Archive

Break Radio Silence

It’s been a while, mainly because I’ve been furiously tippy tapping away on TMR 1 and Friday (blog day) is usually the day small people decide that cool kids don’t sleep.

Now, I’m conscious of the fact that groundwater problems have been a consistent theme of this blog for sometime now and you’re probably bored of it by now…oh well nevermind. The saga continues and this week we have had some grout injection contractors in to attempt to seal the holes. They’ve only managed to drill and grout 1 hole today, and the water still runs, so look out for the next update. On the plus side this comedy of errors made a decent TMR subject.

We’ve got a first floor slab poured on my block now but because of all the delays it looks like the building has had a massive bite taken out of it. All the old hands have repeatedly said that it will start going fast once we’re out of the ground, we’re not fully out of the ground yet but it’s still moving quite fast, mostly because we have a really good foreman and gang on my block. My new challenge is getting motivated over finishes and brickwork, it’s becoming clear that the people around me think like builders rather than engineers.

Taking shape.

This week as seen good progress for the first 3 days as the steel for the southern face of abutment wall A was placed. The vertical bars are over 9m in length so we hired in a 55T crane (the project has 20T & 25T Franna Cranes on permanent hire which are ‘booked’ through the superintendent) as the reach on a franna was not enough. It did look rather odd seeing a 55T crane lift 3 reo bars at a time so they could be placed vertically aginst the scaffold and secured but we required for the reach only. We also managed to form up and pour the wall sections of the outer deflection walls so two are complete with the wall for the third and the base for the fourth (currenty using that area as a laydown area) outer portions hopefully being poured next week.

We had a site walkabout with the rail saftey manager (a huge guy called Dragan) as we are looking at the alterations we will need to do to convert the site. This mainly consisits of alot of fencing and knowing who the Protection Officer (PO) is for that section. The PO is our link to the rail issues that may affect us. He will brief us in the morning on what work and dangers are present for that day and if we inform him if we need to gain access to the rail corridor. As our plan is to install the PSC beams early to let the rail team come through the site without us having to work within the rail corridor this should make our lives a little easier.

Thw CSR has finally been laid across the fron of abutment B and concrete encased and the backfilling complete so that we can finally start erecting the scaffold on abutment B a week late. We would havss started sooner but rain on thu and fri washed out the remainder of the week – quite literally. I am looking forward to pouring the abutment walls as it will be a chalenging pour but also because we finally get away from the ground for a while before we move back to the wing walls and retaining walls. It will probably rain on a daily basis by then.

Other challenges in life at the moment involve dealing with a 10 month old boy who suddenly decided to start crawling a week last wed. Since that day he hasn’t stopped moving and you really do need eyes in the back of your head – or you need to contain them! Decidied to pop down to Bunnings (B&Q) and buy a baby containig kit which has helped. Changing a categroy 5 pooey knappy on a little boy that will not stay still is probably one of the hardest tasks in life!

Finally back at work!!!

Its been a relaxing 3 weeks away from work but I’m finally back. The 2 weeks in Italy were great however coming straight back to MA module A was a reality check.

I had expected a lot of progress on site, who was a kidding. There seems to be very little change in the 3 weeks away. However this week has seen it all come together, the simple reason is that the excavation sub contractors start work next Tuesday and it all had to be in place. The temporary works that I have been heading up have all come together at the 11th hour. The steel platform, which has been the thorn in my side since arriving, has finally been erected. Although as predicted there were numerous adjustments that had to be made. Top tip, never get a structure fabricated off site and expect it to go into a complex location without some serious on site alterations.

Since getting the steel platform in this week other components have begun to arrive and get put in place. As you can see, the generator, receiver, compressor, MDU and finally the Siltbuster HD unit (which will neutralise the PH level of the water before discharge) have all been put in place. The water treatment system will be in place by the end of next week, consisting of a concrete washout, settlement tank and the Sitltbuster HD unit. Fingers crossed that this system will work, as other sites around London have had some serious issues with the water treatment systems they have in place.

The Muckbin has also been completed this week, including the propping of the sub basements in both our building and the adjacent buildings. The only issue now is some debris netting to be put in place in order to protect the public footpath and our building, as it’s a listed building. The Muckbin will be accommodating the 200m3 of soil that will be obtained from each 1m depth of shaft excavation. My only concern now is that the Muck skip or the excavator will knock into the building and stop works for a considerable amount of time. I have had a designer produce a scaffolding barrier that would protect the building, however the powers to be have decided against it. We shall see who is right in the weeks to come.

The equipment platform has been completed with my first large concrete pour. Inspection cubes were taken and the whole procedure went fine. This was the final temporary works structure to be completed before Barehale (sub contractors) began to take over the site. On the whole the three temporary work structures have gone pretty well and I’m pretty chuffed.

The 80T heavy-duty crane arrived today, hence me being in on a Saturday. What a beast. One of the smaller cranes is being used to assemble the 80T crane. We are lucky to have even got the crane in the first place. There are only two cranes capable of fitting onto our crane platform, due to the restricted nature of the site, which were also capable of the lifts. Additionally Crossrail have insisted all plant are fitted with specific exhaust filters, you guessed correctly, neither of these two models were. However we applied for dispensation and hope that Crossrail will agree. We await their response, however we have taken a gamble and installed it any way.

The site looks like we are ready to start the excavation works now. As you can see from the photo below, once the settlement tank and siltbuster are moved out of the shaft and the 80T crane is built the excavation work can begin.

As I have mentioned in other posts, the paperwork involved in the project has been obscene. To obtain the authority to begin the excavation phase we have had to demonstrate to Crossrail that all our paperwork is up-to-date. This has involved Material Compliance Records (MCR) for every component used in the setup of the site and for the excavation phase itself. Each component we use from; Hilti bolts, paint, concrete, steel, reinforcement etc has to have a document produced with proof that the product meets the required standard. The document then has to be approved by Crossrail, you can imagine the implications of this. On top of the MCR’s an Inspection and Testing Plan (ITP) has to be produced for each phase of construction. This has involved obtaining welders qualification certificates, steel mill certificates, concrete batching plant certificates, the list goes on. However I think we have finally got there.

My final bitch concerns jack blokes. When I started on site there were only two Engineers, myself and Gemma. Now that the site is properly under way, they have surged more manpower to us. This has come in the form of a new boss, Aleandro from Spain, who speaks limited English, arrives late on a Monday and leaves early on a Friday to go back to the failing Eurozone. The term ‘useful as a chocolate fire guard’ comes to mind. Additionally another sub-Agent has arrived, who spends all his time on Linkd In, looking for his next job. I have been watching him, he has produced 4 documents in over a month. I wish he would move to Spain as well. As you could imagine the atmosphere in the office could be cut with a knife most of the time. I predict it is only a matter of time untill Gemma explodes with one of these two individuals, I can’t wait!!!

Where does the time go? 21st May

Well then, sat in the KLM lounge at Schipol, supping on Bombay Sapphires, I thought that now was a perfect time to update you on my goings on. Generally I’m in a bit of a three-way: on Tuesdays I’m in Etten-Leur, progressing the 3rd PWRI pump, while the rest of the week is roughly an 80/20 split between WGPSN’s mechanical team and BP’s Projects and Mods team. Life is good and busy as ever, and since I’ve been talking specifics recently I’ve added a few figures to this month’s blog!

- Flowserve. As BP/WGPSN’s technical expeditor I’m the interface that has been credited with getting the £3.5m 3rd PWRI Pump project up and running again. Most of this is done by ensuring that conversations are “more friendly” and that all parties are aware of the others’ issues. I am projecting my personality to get the best out of all involved and as such the project is progressing much better. This gives me a great insight into relationships and all that management stuff, but also the intricacies of a project and the little things that make a big difference and delay projects. This includes:

- Documents not being signed off in a timely manner – when I started the project there were 44 outstanding documents for review (by WGPSN); today there are only 6.

- People (BP management) getting angry as they’re not in the loop on what’s going on.

- The WGPSN package engineer and Flowserve project manager having a pissing contest and looking for faults rather than workable solutions.

- Technical Authorities (TAs) getting “overly” involved (maybe – see below).

It’s also been good to see the parts coming in from the supplier and getting fabricated – although I’m sure I could tick this box by visiting a fabrication shop (as indeed I have done!)

- WGPSN Mechanical Team. Based in the same office as BP (part of the Focus contract), I’m now working as a [mechanical] discipline engineer alongside two CEngs and a lad on a graduate scheme. My work is primarily based on the 3rd PWRI pump and has included/ includes the following:

- Checking valve spec for the lube oil skid for the 3rd PWRI Pump. This was good as it allowed me to get stuck into BP’s Engineering Technical Practices (ETPs) and other documents – mostly ASME and API, that are the industry standard.

- Writing the specification for pickling and passivation processes that must be followed after a test fit between the super duplex shaft and a carbon steel replica of the housing (for the PWRI pump). This was good as I had to research exotic steels, the natural passivation of stainless materials, the pickling process that allows the surface microstructure to be “cleansed” and then methods for testing the purity afterwards. I then submitted this to WGPSN’s Quality Assurance (QA) for approval and it will be used in the future.

- Looking at the NDE for the super duplex components. This is interesting but I’m still trying to find the line between getting overly and unnecessarily involved because the TA is mad-keen on it (everyone needs a hobby and his is metal) and ensuring the right QA is met and the super duplex components are the right spec.

- Working on the most-hated project (by both me and the new SPA) that I was SPA for, the “compressor mods” project (currently valued at £2.3m). I’m now responsible for the mechanical work on the degassers – vessels that “bubble” nitrogen through a sparge pipe to remove hydrocarbon gasses from the seal oil that is recycled through the system (Figures 1&2). This is good as includes me researching sealing methods, cutting, confined spaces, and working with the supplier, Swift. It is also good to be a small part of a project that I was running a few months ago, as I can now see the frustrations the mechy had!

I’ve also got some good CPD done: a trip to Exona materials lab to see their testing methods (very similar to what I saw at uni a decade ago) and a Factory Acceptance Test (FAT) of a pig launcher that’s being installed at the end of the Magnus TAR. There’s an IMechE lecture in town tomorrow night about the Pelamis Wave Generator – I can’t wait!!!

- BP Projects and Mods. Here I’m carrying on with the two remaining projects that I have sole responsibility for: the insertion of a glycol balance line (£67k) and the replacement of single isolation valves with a double block and bleed system (£250k). This has included some risk management meetings relating to the management of change – essentially making sure that there’s full agreement (from the Asset) on all the changes that I’m making to the plant so that if it goes tits up in the future then my decisions have some higher-level sign off. No problems so far, I’m pleased to say.

I’ve also been I’m also been advising on some of the projects that I’ve handed over, including the decommissioning of various gas trains (£550k) and the automated relief of the cold boot (£670k) that are being executed this summer, and the exchange of the B Crane (c£8m) and the installation of additional living quarters on ETAP (c£10-15m) that are still in development.

- Other news (the interesting bit):

- As I’m getting thinner (now at 68kg in prep for the Edinburgh marathon this Sunday) Dougal is getting bigger and now weighs over half what I do. To Liz’s delight he is also learning how to leopard crawl through the dirtiest of ditches (Figure 3) and frequently finds tadpole-filled ponds to swim in. He’s amazing.

- Liz and I both raced around Balmoral in various trail races a few weeks back – Liz finished in the top half of the 10k race and I was 12th (from 297) in the 15 mile race.

- I did some climbing instructing in Wales this weekend on the REMEC meet, really good to be out and about with sappers again and surprisingly good weather.

- We ticked off another idyllic island a few weeks back: Lewis and Harris, with some beautiful white sand/ blue sea beaches (and drizzle). Off to Orkney for a long weekend at the end of the month too – see if I can get Liz up the Old Man of Hoy?

- Looking further forwards, we’ll be moving to a quarter in Kinloss in July. After Phase 4 I’ll be based around Aldershot whilst I do my PDT/MST and then deploying on HERRICK 19 as SO2 Infra from November (subject to the SO2 board – otherwise I’m jobless!)

- And finally – I got a business card from someone last week and it listed MInstRE with his post-nominals. Turned out he’s in The TAs and was a thoroughly nice chap. However, I was a little bit sick in my mouth when later on I saw the reverse of the card: a ¾ profile mug shot of the said engineer! Have any readers of this blog had similar suprises with business cards?

Progress is not a dirty word……

It has come to the point now where none of my office can talk to the Contractor’s Executive Officer (big cheese on site) without wanting to commit serious injury to him. To say this guy is unhelpful is an understatement. It seems the expansion joint issues are not the only show stoppers he is employing to buy more time and money.

The past weeks have been spent mostly in meetings. After a partnering session last week it was decided there was not enough inter stakeholder communication so to make up for that we had four meetings in a week: a whole site meeting to up date the Client on all projects on camp, a health and safety meeting with the contractor, a partnering session with “all” stakeholders and a site specific update meeting with the client.

The first meeting was very long, had lots of top level squabbling and achieved nothing in my opinion.It did have donuts.

The second was our first attempt to get the contractor back on schedule. As it stands the Health and Safety Officer for the contractor has yet to produce a piece of work that would constitute a complete H&S assessment so we cannot authorise work to proceed. The Executive Officer swears blind (for a whole hour on send only) that this guy is amazing but this is not supported by the paperwork he submitted. The big issue is that work needs to be done 80ft up in the air and a fall arrester system needs to be employed. A Qualified Person must design a system in accordance with USACE guidelines (they must have an engineering degree and experience in the fall arrester industry). This H&S guy is only Competent at best through a 5 day course run by a manufacturer and a distance learning package done on line 5 years ago. However the Contractor insisted his name is submitted as the Qualified Person but then said he was going to get in Qualified Fall Arrester Engineers to design the system anyway! The H&S guy also submitted a Risk Assessment (Activity Hazard Analysis (AHA) over here) for a cherry picker with only 3 risks identified – People falling, things dropping, the rig moves! This was only the first that I have been checking over, the remainder are equally poor including the Rescue Plan (“fire department will be used if there is an accident” – not a bad idea accept if they had talked to the on site fire department they cannot deal with problems in the building as there are no ladders long enough!) . His response – “Tell me what you want me to say” or “This is the way we have always done it”. He is on his final warning, but I am not sure what constitutes the last straw yet.

Our third meeting between stakeholders was equally frustrating. The Design Contractors and USACE cannot believe the contractor has been on site since Oct 12 and is using phrases such as “I have not had the chance to look at the building so I have no plan on how I am going to proceed” and “I don’t know what order to do things because I don’t want to disrupt anyone”. The contract states work cannot be inhibited but as a change to the contract temporary offices for 105 pax will be set up to house office workers whilst their department is up graded. The Contractor Schedule says it will not be until this time next year that a temporary office will be ready to move in to and they are only setting up portacabins! Another hour was wasted discussing how the contractors proposed plan might affect the office workers. At this point I pointed out that if they had a Rep from the Office building who knew what the impact would be at future meetings then they would have saved themselves a lot of wasted time guessing. I think my accent might have confused them because the look I got from round the table was close to the one I would expect from saying “I am going to cover myself in chocolate and let you lick it off”!

The fourth meeting was a simple catch up on all the week’s meetings where it is was agreed that all the other meetings had been productive!

What I have learned is the following:

1) The Contractor’s Executive Officer cannot delegate down and never approaches the necessary department if he has a question – he has always done that. He must also be a blood relation to the H&S Officer.

2) In the Stakeholder Analysis the occupants of Building 2001 were never identified as important.

3) The Meeting Agenda is rarely a guideline for how the meeting will actually go and recording and publishing minutes (my idea in two of the meetings!) is a good way of confirming what was discussed with everyone involved (except the Executive Officer who disagrees with everything)

4) American meetings are more about donuts and talking loudly then they are for solving problems

We wait in anticipation for the next wave of unhealthy and unsafe submittals to cross our desks with no start to the construction phase in sight…

On the plus side I did get to see a Levy and Pump Station that had been flooded out in North Pennsylvania in 2011. The river had risen over 30ft after heavy rain and had flown over the levy knocking out the pump house and resulting in the area flooding. The on site engineers were asking for $1 million from the Corps to raise the pump station up 10ft so that it would not flood next time . However it only protects some very old houses where everybody escaped unharmed, which the Corps has not seen as essential. At a time of cut backs I would have to agree.

The river is a 100m to the left. The pump station and (now broken) generator hut were completely submerged.

The River today. Note the 30ft trees that were swept away in the flood still in the river. The bridge in the back ground was completely submerged.

This weeks country hits:

Timber! I am falling in love

Truck Wheels in the Moonlight

Roadkill Round Up:

30+ deer (saw a guy parked in the central reservation in rush hour collecting a 2 day old carcass that he could not have hit and he was not the state clean up team either)

15 racoons

6 Ground Hogs

5 piles of red mush (could have been one deer)

And in other news:

Apart from mass shootings on Mother’s Day, tornadoes in the deep south, girls being found in a house after 10 years of being missing, a $580 million lottery winner and IRS scandals, I am pleased to announce Warrick will be graduating from Kindergarten in a months time, complete with certificate presentation and Mortar Board. Only in America……

I am also signed up for the Army Ten Miler in DC where 30,000 people with service connections will run round the Pentagon and back early on a Sunday morning in October. Time for some training…

More Slabs, More Safety

Finally we get the go ahead to pour Zone 5 Upper Basement slab. The contractor found that his pumping strategy didn’t work on arrival of the mobile pump so changed the plan. It then involved a mobile pump and about 35m of hose. This wouldn’t have been such an issue if they had started from the back and worked forward but due to the restricted angle to pump could boom it meant that we had to start at the front and work backwards before coming back again. In all, it was a very awkward pour. From the pumping location I noticed that there was likely to be area that would be left for several hours before the pour line met it once again. After the issues of the last slab I was involved with I did not want this to happen, so called the JHG supervisor to remind the subcontractor of this issue. It eventually took the movement of a kibble from the other end of the site and a commandeering of the crane to get some concrete down and keep the edge alive. As the pour was ending the supervisor called forward to the batching plant with his excess to the ordered quantity, to ensure that the pour did not go short, expecting the final programmed truck to arrive. It didn’t, the concrete batching plant had decided to retain the last 5m3 of the mix to send at the same time as the excess. Why?! If somebody has ordered concrete, why wouldn’t you send it! This resulted in a further hour delay in pouring. The whole pour took about 7 hours, and the concreters were still there at 2000 finishing the surface.

The surface was not good. It appears the concreters got bored about 2000 and went home. This initiated the next phase of my week – Getting involved with quality control. When a task is not performed correctly a Non-Conformance Report is raised detailing the issue to the contractor and asking for their rectification methodology. Unfortunately Crown (Concreters) have been at the end of my wrath this week. A poorly finished slab and then I found some reinforcement sticking through the surface of a poured slab. Actually the client found it and asked if I had, I went down for a quick look so that I wasn’t lying when I emailed a reply that I had. This formed the second NCR for Crown. Subcontractors don’t want to pay to remediate their own poor work, they would much rather we sent them a site instruction so they can be paid to do it. The backlash to my NCR’s was interesting, I was surprised that “The dog ate it” didn’t feature in the reply. I stuck to my guns and quoted contractual points that they are responsible for the finish no matter what and that if there are issues with the reinforcement they have a duty to raise it during construction. As yet I have had no comeback to my last.

We finally poured concrete using the Boom Mast on Friday. The pipeline that was serviced by a semi-permanent pump in the slip-lane was finally plumbed in and was tested on the columns in SB Zone 2 in order to set the conditions for pouring of the ground floor slab with is a milestone for May (not likely). Things actually went quite smoothly for a change, apart from one column requiring formwork remediation and mixes changing from 65MPa to 40MPa and back again – not ideal but necessary.

The final parting shot of the week was from the concrete boom mast, that decided to shed its top ladder (approx. 200kg) when it was being put away. The ladder fell approximately 20m onto a thankfully empty deck (at 1700 on a Friday site was effectively a ghost town anyway). Cue ComCare on site once again Monday morning – they may as well get an office here! The investigation is ongoing.

This weekend was spent dashing like warriors around a 5km muddy obstacle course. The RE contingent (Steve and I) was strong, and we both managed to rope our wives and a couple of lads and lasses from work in too. I was so enthused that when I returned home I signed up for a 20km version in October – apparently this one is a bit tougher. I think I may miss the green a little!

Believe in me

It has taken 5 weeks of blindly stumbling along in the dark fug of unknowingness, but finally I feel like I am adding value!

P60 Bridge Access Platform

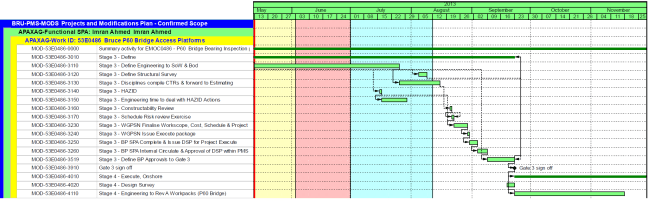

I made the trip down to Manchester last week and it was good to finally get the ball rolling on this project. In an amusing turn of events, the senior structural engineer assigned to this project is new to Wood Group, so that makes up all of the members of the team essentially new to role and inexperienced in one way or another. In the two hour meeting I successfully bluffed my way through the kick off review and drew up a baselined plan that correlates the job responsible engineers (JRE) plan and my Project Execution Plan.

As you can see, the PEP does not go much beyond September when I have to meet the only milestone and circulate the Decision Support Package for end of Define Gate. I’ve been told in no uncertain terms that this project is unlikely to ever become more than a desktop study and in the knowledge that the scaffolding contractor currently builds the temporary scaffold and leaves it up for a year before destruct and re-build, I tend to agree.

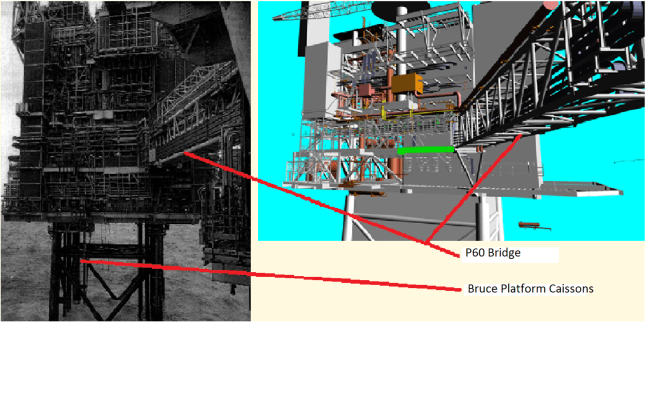

That said, there is still money to be spent and a Basis of Design must be delivered. It is not a complicated design as you can see below, but as ever the devil will be in the detail coming up with a method of attachment that does not require welding due to the process pipelines that the bridge carries between modules and the pre-eminent fear within the industry of something being on fire that shouldn’t be.

I have an off shore survey planned for early August that, so long as it doesn’t get bumped, will give me and the lead structural engineer an opportunity to see the scaffold in situ, the bridge bearings as well as the sea water/ fire water caissons. On the whole it is a good little project to cut my teeth with very little space to really screw things up.

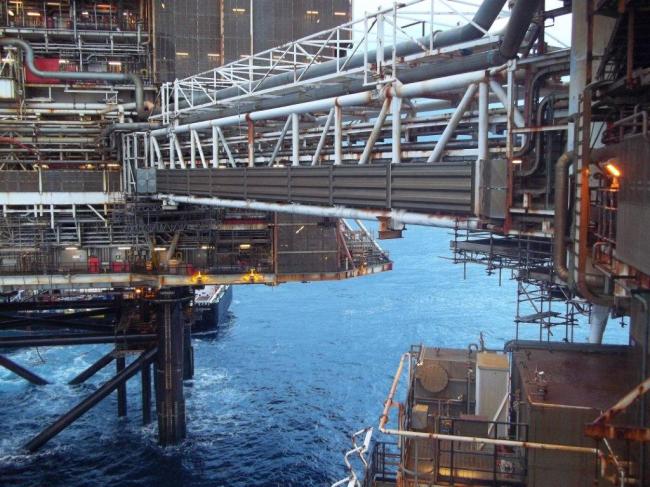

Temporary scaffold currently installed on the P60 bridge to allow access to and jacking of the bridge for bearing inspections:

Dance floor scaffold beneath D end of the P60 bridge.

View from the D platform landing, the shrouded area is protecting area surrounding the bearings.

Looking from the PUQ platform back toward the D platform.

This bridge is f*****g huge!

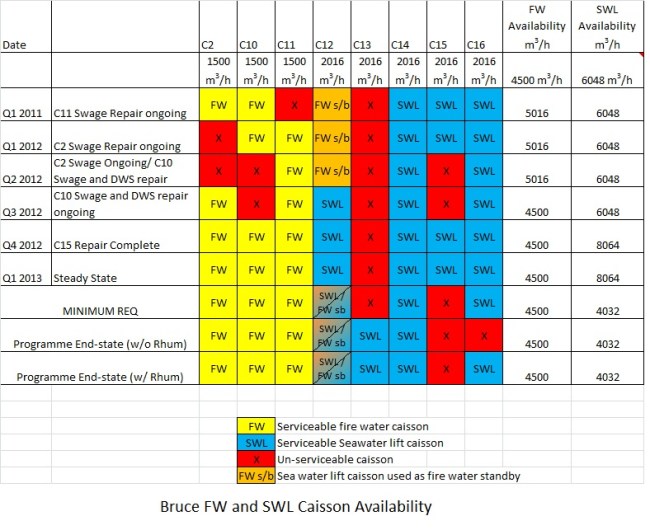

Seawater Lift Caissons

The results of my investigation into the business drivers for replacing the Bruce seawaterlift caissons have been very interesting indeed. The original caissons were underdesigned to reduce weight so that they could be lifted into place on the installation during the initial construction. They started to show premature wear about three years after commissioning and have been a source of problems ever since.

The original Capital Value Process for a replacement programme was instigated in 2009/2010 with the Select phase ultimately recommending a full programme to re-instate all but one of the sea water lift caissons. This was based on a series of structural surveys conducted in 2009 that showed that all of the caissons were in danger of total structural failure. The programme has progressed in that C13, the closest to falling off, was removed in 2010, but the challenging plan to replace it has not yet come to fruition. It has been designed and is ob the verge of being fabricated, with an installation planned for summer next year. Next year is a TAR year for Bruce, a process that adds to production in real terms, whereas the caisson only adds to production in secondary ways such as a reduction in PoB for surveys, fewer emergency interventions e.t.c. While replacing all of the caissons makes excellent engineering sense, the business drivers are far less clear and the reinstallation of C13 is highly likely to be delayed until 2015. The scope of this investigation is to:

- Understand the drivers for the caissons programme: integrity concerns, operational availability of seawater and firewater pumps?

- Re-examine the key drivers to determine whether these are still valid ensuring agreement from the appropriate stakeholders

- Propose a forward caissons programme based on revised understanding of the key drivers

In light of this, I’ve spent a lot of time reading the reports of work that has been planned and completed (or not in some cases) and meeting the stakeholders to develop a technical note assessing the importance of the key drivers and a revised programme to deal with the issue. Buy in from all of the key stake holders; the asset (Area Engineering Support Team Leader), the structural engineers in Discipline, the asset mechanical engineer and the Life of Field team who will authorise the budget in the longer term, is fundamental to getting this programme back on some kind of track and I think the original failing may have been lack of commitment from the asset with the plan being devised in isolation. My rationale for this is that the high level plan specified in the Select Decision Support Package makes no account for the impact of TARs on the plan, which is strange considering the complexity of the project and ultimately it was this oversight that has delayed the project thus far.

The bottom line is that Cessation of Production for the Bruce field is forecast for somewhere around 2020, but the installation will still require the caissons for the decomissioning process of some 7-10 years duration. There is added complication in the form of the Rhum oilfield which is tied back to the Bruce installation. One of the partners in the Rhum field happens to be the Iranian government and production has been on hold for about 4 years, the up shot being that if Rhum is turned back on then CoP moves out by another 4 years and more water will be required for process cooling.

I am looking forward to Tuesdays meeting as it will be my first time in the Bruce ACE (Advanced Collaboration Environment – video conference room with the platform) and a great opportunity to understand the situation from the off shore point of view.

I’m getting some good traction with this caisson work and things are looking promising for picking up some work on the Clair caissons. I’ve been complimented on how quickly I have broken down this issue and provided clarification, which is nice.

In other news…

I shall be enjoying not watching Eurovision and instead will be attending the village barbeque (in the rain). Corine has found herself a second job, this time with the Grampian Housing Assoc so we are scrambling to find childcare in the local area. Amusingly, she had a complaint from one of her french students for speaking french during a lesson this week. Apparently in his book this did not constitue a valid technique for teaching french. You just can’t make this stuff up!

Rail opens up second front!

It is now starting to feel like we are constructing a rail line with rail now being laid from both directions. The stabling yard has been a RISI (Rail Inustry Saftey Induction) site for a few weeks but now the far eastern end of the track has now changed to a RISI site which means we are very much working to the rail timeline. The predicted rate of 400m a day means they will be at the Scalabrini and Dickson Rd sites within 4 weeks and Kemps Creek bridge will be handed over to the rail team by wed 22 May – the second bridge to be handed over out of the four.

Dickson Rd has progressed steadily but not according to programme, I think the programme was optimistic having now gained experience of how the site dynamic works between sucontractors, suppliers etc. We are at least a week behind on the abutment walls but have been able to carry out concurrent activity on the embankment retaining walls so may have gained afew days there. As we are expecting rail to be laid through the site about mid-june we have a tight schedule to pour both abutment walls and have brought forward the delivery of the PSC beams so that we can position them across the abutments therefore leaving the span area of the rail alignment free for rail to move through. Our focus will then be to pour the wing walls and the abutment retaining walls. We have just aout completed the scaffolding around abutment A so that the steel fixers can start next week. The outer parts of 3 of the embankment retaining walls will b completed next wed with the wall stems to be poured. The fourth ERW has not yet strated as we are utilising the concrete blinded area to lay the 10m high shutters for the abutment walls. I hope that abutment wall A can be poured by the end of next week on Fri but realistically it’s more likely to be Mon the following week.

Kemps Creek bridge has now been cleaned up at waterproofed. Next week will see shock matting laid over the waterproofing which provides a bed for the bottom balast to be laid on which will also start next week. We still have a few bays of CSR walkway to pour at abutment A after placing the last remaining parapet sections which we should/need to complete by wed before the handover. We are handing over the site to the rail line but we still have few minor jobs to do but these consisit of access walkways below the bridge around the abutments and piers and access stairways.

We have now closed off Scalabrini bridge so that we can clear the 6 months worth of dirt off the deck ready for waterproofing following Kemps Creek. Defects patching work is also being carried out but we are now very close and completing three bridges with the remaining focus being Dickson Rd with an estimated competion of around Oct.

I am starting to notice the change in weather now as winter starts to creep up on us – the temp has creeped into single digits a few times in the morning but still tends to be in the high teens at its worst by lunch time. The main concern here is winter brings rain and as we all no rain in australia shuts down construction sites.

It’s all in the spec’

Building 45:

Having gotten over the moral and ethical issues I have with spending tax payer’s money on a project that is adding no value what-so-ever I have been pressing ahead with additional work on the seismic calculations and retro-fit options. The Geo-tech guys were really kind and decided to change their site classification from an E to D…..great….. it basically means I get to start all over again with the calcs but the overall forces involved will be lower – meaning fewer bolts and connections in the final design. Other variations keep cropping up as the Architects periodically change their minds about what they want to put in there. I feel a spreadsheet coming on.

I have started writing specifications for concrete, steel and timber for the final project which is possibly the most tedious thing ever….but also the most important aspect of the documentation. In any discrepancy between drawings or scopes of work etc, the specs will take precedence so they have to be right. Apparently I’m an expert now have been asked to review other people’s as well….kill me now.

I am also writing the scope of works for this and thankfully this is a little more engaging. When you’re doing a new build – you want everything to be new and shiny and anything less than that will result in a slap on the wrist and an early bed time for the contractor. On a renovation where you’re on a tight budget however, that’s a different story. Exactly how much section loss are we allowing before we have to replace a joist? How much cracking constitutes needing a replacement? What level of water damage is acceptable? If you’re not careful about how you scope this you’re basically drawing up a lovely shopping list for the contractor who will kick the arse out of it and tell you that EVERYTHING is suffering some sort of deterioration. I’m working on making this thing as detailed but user friendly as possible to ensure that when this goes out to bid, all contractors will know exactly what they are bidding on. It’s going to go forward with an estimate of how much damage we think is likely to be present (bearing in mind we don’t even have access to all the damaged areas) and then we’ll be asking for a unit rate for variations above or below that price.

I hate to admit this – but Auto CAD is currently kicking my ass.

Levee Repairs:

A significant crack has been found on a hefty retaining wall in Pennsylvania. They are trying to get a rapid turn around to effect some repairs prior to hurricane season. One concern was to make sure the contractor is able to provide a ‘temporary plan’ to protect the levee system if a flood even occurs during the construction phase. The main engineer and the technician were banding around all sorts of temporary framing and ‘if this happens then do x y or z’ until I suggested to simply make the actual shuttering for a concrete pour capable of withstanding the full flood event in itself. This way there is no plan b to go wrong or get mixed up. I helped them create a configuration that allows the formwork for the pour (including a corner expansion joint) to be installed safely whilst fulfilling the temporary / flood emergency criteria.

Poplar Island:

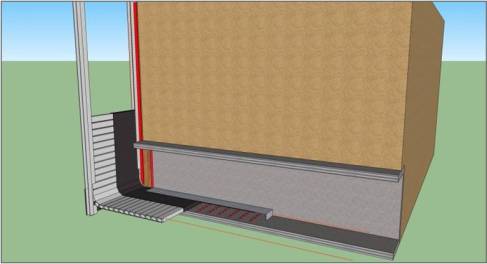

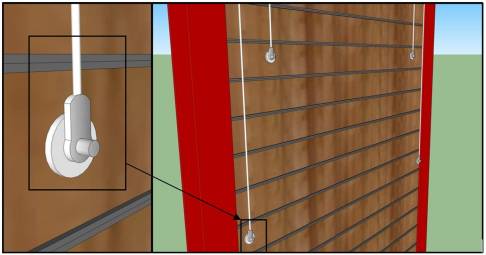

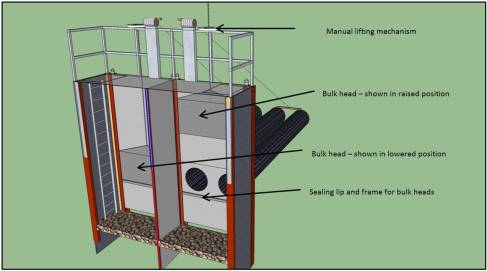

Some great advances have taken place on this project. As part of the research I appraised a number of additional options for decanting water over a ‘weir’ structure and into a tidal inlet structure. I developed my concept of a roller-shutter configuration and demonstrated it to the Engineering Research and Development Center (ERDC) who ware very positive about its potential application in a ‘clean’ environment. They are looking at possible ways of attracting some money so they can look at wider applications.

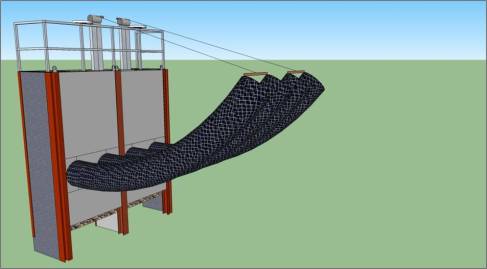

An option that was actually suggested by ERDC and adapted to my application was for a flexible skimming weir which I have appraised and (unfortunately) had to discount due to a raised likelihood of increased approach velocities. A variation of this is actually going to be built at one of the other districts. I have established lines of communication for the teams so they can review progress of the design and application

To get over the complete lack of emergency discharge options – I generated an option that would allow stop-log stack to be forcibly ripped out of their frames. Again this has been presented to ERDC who have now taken the concept another step further with the use of ‘rebar pullers’ to avoid the requirement for a crane to lift the stacks.

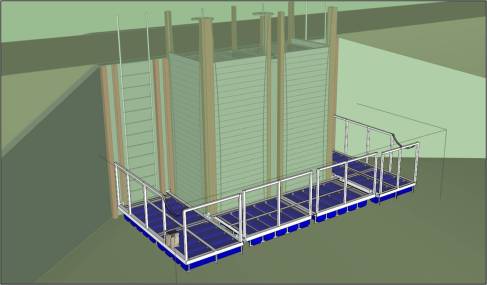

Eventually – I drew a close to the research and appraisal and drew a final proposal together based on all of the best practice, lessons learned, material properties, constructability and practicalities. The proposal has significantly improved safety and access provisions. (Floating platforms – safety rails – inclusion of emergency discharge options etc)

I delivered a presentation on the research and the final proposal to the USACE Poplar Island team who have been extremely supportive and complementary about the proposals (To the point that they have little to no changes to prpose other than possible tweaks to the main bulk-heads to make them less substantial). They want me to re-package the brief into a contractor friendly version (I’ll do it all in cockney rhyming slang) so I can present it to the Port Authority and the primary contractors. Initial estimates are that the combined structure will make savings in the region of $2.2M for the expansion alone. (Mainly generated by construction efficiencies in not having to re-mobilise plant and equipment and reducing bulk earth movement). The green light has been given for the detailed design to go ahead after these presentation / feedback sessions have occurred……so it was all worth it.

I continue to generate further links with other districts via the ERDC where folks are tackling very similar issues but from a different perspective. I believe that because the team here has been ‘doing what they do’ for so long now they stopped looking further afield for inspiration. Hopefully I can generate some positive cross-pollination of ideas and methods as a result.

In Other News:

There is a nice little town by the name of Intercourse in PA. The wife want to go shopping for arts and crafts (or a giant steel moose head depending on how you look at it). So I figured it would be worth inviting our new neighbours Nick and Caroline along via text message from my wife’s phone….”Hi Nick. Seeing as we’re all getting on so well, Matt and I wondered if you’re interested in Intercourse this Saturday.” Perhaps it was a bit too formal. Either way – Nick is not so easily fooled.

We also found genuine tins of Heinz baked beans…our first in 15 months. It started off in a civil manner as the wife and I savoured a brief (slightly less sweetened) taste of home. It quickly degenerated into accusations of bean theivery and possessiveness from both parties. We quite literally need to hire a bean counter in order to maintain domestic harmony. Undeterred I have begun a secret stash at work…..pity my colleagues!

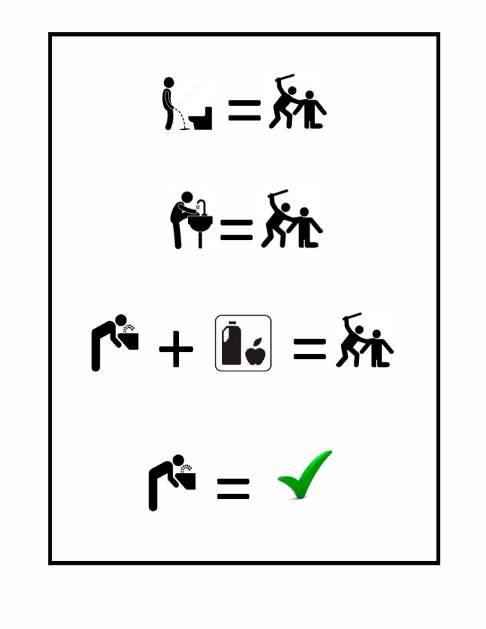

Finally – I offered my creative skills to the poor folks who run the maintenance in the building. After a series of confusing and contradictory notes appearing around the office – I conducted my own non-verbal communication exercise to help them out and get the real meaning across.

My name is McFry – and I approve this message.

Onwards and upwards

This week has seen reasonable progress although in my humble and inexperienced opinion the subcontractor carrying out the FRP works holds too much control over proceedings and the rate of progress. We have a programme which most of the engineers/management look at it and utilise but I am more convinced following this week that the subcontractor couldn’t care less what the programme says as they tend to look no more than 3-4 days in advance depending on their mood that week and a more honest appraisal would probably bring that down to a ‘one day at a time’ philosophy. At present we have no regular meetings/O groups regarding Dickson Rd as with all the other structures there seems no ‘stomach’ for them or belief that anything good will come from one. There is a weekly Structures Team meeting which lasts around 90 mins and does a great job of providing situational awareness to the rest of the team regarding all the work throughout the project. My goal over the next few weeks is to try and implement a weekly progress/forecast meeting by where we review the work done the previous week against the programme and highlight any issues and more importantly forecast what we want to achieve next week and get the subcontractor to ‘buy in’ and agree what we can achieve which may be different. We engineer’s seem to chat a lot and decide when things will be done without consulting any of those actually carrying out the work. The subcontractor seems to be a sensitive beast to me (apparently not the best but certainly the cheapest) which I am sure has nothing to with the fact they are all Irish but certain management individuals are somewhat prickly by nature.

Dickson Rd is progressing with both Pile Caps now complete and backfilling of material complete on one and about 80% complete on the other. This now means we can focus on the abutment walls which I was hoping the subcontractor would start with erecting the scaffolding late last week. Clearly this wasn’t organised earlier enough to get it delivered on site for Fri morning or it was decided they had worked hard enough for the first 4 days and fancied a slack Fri before the weekend. Both abutment walls are 14m wide and 9.4m at the heightest point (due to cross fall) and we intend to pour both continuously which will be about 140m^3 each. Concurrently throughout the week we have constructed the shutters for abutment A and we have completed the steel fixing and forming up of the outer base slabs of the Embankment Retaining Walls (deflection walls) which we will pour on Mon morning. I am very close in being able to close down my first worklots which were the piling works but I am still waiting on the 28 days concrete test results and the Pile Integrity Test results. It seems the PIT’ing didn’t go well and the results were inconclusive. This seems to be down to the individual who carried out the readings who was actually the supervisor when we were piling. The Engineer who interprets the results has said he will now come out and re-test (free of charge) but clearly we now have a 1.2m deep pile cap between the surface of where he can test and where he should be testing – I wait in anticipation of the findings!

Kemps Creek bridge is really becoming very tight for time as we approach the handover deadline to the rail team. I was on Sat duty and predominantly carried out labouring duties as we worked towards having the bridge deck ready for the waterproofing subcontractor to start on Tue and a joint sealing subcontractor to fill in the gaps between the parapet wall sections on Mon. A slight annoyance has been that the remaining pre-cast parapet wall sections were delivered without halfen channels cast into them so that we can bolt them on to the brackets. Out of around 2500 parapet sections on this job these four are the only ones without fixing points and they were actually detailed on the drawings as so which none of us picked up on. The designers response was “we didn’t think you would need them” which was puzzling. So Sat was spent drilling new fixing points and grouting in threaded bars ready for Mon so we can install the remaining sections and then pour the final CSR walkway sections to tie them in. Other work includes crack repair and closing out certain Non Conformance Reports so that that Rail can take over the site.

Sorry for the lack of photos but I have had a media issue today – misplaced camera.