Is there such a thing as half a pour?

More rain again this week, but surprisingly Centre block decided to push ahead with a 620m3 pour that both started and finished in the rain. At some points it was torrential; the concreters walked off the slab several times and it was hit or miss whether they would have to place an emergency construction joint. The decision was taken to push through as the slab was not being poured to a finished surface. The pour took 13 hours to complete!

Concrete Finishes (South Block Golfball effect / Centre Block after the pour(ing rain) / the drip marks from overhanging formwork)

The following day was not quite as wet, but a very wet start caused the concreters to walk off site swiftly followed by all the other trades. This was supposed to be pour day for my SB GR Z2 slab but as nothing was completed the day before it was put off till Sat. I went on a site walk with the South engineers to just generally have a poke around at what was going on in the North and Centre. It was also a good opportunity to see techniques that will be incorporated into the South build shortly.

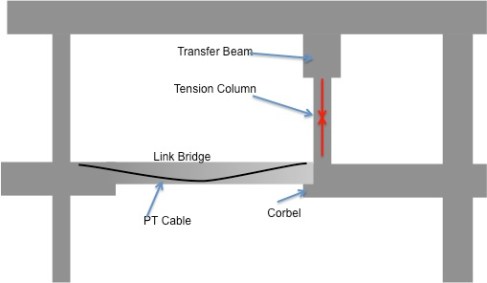

I had only heard of a tension column once before, not sure where though. It is pretty simple in concept really, the column hangs from a substantial transfer beam above, which sits on 2 hefty columns. The column will hold up a link bridge between the East and West blocks. The bridge itself, though only about 20m span has 4 longitudinal double PT beams which appeared to be overkill but when looking at the other end of the beams they extend 2m into a large transfer beam which must take a larger proportion of the bridge load to leave the tension column with less. I do question why it is a concrete column as a cable could probably do the same job more efficiently, but assume that architecturally it must fit with the aesthetic of the building.

My real issue this week is that of the topping layers. I have written briefly about the integrally poured topping layers before and I think I expressed my concern about pouring an additional 150mm on top of a structural slab with the initial pour. Essentially this is a money and time saving exercise (Concrete is cheaper than a screed layer poured at a later date) at the expense of quality (finish). The standard of concrete slab poured on the project so far has been pretty poor in my opinion (undulations mainly), so to increase the depth of concrete slab poured to over 500mm increases the potential for undulations. This was found on the pour of SBGRZ6 recently (The deck rings/snakes worked by the way though the steel fixers thought that they were too much work), where there is not fairly deep undulations in the surface of upto approximately 20mm – well over the tolerance allowed in the Aussie Standard.

The second issue is that immediately pouring to the FFL leaves no room for making good. What is poured is what you get. To pour a screed layer later is not only be expensive but time consuming but it does give the opportunity to produce a finish that will be accepted by not only the client, but the follow on trades. In some cases in the South after a light shower after the end of the pour the entire surface became pocked, similar to a golfball. This is not acceptable for the waterproofing trades so remedial action is required to grind down the surface to a smooth steel trowel finish which will not only cost additional cash it will be difficult to attribute to the concrete subcontractor as they had finished the job, but contractually they are responsible for the concrete finish. Difficult. From a JHG perspective it’s their problem, but from my firmly set moral compass I find it difficult to do.

SBGRZ2 finally got poured this week. After negotiation with the structural engineers I managed to place a delayed pour strip in the thinnest area of the pour. The reason for this was that the slab thinned to 4m wide a one point and it was assessed that the slab when poured would shrink in opposing directions as shown on the diagram below. This actually helped when it came to the pour this Saturday as due to the wet weather it was only possible to finish the slab, so we could concentrate on pouring up to the delayed strip location. The idea now that both halves of the slab can now shrink in their own direction without inducing cracking at the neck point, and the gap can be filled at a later date when the shrinkage has reduced to a minimal level.

Hi Nik,

Like the nice concrete effects – If I were your client I’d be asking you to core and test because if there’s that much additional water in the pour I don’t think you’ll have manged even compaction and the w/c ratio will be adrift… Now you know why in the UK temporary structures called concreting tents exist (although it must be said we need them to give a reasonable curing temperature which presumably you still have despite the rain. If there is an obligation on the concreter to provide a class 1 finish don’t feel any pain if they fail becasue they didn’t protect their works from the elements; it can be done and it’s their choice to risk not doing it, you are only holding up your employers end of the deal when the contractor has gambled and lost. No moral/ethical issue at all.

Your tension column is effectively a large cable as you describe it but, becasue it is cased in concrete, it has an amount of durability and fire protection. It might also have the ability to provide a support that is fixed in position (effective length of bridge beam??). All of the tensile load will be taken in the steel and the concrete will allow for load reversals in a siesmic area. I’d suugestits a more useful cable!

Yours,

Richard