Archive

Progress is not a dirty word……

It has come to the point now where none of my office can talk to the Contractor’s Executive Officer (big cheese on site) without wanting to commit serious injury to him. To say this guy is unhelpful is an understatement. It seems the expansion joint issues are not the only show stoppers he is employing to buy more time and money.

The past weeks have been spent mostly in meetings. After a partnering session last week it was decided there was not enough inter stakeholder communication so to make up for that we had four meetings in a week: a whole site meeting to up date the Client on all projects on camp, a health and safety meeting with the contractor, a partnering session with “all” stakeholders and a site specific update meeting with the client.

The first meeting was very long, had lots of top level squabbling and achieved nothing in my opinion.It did have donuts.

The second was our first attempt to get the contractor back on schedule. As it stands the Health and Safety Officer for the contractor has yet to produce a piece of work that would constitute a complete H&S assessment so we cannot authorise work to proceed. The Executive Officer swears blind (for a whole hour on send only) that this guy is amazing but this is not supported by the paperwork he submitted. The big issue is that work needs to be done 80ft up in the air and a fall arrester system needs to be employed. A Qualified Person must design a system in accordance with USACE guidelines (they must have an engineering degree and experience in the fall arrester industry). This H&S guy is only Competent at best through a 5 day course run by a manufacturer and a distance learning package done on line 5 years ago. However the Contractor insisted his name is submitted as the Qualified Person but then said he was going to get in Qualified Fall Arrester Engineers to design the system anyway! The H&S guy also submitted a Risk Assessment (Activity Hazard Analysis (AHA) over here) for a cherry picker with only 3 risks identified – People falling, things dropping, the rig moves! This was only the first that I have been checking over, the remainder are equally poor including the Rescue Plan (“fire department will be used if there is an accident” – not a bad idea accept if they had talked to the on site fire department they cannot deal with problems in the building as there are no ladders long enough!) . His response – “Tell me what you want me to say” or “This is the way we have always done it”. He is on his final warning, but I am not sure what constitutes the last straw yet.

Our third meeting between stakeholders was equally frustrating. The Design Contractors and USACE cannot believe the contractor has been on site since Oct 12 and is using phrases such as “I have not had the chance to look at the building so I have no plan on how I am going to proceed” and “I don’t know what order to do things because I don’t want to disrupt anyone”. The contract states work cannot be inhibited but as a change to the contract temporary offices for 105 pax will be set up to house office workers whilst their department is up graded. The Contractor Schedule says it will not be until this time next year that a temporary office will be ready to move in to and they are only setting up portacabins! Another hour was wasted discussing how the contractors proposed plan might affect the office workers. At this point I pointed out that if they had a Rep from the Office building who knew what the impact would be at future meetings then they would have saved themselves a lot of wasted time guessing. I think my accent might have confused them because the look I got from round the table was close to the one I would expect from saying “I am going to cover myself in chocolate and let you lick it off”!

The fourth meeting was a simple catch up on all the week’s meetings where it is was agreed that all the other meetings had been productive!

What I have learned is the following:

1) The Contractor’s Executive Officer cannot delegate down and never approaches the necessary department if he has a question – he has always done that. He must also be a blood relation to the H&S Officer.

2) In the Stakeholder Analysis the occupants of Building 2001 were never identified as important.

3) The Meeting Agenda is rarely a guideline for how the meeting will actually go and recording and publishing minutes (my idea in two of the meetings!) is a good way of confirming what was discussed with everyone involved (except the Executive Officer who disagrees with everything)

4) American meetings are more about donuts and talking loudly then they are for solving problems

We wait in anticipation for the next wave of unhealthy and unsafe submittals to cross our desks with no start to the construction phase in sight…

On the plus side I did get to see a Levy and Pump Station that had been flooded out in North Pennsylvania in 2011. The river had risen over 30ft after heavy rain and had flown over the levy knocking out the pump house and resulting in the area flooding. The on site engineers were asking for $1 million from the Corps to raise the pump station up 10ft so that it would not flood next time . However it only protects some very old houses where everybody escaped unharmed, which the Corps has not seen as essential. At a time of cut backs I would have to agree.

The river is a 100m to the left. The pump station and (now broken) generator hut were completely submerged.

The River today. Note the 30ft trees that were swept away in the flood still in the river. The bridge in the back ground was completely submerged.

This weeks country hits:

Timber! I am falling in love

Truck Wheels in the Moonlight

Roadkill Round Up:

30+ deer (saw a guy parked in the central reservation in rush hour collecting a 2 day old carcass that he could not have hit and he was not the state clean up team either)

15 racoons

6 Ground Hogs

5 piles of red mush (could have been one deer)

And in other news:

Apart from mass shootings on Mother’s Day, tornadoes in the deep south, girls being found in a house after 10 years of being missing, a $580 million lottery winner and IRS scandals, I am pleased to announce Warrick will be graduating from Kindergarten in a months time, complete with certificate presentation and Mortar Board. Only in America……

I am also signed up for the Army Ten Miler in DC where 30,000 people with service connections will run round the Pentagon and back early on a Sunday morning in October. Time for some training…

More Slabs, More Safety

Finally we get the go ahead to pour Zone 5 Upper Basement slab. The contractor found that his pumping strategy didn’t work on arrival of the mobile pump so changed the plan. It then involved a mobile pump and about 35m of hose. This wouldn’t have been such an issue if they had started from the back and worked forward but due to the restricted angle to pump could boom it meant that we had to start at the front and work backwards before coming back again. In all, it was a very awkward pour. From the pumping location I noticed that there was likely to be area that would be left for several hours before the pour line met it once again. After the issues of the last slab I was involved with I did not want this to happen, so called the JHG supervisor to remind the subcontractor of this issue. It eventually took the movement of a kibble from the other end of the site and a commandeering of the crane to get some concrete down and keep the edge alive. As the pour was ending the supervisor called forward to the batching plant with his excess to the ordered quantity, to ensure that the pour did not go short, expecting the final programmed truck to arrive. It didn’t, the concrete batching plant had decided to retain the last 5m3 of the mix to send at the same time as the excess. Why?! If somebody has ordered concrete, why wouldn’t you send it! This resulted in a further hour delay in pouring. The whole pour took about 7 hours, and the concreters were still there at 2000 finishing the surface.

The surface was not good. It appears the concreters got bored about 2000 and went home. This initiated the next phase of my week – Getting involved with quality control. When a task is not performed correctly a Non-Conformance Report is raised detailing the issue to the contractor and asking for their rectification methodology. Unfortunately Crown (Concreters) have been at the end of my wrath this week. A poorly finished slab and then I found some reinforcement sticking through the surface of a poured slab. Actually the client found it and asked if I had, I went down for a quick look so that I wasn’t lying when I emailed a reply that I had. This formed the second NCR for Crown. Subcontractors don’t want to pay to remediate their own poor work, they would much rather we sent them a site instruction so they can be paid to do it. The backlash to my NCR’s was interesting, I was surprised that “The dog ate it” didn’t feature in the reply. I stuck to my guns and quoted contractual points that they are responsible for the finish no matter what and that if there are issues with the reinforcement they have a duty to raise it during construction. As yet I have had no comeback to my last.

We finally poured concrete using the Boom Mast on Friday. The pipeline that was serviced by a semi-permanent pump in the slip-lane was finally plumbed in and was tested on the columns in SB Zone 2 in order to set the conditions for pouring of the ground floor slab with is a milestone for May (not likely). Things actually went quite smoothly for a change, apart from one column requiring formwork remediation and mixes changing from 65MPa to 40MPa and back again – not ideal but necessary.

The final parting shot of the week was from the concrete boom mast, that decided to shed its top ladder (approx. 200kg) when it was being put away. The ladder fell approximately 20m onto a thankfully empty deck (at 1700 on a Friday site was effectively a ghost town anyway). Cue ComCare on site once again Monday morning – they may as well get an office here! The investigation is ongoing.

This weekend was spent dashing like warriors around a 5km muddy obstacle course. The RE contingent (Steve and I) was strong, and we both managed to rope our wives and a couple of lads and lasses from work in too. I was so enthused that when I returned home I signed up for a 20km version in October – apparently this one is a bit tougher. I think I may miss the green a little!

Believe in me

It has taken 5 weeks of blindly stumbling along in the dark fug of unknowingness, but finally I feel like I am adding value!

P60 Bridge Access Platform

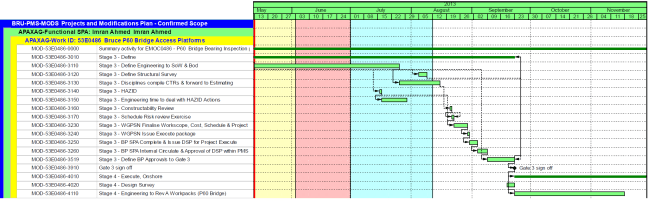

I made the trip down to Manchester last week and it was good to finally get the ball rolling on this project. In an amusing turn of events, the senior structural engineer assigned to this project is new to Wood Group, so that makes up all of the members of the team essentially new to role and inexperienced in one way or another. In the two hour meeting I successfully bluffed my way through the kick off review and drew up a baselined plan that correlates the job responsible engineers (JRE) plan and my Project Execution Plan.

As you can see, the PEP does not go much beyond September when I have to meet the only milestone and circulate the Decision Support Package for end of Define Gate. I’ve been told in no uncertain terms that this project is unlikely to ever become more than a desktop study and in the knowledge that the scaffolding contractor currently builds the temporary scaffold and leaves it up for a year before destruct and re-build, I tend to agree.

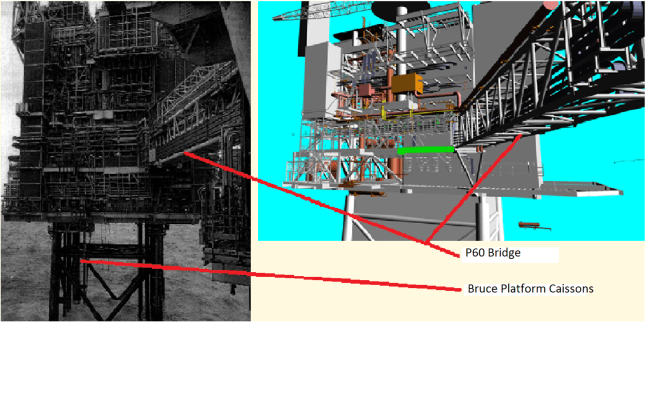

That said, there is still money to be spent and a Basis of Design must be delivered. It is not a complicated design as you can see below, but as ever the devil will be in the detail coming up with a method of attachment that does not require welding due to the process pipelines that the bridge carries between modules and the pre-eminent fear within the industry of something being on fire that shouldn’t be.

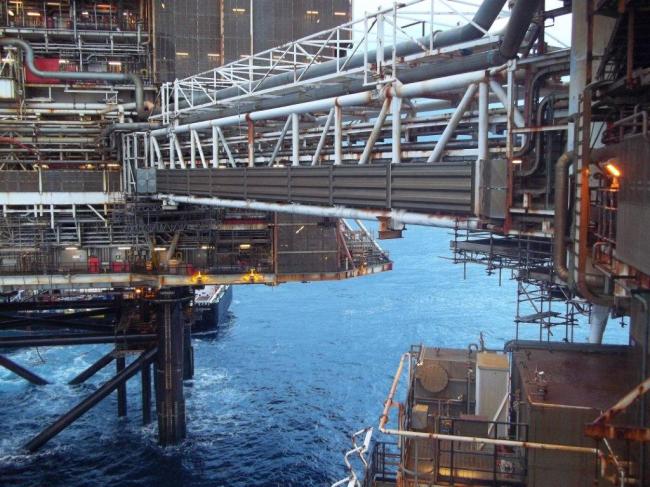

I have an off shore survey planned for early August that, so long as it doesn’t get bumped, will give me and the lead structural engineer an opportunity to see the scaffold in situ, the bridge bearings as well as the sea water/ fire water caissons. On the whole it is a good little project to cut my teeth with very little space to really screw things up.

Temporary scaffold currently installed on the P60 bridge to allow access to and jacking of the bridge for bearing inspections:

Dance floor scaffold beneath D end of the P60 bridge.

View from the D platform landing, the shrouded area is protecting area surrounding the bearings.

Looking from the PUQ platform back toward the D platform.

This bridge is f*****g huge!

Seawater Lift Caissons

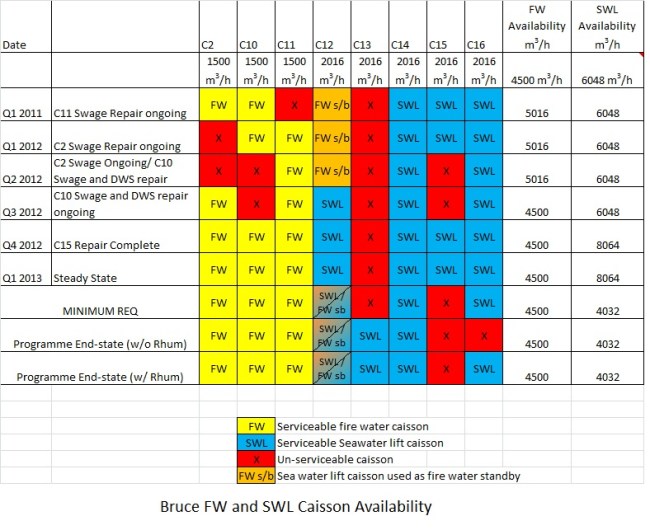

The results of my investigation into the business drivers for replacing the Bruce seawaterlift caissons have been very interesting indeed. The original caissons were underdesigned to reduce weight so that they could be lifted into place on the installation during the initial construction. They started to show premature wear about three years after commissioning and have been a source of problems ever since.

The original Capital Value Process for a replacement programme was instigated in 2009/2010 with the Select phase ultimately recommending a full programme to re-instate all but one of the sea water lift caissons. This was based on a series of structural surveys conducted in 2009 that showed that all of the caissons were in danger of total structural failure. The programme has progressed in that C13, the closest to falling off, was removed in 2010, but the challenging plan to replace it has not yet come to fruition. It has been designed and is ob the verge of being fabricated, with an installation planned for summer next year. Next year is a TAR year for Bruce, a process that adds to production in real terms, whereas the caisson only adds to production in secondary ways such as a reduction in PoB for surveys, fewer emergency interventions e.t.c. While replacing all of the caissons makes excellent engineering sense, the business drivers are far less clear and the reinstallation of C13 is highly likely to be delayed until 2015. The scope of this investigation is to:

- Understand the drivers for the caissons programme: integrity concerns, operational availability of seawater and firewater pumps?

- Re-examine the key drivers to determine whether these are still valid ensuring agreement from the appropriate stakeholders

- Propose a forward caissons programme based on revised understanding of the key drivers

In light of this, I’ve spent a lot of time reading the reports of work that has been planned and completed (or not in some cases) and meeting the stakeholders to develop a technical note assessing the importance of the key drivers and a revised programme to deal with the issue. Buy in from all of the key stake holders; the asset (Area Engineering Support Team Leader), the structural engineers in Discipline, the asset mechanical engineer and the Life of Field team who will authorise the budget in the longer term, is fundamental to getting this programme back on some kind of track and I think the original failing may have been lack of commitment from the asset with the plan being devised in isolation. My rationale for this is that the high level plan specified in the Select Decision Support Package makes no account for the impact of TARs on the plan, which is strange considering the complexity of the project and ultimately it was this oversight that has delayed the project thus far.

The bottom line is that Cessation of Production for the Bruce field is forecast for somewhere around 2020, but the installation will still require the caissons for the decomissioning process of some 7-10 years duration. There is added complication in the form of the Rhum oilfield which is tied back to the Bruce installation. One of the partners in the Rhum field happens to be the Iranian government and production has been on hold for about 4 years, the up shot being that if Rhum is turned back on then CoP moves out by another 4 years and more water will be required for process cooling.

I am looking forward to Tuesdays meeting as it will be my first time in the Bruce ACE (Advanced Collaboration Environment – video conference room with the platform) and a great opportunity to understand the situation from the off shore point of view.

I’m getting some good traction with this caisson work and things are looking promising for picking up some work on the Clair caissons. I’ve been complimented on how quickly I have broken down this issue and provided clarification, which is nice.

In other news…

I shall be enjoying not watching Eurovision and instead will be attending the village barbeque (in the rain). Corine has found herself a second job, this time with the Grampian Housing Assoc so we are scrambling to find childcare in the local area. Amusingly, she had a complaint from one of her french students for speaking french during a lesson this week. Apparently in his book this did not constitue a valid technique for teaching french. You just can’t make this stuff up!

Rail opens up second front!

It is now starting to feel like we are constructing a rail line with rail now being laid from both directions. The stabling yard has been a RISI (Rail Inustry Saftey Induction) site for a few weeks but now the far eastern end of the track has now changed to a RISI site which means we are very much working to the rail timeline. The predicted rate of 400m a day means they will be at the Scalabrini and Dickson Rd sites within 4 weeks and Kemps Creek bridge will be handed over to the rail team by wed 22 May – the second bridge to be handed over out of the four.

Dickson Rd has progressed steadily but not according to programme, I think the programme was optimistic having now gained experience of how the site dynamic works between sucontractors, suppliers etc. We are at least a week behind on the abutment walls but have been able to carry out concurrent activity on the embankment retaining walls so may have gained afew days there. As we are expecting rail to be laid through the site about mid-june we have a tight schedule to pour both abutment walls and have brought forward the delivery of the PSC beams so that we can position them across the abutments therefore leaving the span area of the rail alignment free for rail to move through. Our focus will then be to pour the wing walls and the abutment retaining walls. We have just aout completed the scaffolding around abutment A so that the steel fixers can start next week. The outer parts of 3 of the embankment retaining walls will b completed next wed with the wall stems to be poured. The fourth ERW has not yet strated as we are utilising the concrete blinded area to lay the 10m high shutters for the abutment walls. I hope that abutment wall A can be poured by the end of next week on Fri but realistically it’s more likely to be Mon the following week.

Kemps Creek bridge has now been cleaned up at waterproofed. Next week will see shock matting laid over the waterproofing which provides a bed for the bottom balast to be laid on which will also start next week. We still have a few bays of CSR walkway to pour at abutment A after placing the last remaining parapet sections which we should/need to complete by wed before the handover. We are handing over the site to the rail line but we still have few minor jobs to do but these consisit of access walkways below the bridge around the abutments and piers and access stairways.

We have now closed off Scalabrini bridge so that we can clear the 6 months worth of dirt off the deck ready for waterproofing following Kemps Creek. Defects patching work is also being carried out but we are now very close and completing three bridges with the remaining focus being Dickson Rd with an estimated competion of around Oct.

I am starting to notice the change in weather now as winter starts to creep up on us – the temp has creeped into single digits a few times in the morning but still tends to be in the high teens at its worst by lunch time. The main concern here is winter brings rain and as we all no rain in australia shuts down construction sites.