Archive

The Devil is in the Details

Just thought I would pop you all a quick post in the heat of the moment…

We’ve been slowly grinding through the the last 10% of the project execution and progress has been okay. The focus is firmly on achieving mechanical completion 1 (MC1) so things like re-instating junction boxes, modifying lighting and connecting instruments is a little in the back seat. Pretty much the last piece of the mechanical puzzle was one valve, HV331077, a 3/4″ ball valve rated at 250 bar. Fitting it would effectively seal the system ready for testing and commissioning.

It is missing…

As of yesterday morning I was informed that it wasn’t off shore, so while WGPSN raised the Engineering query I did a little digging.

It was on the Destruct P&ID as part of the destruct scope…

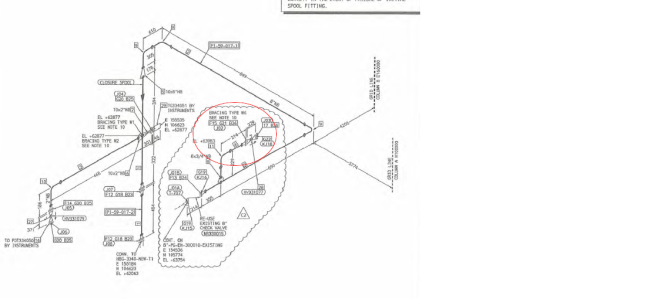

It was on the destruct ISO and not identified for retention and re-use…

It is on the construction ISO…

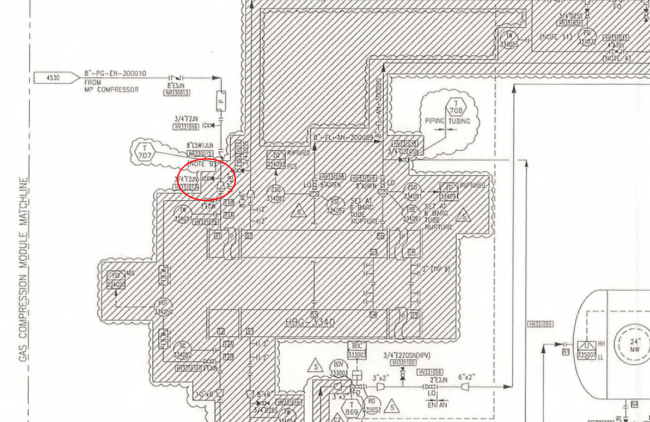

And here’s the little bugger on the construct P&ID, the finished product…

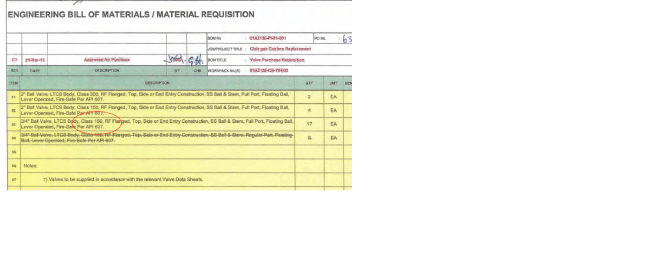

However, we haven’t bought a new one as you can see in this BOM (the pressure class of our valve is 1500):

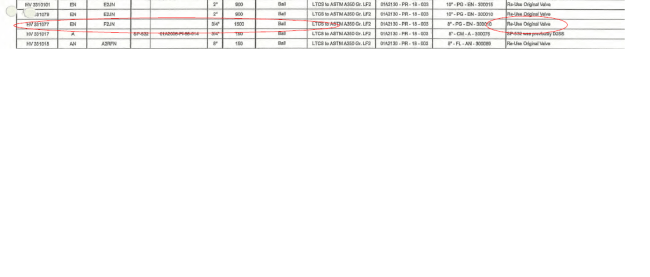

Because someone thought we were keeping the old one and re-using it as per this construction valve schedule:

So what happened?

A lot of attention was paid to the removal and construction of the big heavy coolers, the pipework and all of the supporting steel. All of the big and expensive items were analysed, as they should, to ensure they would operate safely and that they were moved around deck safely. However no-one thought to write a destruct valve schedule, check off the valves for re-conditioning and re-use as and when the lines were destructed. No one thought to check the construct valve schedule against the destruct ISOs and do a sense check. Bottom line is, WGPSN have cocked up and now we are chasing a very real deadline.

Several hours later…

Resolutions

I’ve spent much of the day chasing down options with the WGPSN JRE, Stewart Russell. He was away yesterday and making any kind of progress was like wading through treacle. Everyone I spoke to just seemed to want to stick their heed in the sand and believe that the easiest options would work out. In the end they kind of are, but there is a lot of work required to get them across the finish line. This has been an excellent opportunity to see how the SPA / JRE relationship is supposed to work and I have spent most of the day coordinating BP and placating the TAR team while Stewart has been chivvying WGPSN along to produce their deliverables.

So…

Option 1: We have an untagged valve of mostly the same specification off-shore that is not required for any other i.e. buckshee. The problem is that the valve stem is rolled and not forged which means a deviation is required to get it authorised for service. On top of that, for the deviation to comply with BP technical practices it must be supplied with certification of the mills fabrication techniques to provide QA. However as the valve is untagged it has taken a while to track down the correct certification and this won’t be complete until morning. I have agreement in principle from the BP mechanical TA that this deviation will fly, especially as it is a deviation that has been accepted before as the standard fabrication technique is to roll and not to forge valve stems. Trust BP to do it the hard way. I am confident that with this approach we can have the valve in place by CoP tomorrow.

Option 2: I identified 48 valves currently held in the BP inventory that possibly fit the bill and WGPSN has narrowed this down to 19 hopefuls. By the morning we may actually have a winner, but there is no guarantee that we could get it to Clair before Option 1 could bear fruit. In support of this option would be the fleet of EC225 Superpuma sitting on the airfield at the moment…

Option 3: Buy a new valve of the correct spec. Ironically this is not really an option due to the lead time.

We also considered blanking of the flange where the valve should sit as this valve is a dead leg on the system. However the valve is probably there for a reason and I am waiting to hear back from ops whether this would be a viable solution. And anyway I would still have to do a bunch of paperwork to get a modification like that passed.

So, as it stands the mechanical window which was due to close in about 53 minutes is wide open and my (Projects and Mods) arse is hanging well and truly out of it. Lets see what we can get done tomorrow!

A Big Week

Progress on site has been fairly significant this week. We have finally completed the Ground Floor! Aside from now being well and truly above ground level, which is excellent for morale, it also means that I no longer have to walk up and down a multitude of steps to access the decks (I have seen my weight increase to my normal fighting weight, so it is either the lack of steps at work, Nicky is baking more, the stress levels have decreased, or a combination of all 3).

The addition of a Project Manager to the South Block team has been a big injection of capacity. The fact that he has come from Leightons, JHG’s parent company may suggest that ‘Mother’ is beginning to take interest in her wayward child, and is reinforcing the project to ensure the success of her investment.

The PM has immediately made an impact at the subbie contractual level. Crown (Concreter) is a notoriously difficult subcontractor to deal with and have point blank refused to pour concrete some days stating that they do not have the manpower. As the concrete pours dates are promulgated daily for 2 days in advance I don’t see this as a valid excuse. It continues to happen though, until after a frustrating day for supervisors and engineers trying to coax Crown to pour some columns that would enable WCF (Formworker) to continue work the following day (Crown and WCF do not get along well), the PM waded in. I’m not entirely sure what he said or promised (I know pizzas were ordered) but not only did they pour the 3 columns we required, they also worked late to 8pm and poured every single column that we had formed, they even brought in an additional mobile pump to get the job done! This was a big win for us as it opened up several additional work fronts and released column forms to prepare for the 1st floor.

A similar issue arose the following day, but this time it was resolved by the issuing of a site instruction to the concreter to pour the upper basement to ground floor ramp regardless of weather conditions. Though the issuing of a site instruction appears to be a caving in to their contractual obligation to pour concrete in all conditions, the site instruction will now be debated at commercial level to decide whether it gets paid or not – I suspect not. Crown’s argument was that the weather (light rain) would not produce the specified finish, correct; but does not alleviate them from poor concrete placement. The contract states “The concrete placement subcontractor is responsible for the finish of the concrete in all conditions, including rain,” and also that the “Concrete subcontractor is obligated to pour concrete regardless of the weather, except in heavy rain,” The latter is a little vague as ‘heavy’ is not quantified but from my objective opinion, and from brief discussion with Richard Farmer back at the Mother-ship, JHG should have no mercy for the subbie in regards to rain – it’s worse in the UK!

In the foreground the drips from the slab above have ruined the surface texture. The remainder of the slab has the (now standard on NCH) golfball effect. You can also see the water runs and to a lesser extent the surface undulations above the grade change.

Core C was my second pour on the job, way back in March, and though all appeared to go well on the day, it was an unmitigated disaster inside the core walls. To add some perspective to this and to put up my own responsibility umbrella, I was handed responsibility of the pour 30minutes before it was due to start. The reinforcement was already installed and checked, the shutters were closed, and the concrete was on the road. The issue was in my opinion one of design. The walls were 400mm thick and heavily reinforced, especially around the header-beams and jack pockets. In some places it was later found that the concrete physically couldn’t get past the reinforcement to the form below creating voids and exposed reinforcement in almost every cell of the core. The structure has now undergone an extensive survey using a mixture of cored samples and scanning costing in excess of $120,000. The rectification work is yet to be completed but will certainly involve the breaking out of large sections of wall (1m squares) to be re-poured.

One of the less significant defects in Core C. This reinforcement has 30mm cover to the surface but due to poor vibration and closely spaced bars, concrete couldn’t get through.

The remediation work has the added issue that it has held up progress on the South floors and subsequent floors that tie into the core will require additional back propping to prevent additional load being transferred to the walls. The JHG solution to the Core C problem was to draft in an engineer with the sole responsibility for ensuring that it didn’t happen again. The next lift of Core C was poured last week, and even with all the additional resources and quality ensuring measures in place, there are still several areas of exposed reinforcement. I think this issue could have been engineered out at the design phase as it should have been fairly clear that the shear volume of steel in the wall was going to make concrete placement difficult. Provision could have been made for either an increased wall thickness or a more sympathetic arrangement of bars in areas of high reinforcement. The concrete is already at a high slump and using a 14mm aggregate to ensure it has the best balance between consistence and strength. This problem will continue for the following lifts unless a preventative solution can be found to minimise the poor flow of concrete around the steel.

I have got myself involved in the procurement package for the concrete precast panel walls. It is a relatively small package at $700,000 but has given me the opportunity to follow the process from initial tender to where it is currently stalled in the commercial department. I was a site representative at the initial interviews with the supplier and the installer and am looking to maintain involvement throughout the process until the phase ends in early December. Time is flying by.

In other project news, and I suppose related to the arrival of a few Leighton managers, is the recent Leighton’s audit of the project that was, I assume, somewhat scathing as it has had the effect or removing the Commercial Director of the project and the General Manager for the Western Australia Region has ‘resigned’. This has also induced a further 2 senior commercial administrators to resign.

Thanks to Mike/Richard for the blog on the shearing of bolts on Reinforcement connectors. I spotted the connectors whilst wandering site and ‘reminded’ them that the heads were supposed to shear off. Luckily they were designed to shear; I had to check when i got back to the office.

ANCON MBT Couplers. This connection was intended to allow the column starters to be replaced at a later date (after the bulk haulage road was finished with). A change in plan meant that it was no longer necessary to do this but we had already gone too far.

In other news, Nicky and I have finally booked a holiday to NZ to do the classic campervan tour of the South Island, and hopefully meet up with my cousin from Wellington. We are also doing the largest swing in the world (nothing dodgy) that we saw on the Australian TV show “The biggest loser,” If it can hold the fatties, I’m sure it will be OK for us! We are off to Sydney to catch up with the Bainger’s and take part in the Tough Mudder event.