Archive

End of month (EOM) costing and further defects

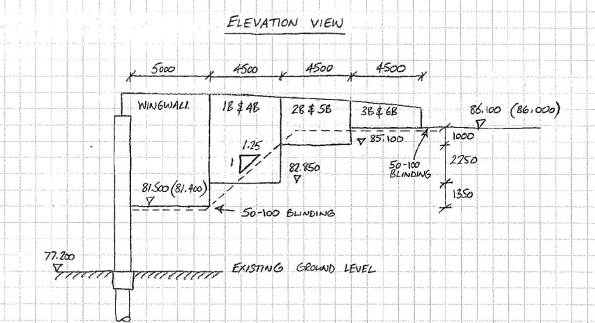

The last two weeks as seen painstakingly slow progress on Dickson Rd as the site remains in the possession of the Civil team undertaking the stage 1 backfill. By fri last week they were about halfway to reaching the underside of the wingwalls and so far a job that was programmed to take 6 days (each side) is now looking like taking close to 4 weeks which will have a massive impact on the completion date of the end of Sept.

The positive side to this delay is that I have been far too busy with other things to focus on Dickson Rd much anyway. Last week was the usual EOM frenzy which refreshingly didn’t take my weekend away from me because the various deadlines all fell during the week. I have become rather wily in ‘hiding’ money in certain areas and cost codes just in case I need it which when pressed I can fully justify but hopefully when I don’t need to utilise it the gain column will look a little healthier. Across the 4 bridges neither one is projected to come in on budget according to the cost reports I produce but I am trying to err on the side of caution and hopefully when I can start closing some of these cost codes in the next couple of months the projected cost to complete can drop into the gain column to level out the cost a little and I am confident in getting all of the bridges within $50000 of the original budget. You make think that any cost over the budget would be bad but currently 3 of the bridges are projected to be $200000 over budget due to the realisation of a very tight budget that was set at tender. It is common knowledge that the JHG tender price os $550 million was about $100 million cheaper than the next rival because of their determination to win this project which was seen as a stepping stone in winning the NW Rail Link – JHG won the tender for the groundworks which is worth $1.1 billion and hope to win the subsequent stages – and the transition of JHG becoming a rail specialist contractor. So, as this is a lump sum contract which was probably underpriced it would be very difficult not to exceed the budget, this just needs to be as minimal as possible.

The other issues of the last 2 weeks has been focused on defects. The conduit issue on Scalabrini that I mentioned in my last post is a bit of a thorn in my side at the moment. I invited the client down to an ‘unveiling’ of the expansion joint cover plates but without a ribbon cutting ceremony and was largely hoping they were ignorant enough for me to bluff them into accepting the conduits as they are. This seemed to go quite well and they left happier than when they arrived and they certainly didn’t insist on us carrying out any remedial action, what they did ask is if we could submit an RFI which would confirm that everything would be alright. The main problem is I have no way of knowing exactly how the conduits were placed as the subcontractor can’t remember or probably doesn’t care and the engineer for this site when they were put in was on holiday for that week. I do have an idea which I communicated to the designer through an RFI, I sent this to the structural designer though so it came back to me that the designer who designed the services (GHD) would be better placed to answer. In the meantime the JHG design manager sent a response stating that it is crucial this is rectified and that the conduits that seem to be restrained by both sides must be allowed to move at that joint. This is exactly the response you would expect but the cost and time that it will take to rectify will be painful. At the moment I have not formally sent the RFI to GHD who may have more to say on the matter but I need to discuss this with the Construction Manager (he has been on holiday for the past 3 weeks) before we start breaking RC out which will probably result in us further damaging the conduits.

The issue of the Dickson Rd abutment A dowels in the wrong position has also played on my mind for a few weeks. I have been told in the past to only submit RFI’s if it is fully justified as each one cost JHG depending on complexity. After requesting the Design Report and calculation sheets for Dickson Rd which at times was pretty hard to follow – their presentation score on a PET project would receive a consolation mark at best. I couldn’t see an issue with the dowels being set slightly out of position within the abutment width. We still have the correct amount of dowels at the correct horizontal spacing and the dowels would still be set into the middle third of the diaphragm therefore within the same reinforcement space. I wasn’t prepared to accept my prognosis without some form of official approval though considering the entire structure is propped through the deck/diaphragm interface. TPD (client) and RMS (eventual asset owner) have not noticed the error during their checks but there is a good chance they will once we start reo fixing the deck and I want to have a response ready if/when they do. I ended up phoning the senior bridge designer at SMEC to see what is opinion was and he was under the same impression that it wouldn’t be an issue but unless he received an RFI he wouldn’t be able to crunch a few numbers and give me a formal response. So I submitted the RFI which confirmed that the dowels are alright where they are. This would have probably cost about $10000 to rectify but more importantly doesn’t delay us anymore than we currently have been waiting for the backfill to finish.

Other issues have been regarding concrete strength results. I have been trying to close out the worklot on the piling works for over two months but as it is a 50MPa tremie mix I had to wait for the 56 day strength tests as per sepcification. Boral the concrete provider have stated that it is a 56 day product but the specification from the designer states that 50 MPa should be reached at 28 days. The 28 day results for 8 out of the 10 piles were under the design strength and at 56 days there were just one pile which had one cyclinder at 50MPa and the secind at 48.5MPa. Another RFI to the designer confirmed this as acceptable and can be justified as a sample defect but the results also showed a number of the 56 day results loer than thye 28 day results. To me the practiacalassumption to make would be again that the samples must have been compromised by either poor compaction or pre-test damage to the cyclinders. The RFI response instructed me to confirm that the concrete compressive strength of the mentioned piles was in fact increasing with time and not decreasing. My first thought was the ring them up and ask them if they could suggest a sensible way in which I could achieve this bearing in mind that piles in my limited experience tend to be subterranean and it is even more of a trend to build further bits on top of them – you could say like a foundation! I can only assume they thought we had more cyclinders available to test but this unfortunately is not a university lab with an abundance of concrete to crush for fun and tests cost money. What I have done is shifted the responsibility over to the concrete supplier to justify the results to appease the designer and finally close the work lot. I have had another sub-design strength result in one of the retaining wall bases which have a design strength of 40MPa but the 28 day result is at 37MPa. Current protocols mean that the second cylinder will be retained and crushed at 56 days. This result should yield a +40MPa result.

More Rain

It has been a pretty slow week this week due to rain and wind which has resulted in approximately 2 days work on site. This is a severe blow as it means that the milestone pour of South Block, Ground Floor, Zone 2. There were far too many issues with the slab that it was decided to switch guns onto zone 6 as a more realistic target and hope that the client is feeling lenient and gives JHG the payment or at least, part of it. In my opinion, JHG has a terrible reputation with the Clients Representative so I expect them to just laugh and close their wallet. We will see what happens.

There have been 2 events of interest this week.

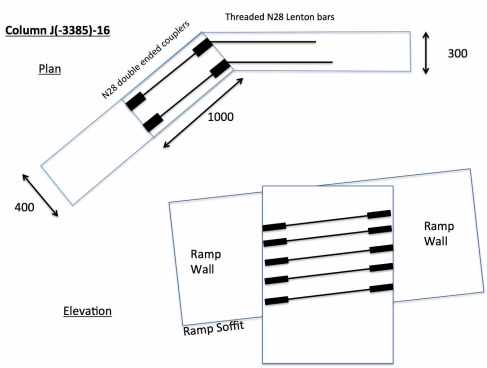

1. Column J(-3385)-16 is a 1000×400 rectangular column that sits along the side of the car park ramp and couples into the ramp slab. It also holds the ramp upstand wall reinforcement. The issue arose when it was discovered that the N28 couplers would not allow a threaded bar to follow the change in angle of the ramp wall. The options investigated were:

> Install straight threaded bars, then heat and bend to angle. (Structural engineer wouldn’t allow it as it was assessed that it would degrade the steel and there would not have the required bending diameter specified in Australian standards.)

> Short threaded bar with either short cog to allow it to be screwed in whilst formwork is in place. This would either have another coupler on the end, or if that wasn’t possible, a straight bar that could be welded to another straight bar to achieve the required lap. This option was dismissed as the manufacturer could only thread or couple a minimum of 250mm from a bend, and this would take the bar outside the perimeter of the wall.

> Break down the column to the underside of the ramp soffit and reinstall starter bars through the existing reinforcement. Messy and expensive, but appears to be the only way.

As it happens the weather has held back play this week, so nothing has been done to date. In my opinion, from looking at the structural design, the scheduler has interpreted the drawing incorrectly, scheduling couplers instead of starter bars. The bars were installed in line with the schedulers marked up drawing by the steel fixers, and the adjacent wall to the column formed up by the formworkers. To remediate this issue I have had to reorder the steel and column links (that will be destroyed during the breaking down of the column) and write site instructions for the steelfixers and formworkers to complete the work. This all has to be backcharged to the steel supplier who schedules the steel. It’s a fairly woolly reasoning especially as the steelfixers should have known better than to install reinforcement that wouldn’t work, and the engineer should have been more aware of the future intent with the column (But JHG won’t backcharge itself and it would be awkward to backcharge both the steelfixers and steel supplier so the scheduler gets it). It felt pretty dirty doing it as I have built up a good relationship with all parties, but it had to be done to get the situation moving.

The 2nd issue this week was the Health and Safety Representative for the formworker being sacked. The first that the South and Centre JHG teams heard about it was at the 0645 pre-start in the morning when the boys were all fired up and ready to mutiny. The root of the problem is all very childish as you would expect. Essentially the Northern formwork company, Crown, won’t let the Southern formwork company, West Coast Formwork, sit in the same lunch room as them (or vice versa). There has been a lot of playground tactics such as moving bags out into the rain, and name calling, but it ended in the WCF HSR heading down to the lunch rooms and essentially offering everybody out for a good old dust-up. Unfortunately for him, when he ‘threatened’ one of the rooms the JHG H&S manager was there and immediately had him removed from site for threatening behaviour.

I think JHG handled this situation particularly badly. Sacking a senior employee of a subcontractor and not at least briefing the JHG teams prior to the morning prestart. It was a difficult meeting as the rumour mill amongst the boys was working overtime and we had no information. You can’t reason with a mob. The situation ended with a meeting with senior JHG managers and WCF managers to no change. Relationships are now further tarnished.

In other news, we spent yesterday at a traditional Australian ‘Christmas in July’ party – strange, but good to have a hearty roast at this cold time of the year, and even more strangely just attended a first birthday party for a dog! If it wasn’t for the beers and BBQ I would not have gone. Still feel slightly dirty though.

Forward Planning Optional

I find myself surrounded by buffoons, I can’t think of any other way to describe these people, specifically people that call themselves senior project managers. So far as I can see that ‘project management’ in Osborne consists of getting as much stuff and many trades on site in one go into the same bit of real estate and then try to fix the f*** up after it has happened instead of thinking about sequencing. I can’t write anymore on this subject because I’m still very angry about it.

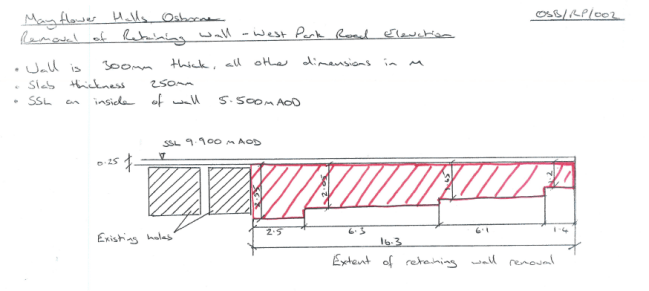

And for my next trick I shall make this wall disappear

I have been given the responsibility for the demolition of a retaining wall in my block, including gathering the quotes, ensuring the structural engineer is agrees with the method statement, coord of the other stuff in support and ultimately supervision. The sketch shows how much wall needs to come out, approximately 31 m^2 of 300mm thick wall, this will then be replaced by block walls which will probably never be removed.

The saga begins like this…The client specified that the project will use the Southampton City district heating scheme, however if the scheme became too expensive in the future the project should be capable of converting to local boilers in the plant room on my block. If future boilers were installed more louvres would be required, the client would be willing to remove block walls but not RC walls. The last point was completely missed by the structural engineer who designed it in RC anyway, so now it has to come down to be replaced by blockwork. I have called it a retaining wall which is probably slightly misleading as the part hatched in red isn’t actually retaining anymore than about 200mm of ground. The quote from the concrete cutting has come in at £9000, there are of course other costs involved, Osborne staff time, provision of access, power etc etc which I haven’t worked out how all that gets billed yet, I need to go and talk to the boring blokes upstairs (one of which believes that having done some ‘outward bound courses’ and reading Andy McNabb entitles him to pull up and sandbag and spin some dits, buffoons!). When placed against the structural engineers overall fee of £900K means that 1% of their fee will go on fixing a simple mistake.

Is the grass greener?

In other news the new bricklayer project manager spent 5 years in the Foreign Legion and has a healthy collection of crap tats. Another overly tattooed individual that doesn’t work on my block revealed himself to have spent 3 years in the QRH, every troop and platoon commander in the Army needs a photo of this bloke:

Sapper “Boss, I want to sign off”

Troopy “Why?”

Sapper “‘Coz it’s shit innit”

Troopy “OK, have you considered the following things that the Army offers that you won’t get in civi street? Pension, paying for work clothes, paying for gym membership, paying for dental treatment?”

Sapper “Yeah, still want to sign off”

Troopy “What are you intending to do for work?”

Sapper “Well my mate’s Dad’s Brother’s Cousin has got a job earning sixty grand driving lorries and says he can get me a job”

Troopy “Have you actually listened to yourself? Do you realise what you’ll actually end up like is this [brings out photo of fat, useless, former QRH bloke with ink up to his jaw bone in his ripped tracksuit bottoms, sweating himself senseless sweeping up a dusty concrete slab in the midday sun] There’s no G10 to mince around in out there you know, turning up for work hung over isn’t considered good fun”

Retention sorted.

I’m sorry I couldn’t bring myself to rant about what I actually sat down to do so but hopefully this will have made you smile.

For Richard, the surface of the moon can be recreated by pouring concrete in the rain

Oh Danny Boy (the pipes, the pipes are calling).

So the Clair Coolers project is in off-shore execute, 27% complete which is actually slightly ahead of schedule and this is good because the TAR itself was running about 2% off schedule up until this week. My role is mostly finished and I just need to ensure that final sign off is completed and a few post implementation actions are carried out before the project closes out further down the line.

Other than a couple of new project scopes I have picked up (more on them in due course), I have been following another issue in the Clair Coolers Saga. You may remember that this was supposed to be a like-for-like change out, with all pre-existing pipework being re-used. Due to various issues the pipework had to be redesigned, doubling the length and creating a whole new pipe route. This pipe work came to a total of 73 spools which were due for delivery from the sub-contractor, SeaFab, about 2 months ago. I’ve been sitting in on meetings with WGPSN (prime contractor), BP and SeaFab because the pipes are not finished. Not even close. Piping construct is set to start early next week and only 43% of the spools have been released and none have been shipped as yet.

The main issue is that there are only 4 companies in Aberdeen who carry out piping NDT, a pre-requisite in the production process. One of these companies is not an approved BP vendor and two of the others are over worked. It appears that everybody uses Euro NDT and it has been taking a minimum of 3 days to get spools through NDT. Added to this Sea Fab have a weld failure rate of around 5.6% and each spool has at least 2 welds, you can start to see the problem.

What has been most striking in these meetings is how unbothered SeaFab appear to be by the fact that they could be in a position where they are delaying a critical path project on the Clair TAR. This would be equivalent to hundreds of thousands of pounds liquidated damages per day….if the contract had any clause to impose financial penalty on SeaFab for late delivery. It doesn’t.

Now I have not seen the contract, I haven’t even had the chance to talk through the subject with the contract manager, but my understanding is that liquidated damages are generally not used in the oil and gas industry. The value of lost production is so high that to impose that on a sub contractor would quickly ruin many of them. Milestone payments are used on larger projects, but the Clair coolers project is only worth £5.6M OPEX, although the NPV would be an order of magnitude higher as the asset cannot produce gas without them.

Other than the issues with NDT, the site contractor cited work force problems as being the main reason for the production delay. His exact phrase was ‘prima donna fabricators’, which makes a little sense to me. Piping, in this industry, is where the real money is. If you see an Aston Martin in the car park, it probably belongs to a pipey (although the one I am working with has an Orange VW Transporter with custom tartan seats). There are only 4 or 5 BP approved piping vendors, of which SeaFab is one and so SeaFab know they have a captive market. It stands to reason that the fabricators know this too and I got the impression that the SeaFab management are currently at the mercy of their workforce. It is no secret that there is a dearth of skilled workforce in Aberdeen and I get the impression that SeaFab can’t afford to have its workforce walk out.

That said, I was shocked by the working practices on the shop floor.

Now you tell me that this is how a shop floor ought to look and I will be happy to call you a liar. WGPSN have issued SeaFab with a priority list, it is clear which spools should be fabricated first to feed the project should the schedule be this close, but at the end of the day, only two of the pipes in that pile are for the Clair coolers project and this visit left me with no confidence that the guys on the shop floor had any idea of the importance of getting this project pushed through.

Yes SeaFab has several other projects on the go, but most of that piping is destined to supply other BP projects and BP has set the Clair Coolers as the number one priority. As much as the WGPSN piping rep wanted to hang around the shop floor to motivate the fabricators, it really is not worth the contractual angst it would cause. That is not to say he has not done his bit to get SeaFab organised, but at the end of the day it is going to be touch and go as to whether the project is delayed because of an inept subby.

I look forward to sitting down with the BP contracts manager so that I can better understand how BP has gotten in to a position where a tiny piping firm has them completely and utterly by the balls. I think I may already know the answer.

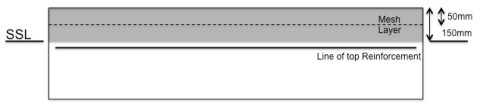

Chairing Mesh

It was decided that the building must be ‘futureproofed’ so one of the measures the architect has taken to ensure this is to pour integral topping layers to slabs so that if the intended use of areas in the hospital changes it will be easier to construct set-downs in the slabs without affecting structural capacity. This first manifested for me the day before the pour of the zone 4 ground floor slab in the South block where it was decreed that an additional 50mm of concrete would be poured on top of the existing structural surface level (SSL) taking the whole slab immediately to finished floor level (FFL). After discussions with the temporary works designer it was established that the falsework design did not have the capacity to support this additional load and could not be easily changed, so the pour continued to maintain programme. Future slabs are to have either a 50mm, 100mm, or 150mm integral topping layer applied to SSL in order to accommodate the futureproofing plan. This throws up several issues in addition to loading such as the placement of services (which were procured and tendered on a 2 stage pour, meaning that drains and ducts are no longer suitable and will require additional work to be completed prior to the pour and after to ensure that the design intent is complied with which will cost more money), and the additional cost that is incurred as a result of pouring quantities of concrete over the contracted limit.

The main issue for me was how to install the mesh at 50mm below the surface of the pour. In the 50mm topping it is not an issue, but for the 100 and 150mm toppings it will mean raising the mesh 50 or 100mm above the level of the top reinforcement. I discussed this with the designer, who hadn’t considered this issue, and the steelfixer, who didn’t want any additional burden (as he was already flat out on the remainder of the project). Due to the depth of the slabs, conventional chairs to raise the mesh were not adequate to do the job, therefore a custom solution was required. I investigated several options and used the scheduler and supplier to advise on manufacturing constraints. The options were as follows:

1. N12 Steel chair that could be inserted through the top mat or reinforcement and be tied to the B layer. An additional tie at the top mat would maintain rigidity and construction of a 1m square dummy bar mesh to support the mesh sheets.

2. N12 Steel Paperclips that sit on the top mat which would also incorporate a dummy bar mesh to support the sheet mesh.

3. Concrete blocks tied to the mesh to sit on top mat.

4. Trench mesh cut to desired height and bent into waves or rings, scattered liberally across the deck to support the mesh. This option came to me in a sudden memory from throwing in a half-arsed slab on ground construction during troopies course, using mesh rings to raise the lower reinforcing

Options 1 and 2 were decided to be both too much work and too costly. Option 3 was a non-starter really as it was reliant upon balance. Option 4, was decided as the best option for speed of construction and quality assurance. They are currently yet to be used on site but the first slab is expected to be poured by the end of the month. Currently I am procuring the strips through the reinforcing supplier at $7.45 each, but they are only able to supply a 100mm wide strip which leaves the 50mm solution unclear. After searching suppliers it will be possible to procure both solutions through a single source at a cheaper price but will involve flying the items from Germany. I am using the current supplier for the next slab but will be investigating the new supplier with commercial this week.

Union activity once again descended on site with another strike on Thursday. This is the second picket line I have crossed now, and find it actually quite fun. I managed to get in through the front gate this time as I arrived early before any padlocks were glued. Only a few of the JHG employees actually made it in on time, but the strike broke at about 1000hrs so everybody could get in then, though the lack of union members who actually returned was low so productivity took a hit. JHG doesn’t recognise unions and therefore can pay what they feel is required for a job (in this case low) which attracts non-Australian workers. From what I have heard, there appears to be a mindset change by construction companies in WA to unions. The number of sites in Perth that are union affiliated is dwindling and I think the unions are targeting the JHG NCH project, due to the scale of the project, in an attempt to regain the backing of the workforce. With the gradual demise of the mining boom it looks like in the future there will be an excess of labour which may crush the unions.

The senior management were aware of the intended strike but made the decision to continue with the pour. This resulted in 6 trucks of concrete that couldn’t gain access to site due to the picket line that were wasted (back-charged to the concrete contractor). At one point whilst chatting to the Project Director he said he was intending to place the traffic marshals out in the main road to stop traffic to ensure the trucks get in and the Police could deal with the traffic jam. I suggested that this would probably not endear the company to the community.

Other issues this week have been:

> The continued discrepancies between architectural and structural drawing details. Though it is understood that the nature of a D&B project breeds changes, I don’t think that JHG are managing the changes adequately. This wasn’t taken well by the design manager but hopefully will spark some action to ensure that these issues are caught earlier. There is a process for initial QA checks called the ‘Redstick’ process, where new drawings, which have been issued for construction, are run past engineers for comment. In theory this works well, but often there is just not the time to check the volume of drawings produced to the level of detail required.

> The reinforcement supplier not being able to supply the required N16 couplers for the ramp and having to supply N20s. Not a huge issue but changes all the reinforcement threaded bar in the ramp.

> Services clashing with beam steel. Memories from Richards lecture I think where services think they rule the roost. Beam trump toilet in this case. Architect….carry on.

> Subcontractors not even attempting to fix simple issues and resorting to firing it straight to the engineer. Couplers perceived to be installed too low for a header beam across a door in stair 8 internal wall but on re-measurement header beam soffit.

> inconceivable stupidity by trying to move an entire office across the road to a new facility and disconnecting the data connection prior to establishing one in the new office. By the time data was connected it had been over 24 hours. Certainly not acceptable on a project of this size.

> Another gratuitous crap concrete shot for Richard:

In other news I have signed up with “Team Ubique” for the Sydney Tough Mudder event. Jon, Myself and 2 other ex-corps lads living out here are going to participate in mid October (Now it is on here, it’s gospel Jon). I am hoping civi-spread has kicked in for them, though one being Will Gooderson, I expect not. Nicky and I went test driving a new Audi SQ5 this weekend, a good mornings entertainment but will probably wait till we get back to the UK to think about getting a new set of wheels. I did get some wheels though, I am now the proud owner or a 50cc hog. The MCI Riviera 50cc will roll from 0-60kph in approximately 2 days and will reach a top speed of 65kph. My mind drifts back to what a wise man once told me. “Mopeds are like fat chicks……great fun to ride until your mates see you!”

Shaft progress

This week has been an up hill struggle against the Sub-contractors.

It seems you must have eyes in the back of your head if you are to stand any chance of catching their numerous ‘cutting corners’ approach to construction. After completing the Ring beam last week the proper job of SCL works has commenced. The shaft has been excavated 1 meter at a time, in quadrants ensuring that the 400mm lining is in place before the next quadrant is excavated. However their method of ensuring the correct profile and thickness of the layers has been sub standard. After watching them use depth pins to ensure the correct thickness I asked the question if there would be an issue with water ingress.

THe issue is that although the sub-contractors have applied with the Material Specification (KT20) by providing 50mm of cover, they have not thought about the water ingress from the clay. understandably there will be very little from the clay be the life span of the shaft is 120 years and the 400mm SCL is now reduced to 50mm in certain areas. AS a result we have instructed them to stop using the depth pins and use an automated monitoring system.

The second issue relates to quality control. In order to prove to CRL that the SCL lining is adequate, we must provide samples. THe testing forecast is stipulated by KT20. KT20 also stipulates that:

‘All on-site and off-site testing shall be carried out by laboratories accredited by UKAS or similar, acceptable national body or by persons accredited to a similar standard. ‘

However when I asked for their UKAS certification it transpired they were not accredited. This has resulted in us raising an NCR (Non Compliance Record) for each one of the tests they have taken. Additionally they forgot to carry out the tests that are required once a month. I was fortunate to realise this had not happened and they are conducting them now, only 2 days overdue (although still not accredited to undertake the tests).

On top of all of this one of the operatives has chopped off two of his fingers. Whilst unloading the kettle skip of concrete washout, the skip rotated back to the vertical position and chopped them off.Personally I have always said ‘dont put your fingers where you wouldn’t put you d**k’ so I have no sympathy for him. However RIDDOR has been notified and the incident investigated. It soon found that the kettle skip wasn’t on the Lift Plan and the lifting operations on site were stopped. All the lift plans had to be revisited and inspected before we could start again. It acted as a good test to see if our record keeping was correct. We had to provide his site induction date and signature, CSCS card, slinger/signaler qualification, daily brief signature, Method Statement signature, the list goes on. The final result is that all kettle skips on the CRL sites have been banned, deemed to dangerous.

All change. Next stop Aberdeen.

I have now moved on to a new project. Progress is so slow that it has taken over a month for the Contractor to give us a revised on how he is going to catch up the 6 months worth of work we reckon he is behind. Having worked out all the work that still needs to be done, only half the paperwork has been completed, most of it was late getting to us and anything health and safety orientated has had several rewrites including the full documentation for a crane lift that was only a page long (apparently as long as everyone wears a hard hat and use a straight back when lifting the operation will run like clockwork on its own!). I think the final straw for me came last week when a RFI was submitted saying that the site plan the contractor had did not match the actually site and that a variation order for 150 new drain pipes was needed especially as part of the building did not seem to exist. When we looked at the drawing submitted it was dated 1985 and did not include the contested “new area” in which the contractor currently has workman in installing a Big Ass Fan!

My visit to Aberdeen proved far more successful. In fact I was offered a position and had a cubicle before I had been on site.

This is $270 million laboratory and training facility for the US Army Medical Institute for Chemical Defense. It is 90% on the construction phase but they are now starting to prep for commissioning. However it is not all plain sailing. The Contractor is desperately trying to make a profit out of this project. When it was put out to tender in 2008 the financial bubble had burst. The original estimate was for $450 million but Clark, the contractor, said it could be done for $250 million and got the award. They do have a good reputation but in this instance things have not gone well with any number of issues and they are now looking at every loop hole to draw more money out of the Government.

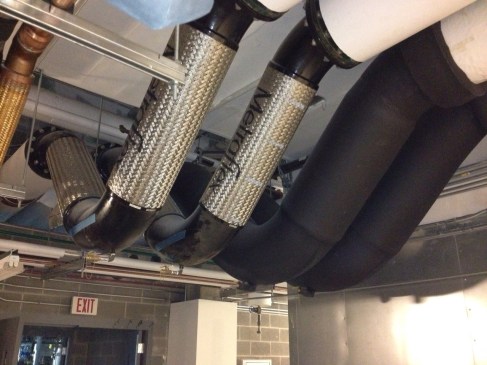

Although not as strict as Ben’s USAMRIID project (that was level 4 and needed special suits – this is level 3 like a hi tech university lab) it has some unique features that set it apart from regular construction. One such system is the enormous Air Handling Units which have filters the size of iso containers and charcoal filtration system in the exhaust to scrub chemical which require huge fans to move the air. This means all the exhaust duct work is heavily reinforced (or it would collapse in on itself the moment it is turned on) and the system has to be commissioned carefully. In the adjacent FBI lab a smaller system was installed and when it was switched on it sucked the roofs out of all the labs because the exhaust was too powerful. This lab is still being rebuilt.

Beefed up duct work

Rat cage sterilisers

Expansion loops for seismic events (the largest are 12inch pipes)

A small AHU.

I will be taking on a direct electrical/mechanical engineer role. There are any number of issues including valves in the exhaust system that leak (not great if they are using Sarin that day), a cooling tower that has bacteria growing in it (type TBC but we requested all workers wear masks in case of legionella. Chinese whispers then turned this in to a site wide outbreak of legionnaire’s disease which was understandably disruptive) and a boiler that appears to be rusting away internally. We have noted that in all the issue resolution meetings, issues that have been resolved are being kept in the minutes. It would appear this is a tactic by the contractor to show that the Government is holding up the progress on site. Interestingly if the Contractor is late it costs him $11,000 a day liquidated damages. If the Government delays we owe $40,000 hence the “record” of Government enforced delays.

Next week I am attending an Electrical Quality Verification Course south of DC to prepare me for the electrical commissioning coming up. This is a real bonus as it is quite expensive and a place came up at the last minute which needed using.

Road Kill Round Up

1x possum

1x ginger cat

5x racoons

1x deer

And in other news:

We had a very pleasant 4th of July where we hosted to a barbecue by my work colleagues and Warrick caught his first fish, we have been to the beach and everyone got stung by jellyfish and furloughs have started. This is unpaid leave for all government employees so now my office is dead Monday and Friday as everyone has enforced long weekends.

I also found this on my travels. Nescafe viagra?

Question?

Jim asked an interesting question the other day. Has anyone done any work to quantify the likelihood that (the oil and gas) platforms will exceed their currently expected lifespans?

At the end of the day, risk is managed on a continual basis and the likelihood of a platform being required to exceed it’s original design life is probably around 100%. However the original design, and any later changes, is required to be constantly being reviewed against the asset Safety Case. The asset Safety Case is the legal document that must identify and manage all hazards relating to the asset. As a starting point the “Integrity of physical resources is assured through design, construction and procurement in accordance with recognised codes, standards and practices.” As time goes on potential hazards in new and existing plant are identified systematically, risks evaluated and reduced to ALARP levels by appropriate engineering and managerial methods. The continuing integrity of plant and equipment is controlled through inspection and maintenance managements.

For example, the Bruce was originally composed of two jackets, the Process Utilities and Quarters (PUQ) and Drilling (D). A third was added 8 years after commissioning to receive and compress gas from the Rhum oil field tie back. Export risers, compression equipment and all manner of controls will have been updated and re-validated to conform to the new operating conditions, changing their design life. These changes are captured through various risk assessment procedures/studies, such as Layers of Protection Analysis (LOPA), Hazard ID (HAZID), Hazard and Operability (HAZOP), throughout every stage of the project. The higher the risk, the higher the sign off required of the risk mitigation within the organisation. I have found that individuals are generally very diligent with respect to their responsibilities when signing off as a technical authority.

Of course this kind of development results in different parts of the asset being designed for different (relative) design lives. Another consideration is that the design process conditions may not ultimately reflect the operational process conditions. The Bruce test well must have showed no indication of H2S in the formation and so the installation was designed with the minimal capacity for sour service. However, there is every chance that the well could have gone sour over time as different areas of the formation were accessed. In the case of Clair, H2S levels have increased consistently, with 500ppm expected over the next few years. This type of change has a significant effect on the life span of pipes, heat exchangers, valves etc. At the end of the day, the design life of the installation is something that is constantly changing and being reviewed on a regular basis.

I do find it worrying that in my 3 months here I have come across several instances of under design despite conformance to the appropriate code.

Bruce P 60 Bridge bearings – aggregate travel of the bearings was many times what was predicted.

Bruce Caissons – Premature structural failure due to under design of the caisson walls. It turns out that secondary forces around the sub and above sea guides were not modelled.

Clair Coolers – Under design of Coolers resulting in shell side weld corrosion.

Clair Coolers – Over stressed piping runs due to apparent lack of consideration of cyclic process conditions. FEA has shown that on start up and shut down the pipe stress exceeds tolerance and the speculation is that the pipes were designed for steady state operation only.

One issue I am currently dealing with revolves around conformance with a BP general practice which recommends that impact tested Low Temperature Carbon Steel is used on all new pipework. By ensuring that impact Tested LTCS is used throughout, the risk of using non-impact tested LTCS in the wrong place is mitigated and Procurement and Supply Chain Management (PSCM) is easier for projects. However the Clair piping specs state that non-impact tested LTCS be used (ASTM A106 Gr B), so I have had to raise and approve a deviation for an approved practice so that we can use a pipe which has a higher specification (ASTM A333 Gr6). A333 has slightly lower % manganese, sulphur, phos and carbon content, but tensile and yeild strengths are identical. The only differences are in the testing regime, with impact testing specified for A333 and not for A106. Here’s the kicker, for A106 to have been used on the cooler project it would have needed impact testing to conform to BP standard practices. The problem lies in the asset piping specs and they are clearly overdue for updating.

Asset longevity is, therefore, a delicate balance of mitigated risk against productivity. The items listed above are all managed with inspection regimes, intervention repairs and replacement programmes. Unfortunately it appears to me that there is potentially a significant amount of un-identified risk within the industry which can only increase as time goes on. In the case of the over stressed pipe work on the Clair, a project is being initiated to survey all of the pipework on the installation that might be at risk from this same issue.

I would be interested to know if the Army uses/has instances where it would need a change management system. The only thing that I have been able to come up with is the seven questions, sort of a management of change on the battlefield. Ideas?

Defects and deflection walls

The past couple of weeks has seen gradual progress on Dickson Rd as we try to complete the deflection walls so that the stage 1 backfill can start. We now have the two inner walls of abutment A side to ppur and they will be complete. It has been a frustrating two weeks to try and keep the subcontractor working at an acceptable pace and realistically we should have finished the deflection walls by the end of last week. The subcontractor is really trying to drag out the work at the moment and now seem to knock off at 1500 every day so that they are paying their workforce for only 8 hours rather than the usual 10 hours.

I have been liaising with the Civil team last week to organise the stage 1 backfill to begin as soon as the abutment B side deflection walls are complete which they now are. I mad it as simple as possible for them and gave them a sketch of exactly how I want them to do the backfill but to be honest they have a reputation for freestyling somewhat so I will have to keep a close eye on what they are doing! They will start to backfill on abutment B side first and once we have completed the delection walls on the other abutment side this week and the required curing period has passed they should be able to start on the other side the following week.

The majority of my time has been spent on closing out defect work on the other three bridges as last week was my first offical week with full responsibility for the section. These defects are mainly patching work but there are also a few outstanding jobs to complete such as abutment access stairs at Kemps Creek. I also have a rather annoying outstanding defect that is lingering about on Scalabrini which was raised by the client. This defect is simple but could cause a lot of remedial work in the not too distant future. It was originally a broken cable conduit between the Expansion joint (deck-approach slab) which was damaged during the stripping of formwork but has raised other issues as to whether we have installed the conduits according to the specification to allow movement. My supervisor being the pro-active chap he is went ahead and fixed the problem without infoming me of how and when as I am required to notifiy the client 48hrs before any remedial work is carried out. Sending this notification is a ‘Hold’ point and the actual message informs them of the ‘Witness’ point. In this case they wanted to know what our COA would be and I probably should have sent an RFI to get our approved solution verified by the designer although for something this simple I think it is debatable. The design shows the female connector cast in the approach slab side flush to the expansion joint and the male end from the deck side inserting stright into the female end. Any movement of the approach slab/deck is then not transmitted to the conduits as they are able to move in and out of the un-glued connector – fine for trains going down main but probably not going up main as the joint is pushed flush togther. The problem is the damaged conduit is right on this connector and the adjacent conduit clearly shows the join in the centre of the joint which poses questions about the other conduits and whether we have followed the drawings. We have stated that we have and it is hard to disprove as they are cast in the concrete so there would be nothing to see and we have said that the conduit with the connector in the centre of the joint is a ‘one off’ and that from a spec point of view it would work in the the same way as originally designed. A simple defect which may grow in size and at its worst lead to us breaking out part of the conduits to either prove or rectify the issue. Coupled with the fact that the joint cover plates, waterproofing and shock matting have now all been laid over the area ready for ballst to be laid could mean a lot of time and money for such a simple issue.

Regarding other news I decided to join the Sydney Harbour 10Km race last Sun to assess how unfit I have become since working 12 hour days and commuting 2 hours every day. I managed a time of 45.31 which is certainly not quick but was better than I thought given that I only managed to pass this 11 year old kid I had in my sights since the start at the 8k mark! I bought all my triathlon kit out with me thinking I must at least do one race while I am out hear but 5 months in and I been on the bike once to go to the park. I have signed up the whole family for the City2surf in Aug which is 14km from the city centre to Bondi beach but as Ethan will only be 1 its going to be more of a family walk with the buggy followed by a well deserved BBQ at the end on the beach courtesy of JHG.

And now for something…. vaguely useful?

For those of you that are reading this in the back of the classroom room whilst pretending to listen to a lecturer you won’t have had the joy of concrete yet. For those of you that are out in the real world but aren’t playing with concrete in the same way that I am I thought it would be useful to see a few things that might make design in the future a little easier. These are the concrete accessories that have appeared on site that didn’t fall into the category of either steel bar or concrete.

Shear Rails

Funnily enough I didn’t have to ask what these did, however I have to admit that I don’t fully understand how you would design for them. These rails are placed in the slab with the ‘mushroom’ end down and the flat bar uppermost. They are placed in a radial pattern around the base of some columns, I can only assume that it is to deal with punching shear in the flat slab (if John Moran answers this first I’ll be berated about my lack of an engineering model and if Richard Farmer gets this first he’ll enjoy dispensing his knowledge). The rails appear to be shorter now we’re starting to get into the post-tensioned slab.

‘Conny/connor bar’ or Anchor Strip depending on who you talk to

This off the shelf product is used in to provide starters without the need to make timber formwork. The steel loops that you can see are tied into the reinforcement cage with the green side flat against the shutter, the wall is cast and when the formwork is struck the green plastic is peeled away to reveal starter bars that can be pulled into position, these are perfect for casting the landings for stair cases. Be careful if you get asked whether you can use these instead of the scheduled starter bars, they ask to make life easier for them but don’t appreciate that slab starters are designed to be 32mm bars for a reason and can’t see why they can’t use the conny bar with 16mm starters.

Baseball Bat

This socket gets cast into the top of columns and serves 2 purposes. Firstly it is used for placing a fall arrest system inside, the red post sits firmly in place and then has an arrester wheel dangled from the end, this allows safe working at height for individual building the decking for the slabs. The second use allows the yellow post to be placed in the socket and provides a firm base to attach an instrument to for setting out, setting out from a tripod on the decking isn’t used because there is too much movement and vibration.

![IMG_2097[1]](https://pewpetblog.com/wp-content/uploads/2013/07/img_20971.jpg?w=300&h=225)