Archive

The Pressure

It has been some time since my last post, so I thought I had better clear a space and get some info into you all.

I had a good trip off shore.

My conclusion is that working off-shore is very similar to working in a patrol base devoted entirely to engineering although with far better facilities and food. Not convinced about the helicopters they use to get there though…

Bruce P60 Bridge

The reason for the visit to Bruce was to mainly have a nose around on the pretext of assisting with a design survey on the landing points of the P60 bridge. I took the opportunity to see the Bruce sea water lift caissons, both from a distance, but also at the point at which they come on board at the cellar deck of the PUQ platform. I am currently awaiting the delivery of the workscopes for this project so that I can write up the DSP for end of Define. I am aware that the project is likely to be killed following the DSP, but there are so many people who believe that this project should be carried into execute I will try and get some buy in. I have hopes that a phased execution will be more palatable to the powers that be, affording schedule flexibility to work around larger, more important projects.

Bruce C13 Caisson Reinstatement

I have been involved in this project for a while now having originally secured the deferment of the scope by 12 months and by providing input to the re-development of the Caisson renewal programme. With the deferment now taking place, I have been asked to take on the C13 scope through to completion of on-shore execute i.e. delivery of Rev C workpacks. Other than that I will have to ensure that certain equipment is ordered next year, but little else. I have put forward the idea to the Programme lead that this project remain with the RE secondment so that I will be able to hand it over to my replacement who would take it all the way through on-shore trials (Sept 14) and into off-shore execute (Apr 2015). The following replacement would then be in a position to close out the project, but also possibly be involved in the next part of the programme. My idea is that this programme has suffered mainly because it has no continuity as people move in and out of the organisation. We may be able to offer some continuity and this idea already has some traction with Kerry Scott and if we have a candidate to replace me, I will keep pushing it.

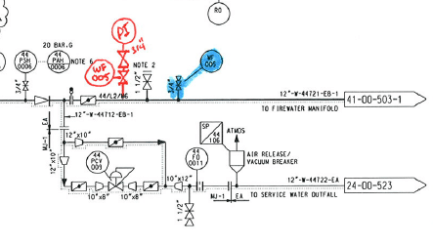

Magnus Firewater Main Overpressure Protection DSP

I am currently at the end of drafting the DSP for this ~£3m project. The project itself is already deep in on-shore execute with the original off-shore execute planned for Oct 2013. at present we have little chance of making the 12W gate criteria, not in the least because the project has no official BP sanction to be in execute. The problem is that the project SPA recently got a new job and left leaving myself and the new SPA to pick up the pieces. There are overdue milestones, unforeseen deviations and a critical scheduling issue confronting the project at present and I am in the process of trouble shooting them. My key concern is that the asset is only permitted 1600hrs downtime in every 365 day period for each of the firewater pumps. This project modifies the overflow route to the outfall and requires each pump to be taken offline sequentially for a period of up to 29 days. At present there is no buy in from maintenance as to the effect of this scope on their schedule. Ultimately an ORA (Operational Risk Assessment) could cover any breach of the Fire water performance standard, but only in extremis.

Clair Coolers Replacement

The SPA for this scope has also gotten himself a new job and so I have been tasked with bringing this project home. The back of it is well and truly broken and the TAR focus has moved on to the Clair Ridge tie back, but there is still plenty to do with a number of issue left to resolve to ensure that the project finishes as per the ‘s’ curve. Thankfully the issues with SeaFab have been concluded, with all of their scope complete. The 7 closing spools have been contracted out to a diferent piping firm (Isleburn) and they are coming along nicely. This will tie in nicely with my thesis as I will now be involved in the commissioning process of the whole scope including a trip to Germany to close out the aspects with the cooler supplier. Further to the current off shore execute I have been assigned the execute of the HP cooler installation which is scheduled for the 2015 TAR, another workscope that I will be able to hand over to my successor if things go well.

Clair Manifold Piping Supports

Having identified that this workscope required a production shutdown, I am trying to find a slot in the plan with a planned shutdown in which to fit this job. I have a couple of meetings next week that should move this one forward.

Competencies

Having had a good look at my competencies earlier in the month I can see that I fall short in section B, much as Chris did before me. I have brought this up with my mentor as pretty much of the work I am involved with is great for A and C, I need to get myself in the ‘2’s for B. With that in mind, I will be looking at getting involved in some work on the new ETAP flowlines, which may offer me the opportunity to exert design influence rather than where I am at the moment which seems to be more design mitigation. I am pretty much at the limit of my capability in terms of projects and so I have started to turn down opportunities. If I get some work on the ETAP then I will be busy right up to Christmas.

In Other News

Went on a sea safari out of Banff a couple of weeks ago where we saw a Basking Shark. I had no idea you could see these in Scottish waters and the 10m long monster actuall swam under out little Rib. I haven’t gotten around to formatting the pictures, but when I do I will post one up here. Other than that things have been pretty busy with visitors almost every weekend for the last two months. I finally caved this weekend and bought myself a Raspberry Pi, so I will be spending the long Scotish winter learning how to programme in Linux, the main reason for this is to anlyse the suitability of my garage for a home brew set up and then as a temperature monitor once I am ready to brew. Thinly veiled excuse to tie together to of my passions, beer and technology. Beats a home made 2d milling machine. Speaking of Mr Hill, here’s a photo to get your motor running…

Caulk is the New Harry Black

The tension has eased in Aberdeen. 2 weeks ago the middle management for USACE and the Contractor got together to discuss the constant clashes that are happening that are resulting in no progress. It was agreed that this was not a good place to be and that a change in attitiude on both sides to a more collaborative approach is needed. Brilliant! How will this be achieved? Well in the land of red tape a new paper form should sort this out. This will only be used when no resolution to the problem is forthcoming at the site level and is basically a one page document stating the issue, the points of view of the Corps and the Contractor with a desired result and then it is passed up to the executive board, a level up, to make the decision. Will it work? Having attended the executive meeting this morning it seems unlikely as there was very little give at this level either. The issue remains in that the contractor is trying to save time by not doing things as per the book, mostly pre commissioning tests, whereas the Corps position is “we have specific requirements, why is it that hard to follow the contract?”. In this instance I think the arbitrator should be the customer. If they are happy with the streamlined commissioning programme over the thorough one they should choose; this project is for them after all! This was actually a relatively productive meeting, most just end in continued disagreement. The Commissioning Contractor has even started to approach the USACE Commissioning inspector so that they get an answer with out the Corps being involved. We have cleared up a lot of issues in other areas but I am handling 2 main ones still. THe tripping motor now appears to be four tripping motors so the contractor is now doing a big regain to get this back on line otherwise there will be no chilled water being pumped at all. Not good when you have said it is ready for commissioning. Secondly we have leaking internal drains. Not that bad ordinarily except these all seem to drip directly on to the Building Automation System rooms where replacement of equipment would cost millions not to mention the disruption of having no voice or data services. Interestingly the main voice communication in this building is by VOIP not telephone, military Skype if you like, although no one can tell me to what level of security this is up to. After a big meeting with all stakeholders the manufacturer confirmed his product had not failed but there were a couple of issues he had identified. Firstly when the drain is installed, it is done so in two parts and flashing is needed between these parts to ensure any water that seeps around the top of the drain and concrete is directed to weep holes that direct the water back in to the drain. There is no flashing installed in these drains. Consequently water gets round the concrete and flows outside the drain. The Sub Contractor has tried using caulk (american for silicon type sealant) to stop the leak but to no avail because of the missing flashing. They have been instructed to find a better solution. A second type of drain is leaking because the seal between the galvanised grating and the porcelain body has no gasket. A bad design I thought, until the manufacturer pointed out this design is generally used for floor drains at grade level so any seepage would just go into the earth. There is a special drain to go between floors but it was not specified correctly and now it is too late to change. How is it going to get sorted? Caulking between the grate and the bowl! In a similar vein we have sound attenuators in the laboratry exhaust systems that are not as per specification. These metal boxes are currently all made of pressed steel bolted together. This is not considered sufficient because there is a chance that gas could escape between the bolted surfaces – not great when you are dealing with Sarin and lots of other nasties. The contractor solution – caulk it! Hence the title for this piece. Having actually caulked the attenuators they proudly showed one of the engineers their handy work whereupon he ripped all the caulking off to show it would not hold up. They are now putting in welded seam attenuators at their own expense. (see below)

In Harrisburg they have finally started replacing the roof. However the same old issues keep rolling on. There is a crunch meeting with the Designer of Records to help sort out who is right. What the Contractor doesn’t know is that he is now losing work at Harrisburg because no one wants to work with this company ever again.

Alas the road kill round up is being killed off because there is very little other than racoons to report on. Instead I am going to pick my favourite incidents from the Corps “Safety – A Week in Review” bulletin. It is amazing what people will do to get off work! LWD = Lost Working Days

1. Employee was walking into the restroom and fell. In catching their fall, the employee received a fracture in their wrist. LWD – 3

2. Employee was returning from lunch, stepped on a rock and twisted their ankle. LWD – 3

3. Ctr. Employee was posting reservation cards on campsite posts using a golf cart. As cart was traveling downhill, the brakes failed on the cart. The cart crashed into a concrete base, occupant thrown, shattered his kneecap. LWD – 15 (is that all!!!)

4. Contr. Employee was digging mud from a duct bank and strained his back while conducting this activity. LWD – 2

5. Contr. Employee was climbing a ladder to check water level inside concrete wall placement. Leaned to far to the right side and fell off the ladder. LWD – 1

These notices are always followed by the deaths of civilians in Corps run areas, mostly lakes. They invariably involve alcohol, deep water, no life jacket and a coroner from any age 1 to 80. The only funny happened last month when a guy dived off his house boat and landed on a corpse. What are the chances…….

In Other News

We have had a very nice week off in Virginia Beach. Apparently it has been one of the wettest summers there on record but was a lot better than most of the summer holidays I spent in Cornwall. The kids have started school and Warrick now goes on the big yellow school bus, just like the Simpsons. And running training has resumed for the Army Ten Miler now that evenings are below 30 degrees and 100% humidity.

Water Depressurisation

Second week back from summer hols and things are progressing nicely. The shaft construction is becoming a bit repetitive so I thought I would give the spraying a go for my self.

Some of the nozzlemen are the highest paid workers on site, which is quite interesting as the course to qualify is only 5 days long.

Anyway we are getting close to the base slab now and that means that we need to depressuirse the water, to ensure there is no up heave when constructing the slab. We contracted this phase out, essentially constructing 2 x 11m small boreholes in the bottom of the shaft. The photos below show the sub contractors digging the boreholes.

Its a very simple solution to potential up heave of the base slab. The two boreholes will allow the water (although there is no water as we are in the Lambeth clay layer which is more like mudstone) to release the pressure. Theoretically once the base slab has been cast and the slab has gone off, the boreholes will be closed off and the base slab will take the force. However as I said there is no water in sight any where).

I have just attended the Waterproof membrane trials at Bond Street. THis will be the next phase, due in about 1 week. Essentially it is a large roll of waterproof membrane. THis roll will be lowered to the bottom of the shaft and pulled to the top, where it will be nailed in place. Once the membrane is in place the secondary/in situ lining will be constructed. THis is the poured concrete. I have just completed the TW design brief for the shuttering. THe shuttering will need to be able to handle lifts of 2m. THe sub contractors have estimated a 28 day period to complete the in situ lining, I am extremely doubtful but I remain optimistic.

I am currently eyeball deep in a CE (Compensation Event) trying to calculate the time delays caused by out of spec concrete. However my next post will probably be about the CE procedure and the lessons (if any) that I have learnt.

Just managed to book myself on the ICE presentation about the Super Sewer construction in London. Looks like it will be a good talk on the 19th Sept followed shortly afterwards by the ‘Hidden Shafts’ talk on the 02 Oct. Let me know if anyone else is planning on going to either of these events.

As there have been some significant changes over the summer break, it is only fair that I should put out a quick blog to keep everyone up to speed with the changes at PEW. As you may be aware, we moved out of Denison Block week commencing the 12 August and took the contents of the building (lock, stock and two empty barrels) over to the Warren Building at Lodge Hill. For those of you on Phase 2, unless something very unexpected happens, this is where Phase 4 will be taking place next year.

This building was formerly the HQ of DEMMS who were clearly a lot better funded than the rest of the RSME as our new accommodation is very comfortable, although somewhat challenging to get to in the morning. Chris Warner is already using it as a training cycle ride so you get the idea. The classrooms are going to take a bit of getting used to as well as the rooms were never really invisaged for the uses that we are putting them to, but I reckon by Christmas we will be firmly dug in and not wanting to go back to the Brompton Massive.

Although e-mail accounts and so forth are unaffected, the phone extensions have all had to change so it may be worth dropping your mentors a line to get their updated contact details if they haven’t changed the signature blocks on their e-mails yet. Other than that the work starts again in ernest on the 27 August when the junior courses come back from leave, after which I suspect all eyes will be firmly fixed on half term in October. On the military news front we now have a new Commandant in Brigadier Dave Southall (we were in the same company at Sandhurst) and a new DG ART in Major General Chris Tickell. I will keep you posted as things develop on the course and at the RSME. Cheers for now.

Jim

Jim

Off Topic – Kind of

I’m hoping some of last years gang are still half reading this though I doubt it.

I’m currently responsible for doing the site waste management plan. It involves collecting the mileage travelled by the workforce and deliveries, coupled with water and electricity consumption. All this is used in support of achieving the required BREEAM rating (but extra stuff is required for that bit too). This is a nightmare and requires me to trawl through lots of signing in sheets, delivery record sheets and waste transfer notes. I’m currently thinking about writing a proposal to Osborne Group about commissioning an App for iOs/Android that should take some of the monkey work away from me, I’ve got a quote from a developer for it and will put it to the company in the next couple of weeks.

Out of interest how is all this stuff done on the other UK sites? (hence the reason some other courses are looking at this as Mike is the only other person still here)

Demolition Man – The Plot Thickens

Those of you who care or who are bored enough to flick back through the blogs may remember that there was a requirement to demolish a significant amount of concrete wall on my Block due to the structural engineer not designing the knock out panels for the future louvres.

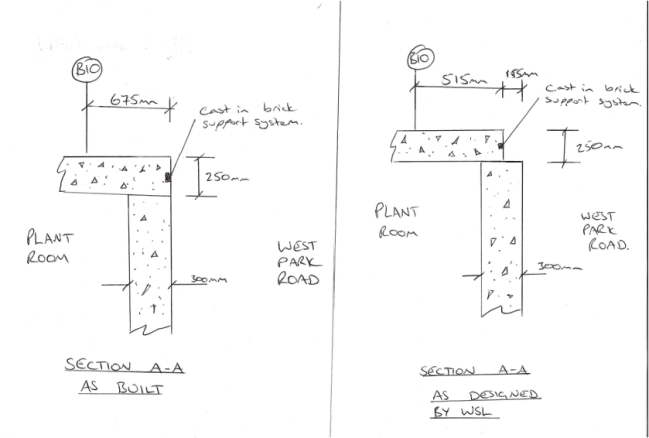

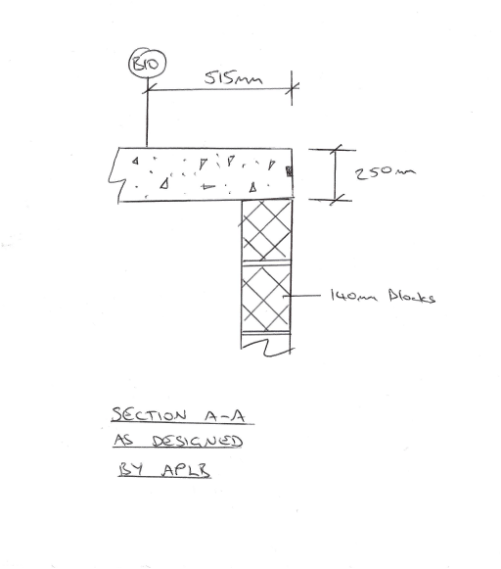

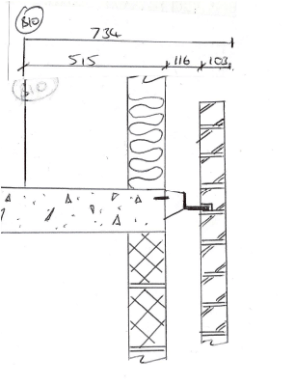

What I didn’t really mention as it was a secondary issue was that the face of that wall was built too far towards the outside of the building by about 155mm. It seems they just read the make up of that section of wall correctly, there is face brickwork here with a cavity behind and consequently just intended to steal some of Southampton on the sly. Once again assumption got the better of me, it seemed it was no secret that the retaining wall was too far forward and the slab edge too but it didn’t seem that much of an issue. When it was only this problem nobody seemed that bothered and figured that something could be done, it was only when the future louvre issue came up that demolition was talked about. My assumption was that because nobody was jumping up and down when the wall was too far forward there must be some kind of clever fix like using a brick slip to save space; so when the wall was removed as previously mentioned on the blog I assumed that they would use the same clever solution to get around the slab edge too far forward problem. How wrong I was. The sketches below show what was built, what was designed by the structural engineer and what was designed by the architect.

This doesn’t really describe the full story because it’s only when I looked at the slab edge detail that I realised there was no clever fix and very few clever people. Below is my reproduction of the slab edge detail comparing the as built section and this sketch shows that with an overall dimension from B10 to the face of the brickwork of 734mm and an as built slab edge of 675mm we only had 59mm to play with which in order to achieve the cavity and the any form of brick would have been impossible.

So more demolition at the cost to the structural engineer as 150mm of slab is cut back and removed across about 24m of construction. All this against a background of a Project Manager desperately trying to get follow on trades into the area see first paragraph of ‘forward planning optional’ who is slowing up the process by not allowing me to clear the area. The frame contractor has had a lucky escape here as the as built is different from the as design by WSL, the structural engineer, otherwise the slab cut would have been paid for by them but because WSL have made the first mistake it’s all going on their flick. Personally I think the as built/as per WSL would have been an interesting argument anyway was there was no section as I have drawn it instead that rather odd arrangement was supposed to have been worked out from the GA below, note the interesting combination of dotted and solid lines all trying to convey different things.

There are other slab edges out there that have been wrongly designed by the structural engineer and are about to be lopped off too, so it’s not a one off mistake. In another update I’ll try to look at the remediation that follows all this cutting, ends of bars are now exposed to the elements and need fire/water proofing and all the U Bars have been cut off too. I just need to work out what U Bars actually do and why it’s so important they’re replaced.

More responsibility

The last 2 weeks has seen the stage 1 backfill at Dickson Rd Abutment A completed and I can finally get the subcontractor back in this week to erect the scaffold to then start steel fixing and forming the wingwalls. I estimate we have lost nearly 4 weeks from this delay but having spoken to the FRP subcontractor supervisor we are both confident of gaining at least 2 weeks back on the programme especially as summer seems to have arrived half way through winter!?

To be honest this delay has been useful as I’ve been busy with other work. The defects work on the three other bridges in my section are close to completion with minor outstanding work like handrails, anti-grafitti guard and underbridge drainage close to completion. The conduit issue at Scalabrini has been shelved at the moment as I have also taken over from another engineer who left last week. I now have responsibility for all the bridge works outside of the two stations which includeds a total of 9 bridges and 18 retaining walls. The majority of work is of course complete but there are a number of defects/issues to close out and some minor work to complete.

I have also been given a HV/LV substation to complete which I have been focusing on last week. This includes padmounts, conduit runs and 6 pits which are situated on the western side of a high pressure gas main. This gas main has been a sticking point for many months and has been the cause of delay of installing rail track due to the client having not submitted the appropriate notice for a concrete protection slab to be constructed. The gas main is highly sensitive and comes with a great deal of red tape but the appropriate clearance has now been granted so work can commence. This means we need to have the substation area complete by 9 Sept when work is scheduled to begin. We have managed to pour the padmounts easily enough and have poured the base of one of the pits and I hope to pour the walls and the base of another pit by the end of the week. An issue I realised on Sat when going through the drawings with a quiet few minutes was a small note that said the concrete for the pit must contain a Xypex waterproofing additive. The handover I got from the engineer who had had this job for well over a month consisted of very little but ‘read these’ and having been initially told two of the pits must be complete by the end of last week – this gave me about 4 days since being handed the job – I cracked the whip to get productivity up – looking back it was at the expense of knowing the finer detail. The fact that it wasn’t briefed to me on the handover made me feel that the pits would be straight forward so thought lets get some concrete in that hole. I also noticed that a betonite/asphalt tape was required to be wrapped around the conduits that entered the pits which would swell on contact with water and stop/slow any ingress of water through the joints. This also made me wonder way it didn’t mention it for the construction joints between the base and walls so I have decided to order more of it and place it at the CJ’s as well. I have been quite frustrated at the inconsistency and lack of detail of the drawings which has made a simple looking job a lot more difficult. The construction manager wasn’t too concerned about my confession this morning about the concrete so I will continue as is with the Xypex batched in with any further works.

Other major works in the future include a RW that has settled and the corner has been crushed as it sits on the edge of a pile cap of Byron Rd bridge. Remedial work will have to include breaking out this corner and re-establishing the joint to not only that RW but three others that sit on the Pile Cap which haven’t yet crushed but may do in the future. The RW above these have also settled and a 50mm+ gap has opened up between panels which also needs filling to maintain noise wall integrity.

There are also some slip form traffic barrier’s to construct at two further bridges but as I will have some further barriers to do at both Dickson and Eastwood which were initially in the scope of works of the civil team I will try to do all the slip forming works together around Oct time. I have to speak to the subcontractor yet and contribute to producing the contract with the commercial team before any of this happens so that will at least give me time to do this and to also write the AMS.

The concrete strength issue of Dickson Rd piles continues with a few developments. The main development is the Project Verifier (who works for RMS as it is a road bridge) noticed that on the third day of four a different concrete mix was delivered. I really should have picked this up when we poured but I was mainly loooking to see that we received B80 (RMS spec) 50MPa 220mm slump tremie mix which we did. What I failed to notice is the different mix code on three of the dockets so I must accept a small part of the blame. However, this was not the mix I ordered which I have proved and why they decided to change the mix on the third day and then revert back to the correct mix the day after is a bit of a mystery. Both mixes are 50MPa with the same slump but the ‘rogue’ mix has a higher cement content and lower w/c ratio. I looked back at all the 10 batches I received for the piles to compare them and you can see that the concrete supplier has fairly consistently cocked up the batching. The first two rogue mixes were batched identically to the previously mix so it appears even though it states a different mix code the mix is practically the same as the project approved mix. The third rogue mix batch was in line with the design mix and is probably the one which will cause an issue with the designer. The project approved mix should have a Total Cementitious Content (TCM) of 515 Kg/m3 with a w/c ratio of between 0.3-0.4 but as you can see from the table below most of the batches don’t conform to this. The one rogue mix that is actually correct should have TCM of 635Kg/m3 with a w/c ratio of between 0.27-0.32 but the project requirements state that TCM should not be over 550 for durability purposes so this is the batch that may be a problem. The origianal issue of strength inconsistency has just about been put to bed as the project approved mix is a 50MPa product at 56 days even though the designer states in the drawings that this strength must be achieved at 28 days. Since there is no 50MPa at 28 days product approved for this project the deisgener has taken the 56 days results, applied the corrective value to convert to 28d strength (1.19 for blended concrete) and is happy that the strength achieved is satisfactory. The issue of some of the results losing strength between 28-56d has largely been brushed aside as I expected and the test samples have been blamed. However with this new information which I submitted to the deisgner through the RFI process this morning we wait to find out what implications there may be. The main issue that has been raised is the potential of thermal cracking due to the high cement content in pile A3 and therefore the issue has now become one of durability where as initially it was of concrete compressive strength.

Outside of work we have celebrated our little mans 1st birthday which to be honest he may not have realised! We and friends had a good celebration anyway with cake, beer and champagne. We also completed the City2Surf run or walk in our case this sunday which is apparently the most popular run in the world. It is certainly one of the most scenic as you go from Hyde Park in the centre of Sydney and finish at Bondi beach. I registerd with JHG so got to wear a JHG running top and sun visor – I saved a visor for you westy! It all finished with a BBQ on the beach in the JHG/Thiess/Leightons corporate tent which was a good way to end the day. As Westy has mentioned we are doing Tough Mudder in Oct which I might add I signed up to before Mr West but I’ll have to share with you his text he sent when asking if I was up for it. It certainly confused me – not that I’m saying you wouldn’t do well in a model competition mate! Not sure I’ve been called Benjo before either!

Is there such a thing as half a pour?

More rain again this week, but surprisingly Centre block decided to push ahead with a 620m3 pour that both started and finished in the rain. At some points it was torrential; the concreters walked off the slab several times and it was hit or miss whether they would have to place an emergency construction joint. The decision was taken to push through as the slab was not being poured to a finished surface. The pour took 13 hours to complete!

Concrete Finishes (South Block Golfball effect / Centre Block after the pour(ing rain) / the drip marks from overhanging formwork)

The following day was not quite as wet, but a very wet start caused the concreters to walk off site swiftly followed by all the other trades. This was supposed to be pour day for my SB GR Z2 slab but as nothing was completed the day before it was put off till Sat. I went on a site walk with the South engineers to just generally have a poke around at what was going on in the North and Centre. It was also a good opportunity to see techniques that will be incorporated into the South build shortly.

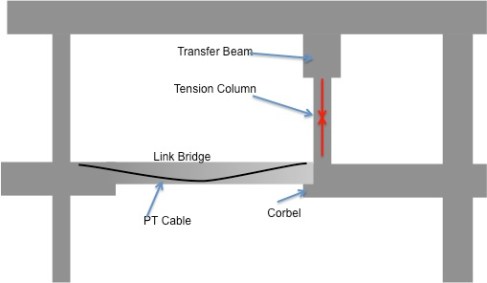

I had only heard of a tension column once before, not sure where though. It is pretty simple in concept really, the column hangs from a substantial transfer beam above, which sits on 2 hefty columns. The column will hold up a link bridge between the East and West blocks. The bridge itself, though only about 20m span has 4 longitudinal double PT beams which appeared to be overkill but when looking at the other end of the beams they extend 2m into a large transfer beam which must take a larger proportion of the bridge load to leave the tension column with less. I do question why it is a concrete column as a cable could probably do the same job more efficiently, but assume that architecturally it must fit with the aesthetic of the building.

My real issue this week is that of the topping layers. I have written briefly about the integrally poured topping layers before and I think I expressed my concern about pouring an additional 150mm on top of a structural slab with the initial pour. Essentially this is a money and time saving exercise (Concrete is cheaper than a screed layer poured at a later date) at the expense of quality (finish). The standard of concrete slab poured on the project so far has been pretty poor in my opinion (undulations mainly), so to increase the depth of concrete slab poured to over 500mm increases the potential for undulations. This was found on the pour of SBGRZ6 recently (The deck rings/snakes worked by the way though the steel fixers thought that they were too much work), where there is not fairly deep undulations in the surface of upto approximately 20mm – well over the tolerance allowed in the Aussie Standard.

The second issue is that immediately pouring to the FFL leaves no room for making good. What is poured is what you get. To pour a screed layer later is not only be expensive but time consuming but it does give the opportunity to produce a finish that will be accepted by not only the client, but the follow on trades. In some cases in the South after a light shower after the end of the pour the entire surface became pocked, similar to a golfball. This is not acceptable for the waterproofing trades so remedial action is required to grind down the surface to a smooth steel trowel finish which will not only cost additional cash it will be difficult to attribute to the concrete subcontractor as they had finished the job, but contractually they are responsible for the concrete finish. Difficult. From a JHG perspective it’s their problem, but from my firmly set moral compass I find it difficult to do.

SBGRZ2 finally got poured this week. After negotiation with the structural engineers I managed to place a delayed pour strip in the thinnest area of the pour. The reason for this was that the slab thinned to 4m wide a one point and it was assessed that the slab when poured would shrink in opposing directions as shown on the diagram below. This actually helped when it came to the pour this Saturday as due to the wet weather it was only possible to finish the slab, so we could concentrate on pouring up to the delayed strip location. The idea now that both halves of the slab can now shrink in their own direction without inducing cracking at the neck point, and the gap can be filled at a later date when the shrinkage has reduced to a minimal level.

Fun and Games

On arriving at the Aberdeen I was given the chance to attend an Electrical Quality Verification Course. Given the chance to get some CPD in I leaped at the chance. The 2 hour commute to Fort Belvoir seemed a small price to pay for this course which is all about using the National Electrical Code to ensure that the work the contractor is carrying out is with in guidelines. The first day started slowly with the biggest problem being translating the various terms being used delivered a thick Mississippi drawl. A receptacle is a plug socket, a raceway is a conduit run, ground is earth, a bell end is HV cable gland, and wires come in standard sizes not cross sectional areas etc. but eventually it all started making sense. We looked at all aspects of electrical installation from contractual, to motors to mass notification systems. Some aspects are different due to the use of 110v and 208v but this proved a very useful way to understand how the US system works. There were even a few jokes (e.g. Completion Date – the point at which liquidated damages start being paid). I now have certificate saying I am qualified to inspect electrical work for the Corps!

Back in Aberdeen the tension is building. With 90% most of the work is complete but we are now coming up to commissioning. However the Contractor is still over budget and desperate to save money. Most RFI’s we are receiving basically ask if they really need to do a complex finishing procedure when a 80% solution is working. With furloughs well and truly in action the office is empty Monday and Friday so we effectively only work a 3 day week which is slowing down responses and frustrating the Contractor. I have been getting stuck in to the RFIs to help clear the back log. My first issue was a chilled water pump motor that trips the breaker every time it tries to start automatically. The other 3 identical motors in the setup are not doing this so it is highly likely that the motor is damaged (probably in the factory) and should be replaced under warranty. This was identified 2 years ago but the Sub Contractor says the problem is resolved because if you manually turn on the motor a couple of times it stays on! This is the typical mind set of what we are dealing with. I have been checking the specifications (deficiency notifications are nearly always challenged by the phrase “show me in the spec where it says that”) and the electrical code to justify why we want a working motor! The meetings this week have been quite passionate and there is now a definite “them against us” feeling. More interesting times ahead as I get further involved.

In Harrisburg work is progressing. We have nearly come to a compromise on the drainage expansion joint issue. A guideline has been quoted from the PVC Pipe Design Guide stating that an expansion loop or an offset (a 90 degree Z type arrangement) is the answer. Although this does not feature in the spec or any of the design guides used it seems the offset solution might be the one we all agree on! There are now 40 odd skylights installed but only 16 left to go in as the manufacturer is behind. Only 1254 to go. The roof reinforcing may start soon and the roof drain outlets are being installed. Some of the Big Ass fans are nearly ready except that there is an issue with some of the fans being too close to existing lights and diffusers. Apparently this was missed by the designer but spotted by the contractor. There may be something for me to inspect next week.

Road Kill Round Up

2x Racoons (anything on the interstate is obliterated in 5 minutes so it is too hard to identify much more)

And in other news:

With my parents over we have taken the opportunity to do some of the things we have not yet got round to such as a Baseball Game (Oriels beat the Red Sox 6-0 and you get a free cap for being in the military), a visit to the Naval Academy at Annapolis, eating soft shell crap (claws, legs and all) and a tea party for the neighbours to celebrate the birth of Prince George. Hurrah!

Ticket to Ride

Funny how when you are waiting for a project, 4 come along at once.

While the work all seems quite bitty, there is a common theme running through everything and all of the systems that I have worked on are interconnected in some way. I’ve found that while I am developing my understanding of how the assets work I am simultaneously trouble shooting issues and developing my ability to use the BP project management systems. I’ve built up a good network of contacts in my previous project work and am starting see the fruit of this as I now know who to go to when I need to discuss a particular issue with a project.

All in all it has been a challenging few weeks and I am really looking forward to my site visit and intend to get a lot out of it. Not least 5 clear days for phys and TMR work!

Clair Coolers

As I mentioned in my last post, this TAR job is now on the critical path thanks to the ineptitude of the piping fabricator (SeaFab). Despite now being directly managed by both WGPSN and BP, with the BP North Sea head of Procurement making weekly visits, Seafab are still falling futher behind schedule! They are running a truly farcical operation with spools being sent for NDT with the wrong documentation, the office being too disorganised for the 3rd part verifier to be able to sign off on the release of apparently completed spools. Unfortunately I have had to take a step back from the daily management meetings due to other work, but I still get the feedback when the project engineer returns each day.

I am still chasing up the IVB process with Lloyds Register, but this really doesn’t account for much of my time.

Clair Manifold Piping Support Bracing

This is part of a project that was executed last year. The main thrust was to standardise the pipe supports on the gas production manifold skid. As a platform develops new wells, it also develops new production lines and for some reason there is no set method for arranging the supports for near identical piping configurations. This project set about to standardise the supports on the 8 production flow lines. I have been given the final part of the project to execute which is to add lateral bracing to the new pipework to eliminate vibrational effects. Everything is fabricated and the work packs are complete, the project just requires organising to take off shore. The show stopper I have found is that because of the of the new bracing, 8 temperature sensors need to be removed and replaced with slightly longer ones. The asset can’t flow these lines while the sensors are removed and this will result in a 3.5 days lost production. The project won’t go ahead with this metric, so I need to find a solution whereby the instruments can be replaced one by one, this would effectively reduce the outage to 0.5 days. I have 10 days to find this solution or the project hits the 12w gate and stalls. Such fun.

Bruce Caissons

This is still chuntering on in the background, but I am still awaiting input from a couple of sources. On a far more interesting note, I may be taking on this whole scope as SPA (i.e. the £26m programme). It wouldn’t mean much for me as the C13 project goes cold at the end of this year (seeing as I made the case for the deferment), but it means that the next two secondees might well be in a position to pick it up when it comes back on line. I need to discuss this with BP, but the Caissons SPA seems to see a lot of possibility in the idea. It would provide some real continuity to a programme that sorely needs it.

Bruce P60 Bridge

Not much to say here other than I will be flying out to the Bruce on Monday for the construction survey. I am very much looking forward to getting off shore for a week, especially as the Bruce is the subject of my next TMR! Winner!

Bruce LPBC Exhaust Mods

You may recognise this project from other well known SPAs such as Capts. Adrian Ishwaria and Warner…

…’you’ll just need to read through the files and close out the project’ he said as he walked out of the office. To be fair it is not much more than that, but the electrical workpack was missing, unbeknownst to everybody involved it seems. However, after some searching Woodgroup have found it and so I will review and sign it off if everything is in order.

Magnus Fire Main Overpressure Protection Mod

I have spent most of the last two weeks writing the Decision Support Package (DSP) for this projects. Despite it already being in Execute, the DSP needed producing to retrospectively prove that it has been sanctioned. You really can’t make this up. I’ve reviewed the project information and submitted my first draft of this document. I look forward to getting some feedback.

In short, the project aims to replace some manual butterfly valves with automated ones that will open when the fire main is brought up to design pressure from its normal operating pressure. The new valves need to open in such a way as to negate about 7 bar of overpressure caused by the pump start up. The DSP breaks down the financial, technical and safety aspects of the project so that the budget holder can sanction it. It feels a little nugatory to be writing a DSP after the decision has effectively been made, but at the end of the day it needs doing and I am hoping that it will raise my profile with this particular Asset Program Lead.

Magnus Cold Boot Relief Upgrade

This is a brand new scope to me and so I will be reading up on it whilst I am off shore. Again this is a project in execute with no DSP, but this time I really have to work the DSP up from scratch. There is certainly more opportunity to get involved in the project engineering too as quite early in the execute phase.

In Other News…

I gave a presentation to Engineering Services today outlining who I am and why I am working at BP. I got some nice feedback and I quite enjoyed getting into barracks dress and wandering around BP.