Chairing Mesh

It was decided that the building must be ‘futureproofed’ so one of the measures the architect has taken to ensure this is to pour integral topping layers to slabs so that if the intended use of areas in the hospital changes it will be easier to construct set-downs in the slabs without affecting structural capacity. This first manifested for me the day before the pour of the zone 4 ground floor slab in the South block where it was decreed that an additional 50mm of concrete would be poured on top of the existing structural surface level (SSL) taking the whole slab immediately to finished floor level (FFL). After discussions with the temporary works designer it was established that the falsework design did not have the capacity to support this additional load and could not be easily changed, so the pour continued to maintain programme. Future slabs are to have either a 50mm, 100mm, or 150mm integral topping layer applied to SSL in order to accommodate the futureproofing plan. This throws up several issues in addition to loading such as the placement of services (which were procured and tendered on a 2 stage pour, meaning that drains and ducts are no longer suitable and will require additional work to be completed prior to the pour and after to ensure that the design intent is complied with which will cost more money), and the additional cost that is incurred as a result of pouring quantities of concrete over the contracted limit.

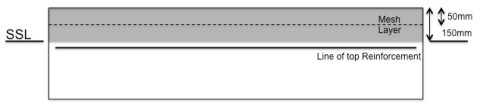

The main issue for me was how to install the mesh at 50mm below the surface of the pour. In the 50mm topping it is not an issue, but for the 100 and 150mm toppings it will mean raising the mesh 50 or 100mm above the level of the top reinforcement. I discussed this with the designer, who hadn’t considered this issue, and the steelfixer, who didn’t want any additional burden (as he was already flat out on the remainder of the project). Due to the depth of the slabs, conventional chairs to raise the mesh were not adequate to do the job, therefore a custom solution was required. I investigated several options and used the scheduler and supplier to advise on manufacturing constraints. The options were as follows:

1. N12 Steel chair that could be inserted through the top mat or reinforcement and be tied to the B layer. An additional tie at the top mat would maintain rigidity and construction of a 1m square dummy bar mesh to support the mesh sheets.

2. N12 Steel Paperclips that sit on the top mat which would also incorporate a dummy bar mesh to support the sheet mesh.

3. Concrete blocks tied to the mesh to sit on top mat.

4. Trench mesh cut to desired height and bent into waves or rings, scattered liberally across the deck to support the mesh. This option came to me in a sudden memory from throwing in a half-arsed slab on ground construction during troopies course, using mesh rings to raise the lower reinforcing

Options 1 and 2 were decided to be both too much work and too costly. Option 3 was a non-starter really as it was reliant upon balance. Option 4, was decided as the best option for speed of construction and quality assurance. They are currently yet to be used on site but the first slab is expected to be poured by the end of the month. Currently I am procuring the strips through the reinforcing supplier at $7.45 each, but they are only able to supply a 100mm wide strip which leaves the 50mm solution unclear. After searching suppliers it will be possible to procure both solutions through a single source at a cheaper price but will involve flying the items from Germany. I am using the current supplier for the next slab but will be investigating the new supplier with commercial this week.

Union activity once again descended on site with another strike on Thursday. This is the second picket line I have crossed now, and find it actually quite fun. I managed to get in through the front gate this time as I arrived early before any padlocks were glued. Only a few of the JHG employees actually made it in on time, but the strike broke at about 1000hrs so everybody could get in then, though the lack of union members who actually returned was low so productivity took a hit. JHG doesn’t recognise unions and therefore can pay what they feel is required for a job (in this case low) which attracts non-Australian workers. From what I have heard, there appears to be a mindset change by construction companies in WA to unions. The number of sites in Perth that are union affiliated is dwindling and I think the unions are targeting the JHG NCH project, due to the scale of the project, in an attempt to regain the backing of the workforce. With the gradual demise of the mining boom it looks like in the future there will be an excess of labour which may crush the unions.

The senior management were aware of the intended strike but made the decision to continue with the pour. This resulted in 6 trucks of concrete that couldn’t gain access to site due to the picket line that were wasted (back-charged to the concrete contractor). At one point whilst chatting to the Project Director he said he was intending to place the traffic marshals out in the main road to stop traffic to ensure the trucks get in and the Police could deal with the traffic jam. I suggested that this would probably not endear the company to the community.

Other issues this week have been:

> The continued discrepancies between architectural and structural drawing details. Though it is understood that the nature of a D&B project breeds changes, I don’t think that JHG are managing the changes adequately. This wasn’t taken well by the design manager but hopefully will spark some action to ensure that these issues are caught earlier. There is a process for initial QA checks called the ‘Redstick’ process, where new drawings, which have been issued for construction, are run past engineers for comment. In theory this works well, but often there is just not the time to check the volume of drawings produced to the level of detail required.

> The reinforcement supplier not being able to supply the required N16 couplers for the ramp and having to supply N20s. Not a huge issue but changes all the reinforcement threaded bar in the ramp.

> Services clashing with beam steel. Memories from Richards lecture I think where services think they rule the roost. Beam trump toilet in this case. Architect….carry on.

> Subcontractors not even attempting to fix simple issues and resorting to firing it straight to the engineer. Couplers perceived to be installed too low for a header beam across a door in stair 8 internal wall but on re-measurement header beam soffit.

> inconceivable stupidity by trying to move an entire office across the road to a new facility and disconnecting the data connection prior to establishing one in the new office. By the time data was connected it had been over 24 hours. Certainly not acceptable on a project of this size.

> Another gratuitous crap concrete shot for Richard:

In other news I have signed up with “Team Ubique” for the Sydney Tough Mudder event. Jon, Myself and 2 other ex-corps lads living out here are going to participate in mid October (Now it is on here, it’s gospel Jon). I am hoping civi-spread has kicked in for them, though one being Will Gooderson, I expect not. Nicky and I went test driving a new Audi SQ5 this weekend, a good mornings entertainment but will probably wait till we get back to the UK to think about getting a new set of wheels. I did get some wheels though, I am now the proud owner or a 50cc hog. The MCI Riviera 50cc will roll from 0-60kph in approximately 2 days and will reach a top speed of 65kph. My mind drifts back to what a wise man once told me. “Mopeds are like fat chicks……great fun to ride until your mates see you!”

It’s a pretty drastic late change to kick the screed into touch – since one of the reasons for screed is to achieve a level finish and the prospect of ponding generally increases with depth of pour – errrr check the spec on slab levels and good luck with that! Might make a TMR I guess

I think the things in front of your bemused troopies are caled ‘snakes’ seen them on slabs 0f 250 maybe 300 but your slab depth seems to be well above this

Thanks for the cr*p concrete fix for the day. Starts the week with a smile. I’m with Jophn on the construction tolerance vs hopsital spec for finished floor issue. I’ve seen plenty sacrificial screed in a past life but not experienced the need to pour additional depth at the same time as the main slab. Any particuoar reason why the additional non structural depth has to be poured integral to the main structural slab? I suspect it’s an interpretation error not an construction need!

John, the snakes were intended to raise the crack control mesh above the top mat of reinforcement to a level 50mm below the FFL, therefore need only be 100mm tall for the largest integral screed. We are going to test the method on a pour this week so i’ll let you know how it goes. As for the ponding, the quality of the concrete finish has been particularly poor anyway. The additional 150mm on top of the SSL will only exacerbate this problem.

Richard, Not too sure of the reasoning behind this but if I were a betting man, i would expect that it has something to do with programme chasing and has been specified as a method to claw back lost time due to strikes and rain (2 things that apparently never happen in Perth!). The Archi drawings have been amended to include these integral toppings which actually now sit higher than the original FFL. Not too sure where the additional headroom is coming from though. Another thing to find out this week.