Archive

Question?

Jim asked an interesting question the other day. Has anyone done any work to quantify the likelihood that (the oil and gas) platforms will exceed their currently expected lifespans?

At the end of the day, risk is managed on a continual basis and the likelihood of a platform being required to exceed it’s original design life is probably around 100%. However the original design, and any later changes, is required to be constantly being reviewed against the asset Safety Case. The asset Safety Case is the legal document that must identify and manage all hazards relating to the asset. As a starting point the “Integrity of physical resources is assured through design, construction and procurement in accordance with recognised codes, standards and practices.” As time goes on potential hazards in new and existing plant are identified systematically, risks evaluated and reduced to ALARP levels by appropriate engineering and managerial methods. The continuing integrity of plant and equipment is controlled through inspection and maintenance managements.

For example, the Bruce was originally composed of two jackets, the Process Utilities and Quarters (PUQ) and Drilling (D). A third was added 8 years after commissioning to receive and compress gas from the Rhum oil field tie back. Export risers, compression equipment and all manner of controls will have been updated and re-validated to conform to the new operating conditions, changing their design life. These changes are captured through various risk assessment procedures/studies, such as Layers of Protection Analysis (LOPA), Hazard ID (HAZID), Hazard and Operability (HAZOP), throughout every stage of the project. The higher the risk, the higher the sign off required of the risk mitigation within the organisation. I have found that individuals are generally very diligent with respect to their responsibilities when signing off as a technical authority.

Of course this kind of development results in different parts of the asset being designed for different (relative) design lives. Another consideration is that the design process conditions may not ultimately reflect the operational process conditions. The Bruce test well must have showed no indication of H2S in the formation and so the installation was designed with the minimal capacity for sour service. However, there is every chance that the well could have gone sour over time as different areas of the formation were accessed. In the case of Clair, H2S levels have increased consistently, with 500ppm expected over the next few years. This type of change has a significant effect on the life span of pipes, heat exchangers, valves etc. At the end of the day, the design life of the installation is something that is constantly changing and being reviewed on a regular basis.

I do find it worrying that in my 3 months here I have come across several instances of under design despite conformance to the appropriate code.

Bruce P 60 Bridge bearings – aggregate travel of the bearings was many times what was predicted.

Bruce Caissons – Premature structural failure due to under design of the caisson walls. It turns out that secondary forces around the sub and above sea guides were not modelled.

Clair Coolers – Under design of Coolers resulting in shell side weld corrosion.

Clair Coolers – Over stressed piping runs due to apparent lack of consideration of cyclic process conditions. FEA has shown that on start up and shut down the pipe stress exceeds tolerance and the speculation is that the pipes were designed for steady state operation only.

One issue I am currently dealing with revolves around conformance with a BP general practice which recommends that impact tested Low Temperature Carbon Steel is used on all new pipework. By ensuring that impact Tested LTCS is used throughout, the risk of using non-impact tested LTCS in the wrong place is mitigated and Procurement and Supply Chain Management (PSCM) is easier for projects. However the Clair piping specs state that non-impact tested LTCS be used (ASTM A106 Gr B), so I have had to raise and approve a deviation for an approved practice so that we can use a pipe which has a higher specification (ASTM A333 Gr6). A333 has slightly lower % manganese, sulphur, phos and carbon content, but tensile and yeild strengths are identical. The only differences are in the testing regime, with impact testing specified for A333 and not for A106. Here’s the kicker, for A106 to have been used on the cooler project it would have needed impact testing to conform to BP standard practices. The problem lies in the asset piping specs and they are clearly overdue for updating.

Asset longevity is, therefore, a delicate balance of mitigated risk against productivity. The items listed above are all managed with inspection regimes, intervention repairs and replacement programmes. Unfortunately it appears to me that there is potentially a significant amount of un-identified risk within the industry which can only increase as time goes on. In the case of the over stressed pipe work on the Clair, a project is being initiated to survey all of the pipework on the installation that might be at risk from this same issue.

I would be interested to know if the Army uses/has instances where it would need a change management system. The only thing that I have been able to come up with is the seven questions, sort of a management of change on the battlefield. Ideas?

Defects and deflection walls

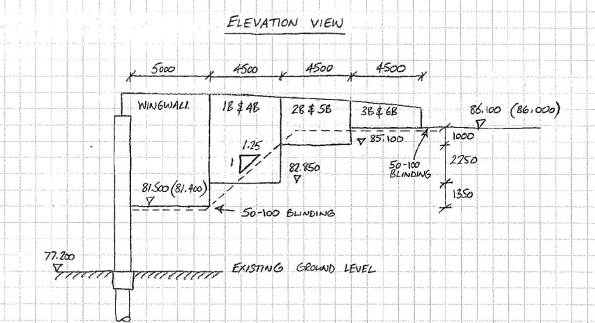

The past couple of weeks has seen gradual progress on Dickson Rd as we try to complete the deflection walls so that the stage 1 backfill can start. We now have the two inner walls of abutment A side to ppur and they will be complete. It has been a frustrating two weeks to try and keep the subcontractor working at an acceptable pace and realistically we should have finished the deflection walls by the end of last week. The subcontractor is really trying to drag out the work at the moment and now seem to knock off at 1500 every day so that they are paying their workforce for only 8 hours rather than the usual 10 hours.

I have been liaising with the Civil team last week to organise the stage 1 backfill to begin as soon as the abutment B side deflection walls are complete which they now are. I mad it as simple as possible for them and gave them a sketch of exactly how I want them to do the backfill but to be honest they have a reputation for freestyling somewhat so I will have to keep a close eye on what they are doing! They will start to backfill on abutment B side first and once we have completed the delection walls on the other abutment side this week and the required curing period has passed they should be able to start on the other side the following week.

The majority of my time has been spent on closing out defect work on the other three bridges as last week was my first offical week with full responsibility for the section. These defects are mainly patching work but there are also a few outstanding jobs to complete such as abutment access stairs at Kemps Creek. I also have a rather annoying outstanding defect that is lingering about on Scalabrini which was raised by the client. This defect is simple but could cause a lot of remedial work in the not too distant future. It was originally a broken cable conduit between the Expansion joint (deck-approach slab) which was damaged during the stripping of formwork but has raised other issues as to whether we have installed the conduits according to the specification to allow movement. My supervisor being the pro-active chap he is went ahead and fixed the problem without infoming me of how and when as I am required to notifiy the client 48hrs before any remedial work is carried out. Sending this notification is a ‘Hold’ point and the actual message informs them of the ‘Witness’ point. In this case they wanted to know what our COA would be and I probably should have sent an RFI to get our approved solution verified by the designer although for something this simple I think it is debatable. The design shows the female connector cast in the approach slab side flush to the expansion joint and the male end from the deck side inserting stright into the female end. Any movement of the approach slab/deck is then not transmitted to the conduits as they are able to move in and out of the un-glued connector – fine for trains going down main but probably not going up main as the joint is pushed flush togther. The problem is the damaged conduit is right on this connector and the adjacent conduit clearly shows the join in the centre of the joint which poses questions about the other conduits and whether we have followed the drawings. We have stated that we have and it is hard to disprove as they are cast in the concrete so there would be nothing to see and we have said that the conduit with the connector in the centre of the joint is a ‘one off’ and that from a spec point of view it would work in the the same way as originally designed. A simple defect which may grow in size and at its worst lead to us breaking out part of the conduits to either prove or rectify the issue. Coupled with the fact that the joint cover plates, waterproofing and shock matting have now all been laid over the area ready for ballst to be laid could mean a lot of time and money for such a simple issue.

Regarding other news I decided to join the Sydney Harbour 10Km race last Sun to assess how unfit I have become since working 12 hour days and commuting 2 hours every day. I managed a time of 45.31 which is certainly not quick but was better than I thought given that I only managed to pass this 11 year old kid I had in my sights since the start at the 8k mark! I bought all my triathlon kit out with me thinking I must at least do one race while I am out hear but 5 months in and I been on the bike once to go to the park. I have signed up the whole family for the City2surf in Aug which is 14km from the city centre to Bondi beach but as Ethan will only be 1 its going to be more of a family walk with the buggy followed by a well deserved BBQ at the end on the beach courtesy of JHG.

![IMG_2097[1]](https://pewpetblog.com/wp-content/uploads/2013/07/img_20971.jpg?w=300&h=225)