Archive

Progress of Sorts

At last some progress is being made although it is not always a smooth ride. We have had some commissioning inspections take place with some passes and some fails. A big issue has been the boilers. We have 4 boilers which run on natural gas and diesel. For the Functional Performance Test in the commissioning process the spec states that only 1 boiler needs to be tested on one fuel type. The Contractor decided to use the only boiler that has been used consistently (more on that later) which was the best of the four and promptly failed the test for NOx emissions. As a result there is now a big concern about the state of the less used boilers especially if the contractor only needs to get this boiler improved to run the test again. Back in July a water sample from the boilers showed excessive iron and bacterial growth in the boiler system which indicated that the cleaning and maintenance of the boiler was not up to scratch. Despite raising this with the Contractor nothing has changed so I have been tasked with checking the monthly maintenance logs for the building, to work out what else is not being maintained correctly. The big concern is that damage is done to big line items (boilers, chillers etc) that will make any warranties on equipment void and will cost a lot of money to put right especially if the service contractors, who will maintain the building, discover this. This has been a huge task made harder by the fact that our hard copies are not in the correct place and the downloadable documents take 20mins to come through and can fail at the last minute. Have looked at the spec the contractor has failed submit a key document on how Temporary Operation and Maintenance is going to be carried out for the building. Instead the focus has been on the temporary conditioning maintenance need to pass commissioning (and that has been dubious so far) and not much else. This week I called a meeting with the future owners to hear their concerns and draw up an action plan to get the concerns addressed. Concerns included the use of pre printed check sheets which only the date changed on, poor record of future maintenance plans and a general lack of information which the client has been asking for.

This week we received the test results back for chiller motor testing. It confirmed that pump 17 has a fault because the in rush current is high even when the load is uncoupled. However the report stated that the issue could be due to valve settings! I emailed to ask how this conclusion could be reached but the independent tester refused to comment. However both the Corps and Contractor agree that the motor is faulty and needs replacing. This does not solve the problem for the system however. The bigger picture is that the pumps are too big for the system and are not running efficiently. The pumps send the chiller water to the cooling towers on the roof. The pumps all feed in to a header and are balanced by butterfly valves. Simple enough except the motors are too powerful (4x 200hp) and so the valves are set at 25% or the roof floods when the cooling towers over flow. The motors are also expensive premium efficiency motors which are not able to perform efficiently if the valves are only 25% open and the power being throttled is going to damage the butterfly valves to the point that they will not be able to completely seal the pipework for maintenance. The designer insists this is as planned but we are all asking if a Variable Frequency Drive can be installed (at a fair cost) so that the pumps can be controlled and allowed to soft start. Another option is to cut down the impeller size in the pumps. This is next weeks battle.

My leaky floor drain has finally been replaced. It was found that there was a fracture in the drain which was allowing water through so a replacement was necessary. However we have also requested that a pan directing water away from the server in the room below should the drain leak again, be installed as an extra safety measure. This was met with a bit of resistance because the drain is now mended. However after a bit of encouragement I have got the agreement to install one after the Corps has been trying for a year. It helps that the Contractor QC head is an old Navy Construction Brigade RSM (think Navy sapper) who dislikes my civilian counterparts and will only deal with me and my US Army counter part on now on tricky issues.

The final issue this week has been dynamic fire dampers in the air handling system. This are spring loaded dampers that activate when the fusible link holding them open melts. Commissioning requires that these be tested with the air handlers running but the manufacturer advises against this (the air flow may break a closed damper designed to activate when the air handler should have been shut down) as does the designer who thinks that despite the installed pressure relief valves in the system the pressure changes may end up pulling down ceilings. However the spec states that the air handlers must be running but no one can say why. We suspect it is to check that the system will cope in case a link fails prematurely but no one as yet can confirm this. The test is on hold.

Yesterday we had a departmental breakfast at Denny’s (the national greasy spoon chain) which was a really good way of seeing everyone out of work and doing a bit of bonding. It was scary to see how much my co workers actually eat – even the smallest guy ate double what I did and I was filled to capacity!

In Harrisburg it has been very productive. The roof replacement is going well and a surprise test of the recovery procedure for someone activating the fall arrest system worked well. We have also identified a cherry picker that the contractor can use to install the over flow drains in the 80ft high Bay Area. These can go through a 35″ door at 123ft but cannot be rented so at $200,000 a pop it will be a big expenditure for our struggling contractor. The QA guys have also noted “inaccurate” claims for materials. A claim for $150,000 of electrical kit was submitted but on inspection there was only $20,000 of kit found. The project engineer let this one go because relations are better but is keeping an eye out for future claims. The customer has also asked that all conduit for fire detection systems be painted red in accordance with site standing orders, not mentioned until most of the electrical conduit had been installed! Fun and games…

And in other news…..

The Navy Yard shooting sent a bit of a shockwave through the sites because it was so close to home. A guy I flew over with was in the compound that day but was in the adjacent building and managed to get away unscathed. There is also another chance for sequestration because the Government here has yet to approve the new budget for the next financial year which starts October 1st. This will affect all non essential civil servants which amounts to most of my office. Could be quiet Tuesday. The Raven’s Game was a fantastic experience. It was one of the best sporting experiences I have ever had as the show is not just about the sport. With Cheerleaders, bands and fireworks they sure know how to throw a good party and football is actually a very exciting sport now that i understand the rules! Fall has started so we are making plans to head to NYC in before it gets crazy expensive for Thanksgiving and Christmas. So much to do and so little time.

The Devil is in the Detail – Addendum 1

MC 1 is now predicted for some point tomorrow. Luckily it isn’t just the Coolers project holding this up, but we are probably the higher profile due to the nature of the issue. We are much closer to having a valve in place, but as ever the last few steps are the hardest.

Option 1 : At about 8 this morning I was informed that the valve would have had a serial number heat printed onto the body. This would allow the identification of the specific valve so the Mill certs could be acquired. A body was duly despatched to sand of the paint from the valve body to discover this magic serial number.

This is what was found:

If it wasn’t for first hand knowledge of the searches that take place when you fly off-shore I would be convinced that somebody out there had been smoking crack. Un-tagged valve my arse. One of the issue with having a couple of hundred miles of water between the site and site office is that you can’t guarantee that the right idiot is giving you the right information. Having that photo would have saved about half a day of effort.

The deviation request is due to be release to me imminently although the review team (Engineering Tech Authorities) that I have had queued up all day have pretty much all gone home. It turns out that even civvies can have REMFs. So another unnecessary 12 hour delay to this solution, but this time I have all of the pieces and I have the chessboard, so long as I can steer the issue through the TA’s then the ball is well and truly rolling.

Option 2: The original list of 50 valves has been whittled down to 6 of which one is a ringer, but for the fact that it has the same requirement for a deviation and so the hoop remains.

Option 3: Buying a new one, this one was never really viable due to the lead time.

Option 4: The possibility of blanking of the valve location was looked at, but as this valve is the entry point for the system leak test, it is not an option. The possibility of finding a similar valve elsewhere on the asset that could be cross decked is being investigated, but I really don’t see that one flying at this point. It would still require a significant amount of paperwork to organise so Option 1 is still looking good.

Point of interest…

Since the coolers project is on the radar some bright spark decided to set the cat amongst the pigeons by pointing out that the pipes were only tested to 199 bar vs. the piping spec of 230 bar. This has set minds racing across the TAR and Asset teams although the explanation is quite simple. The new piping is specified for 230 bar by fabrication but it is only tested to 1.5X design pressure. It doesn’t really make any sense to test to specification as this would be tantamount to testing to destruction as far as I can see. I am awaiting a comment from the piping engineers to confirm my view before answering the growing panic, but at this point it is the last thing needed.

The Devil is in the Details

Just thought I would pop you all a quick post in the heat of the moment…

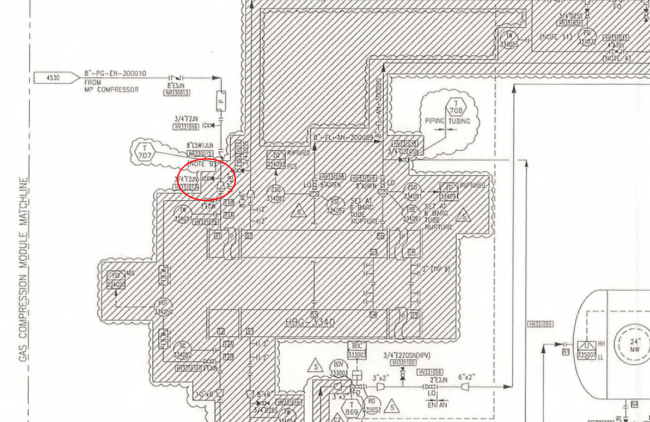

We’ve been slowly grinding through the the last 10% of the project execution and progress has been okay. The focus is firmly on achieving mechanical completion 1 (MC1) so things like re-instating junction boxes, modifying lighting and connecting instruments is a little in the back seat. Pretty much the last piece of the mechanical puzzle was one valve, HV331077, a 3/4″ ball valve rated at 250 bar. Fitting it would effectively seal the system ready for testing and commissioning.

It is missing…

As of yesterday morning I was informed that it wasn’t off shore, so while WGPSN raised the Engineering query I did a little digging.

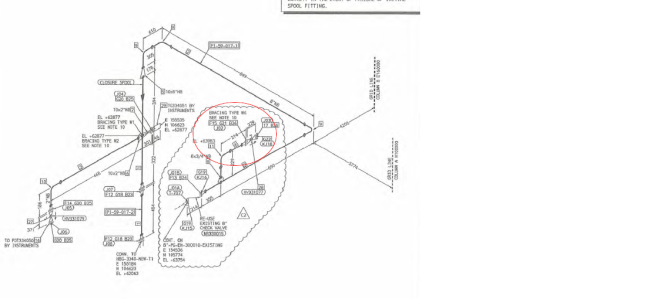

It was on the Destruct P&ID as part of the destruct scope…

It was on the destruct ISO and not identified for retention and re-use…

It is on the construction ISO…

And here’s the little bugger on the construct P&ID, the finished product…

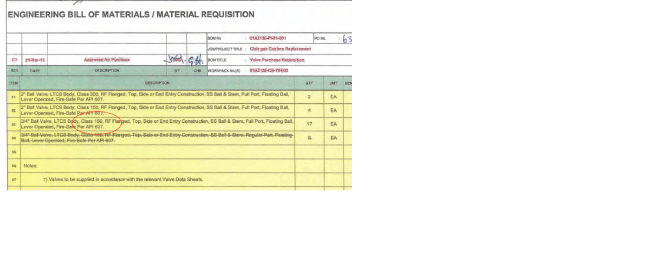

However, we haven’t bought a new one as you can see in this BOM (the pressure class of our valve is 1500):

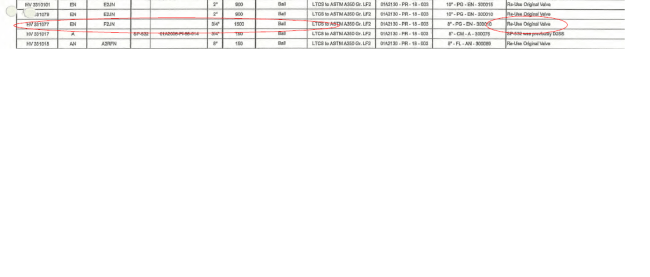

Because someone thought we were keeping the old one and re-using it as per this construction valve schedule:

So what happened?

A lot of attention was paid to the removal and construction of the big heavy coolers, the pipework and all of the supporting steel. All of the big and expensive items were analysed, as they should, to ensure they would operate safely and that they were moved around deck safely. However no-one thought to write a destruct valve schedule, check off the valves for re-conditioning and re-use as and when the lines were destructed. No one thought to check the construct valve schedule against the destruct ISOs and do a sense check. Bottom line is, WGPSN have cocked up and now we are chasing a very real deadline.

Several hours later…

Resolutions

I’ve spent much of the day chasing down options with the WGPSN JRE, Stewart Russell. He was away yesterday and making any kind of progress was like wading through treacle. Everyone I spoke to just seemed to want to stick their heed in the sand and believe that the easiest options would work out. In the end they kind of are, but there is a lot of work required to get them across the finish line. This has been an excellent opportunity to see how the SPA / JRE relationship is supposed to work and I have spent most of the day coordinating BP and placating the TAR team while Stewart has been chivvying WGPSN along to produce their deliverables.

So…

Option 1: We have an untagged valve of mostly the same specification off-shore that is not required for any other i.e. buckshee. The problem is that the valve stem is rolled and not forged which means a deviation is required to get it authorised for service. On top of that, for the deviation to comply with BP technical practices it must be supplied with certification of the mills fabrication techniques to provide QA. However as the valve is untagged it has taken a while to track down the correct certification and this won’t be complete until morning. I have agreement in principle from the BP mechanical TA that this deviation will fly, especially as it is a deviation that has been accepted before as the standard fabrication technique is to roll and not to forge valve stems. Trust BP to do it the hard way. I am confident that with this approach we can have the valve in place by CoP tomorrow.

Option 2: I identified 48 valves currently held in the BP inventory that possibly fit the bill and WGPSN has narrowed this down to 19 hopefuls. By the morning we may actually have a winner, but there is no guarantee that we could get it to Clair before Option 1 could bear fruit. In support of this option would be the fleet of EC225 Superpuma sitting on the airfield at the moment…

Option 3: Buy a new valve of the correct spec. Ironically this is not really an option due to the lead time.

We also considered blanking of the flange where the valve should sit as this valve is a dead leg on the system. However the valve is probably there for a reason and I am waiting to hear back from ops whether this would be a viable solution. And anyway I would still have to do a bunch of paperwork to get a modification like that passed.

So, as it stands the mechanical window which was due to close in about 53 minutes is wide open and my (Projects and Mods) arse is hanging well and truly out of it. Lets see what we can get done tomorrow!

A Big Week

Progress on site has been fairly significant this week. We have finally completed the Ground Floor! Aside from now being well and truly above ground level, which is excellent for morale, it also means that I no longer have to walk up and down a multitude of steps to access the decks (I have seen my weight increase to my normal fighting weight, so it is either the lack of steps at work, Nicky is baking more, the stress levels have decreased, or a combination of all 3).

The addition of a Project Manager to the South Block team has been a big injection of capacity. The fact that he has come from Leightons, JHG’s parent company may suggest that ‘Mother’ is beginning to take interest in her wayward child, and is reinforcing the project to ensure the success of her investment.

The PM has immediately made an impact at the subbie contractual level. Crown (Concreter) is a notoriously difficult subcontractor to deal with and have point blank refused to pour concrete some days stating that they do not have the manpower. As the concrete pours dates are promulgated daily for 2 days in advance I don’t see this as a valid excuse. It continues to happen though, until after a frustrating day for supervisors and engineers trying to coax Crown to pour some columns that would enable WCF (Formworker) to continue work the following day (Crown and WCF do not get along well), the PM waded in. I’m not entirely sure what he said or promised (I know pizzas were ordered) but not only did they pour the 3 columns we required, they also worked late to 8pm and poured every single column that we had formed, they even brought in an additional mobile pump to get the job done! This was a big win for us as it opened up several additional work fronts and released column forms to prepare for the 1st floor.

A similar issue arose the following day, but this time it was resolved by the issuing of a site instruction to the concreter to pour the upper basement to ground floor ramp regardless of weather conditions. Though the issuing of a site instruction appears to be a caving in to their contractual obligation to pour concrete in all conditions, the site instruction will now be debated at commercial level to decide whether it gets paid or not – I suspect not. Crown’s argument was that the weather (light rain) would not produce the specified finish, correct; but does not alleviate them from poor concrete placement. The contract states “The concrete placement subcontractor is responsible for the finish of the concrete in all conditions, including rain,” and also that the “Concrete subcontractor is obligated to pour concrete regardless of the weather, except in heavy rain,” The latter is a little vague as ‘heavy’ is not quantified but from my objective opinion, and from brief discussion with Richard Farmer back at the Mother-ship, JHG should have no mercy for the subbie in regards to rain – it’s worse in the UK!

In the foreground the drips from the slab above have ruined the surface texture. The remainder of the slab has the (now standard on NCH) golfball effect. You can also see the water runs and to a lesser extent the surface undulations above the grade change.

Core C was my second pour on the job, way back in March, and though all appeared to go well on the day, it was an unmitigated disaster inside the core walls. To add some perspective to this and to put up my own responsibility umbrella, I was handed responsibility of the pour 30minutes before it was due to start. The reinforcement was already installed and checked, the shutters were closed, and the concrete was on the road. The issue was in my opinion one of design. The walls were 400mm thick and heavily reinforced, especially around the header-beams and jack pockets. In some places it was later found that the concrete physically couldn’t get past the reinforcement to the form below creating voids and exposed reinforcement in almost every cell of the core. The structure has now undergone an extensive survey using a mixture of cored samples and scanning costing in excess of $120,000. The rectification work is yet to be completed but will certainly involve the breaking out of large sections of wall (1m squares) to be re-poured.

One of the less significant defects in Core C. This reinforcement has 30mm cover to the surface but due to poor vibration and closely spaced bars, concrete couldn’t get through.

The remediation work has the added issue that it has held up progress on the South floors and subsequent floors that tie into the core will require additional back propping to prevent additional load being transferred to the walls. The JHG solution to the Core C problem was to draft in an engineer with the sole responsibility for ensuring that it didn’t happen again. The next lift of Core C was poured last week, and even with all the additional resources and quality ensuring measures in place, there are still several areas of exposed reinforcement. I think this issue could have been engineered out at the design phase as it should have been fairly clear that the shear volume of steel in the wall was going to make concrete placement difficult. Provision could have been made for either an increased wall thickness or a more sympathetic arrangement of bars in areas of high reinforcement. The concrete is already at a high slump and using a 14mm aggregate to ensure it has the best balance between consistence and strength. This problem will continue for the following lifts unless a preventative solution can be found to minimise the poor flow of concrete around the steel.

I have got myself involved in the procurement package for the concrete precast panel walls. It is a relatively small package at $700,000 but has given me the opportunity to follow the process from initial tender to where it is currently stalled in the commercial department. I was a site representative at the initial interviews with the supplier and the installer and am looking to maintain involvement throughout the process until the phase ends in early December. Time is flying by.

In other project news, and I suppose related to the arrival of a few Leighton managers, is the recent Leighton’s audit of the project that was, I assume, somewhat scathing as it has had the effect or removing the Commercial Director of the project and the General Manager for the Western Australia Region has ‘resigned’. This has also induced a further 2 senior commercial administrators to resign.

Thanks to Mike/Richard for the blog on the shearing of bolts on Reinforcement connectors. I spotted the connectors whilst wandering site and ‘reminded’ them that the heads were supposed to shear off. Luckily they were designed to shear; I had to check when i got back to the office.

ANCON MBT Couplers. This connection was intended to allow the column starters to be replaced at a later date (after the bulk haulage road was finished with). A change in plan meant that it was no longer necessary to do this but we had already gone too far.

In other news, Nicky and I have finally booked a holiday to NZ to do the classic campervan tour of the South Island, and hopefully meet up with my cousin from Wellington. We are also doing the largest swing in the world (nothing dodgy) that we saw on the Australian TV show “The biggest loser,” If it can hold the fatties, I’m sure it will be OK for us! We are off to Sydney to catch up with the Bainger’s and take part in the Tough Mudder event.

Same old, same old

Everyday and with every new part of construction the same issues keep popping up, no power (or faulty generator), water logged floors or roofs, inadequate storage or working areas, unscheduled deliveries. Occasionally a real problem rears its head but that is usually squirreled away to the designers before we have a chance to really look at it. I’m getting to saturation point on what I feel I can gain from the site, it is becoming very frustrating, I have asked to spend some time at head office with the pre-construction team to see how the bid process can be got so wrong as it has been in Southampton.

I do find myself wondering whether I’m completely missing the point, one of my early posts ‘A Building is a By-Product’ talked about the fixation of winning prizes like Considerate Constructors but what I wonder now is whether cashflow really is more important than product or profit even. This project almost certainly won’t be profitable, it won’t be on time (massive LADs) and has been beset by design and management issues from the outset and yet nobody seems to be getting angry about it, especially the levels above contracts manager who you would expect to be getting nervous. The only solution that I can guess at is that there is some clever back room processes that can get ‘Sad Ken’ across the line ahead of the field in the 1530 at Chepstow and turn a profit by some miracle. People that are clever with contracts any views?

One thing that has kept me interested recently is being given pretty much the entire responsibility for bringing ALL the utilities onto site in the same week on the same road. A planning condition is for a single road closure for service installation (in reality we pushed our luck with the transfer beam and got away with it) and so starting next week in a stretch of road about 80m long I will overseeing the circus that will see geothermal heating, gas, mains water, HV electricity, BT and the foul water system all connected in 5 days. In sorting some of this stuff out I’ve had an interesting blast from the past, it started off a little like this:

PM ‘You need to either speak to Keith Olbury or Frank Dickinson at Lanes for Drains’

Rich’s internal monologue ‘No it can’t be even with that name’

Later on the phone man with distinctive squeaky Yorkshire accent ‘Hi is that Rich’

We talk business and then I say : ‘You’re not a former Royal Engineer are you?

‘Yeah I was’

‘A plant operator?’

‘Yeah, why?’

‘I thought it might be you’

‘Where do you know me from then?’

‘I was your Troop Commander in Tidworth’

‘Really?’

I guess I made a real impression then.

Yes Frank Dickinson was a particularly poor LCpl in my Troop that I was now relying on for a service in the real world, both of us with ‘manager’ in our titles, oh dear.

No concrete!!!!!……………Again

The last post finished off at the point of the base plug being poured and the Waterproof sheet membrane being fitted to the shaft bottom. This week has seen 75T of steel being fitted into the base prior to the “2nd” base slab being poured.

Base Plug pour

Waterproof sheeting installed

Whilst the job of installing the rebar has been taking place, the new Sub Agent (Filipe) and I have been trying to coordinate the next two phases. The next phase in the construction of the shaft is to pour the base slab (430m3). However there have been a number of issues. The Concrete mix design that was submitted by the Sub Contractors (Barhale) failed to reach the spec required by KF10 ( Materials and Workmanship Spec – In Situ Concrete). This is because it had not been tested for ‘Dry Shrinkage’ . The result of this has meant that I have been going through legacy concrete mixes, approved for other component ie Piling, Ring Beam to see if the mix complies with KF10. However there is no mix that has been tested for Dry Shrinkage. As a result the construction could be placed on hold for 90 days whilst a new concrete mix is designed and trialed/tested (requiring 90 day results) or continue with the pour and hope that the samples taken today reach the ‘dry shrinkage’ requirements in 90 days. THerefore I have just sent them this recorded Email:

‘1. They have failed to provide a mix with the appropriate testing information to confirm compliance with the relevant specifications (KF10) 2. It is their decision to proceed with pouring the base slab with a non compliant mix, and therefore is their risk 3. Any remedial works that are required to be carried out as a result of excessive shrinkage occurring will be covered entirely by Barhale 4. They will need to take appropriate samples at the time of the concrete pour and organise testing to confirm compliance of the placed material with relevant standards (KF10).’

Fast forward 28 days and hopefully the base slab will be poured, it will pass the dry shrinkage tests and the remainder of the shaft is waterproofed with sheeting. At this stage the In Situ lining will be poured. Amazingly again Barhale have failed to provide a concrete mix that reached the KF10 requirement. Again myself and Filipe have tried to recover the situation. THe only mix that complies with the In Situ lining requirement is the Segment mix. This mix is designed with a 30min life cycle. THe idea being that 250 pre cast segments are produced each day at Old Oak common. These segments are then delivered to site. However in our case we need to get the wet mix to Fisher street and let it cure in situ. Clearly the life cycle needs to be extended to approx 4hrs. This requires approx 4% retarder, however this is a change in the Mix design. AS a result we need to carry out trials and testing, hence I am going to Old Oak Common on Monday to pour 4.2m3 of “Segment Mix” and 5.5ltrs of retarder and probably an extra 50ltrs of water (the water is required as our mix will be pumped and the segment mix is too dry for pumping). Hopefully I will be able to record the correct slump (S4) and the correct life cycle (approx 4 hrs). If I can do this I will pour it into 3 x panels, then Test Consult (concrete laboratory) can collect the panels and carry out the required testing (Compressive strength, water penetration, dry shrinkage etc). CRL have agreed that if the 7 day results are OK then we can use the mix for the insitu lining, as adding retarder should not effect the qualities of the already approved “segment” mix. As you can see, how it has got to this position I do not know. I would have thought that before the shaft construction went ahead, someone would have double checked that we had all the required mixes in place and ready to go. Im being a little harsh, as the detail of this saga is a little more complex but unless Filipe and I can produce a concrete mix with 4 hrs life cycle and a S4 slump, the shaft project will go on hold….again.

However on a positive point, Im off to the ICE presentation on the London Super Sewer in an hour and Donaldson Associates have accepted me for my 3rd phase placement, meaning I will be located at the base of the Shard by Jan next year.

Rolling in the deep.

Quick post this week.

Everything has pretty much fallen by the wayside for two of my Clair scopes. The first is the Clair coolers replacement project which, as you know, is about 90% complete offshore and is on the TAR critical path. The mechanical window for the TAR is 27 Sept (3 days later that originally planned due to delays) at which point all process and safety systems are required to be buttoned up and ready for pre-commissioning testing such as low pressure nitrogen leak testing. The last two of my closing spools were sitting on the quayside as of COP last Friday and their boat should be leaving today. This leaves a very tight window for their installation and I have all of my fingers and toes crossed that they are going to fit first time. Should they be out then I have 2 spools sitting at the fabricators partly made up, but the lead time to have them off-shore would still be about a week. So, if the final closing spools don’t fit I will still be delaying the TAR completion at a cost of around £3.5M a day. I am really hoping this doesn’t happen, as you might imagine.

Further to this, I have fusible loop modifications which need to be installed by 20 Sept in preparation for testing by my contractor. With 4 days to go I am not confident that we are going to be ready although the off-shore team have been aware that this needs completing for over a week. Then there is the corrosion coupon being fitted to one of the process lines which again I am awaiting a progress report on. It seems that Stuart jumped ship at the right time and my days are generally filled with trouble shooting the issues that remain with this project.

By far and away the most pressing is the fact that the TAR plan has not incorporated any of the E&I scope (about 600hrs in total). I discovered this early last week, basically the WGPSN plan over estimated the job card hours and quite early on the TAR team mugged off the WGPSN plan in favor of their own baselined plan with more accurate job duration forecast. The fallout from this is that they have only concentrated on the jobs directly under their noses, removing the old coolers and pipework and fitting the new, as is their wont. It seems most people were aware that there existed a discrepancy between the plans and that the TAR team were riding on a wave of false security, but nobody thought to action it until early last week. With the TAR plan re-baselined to include the new E&I scope the project went from 5 points ahead of schedule to 5 points behind. I am hoping that with off-shore input to include what in the E&I scope has actually been completed we will come a little closer to the ‘S’ curve, but I am confident that we are going to remain behind it until the close now. It just goes to show how important accurate planning is and how damaging having two plans can be.

The other scope featuring on my plate at the moment is the installation of additional bracing to the Clair production manifold. I am inside the 12w gate now and following some fancy footwork I have managed to narrowly avoid being red-flagged. However I still don’t have a workable plan to get this executed off shore. My issue is that to install the new steel I need to replace 8 temperature transmitters with longer assemblies. To this the instruments must be removed and the pipework can’t be flowed while this is done. The project does not have the clout to warrant an outage and so I have to fit it in to a planned outage. There is one planned for December and I am making progress, but I have a feeling it is going to be a messy execute which is not ideal. The wells are taken down based on the requirement dictated by the controls team off-shore and the process engineers offshore, so there is no defined plan of which well will be down and when. My feeling is that I am going to have a team off-shore who will be sitting around waiting for the right well to be off-line to do their work over a period of 2 or 3 weeks. If this is the case then my justification for running the project is weakened I might get bumped out of my slot. At this stage, the more robust I can make the plan, the more likely it will get through the next gate. What would be hand would be a JRE to handle the material and workforce coordination, but I am still waiting for confirmation on who this is.

In other news…

I ran the Great North Run on Sunday and was narrowly beaten by Mo Farah finishing with a time of 2 hrs 3 mins (me not him). Not the fastest time in the world, but then I’ve never been the fastest runner in the world. I was just chuffed to finish so close to the 2hr mark considering how sporadic my training has been.

Scotlands’ summer is well and truly over and we have had the heating on every morning in the last week. It’s going to be a long cold winter methinks.

The Waiting Game

Right now we should be on the verge of commissioning the mechanical and electrical services but there are quite a few issues to resolve before that can happen. The weeks are filled with meetings where we discuss at length what needs to be done but nothing ever seems to get done. The disagreements are getting few thanks to the system of referring them up the chain of command but the results are no quicker, as predicted! Part of the problem in commissioning is down to the people trying to reinvent the wheel. USACE employ a contractor to produce the specifications for successful commissioning. They also require the contractor to employ an independent Commissioning Contractor who is under the Contractor’s pay (so not that independent), so that all testing is impartial. However the Contractor can also have a say in how the Commissioning is carried out and can over rule their own Commissioning Contractor. They can in turn be over ruled by our Commissioning Contractor thus leading to multiple conflicts of interest. The main issue revolves around the check list for the various stages of testing. Initially you must have a Start Up when the equipment is turned on for the first time, then a Pre Functinal Check (PFC) which gets the system running then a Functional Performance Test (FPT) to show that the system works as per the specification before having an Interactive System Functional Performance Test to show that all the systems are working in harmony and not in isolation. Our commissioning contractor has written very detailed lists that need to be used but the Contractor’s Commissioning Contractor does not want to deviate from their own standard lists which often get rewritten by the Contractor when they are submitted to try and speed up progress by removing any “unnecessary” tests. A perfect recipe for a hold up! Of course the Contractor is cutting its own detail by carrying out its own PFCs without notifying the Corps to try and get round us and speed up which as quite annoying form our point of view because we are meant to sign off that the tests met our standards which we are being asked to do without seeing the tests. Apparently it is illegal for our commissioning contractor to carry out the commissioning testing themselves which is crazy. It is not as if they installed all the equipment themselves!

Further more there are still on site issues.

We finally had the electrical testers out to look at the pump motors that keep tripping the circuit breakers. I took it upon myself to look at the co-ordination study which identifies how the circuit breakers and fuses are rated to avoid discrimination. This study (which had been approved!) had a lot of conflicts! When I challenged the Contractor they said this one was out of date, but we didn’t know that. When the tester arrived he brought the wrong tester which could not test for trips at less than a second. The next day the correct tester was used and we established the following:

1. All motors are drawing far too much in rush current on start up. For a 220A motor 1300A in rush was expected (6x running current). The regular motors were drawing 2200A probably because they are oversized for the job.

2. The faulty motor is drawing 3600A in one phase, 3450A in another and 3300A in the third. This probably due to damage in the windings where the insulation is susceptible to degradation by the ingress of water.We are still waiting on the results to be confirmed but it looks like this motor will be getting swapped out.

The Mechanical Contractor has also failed to establish why the drain over the BAS server leaks. They are going to cut it out to work out why.

A new project is happening next to the Lab. The office will be expanding by 40% to accommodate the in rush of Medical Corps personnel (mostly civvies) who will be needed. However the contract has just been stamped Ready To Advertise (put out to tender) and the Contract Officer’s Representative has noticed that there is no design for the upgrade. As the drawings have been stamped 100% any changes now will be expensive. I have been tasked with designing the new trailer. Not sure to what level of detail yet but it is very similar to one of course projects except that civvies take 2 weeks to give you an answer, not 2 minutes. There is no budget to work to either. When I pointed out that the longest side of this office was going to be south facing which would mean higher energy bills because the HVAC will be working hard the response was “And?”. Should keep me busy for a couple of days…..

This week I also took part in the Officer Professional Development day where all the military guys in the District get together and swap war stories whilst doing some work with the local community. This got off to an exciting start with an RV at 0600hrs next to the National Security Agency gate (think GCHQ) heavily sign posted with Keep Out signs (not mentioned in the instructions), where going to the gate by accident can result in a full body cavity search and vehicle strip down even for the US soldiers. After a few near misses we set off for the project. In this instance we installed nets to prevent the Canada Geese from eating the plant life in a designated Wet Land area of the Anacostia River just east of DC. This land was created by dumping dredge material in an underused river to create new wetlands and encourage the growth of wildlife. When the plants are eaten they fail to hold the dredged material in place and it washes away. We were given waders then had to go across a waist deep stagnant river to hammer in pickets and zip tie on the netting.

Unfortunately the civvie in charge had not banked on us being very efficient and we ran out of zip ties in 30 minutes. We did manage to carry material over to the site and put all the pickets in place (daily trivia – they call a monkey a pounder over here) before heading off to remove invasive weeds from the municipal golf course adjacent to the river. This was followed by a presentation on how civil works projects in the Corps are funded. This was interesting because Civil Projects (such as our wetland creation) must have a civilian organisation as a financial partner before they are approved. This is quite hard to achieve because these projects can take 20 years to come to fruition so finding somebody who is financially strong enough to last that long is quite hard. This project was part funded by Walmart, fitting really considering the banks of the river were covered in plastic bottles and other supermarket trash. The day concluded with lunch at a micro brewery and a fun day was has by all.

Harrisburg is still progressing well. The new roof insulation being installed will take the R value from 12 to 30m2K/W which should make a difference to the bills. We have finally managed to get the world’s worst Site Safety and Health Officer sacked for not performing up to the standards expected. Apart from his inability to submit useful paperwork and carry out relevant tool box talks (he actually did the same talk 3 weeks in row) he considered the best place to inspect his site was from the safety of his truck which would have been fine if the truck was on the roof not 40 feet below it.

A roof replacement in progress.

And in other news:

I have won a 3 day holiday courtesy of the Maryland State Fair we went to 2 weeks ago. All I have to do is pay $75 and attend a timeshare brief for 90 mins and I get a 3 day holiday in North Virginia. I am also going to the opening home match for the Ravens football team courtesy of a work colleague with a spare ticket. These are like rocking horse stuff and generally cost $300 so this is an awesome opportunity. We spent Labor Day weekend on the beach with the kids picking up fossilised shark teeth and going to the the State fair which cost $60 to get the kids on 5 rides!

As requested the top 5 things this week that I have discovered in which the US and UK differ:

1. American Army Officers’ Clubs do not hold the same status as a Mess. They are generally avoided and do not have living in members.

2. Smart Casual in the US Army is flip flops, shorts and T Shirt.

3. American Public schools (think UK comprehensives) get by financially by getting parents to sign contracts that “encourage” them to “donate” large amounts of cash to help fund the school. We have already donated $50 and a joined the PTA for $5!

4. In the state of Maryland you do not need a license or background check to own a shotgun, a muzzle loading deer rifle (accurate to 350 yards with a scope and fires a 0.5inch round), crossbow or compound longbow.

5. It is now deer season but only if you are using a bow. In some states crossbows cannot be used because they are deemed too accurate. (As you can tell there are a lot of hunters in my trailer!)

Proof the old Pope is alive and well and living in Baltimore whilst commuting to DC.

Has anyone come across this in the work place?

My Big Swimming Pool

As I mentioned in the last blog, the SCL works for the shaft are now complete. As a result the base plug, some 230m3 of concrete was poured to ensure there was no effect from the uplift heave. The plug was left to cure and then the 3 x depressurisation wells were grouted to seal them.

The next phase was to start installing the waterproof sheeting. However this could not be put in place untill the protective layer was installed. The protective layer is essentially a sheet of thin white foam. The foam stops the steel fibers that are in the SCL from penetrating the waterproof sheeting.

The protective layer is nailed into place, allowing a large washer to be installed allowing the waterproof sheeting to be welded. This ensures that the waterproof layer is never punctured by nails.

As you can see from the photos the waterproof sheeting comes in rolls of approx 2m. As a result the sheeting needs to be heat welded to each other to ensure a watertight fit. To make certain that the waterproof sheeting has been welded together correctly the joints are pressure tested. The overlap between each sheet is filled with air and the pressure is taken for 10 mins. If the pressure decreases the seal is not 100% perfect, as a result the weld is redone.

The final result is that the base is looking like a giant swimming pool.

The next phase is to install the huge reinforcement cage into the base and then pour a further 450m3 of concrete. It seems like a huge overdesign but the designers have insisted on the second pour. Once the second pour has been completed we will be at the Adit level. This will be the point that the waterproofing for the shaft sides will be installed, shortly followed by the Insitu lining.

On a different point, Gemma Quickenden (Sub Agent) has now left the project. This has allowed me to take over the running of the Compensation Events. With the completion of the SCL works the SCL CE’s are being dealt with. I arranged the first meeting with Barhale yesterday to talk through all their CE’s. I had hoped we could agree on the majority of the 26 CE’s however we have agreed upon 5. This has been the most enjoyable part of the secondement so far, as it allows you to debate/argue with those individuals you have been wanting to shout at for the past 6 months.

Backfill issues

The last few weeks have been hectic to say the least trying juggle sevral different sites. Dickson Rd Overbridge progresses but not in synch with the programme. I have re-written the programme which has been scrutinised by the Construction Manager and he concedes that a completion date of 20 Dec is realistic. The issue here is the backfill, we requested the backfill to be done quite specifically (recall my sketch in an earlier post) which battered back to the level of the top RW. We intended to step up to the next RW level by forming up shutters and vertically blinding with snape sand to the required RL then we would repeat for the next one. This was the method used at Eastwood Rd Overbridge but with hindsight we should have just backfilled to the level of the wingwalls and then backfilled to the formation level of the next RW as we progressed. Because Eastwood Rd has displayed signs of settlement due to poor backfill/compaction the Construction Manager has stressed to me that we must get it right this time and so I have decided to prioritise the deck so that we can backfill against the blade wall before starting the RW’s. We have currently completed the wingwalls at both abutments and will pour the deck/diaphragms in one pour this week. Once the deck is complete this props the structure so that we can start to backfill either side simultaneously up to the RL of the first RW’s. Meanwhile I hope to prefab the steel for the first RW bases so that we can lift them into place once we have backfilled, excavated part of the batter and blinded the area. We can then keep alternating from abutment A to B backfilling and pouring the RW’s in pairs. This issue with the battered back backfill means we have significantly reduced our working areas at either abutment which coupled with the fact that we have rail track through the span means the requirement for craneage (if that is a word) has significantly increased and will continue to do so. I had no choice but to hire a 130T crane the other day to strip the shutters from abut A wingwalls and move them over to the abut B purely because of reach where normally I would use a mobile 25T Franna crane – the cost was $7000/day compared to $3000/day and this will be typical from now on as we complete the RW’s. The batter also means the backfill at the edges will not be adequate enough and we will have to excavate and then re-compact.

Eastwood Rd Overbridge is showing signs of settlement on both sides which has been attributed to poor compaction by the civil team doing the backfill – not the first time this has happened. As this bridge is open to the public I am currently monitoring to see if it still moving which early indication says no it isn’t. However there are some worrying looking cracks on the traffic barriers as you can see from the photos.

I have also had 6 x LV pits and conduit runs to build at Cowpasture Rd Substation. These look simple but have been an absolute nightmare, they seem to be massively over designed and the 200m walls are practically full of steel. We have poured 4 of the 6 with the 2 pits that lead up an access track to a utility metering panel not yet started. The lids are placed on top at the moment but we will need to concrete them in and over them but I plan to do all 6 at the same time as I will have to order a small quatity of our usual 40MPa mix but with agg of 10mm or less so that the concrete will form into the metal lids. I have had to get another FRP subcontractor in for these pits as the one I was using also works on Dickson Rd and I need all their available manpower for the bridge. Their steel fixer practically refused to do another one after the trouble he had fixing the first two and the constant moaning that came with it I was happy to hire in another subby! All this work is on dayworks which I estimated to take 650 hrs, I last calculated I had about 100 hrs left in the budget to complete the last 2 but with a bit of JH labour in reserve.

I also have a number of Non Conformance Reports (NCR) and associated RFI’s to deal with on practically all the remaining bridges and a few retaining walls but nothing exciting. These are mainly crack repairs, patching work and out of tolerance ‘as-built’ surveys. Settlement at the approach slabs on just about all the bridges has occurred up to about 30mm which is noticeable on the pre-cast parapet sections and on Cowpasture Rd viaduct the approach slab has settled showing a gap between the walkwy and slab which you could get your hand down. This has bee recorded by the client but has subsequently been covered over by ballast and tracj by the rail team so if any remedial work will be required it will be a complicated job. The RW’s in this section have also settled and a gap has appeared between two adjacent panels. The movement has been 70mm back and 20mm down which the designer has said is acceptable has they were expecting movement of up to 100mm. The rectification method will be to fill the gap with a grout but this is on the back burner for now as I have no manpower or time to invest in it at the moment. There is also the issue of improving the access track that is below the wall so we can carry out the work. This small RW (RW14Ua) sits on top of a larger RW (RW14U) which has also settled but the corner of the wall rests upon the corner of the pile cap to Byron Rd bridge. This has resulted in the corner of the wall being crushed and the concrete has broken away. This is also another job on the list but will require the corner to be broken out the ‘stiffjoint’ material and appropriate gap reinstated between the wall/abutment/pile cap and then the corner re-formed. There are also another two corners which have not crushed but will have to have the same treatment so that if the wall does settle on that side then it will not crush. The fourth corner does not rest on the pile cap.

The Scalabrini Creek Underbridge conduit issue continues. I have had acceptance from the client and the services designer to cut the conduits that do not have a joint for expansion providing that we have operational controls in place for installing the cables. This basically consists of liaising with the rail team so that they are aware of what we are doing and making sure that they have procedures in place for installing the HV cables with a gap of about 50mm at the EJ’s. As all the pulling ropes have been installed using a compressor that blows a sock down the conduit with the cable attached to its tale, the only real concern is any sharp edges on the conduits that have been cut. As the forces involved when they pull theses cables through can be quite high any burring on the edges could damage the cables along its entire length. The metal cover plates will remain off so that a visual can be maintained while the cables are installed but will be bolted back down once they are in place. The main issue at the moment is how to actually cut the conduits. Myself and the supervisor had a go ourselves last week as we had no other labour available at the Rail Team are hounding us to get this done so that they can install power to Leppington station ASAP. We managed to cut the top ones easily enough with a Panel saw from Bunnings (B&Q) but the lower 150mm dia conduits are about 700mm down within the joint and there is only a 70mm gap, not really enough to even get your hand down. I have had two different concrete cutting subbies out to have a look and one said they had a wire cutting diamond saw which sounds hopeful. The construction manager was concerned it might not give a smooth enough cut and asked me to look into Hydro dem (UHP water cutting). He hasn’t yet seen the handy work of the two oxygen thiefs I had to employ on dayworks the other day to cut the upper conduits on the other abutment – if he had he wouldn’t be worried about a rough finish! Having looked into hydro dem companies in the area and having seen this sort of stuff in action when cutting into bomb casings I really don’t want to mess around with that stuff for the sake of cutting a few UPVc conduits so I intend to give the diamond wire saw a go as soon as they can do it – which I was hoping would be this afternoon but they have now said next week.

![IMG_2154[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21541.jpg?w=357&h=268)

![IMG_2129[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21291.jpg?w=357&h=476)

![IMG_2130[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21301.jpg?w=357&h=476)

![IMG_2144[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21441.jpg?w=357&h=268)

![IMG_2119[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21191.jpg?w=357&h=268)

![IMG_2122[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21221.jpg?w=357&h=268)