on and so we need to have completed that end of the bridge so that the capping layer can be laid. We managed to pour the last segments of walkway at abutment B which faces the yard so come monday the civil team have a completed end to lay the capping up to. We still have the remaining walkways which house the Combined Services Routes (CSR) within them for the remaining 70m length of the bridge and we have been told we are on the critical path. We need to complete this bridge by 15 May for the track to continue from the stabling yard. Track is also being laid from the Glenfield end from 4 May so the bridge at Dickson will soon become critical also as the track approaches from Glenfield which is about 8Km away at a rate of 400m a day. Our aim is to complete the abutment walls by mid may so that capping, ballast and track can be laid between us.

The pre-cast parapets have been installed and propped before the CSR walkways are poured which tie-in and secure the parapet sections permanaently.

At the end of the week I got an opportunity to visit Civilbuild who are producing all of the pre-cast work for the project. These include the pre-cast parapet sections for all bridges for which there are over 2000 of various sizes and the pre-stressed concrete beams for Dickson Rd which was the reason I visited. I went up with the Project Verifiers to witness them pouring 4 of the beams for Dickson Rd but they eneded up cancelling the pour without informing any of us after a 3 hour drive to get there. 3 hours is considered popping down the road in Australian terms but having driven back to the project after an hour at the pre-cast yard and then driving home it ended up being 7 hours of driving. I did manage to see 4 beams they had already cast and 4 more that were formed up and ready to pour on mon. We require 22 beams for Dickson Rd and the yard has the capacity to pour 4 in a day. Each beam has a 300mm cylindrical void in the centre to reduce weight and is pre-stressed using 20 x 15.2mm (7 wire) strands with a force at mid-span for each strand once the tensioning jack is released of 175kN.

Organisations need a direction….if only someone could tell us which one!

Afghanistan Bunker Collapse:

After some additional feedback from Richard Farmer I re-visited this report (as it had kind of become my favourite drum to bang on). Just to add some more murk to the mire I went through some of the background information such as the early statement of works and it would appear that the mad design was almost dictated to the contractor by the USACE. It detailed that the walls would be of HESCO and would support the roof structure. There is sufficient verbiage in there to be sure that the contractor shoulders all risk but now I am of the mind set that the contractor was pretty much set up for a fall. I have had further battles with the USACE Engineering and Research Development Center (ERDC) to get them to carry the torch on this and sort it out. BLUF = Put actual numbers in the design guides for what loads the concertainers can safely carry (bearing in mind poor local construction methods and materials) and we’ll have more peace of mind.

I finally got authority to release sanitised photographs to HESCO (Jake McQueen) so that they can use them to educate the RE, the USACE and the industry in general. Subsequent contact with Jake has highlighted that he has been invited to go and visit ERDC with relation to loading tests on bunkers…so even though they haven’t admitted it (to us) it seems the ERDC are actually taking my comments on board.

Poplar Island:

Here’s the pop-quiz: water flow over a crest, into free fall, to then land in a crash zone before flowing into a pipe which has an existing (variable) tidal level which then has to normalise under gravity….. Having tried to develop a model for what appears to be the most complicated fluid dynamics question I could have possible attempted – I gave up in favour of identifying common features for identifying and comparing various designs that will allow me to decant the top layer of a dredge material through a level culvert and into the sea. At least it gives me comparables to make decisions. If anyone is feeling clever – please feel free to give me a hand!

I suppose the question would be something like “A lake is 1000m by 1000m and 4m deep (assume a datum of 0). A 2m wide weir is used to allow water to flow into a 2m by 2m square chamber. At the bottom of the chamber is a 2m by 2m square culvert with a zero incline. The culvert opens out into the sea which is currently filling the culvert to a depth of 1m. What is the maximum allowable release depth of the weir that will maintain efficient flow through the system?”…….well I’m buggered if I can figure it out…..and the hydrologists here at work make excuses or fake heart attacks when I present it to them. I think I’ll stick to my stick and string engineering for now!

I am now confident that the entire operation at Poplar Island has never had any kind of plan for emergency discharges into the bay (for if the main dikes were in danger of being compromised – we need to be able to balance any head differences as quickly as possible). Having applied some thought process to this I now see that traditional methods of using stop-logs to create the weir crests would actually be too dangerous to operate in such a manner. The more logs you remove, the quicker the velocity of the water (and the deeper the water) gets, making it extremely difficult and dangerous. So the answer to the emergency discharge question is ubiquitously ‘it’s never happened….yet’. If the need ever arises – they are currently screwed. I’m looking at some ways around this – none of which have ever been tried before by anyone in USACE at least. One idea was for a large scale mechanical roller-shutter device. Whilst the idea is probably a non-starter for a silty environment, it may have a wider application on flood defences where space and access issues are a concern. I discussed the idea with a roller shutter manufacturer – warning them that if they stole my idea I’d hate to have to hunt them down and kill them! Another idea which I am trying to develop uses an array of flexible tubes that will increase the flow into the structure…but more to follow once I get my own head around it first.

Building 45:

One Colonel promises another Colonel he can get his staff a lovely new home because they are being cruelly kicked out of their current offices. His staff prepare a request for some dollars from congress to re-fit building 45 for the purpose. They balls up the estimates but it gets approved. All wheels are now in motion but now it’s kind of clear that they will not be able to get what they promised congress they would be able to for that money. A bunch of the funding has already been spent on looking at options and now it falls to USACE to try and fix the issue. Make savings of about $2M by ‘getting creative’ so that the project manager that screwed it up doesn’t get sacked and the colonel doesn’t end up breaking his promise.

My role has been to do the seismic analysis which has demonstrated that the building does not currently fulfill the code requirements and I am designing a bracing system to overcome this. A number of structural defects are also present that will need to be repaired and I am drawing up some specifications to allow the work to be bid for. The drawings are proving a little challenging even though we had that really long CAD course at PEW.

The really interesting thing in this one for me is the way in which everyone is now in complete denial about how this is going to turn out. The Project managers are continually trying to come up with creative methods of mixing and matching different sources of funding to make up the numbers – but this is where people go to prison. “Dear Mr Congress man – I asked for a bunch of cash to build X but I actually borrowed from Y and Z as well and gave you less than we promised we would in the first place.”. More than a month has passed and the brass are still unable to come to terms with the fact that someone needs to put a copy of the yellow pages in their breeches and go and take the spanking. All the while we have been cutting from the electrical, mechanical, architectural and fire control systems to the point that we aren’t actually doing anything except make the building structurally sound… Others are worried we may be leaving too much money left on the table, to which the response form the Branch Chief was ‘don’t worry – it will be a sole source bid so they’ll spend as much as we tell them to”!!!! WTF!!! Reminding people that this is tax payers money seem to be un-cool apparently. The final straw for me was when I asked sufficient questions to basically get them to admit that while ever the Client (Army Support Group) can’t make up their minds, we are happily employing people and spending ASG money because there is little work elsewhere for the architects…..again – we are wasting tax payers money for no other reason than we can’t generate work from other sources. We now have internal Government organisations screwing each other over so they can get the money….which all comes from the same pot…..shoot me now.

I keep offering to go and be the bearer of bad news and even help the Client look at other options (like how the re-shuffle could be accommodated by moving other personnel etc) but if I do that I will dry up their source of tax money sooner rather than later… so this is not the preferred option (even if it’s the ethical option).

Costings Briefs:

In an effort to get a better understanding of the costing problems I saw with the canopy project for Ft Meade, I liaised with the head of costing to see if he could give myself and Ben a run down of how they do detailed cost analysis. This essentially turned into a CPD session and was extremely beneficial. He showed us how the contingency that is added is reduced further into the project development to account for unknowns and level of clarity. He showed us his sources of info, from means spec to direct quotes and how his software builds up the analysis to include estimates for contractors overheads, sub-contractor overheads, contingencies and tax.

I have since seen his data spectacularly abused by the project managers on the building 45 project. “it says here base price of $1.8M which puts us on budget.”…..well if you want to go to bid with no contingency, expect no modifications or changes or unexpected surprises, for the prime to do all the work and not sub anything out AND get the best dollar on all quotes from a sole source……be my guest. The result will be no bids within your budget and a colossal waste of time effort and money.

Internal Quality Assurance:

I have finished preparing a Quality Assurance system for use within the structures section and delivered training to the group on how it is to be used, monitored and maintained. This involved getting to grips with all kinds of tasks that the section undertakes, from civil, military, domestic, overseas, bridge inspections, dam inspections and levee inspections to be able to come up with a method of making sure that a simple, effective, user friendly structure was achieved. There were several iterations with user feed-back before going firm and handing over the product which is now being used across the section.

Officer Professional Development:

All of the District Officers (14 in total) attended a mammoth OPD spanning 3 days and camping out in -6 degree weather. The development included a battlefield tour of the Gettysburg civil war site with specific reference to the principles of war (the yanks have 9 – and they aren’t really like ours), a tour of the 23 mile long recreational lake that USACE maintains at Raystown PA, a tour of the level 4 biomedical research facility that is currently under construction at Ft Detrick, a tour of the Raystown Dam facility, a tour of the Raystown hydro power station and a bunch of environmental briefs (it seems the environmentalists are hell-bent on killing stuff….perhaps it’s an american thing). The highlight was a dining in function which Ben and I coordinated with more than a hint of British tradition and an opportunity to make some presentations on behalf of PEW and MKC for the ongoing partnership between PEW and USACE. At first I was pretty pissed off when they decided to make me Mr Vice – until I found out the role is slightly different to back home. I was basically in charge of keeping the entertainment going and dishing out fines to all and sundry. It’s probably the first and last time I will ever get to give forfeits to full colonels and get away with it! The Commander here has said he would like to fly me back to do it again for next year’s OPD – and I might just try and hold him to it!

REVIT Weakness:

The penny dropped whilst working with some drawings that appeared to have varying details depending on which set you were looking at. Upon questioning this with the senior structural engineer it turns out that REVIT doesn’t deal with multiple skinned walls. As a result we appear to have a window over a column that has gone unnoticed for a while and a modification is required. I was immediately reminded of my earlier role as Project Engineer on a reservist center where exactly the same thing happened. Many RFIs were sent back to the architects and engineers at District who continued to reference the drawings that seemed to make sense (inner skin drawings) – whilst all the while on site there was quite clearly a beam showing through one of the windows (outer skin drawings). In the end it was the contractor’s fault and he made the mods himself. There were many bad words said by both parties on site about the apathy from District on that occasion – but I now see how this comes about. There is insufficient residual knowledge and training to ensure that this is resolved for future projects and I’m sure we’ll see it again.

Developing Future Engineers (and me!):

I have observed that there is a great divide between the experienced ‘old guys’ (of which there are 2) and the ‘young bloods’ in need of training (of which there are 5). The experienced guys are so overworked they have too little time to help develop the young bloods, but without the young bloods taking on more work, learning more and becoming more independent the situation will never change. Speaking with the head of department it seems they lost a load of experienced guys and not all were replaced. Those who did join the group are young graduates with little experience. I have outlined a plan with the boss (for after the thesis deadline) to start a mentoring process and to formalise the interaction between the experienced and the junior engineers. I have begun to find other engineers from outside of the group to be able to mentor the group and offer ‘lessons I wish they’d taught me before I got here’. I will report more as it takes shape.

And in other News:

It was great to welcome Nick Colvin to the fold and help him start getting his clan settled. My wife is still plotting on how she can kidnap his children. I am working on how we can harness the energy they produce as it might solve some of the worlds power issues. It has highlighted however, how little time is left before the big push and CPR.

It’s great to see all the new blogs appearing and to be kept up to date with the new round of activities – best of luck to you all.

The kids are in their last 48 hours with us before they go back to the UK and back to school. We just got back from a mini vacation with them to Canada where we visited Toronto and Niagra Falls. Lukas did some of the driving and Ulli and I did all of the panicking and screaming. (Just for Richard – road kill along the way included raccoon, deer, a bird (difficult to gauge other than a ‘big black one’) and you’ll be pleased to hear we saw our first flattened beaver in the carriageway. As spring is coming we also clocked several ‘yellow splats’ on the windscreen and some ‘red splats’ on the windscreen. I thought we’d discovered and immediately wiped out a new species of ‘purple splat’ but it turned out to be a red on yellow coincidence.)

I now realise that this blog is becoming thesis avoidance (whilst maintaining clear conscience because it’s work……honest) – so I will leave you be and get back to my scale model of ‘fluid mechanics for idiots’ using the sink bowl, a set of straws, a toilet roll tube and some sticky back plastic. Who said engineering can’t be fun?!?….although Ulli’s going to kill me when she sees the mess I’ve made.

McFry

Wanted: Dutch boy for permanent position under a ground floor slab

This week has seen a number of changes, specifically with the sub-contractor, a number of new black hats have been handed out (the mark of a supervisor on our site), civilians don’t seem to get the phrase ‘You’ve changed!’

Artesian water continues to flow, sometimes I feel like we’re de-watering Southampton, without the help of a pump. The visit from our geotechnical expert was pretty unsuccessful, in truth he was an environmental expert that was going back to report on what he had seen to his geotechnical experts. The geotechnical experts have said ‘You’re F*$!ed’ clearly I’m paraphrasing, the best solution that has been suggested is to try and over bore, or encapsulate the former borehole location with a hollow casing allowing it to find a level and then backfilling with a tremie pipe using a grout, they are fairly non-committal on the possible success rates of such an undertaking and there will be a significant cost associated with getting something done and getting a specialist to deal with it. This would be all very well and good to try except for a couple of problems:

1. We don’t really have time to experiment, this is now holding up the build, I find this situation pretty frustrating because everyone seems to have ignored it for quite sometime now.

2. The attempt to cap the water with the concrete plug means that to execute this plan would require breaking out of about 6 m^3 of C50 concrete, so we’re going to get hammered for dayworks.

This leaves us with the french drain option, drawing the water off to a point where it can be collected and enter the drain system, the Environment Agency don’t seem too worried about the situation but winning over Southern Water might be a harder sell. A conversation with the Great Orator has helped, but in reality nobody can be sure of what may happen. I’ve done a bit of research and the waterproof joints that have been put in use a product that’s certified for 80m, we’re only talking 3m on my site and therefore it should shrug it off as long as the workmanship is up to scratch.

Such a seemingly simple problem has become quite a big issue, it is made so much worse considering the option to cap the piezo on the first place was offered up for a mere £600 per borehole, I would say we’ve easily spent that in fuel to run the pump. I think next week will see an attempt at the french drain option attempted, perhaps we’ll pull it off.

Who ever knew that starting the construction phase would require so much paper work.

We are now only 2 weeks from starting the shaft excavation. The Section 61 noise consent form has been accepted by the council. The predicted water discharge consent form has been approved by Thames Water even the British Heritage have signed off on the refurbishments to the office building. It looks like we may even hit the Crossrail Milestone of starting the shaft excavation by the 2nd May.

The major issue for this site has been its restricted site. The amount of equipment necessary to excavate an 8m radius shaft 80m deep has been enormous. This has led us to produce extra space in the form of 2 storey steel platforms. Rich Phillips would be proud of my Google sketchup concept sketch that I used in the Temporary Works Design Brief. See below Rich.

After being volunteered … I have now been nominated as the site Temporary Works Co-ordinator after successfully passing the Kier ran Temporary Works course 1 and 2 and a scaffolding course.

This has meant that a number of site issues have been left to me to resolve, the one causing the biggest headache is the muckbin area.

Muckbin Area

Unfortunately, no one joined the dots together and realised that for each 1m of the shaft excavated there would be approx. 370m3 of soil. Where to put it on such a restricted site?

The only place to store the soil is on a road between two existing buildings. However both buildings have basements and sub-basements that would require propping due to the additional loading. Anyway a solution has been found, the sketch below illustrates the concept.

With the addition of a void former the additional load can be carried pass the adjacent buildings basement and sub-basement. The only issue now is deferential settlement on the unknown services that run below the road. However we will resolve that next week.

The Temporary Works Co-ordinator role has been quite an eye opener. In recent weeks we have had to produce briefs and partial designs for: sub-basement propping, muckbin area, 80T crane platform, 2 storey steel platform to house the generator, compressor and receiver and a single storey steel platform to house the concrete remixer and concrete pump.

The next 2 weeks are extremely important. All of the temporary works must be in place before we can start the main excavation. Hopefully between now and the 2nd May you will see some big changes to the site.

I got piles!

This blog covers the last two weeks as it has felt like a continuous week with one aim to get 10 piles completed for the foundations to Dickson Rd overbridge. There was Fri and Mon off of course for easter and all ‘non salary’ personnel had last Thu off as well so that was a non productive day.

MGI piling were the sub-contractors who we brought in to carry out the piling and the main realisation of the last two weeks is related to the AMS and site control. MGI piling arrived the Tue before Easter and the AMS was briefed to everyone so that they can ‘sign on’ to the method, then a services brief was carried out and the permit to excavate signed (this permit is about 50 pages long with 98% of the content irrelevent to my actual site and has remained on the back seat of the Ute ever since!). It seems an AMS is similar to an “Admin Instruction’ in the Army where the Engineer/Officer spends a great deal of his time to produce a document that very little people read unless I suspect an accident/incident happened where it would be scrutinised with a fine tooth comb. Even though everyone on site had signed on to the AMS to say they agree with it etc, a sub-contractor will invariable do what he has always done regardless! I have no big specific gripe on this issue it has just been an observation throughout the piling works.

As we had ordered oversized cages in the event we had to drill further than expected the Geotech Engr and subby concluded we would just drill further anyway to the depth of the cages so that we would not have to cut and weld on site – we had already got the welder on site ready to go before this was decided to the slight annoyance of the superintenedent who had to re-employ the welder that day and is another case of the sub-contractor deciding something without consulting either the suprervisor or myself, having already agreed to the methodology. A possible concern with this was if the sub-contractor would charge us more for drilling further and pouring more concrete but the time saved would be of more benefit in the longer term.

Each pile was drilled through the road surface and was fairly straight forward, I remained on site for the majority of the works in order to check off the Inspection and Testing Plan (ITP) checklist as the works progressed for QA purposes and to control the concrete coming on to site. We encountered water at about 9m of a 9.5m depth drill and in some it was only about 50mm at the bottom once the bucket had cleaned the toe out so on most occassions I eneded up calling the concrete forward so we could pour the pile before an excessive amount of water could trickle in through the shale below.

The sub-contractor arrived on site with a different rig (T-108 rather than a Mait 130 if your interested) than what we were expecting which meant the whole works took an extra day than we thought. As the reo cages did not need cutting we did save time here and each cage weighing 1.7T were positioned to the rear of the rig with a Franna crane and easily lifted by the rigs winch and lowered into the pile hole. Concrete placement was done by a ‘lay flat’ hose as opposed to a tremie pipe due the lack of water although on one or two in my very inexpert opinion it probably should have been tremied. They would check the water level in each hole before we poured and inform either myself or the supervisor depending who was there and we would be happy to expect about 100mm (65 litres of water) with the lay flat. On one pile post pour I observed water about 100mm below the top of the reo and considering there was a 1000mm projection and 400mm overpour this meant we had a least 400mm (320litres) of water in there. Water being lighter than concrete means it probably isn’t an issue providing the ‘lay flat’ worked like a tremie as they assumed.

I learnt a great deal about the practical issue of placing concrete this past couple of weeks. I had calculated 4.7m3 per pile and thinking that this figure was not allowing for the displacement of reo an order of 9.4m3 for the first two which we poured together would be alright – it was just! There was nothing left on the last truck and we just managed to fill both piles but I didn’t want it to be that close again so ordered 5 per pile/truck for the rest. I also learnt that you can never underestimate the stupidity of a concrete truck driver. One decided to drive past the site twice after us flagging him down but he still decided to go on a personal tour of the entire alignment before realising he had legs and could get out of his cab and ask someone where he should be! This meant the concrete was an hour old before it arrived and we had 30 mins to place it which wouldn’t have be an issue if it hadn’t failed its slump test twice (tremie mix 180mm slump). We ended up ready to pour just before the 90 min mark having added the maximum amount of water we could so not to affect the w/c ratio, it was 1645 in the afternoon and the Project Verifier had just arrived to witness the pour. In the end I decided that we had been fairly quick in placing the concrete with the other piles and we wouldn’t get another truck until tomorrow so I decided to go ahead thinking if we start to pour on 90 mins it will be alright. It went alright up until the last 0.5m where the concrete was fairly unworkable and kept clogging the hopper. With hindsight I wish I had just turned that truck away and even if we poured the next day we still would have completed all works on the same day. A Non-Conformance Report (NCR) may have to be raised although the PV has not mentioned anything about it and I have got his signature on the ITP checklist already. As we are overpouring by 400mm this will help and I think the top will be where the problems may lie but we can visually check the top of the pile once we excavate and trim. Although the tremie mix is self compacting we could have also tried comapcting the top 1m or so, another lesson learnt.

Corporate pose – inclonometer readings.

Corporate pose – inclonometer readings.

Another annoyance was the back-filling of the holes as we had at least a 1.5m drop to the top of the cages from ground level we were to backfill the holes after 24hrs for safety reasons but the sub-contractor was quite keen to do this after about 3 hrs which included covering the inclonometer tubes. Fortunately I had made sure they were capped but having to dig them out again to take readings was a little irritating. I have taken readings on abutment B (24-72 hrs after pouring follwed by a second 24-72 hrs after the first) but have been unable to take the second reading at abutment A as the civil team have arrived and on Fri morning I went on site to see abutment A piles with a little earth covering them!

The 5 piles of Abutment A are under there somwhere.

The 5 piles of Abutment A are under there somwhere.

Some interesting local Sydney news for you over the Easter weekend: “Police were called to a domestic disturbance of a retired couple over the weekend. A 64 year old male has been discharged from hospital after having superglue poured into his ears and eyes. A 62 year old female is also accused of beating him with her prosthetic leg!”

A Long 4 day Week

After a relaxing, if short 4 day Easter break on Rottnest Island off the coast of Perth I returned to a 4 day week that has felt like a month. Prior to leave a milestone had been missed and it was now best effort to get the South Block Upper Basement Zone 2 suspended slab (320m3) poured by Wednesday and the following Zone 3 (120m3) poured by Friday. Even to my inexperienced eye I could see this was pushing it especially because the Senior Engineer was off for the week and it was down to me to manage.

I was handed control of the pour with about 50% of the Reo on Zone 2 complete but for a first slab it was a bit of a nightmare to comprehend. It was not regularly shaped, it had 3 step ups, 6 integral beams (4 with PT), 2 Temporary Movement Joints (TMJ) (for seismic design), 3 ramped sections, 1 stairwell, and 2 penetrations (one of which was to accommodate the up ramp from Lower Basement). To deal with the more interesting details in a little more details:

The reo schedules and mark-up drawings were fairly epic in themselves and took me a good couple of days to get my head around which was unhelpful as I was being asked questions from the point of arrival on Tuesday morning. This mainly involved multiple trips to the slab deck to identify the issue, to steel fixers (NRG) office to discuss a solution, then to the site office to call the scheduler to check measurements, delivery dates and bar marks to ensure all the required steel was there to complete the task. Having been on the task for 3 weeks at this point with minimal top cover, it was inevitable that there were going to be issues. There were plenty, culminating on the night before the pour, after the structural designer had completed his structural check, that we found we were missing wall starters and were unsure of the wall dimension. After a few frantic emails and an early morning dash around site, the size of the pour became an advantage as after the 0600 pour start we had approximately 3 hours to get it rectified if we poured in the correct configuration. We didn’t pour in the correct configuration but luckily the fixers were quick and it was done in the hour.

Slab joints are a fairly new one for me, and it seems that the TMJ technique used on the NCH is for a lot of people in Perth. The TMJ’s are designed to give the structure a degree of flexibility between slab edges during construction to accommodate shrinkage due to curing and PT. The project is using a range of Ancon shear connectors that are either locked off after a specified period or allowed to accommodate movement throughout it’s life. The benefit of using the shear connectors is that it speeds up the rate of construction as it reduces the requirement for complicated or additional formwork, and only leaves a small joint and connector that required grouting to finish the connection.

Post Tensioning in the beams is quite an issue, it appears that the structural drawings when sent to the contractor to produce shop drawings get changed ever so slightly that they always clash with the top reo. There has been several issues with the lateral placement of the ducts as many are detailed to pass through columns, but as the PT shop drawings were not complete at the time of column pour the bars were cast in the standard positions, therefore requiring bars to be removed and replaced by drilling and epoxying new starters in place. The issue that I have now found to be the biggest issue is the lack of any consideration in programming for the lag that occurs in construction due to tensioning. The initial stressing can occur at 24hrs post pour (concrete approx. 9MPa), however as per the structural specification the final stress can not occur until the slab reaches 22MPa and 5 days post pour. This builds in an additional 2 days per slab to each pour date. I have looked at the sequencing of the slabs and think there may be a more efficient way of doing it, but I need to speak to the programmer to ascertain the assumptions behind the decisions.

From a RE background of pouring a maximum of 5m square flat slabs, the idea of moulding the concrete into ramped sections concerned me a little – it turns out to be pretty much by eye. Pouring 320m3 of concrete in one hit was pretty hectic considering steel was still being fixed at the other end of the slab. This was the last ‘easy’ pour as the truck mounted pumps will no longer have access to the bottom of the hole. From now on concrete will be pumped from the access slip lane into a standing boom pump, which will pour to the final destination. The complication comes in the fact that the agitator trucks will not have the space to wait in the slip lane, where all the other deliveries arrive, so coordination is vital. This will be yet another task for the site engineers but in my view is so crucial it should have a single responsible person as there is so much scope for errors and with the prospect of turning concrete/reo away due to lack of space it could get pretty costly.

One of the overarching issues for me is the complication that so many contractors on one job creates. Not just the usual issues of construction but also the issues between themselves (Rivalry, Unions). I realise the intent of employing workers and sourcing materiel separately is to cut the costs of the project, but it appears that the time taken to liaise between the various consultants (architects, structural, services), the individuals who are doing the work, and those sourcing the materiel takes the vast proportion of the engineers day leaving only a small element for actual forethought and fault finding prior to construction. I don’t think that many sub-contractors makes light work and cost effective construction, quite the opposite actually.

A Slow Week

No blog last week as I was on leave with nothing significant to report other than an interview for my design placement at Ramboll UK.

It was been a slow week for personal involvement, and therefore a short blog.

With the first slab poured on my block just before I went on Easter leave the transformation in the time I was away was significant, starter bars had become walls, starter bars for columns were still awaiting design details which made things a little awkward, the M&E fairies were still trying to magic holes in walls by the power of though alone. Most of Tue and Wed were spent setting up a significant retaining wall that when poured will mean that we can backfill and progress at a much faster rate; as much of the areas awaiting groundworks are at a higher level posing a problem for formworking and working at height. One thing that has become very clear is, the instant a slab is hard enough to walk on every man on site want a little bit of space on it, either the carpenters, the steel fixers or just for storage. It is impossible to keep a slab clear and no matter what you put in place to try and control the space it won’t control the people, short of being there constantly there is no way to stop it from degrading into a mass of men and materiel.

The most interesting thing that happened this week was to go on a day long crane rescue course. The background to this is about the requirement in both Working at Height Regulations and LOLER to have a rescue plan and competent people to conduct the rescue. The emergency service can’t be relied upon to recover people from tower cranes as in general a standard firefighter lacks the techniques and equipment to do so and the urban search and rescue teams aren’t a continually formed unit and therefore are slow to respond. So it falls down to 3 people who have done a 1 day course to drag a large man from a small cab up a tall tower. The system is quite easy to use and doesn’t require any knowledge of knots or rope systems. Our site has been operating without an evacuation plan for the cranes, one for working at height in general is in place and now it will probably fall to me to write the rescue plan. The one question it has raised in my mind is how we plan for the use of the dems harness or ISHK on exercise, never have I been briefed on a resuce plan for someone that falls from a dems bridge and dangles from a lanyard and as an exercise conducting officer I’ve never used it although I would not have planned for that eventuality, thoughts from the floor?

Our artesian water problems continue and have been exacerbated by attempts to stem the flow whilst I was on leave. The rather unscientific solution of dig down further and chuck a load of concrete on it has failed and now the flow of water has increased. Today will see a visit from RSK (the environmental and ground consultants) who will see what could be done, I don’t believe there is one personally, the nature of the ground gives multiple routes to the surface for the water through the fissured clay that sits below my block. A chance conversation with someone who was involved in the foundations of the BBC Radio Solent building next door has revealed that they had the same problem, an uncapped borehole that continued to flow under artesian conditions, and in the end they resorted to what was in effect a French drain under the slab to the nearest point where the water could be disposed of.

Rich

Oppa is Gangnam Style

New Start

Well, things have definitely progressed. I have been assigned a new laptop and although I am yet to get my hands on it, it comes with a BP identity and all the perks therein. Basic Offshore Safety Induction and Emergency Training (BOSIET) and Minimum Industry Safety Training (MIST) have been confirmed for the second week of April, but luckily this will be local to the BP office allowing me to get a hold of said laptop and confirm my first project, the P60 Bridge Inspection Platform on the Bruce asset.

Bruce P60 Bridge Bearing Change out

The Bruce asset is comprised of three platforms, one each for drilling (D), Process\Utilities\Quarters (PUQ) and Compression Reception (CR). The P60 bridge spans the gap between the D and PUQ platforms allowing access but also piping carrying live hydrocarbons (sounds exciting doesn’t it). It is secured by three free bearings, a guided bearing and a fixed pin, then upshot being that since 1995 the bearings have been failing on a regular basis requiring quarterly inspections that involve the installation of temporary scaffolding over the edge of the platform. Interestingly no-one has a clue of what effect the bridge seizing in place would have on the two structures and a long term study has been recommended, but as long as the bridge is being inspected regularly, it is not really an issue.

The End Appraise Stage Decision Support Package for the Bearing Replacement Study has indicated that doing nothing to the bearings is actually the best way forward at present although building a permanent inspection platform to mitigate the cost of quarterly inspection and maintenance would be a really good idea. Step forward Ish Mk III. The yearly bill for scaffolding comes out at £100,000 and the estimated capital cost comes to £250,000, a drop in the aquifer in real terms and my gut feeling is that this should drop out as an independent project starting in the Select phase, so options evaluation, contractor engagement, design; all the good stuff. Hopefully this will be a good opportunity to tackle some UKSpec competencies! If this does go to sea, then it looks very much like it would be in 2015, which is a shame, but potentially good for Ish Mk IV. I look forward to finding out more after Easter.

Primary Engineer

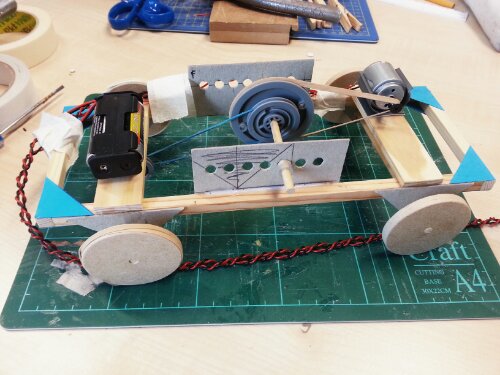

I had the pleasure of attending a training session for the Primary Engineer Scheme on Thursday. This is an IMechE sponsored initiative to encourage the teaching of STEM at primary (and secondary) level to inspire the next generation of Dysons and Nobles. I had great fun ‘helping’ two Primary teachers build this;

I’ve made some connections and will be attending at least one local primary to assist in delivering this area of the syllabus. The scheme is supported by BP who are very strongly engaged with the local

schools and quite rightly too! I also attended an interesting presentation on the Kincluny Village proposal, a sustainable concept village which is awaiting planning permission from the council. It utilises a ‘closed loop’ approach that seeks to maximise self sufficiency within a defined community space in terms of energy and water consumption. There is definitely scope for a TMR there and so I won’t give to much away yet!

In Other News

It has stopped snowing. We are off to Edinburgh this week for a little sightseeing, which will be nice. This week I have been mostly been listening to Gangnam Style as Hugo has been teething quite badly and this is one of the few things that will pacify him…for about 4 mins 13s.