All change. Next stop Aberdeen.

I have now moved on to a new project. Progress is so slow that it has taken over a month for the Contractor to give us a revised on how he is going to catch up the 6 months worth of work we reckon he is behind. Having worked out all the work that still needs to be done, only half the paperwork has been completed, most of it was late getting to us and anything health and safety orientated has had several rewrites including the full documentation for a crane lift that was only a page long (apparently as long as everyone wears a hard hat and use a straight back when lifting the operation will run like clockwork on its own!). I think the final straw for me came last week when a RFI was submitted saying that the site plan the contractor had did not match the actually site and that a variation order for 150 new drain pipes was needed especially as part of the building did not seem to exist. When we looked at the drawing submitted it was dated 1985 and did not include the contested “new area” in which the contractor currently has workman in installing a Big Ass Fan!

My visit to Aberdeen proved far more successful. In fact I was offered a position and had a cubicle before I had been on site.

This is $270 million laboratory and training facility for the US Army Medical Institute for Chemical Defense. It is 90% on the construction phase but they are now starting to prep for commissioning. However it is not all plain sailing. The Contractor is desperately trying to make a profit out of this project. When it was put out to tender in 2008 the financial bubble had burst. The original estimate was for $450 million but Clark, the contractor, said it could be done for $250 million and got the award. They do have a good reputation but in this instance things have not gone well with any number of issues and they are now looking at every loop hole to draw more money out of the Government.

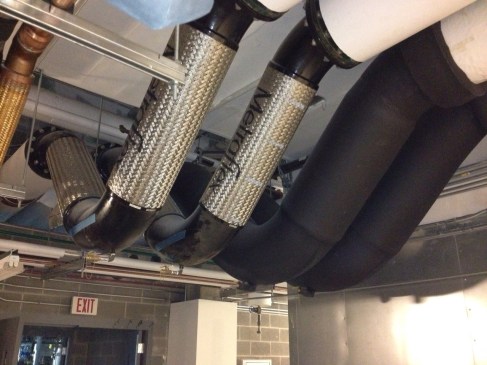

Although not as strict as Ben’s USAMRIID project (that was level 4 and needed special suits – this is level 3 like a hi tech university lab) it has some unique features that set it apart from regular construction. One such system is the enormous Air Handling Units which have filters the size of iso containers and charcoal filtration system in the exhaust to scrub chemical which require huge fans to move the air. This means all the exhaust duct work is heavily reinforced (or it would collapse in on itself the moment it is turned on) and the system has to be commissioned carefully. In the adjacent FBI lab a smaller system was installed and when it was switched on it sucked the roofs out of all the labs because the exhaust was too powerful. This lab is still being rebuilt.

Beefed up duct work

Rat cage sterilisers

Expansion loops for seismic events (the largest are 12inch pipes)

A small AHU.

I will be taking on a direct electrical/mechanical engineer role. There are any number of issues including valves in the exhaust system that leak (not great if they are using Sarin that day), a cooling tower that has bacteria growing in it (type TBC but we requested all workers wear masks in case of legionella. Chinese whispers then turned this in to a site wide outbreak of legionnaire’s disease which was understandably disruptive) and a boiler that appears to be rusting away internally. We have noted that in all the issue resolution meetings, issues that have been resolved are being kept in the minutes. It would appear this is a tactic by the contractor to show that the Government is holding up the progress on site. Interestingly if the Contractor is late it costs him $11,000 a day liquidated damages. If the Government delays we owe $40,000 hence the “record” of Government enforced delays.

Next week I am attending an Electrical Quality Verification Course south of DC to prepare me for the electrical commissioning coming up. This is a real bonus as it is quite expensive and a place came up at the last minute which needed using.

Road Kill Round Up

1x possum

1x ginger cat

5x racoons

1x deer

And in other news:

We had a very pleasant 4th of July where we hosted to a barbecue by my work colleagues and Warrick caught his first fish, we have been to the beach and everyone got stung by jellyfish and furloughs have started. This is unpaid leave for all government employees so now my office is dead Monday and Friday as everyone has enforced long weekends.

I also found this on my travels. Nescafe viagra?

Nik,

Forgive my Civil Engineering ignoranc but surely and exhaust system is blowing i.e. positive pressure and an intake sucks (rather like long upaid weekends do…)?

That does not look like Aberdeen to me…

Rich,

Because of the charcoal filters there are huge fans along the exhaust system to overcome the friction created through the filters. If there was an increase in this friction, like a blockage, the pressure could drop beyond the filter and hence collapse the duct. In the FBI building this pressure balance was completely wrong and the exhaust fans reduced the pressure in the labs too much pulling the roofs down.

Imran,

It is on the coast and it as rained one day since I have been here. But apart from that there is little commonality. They haven’t even heard of deep fried Mars bars here!