Demolition Man – The Plot Thickens

Those of you who care or who are bored enough to flick back through the blogs may remember that there was a requirement to demolish a significant amount of concrete wall on my Block due to the structural engineer not designing the knock out panels for the future louvres.

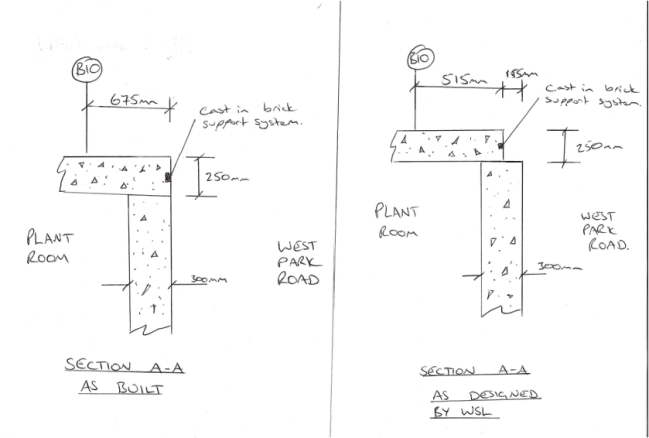

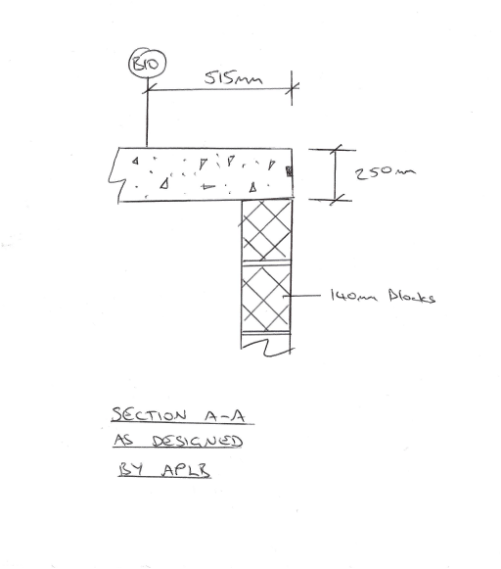

What I didn’t really mention as it was a secondary issue was that the face of that wall was built too far towards the outside of the building by about 155mm. It seems they just read the make up of that section of wall correctly, there is face brickwork here with a cavity behind and consequently just intended to steal some of Southampton on the sly. Once again assumption got the better of me, it seemed it was no secret that the retaining wall was too far forward and the slab edge too but it didn’t seem that much of an issue. When it was only this problem nobody seemed that bothered and figured that something could be done, it was only when the future louvre issue came up that demolition was talked about. My assumption was that because nobody was jumping up and down when the wall was too far forward there must be some kind of clever fix like using a brick slip to save space; so when the wall was removed as previously mentioned on the blog I assumed that they would use the same clever solution to get around the slab edge too far forward problem. How wrong I was. The sketches below show what was built, what was designed by the structural engineer and what was designed by the architect.

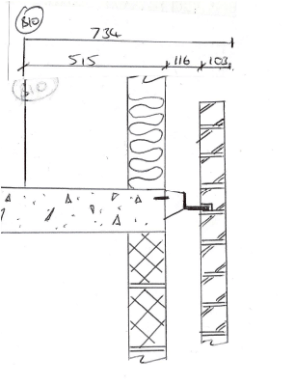

This doesn’t really describe the full story because it’s only when I looked at the slab edge detail that I realised there was no clever fix and very few clever people. Below is my reproduction of the slab edge detail comparing the as built section and this sketch shows that with an overall dimension from B10 to the face of the brickwork of 734mm and an as built slab edge of 675mm we only had 59mm to play with which in order to achieve the cavity and the any form of brick would have been impossible.

So more demolition at the cost to the structural engineer as 150mm of slab is cut back and removed across about 24m of construction. All this against a background of a Project Manager desperately trying to get follow on trades into the area see first paragraph of ‘forward planning optional’ who is slowing up the process by not allowing me to clear the area. The frame contractor has had a lucky escape here as the as built is different from the as design by WSL, the structural engineer, otherwise the slab cut would have been paid for by them but because WSL have made the first mistake it’s all going on their flick. Personally I think the as built/as per WSL would have been an interesting argument anyway was there was no section as I have drawn it instead that rather odd arrangement was supposed to have been worked out from the GA below, note the interesting combination of dotted and solid lines all trying to convey different things.

There are other slab edges out there that have been wrongly designed by the structural engineer and are about to be lopped off too, so it’s not a one off mistake. In another update I’ll try to look at the remediation that follows all this cutting, ends of bars are now exposed to the elements and need fire/water proofing and all the U Bars have been cut off too. I just need to work out what U Bars actually do and why it’s so important they’re replaced.

U Bar, – transfer zone, lap length, end teermination call it what you will but the steel can’t start to work unless the stress is transferred into it. Cut them off and you need to check the moment in the slab and be sure that it can be carried. Pluss, presuming design to EC2 the shear is being taken in a strut and tie model so there’s a need for active tensile steel right up to the slab edge. Options are numerous: cut back enough slab to weld new bars to the existoing and re-cast the slab edge, over cut and resin anchor new steel …. No steel at the slab edge is likely to lead to shear failure if not bending failure and I dpon’t know what you have by way of torsion going on.

Being repetative about it all : Actions, Geometry, Materials.

Work out what your applied actions are, how they are tranferred through your structure, how they will then represent themselves as intenal stresses (BM, Shear, tension, compression…) and what part of your structure is going to be carrying them. look at the goeometry provided and the materials. You will quickly see why you might want some active steel on a slab edge.

Forgot to ask, is the drawing extract the architects or the engieers? If the latter does it have a note saying “to be read in concert with the architects and other specialist drawings, specifications and schedules, in the event of discrepency the engineer is to be consulted”? It certainly would have done in the consultancies I worked in and that quickly makes it either a setting out error on the architects part (architects do dimensions, engineers do construction details), or, a failure on the part of the contractor to notify the design team of a discrepency before continuing AT RISK with an unclear detail. Not the structural engineers error or cost!

Rich, we really do care, and are never bored. We do it out of genuine interest.

Were there any repercussions following your discovery of fake safety cards?

Richard, interesting second point, there seems to be no argument that this is the structural engineer’s fault especially given the concrete retaining wall that shouldn’t be there is part of the same area. The other 2 areas where this has happened have been where extra ‘nibs’ have been added on the structural engineer drawings to reflect a step out in the architect drawing BUT they haven’t tied the detail up between themselves or the structural engineer has misunderstood what is happening. The key example was where the nib was included on the SE drawing to follow the architect’s GA but in reality the extra dimension was a change in cladding from insulated render (sits close to the edge of slab) to bauclad (sits much further out) and hey presto extra concrete. Again here SE being blamed BUT:

1. Architect is supposed to be the lead coordinator (I believe) and should be checking stuff like that.

2. Your point that WE should be checking more rigorously.

This all demonstrates the rush to construction or lack of Stage E coordination that the project went through (if you’re still lucky enough to sit near the great orator he can shed a little light on it, it will be the subject of a future blog)

David, other than winning a free breakfast very little. The CSCS people take it very seriously and want it reported to their fraud office with details of it all and require a crime number from the Police. The Police find the process of taking details for the issuing of a crime number long and boring because frankly they understandably don’t care (to them this is the equivalent of getting access to a club on a fake student card). So when I found a second fake card I threw the bloke off site mentioned it to the project manager and told him I wasn’t going to waste time on reporting it. My shiny new phone that I own has the ability to use the CSCS card app which can read the smart chip using NFC so that fake cards can be proved very easily, this is REALLY sad to admit but the H&S bloke nearly wet himself with delight.

Thanks Rich,

The orator and I are next door to one another and continiue to share coffee bomb facilities so we’ll no doubt discuss the co-ordination issue; it is one that is a continual frustration as you will find when you move over to consultancy. Architects and engineers only ever see the pain side of pain/gain share; no contractor that I am aware of has ever said ‘we made a gain there so here’s some extra cash for you from our gain’ but they’ll all quickly try to pass on a cost. The result is that consultants work to a fixed budget with as much contigency as they can hold on to (thier gain or pain if needed to meet costs!). This means that drawings are crashed out and only checked if a discrepancy is notified. To check them would cost more than the winning tender price or squeezed novation agreement allowed for. It’s a risk based thing!

Some obs

Whether enforcable or not …on my drawing issues Note 1 is that the drawing is to be read in conjunction with …..it’s t least an attempt to pass responsibility for the fact theat the drawings may not agree to the contractor to resolve before building

I had a similar issue some years ago…. my GAs did not tally with the architects and the contractor claimed to have set out to mine…ordered a shed load of pcc flooring ..with, as they sa, hilarious results…I was on hols….no mobiles back then…very quiet design office on my return…..Anyroadup I took a chain man out with me and the setting out didn’t tally with mine or the archichoke …..cost shared ….phewww!

S.E. wil knock it on their PI if it’s a biggun

On your note you say that there wasn’t a section on the SE’s drawing …but there’s a section mark shown

I don’t understand …the blockwork isn’t structural so why cast as r.c. in the first place….was it ahoen as an r.c wall on the SE’s perhaps…. was it below ground and assumed as a retaining wall?

Well spotted John, the section marked on that drawing is the section at pile cap level and in an identical place to the section marker on the GA for the level below, draughting error methinks.

I haven’t had time to track back through the architect drawings to decide where the error lay, I do remember seeing an M&E drawing with lots of louvres marked then a revised one with only the 2 that were required for initial construction. I would imagine that it was one of those things buried in the minutes of a design team meeting somewhere that nobody in the SE office picked up.