The Devil is in the Details

Just thought I would pop you all a quick post in the heat of the moment…

We’ve been slowly grinding through the the last 10% of the project execution and progress has been okay. The focus is firmly on achieving mechanical completion 1 (MC1) so things like re-instating junction boxes, modifying lighting and connecting instruments is a little in the back seat. Pretty much the last piece of the mechanical puzzle was one valve, HV331077, a 3/4″ ball valve rated at 250 bar. Fitting it would effectively seal the system ready for testing and commissioning.

It is missing…

As of yesterday morning I was informed that it wasn’t off shore, so while WGPSN raised the Engineering query I did a little digging.

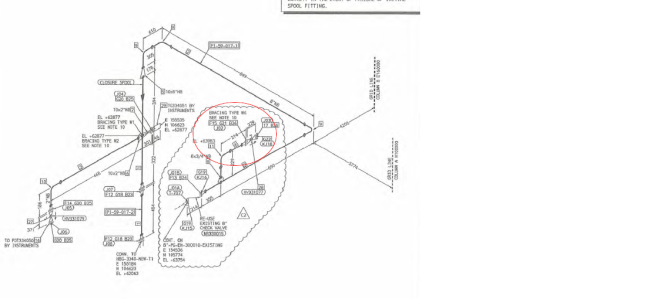

It was on the Destruct P&ID as part of the destruct scope…

It was on the destruct ISO and not identified for retention and re-use…

It is on the construction ISO…

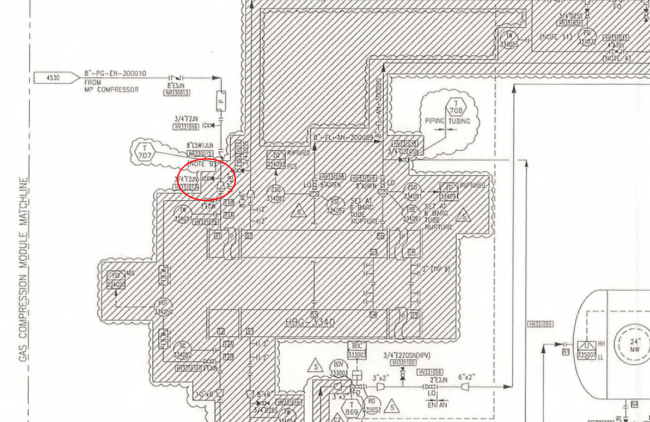

And here’s the little bugger on the construct P&ID, the finished product…

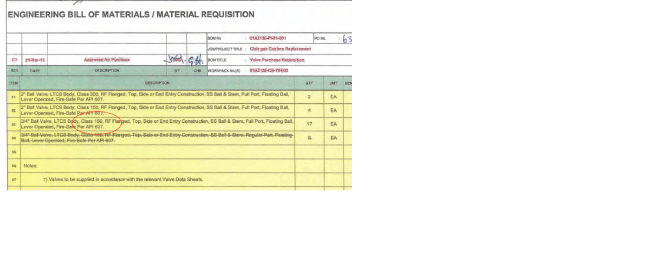

However, we haven’t bought a new one as you can see in this BOM (the pressure class of our valve is 1500):

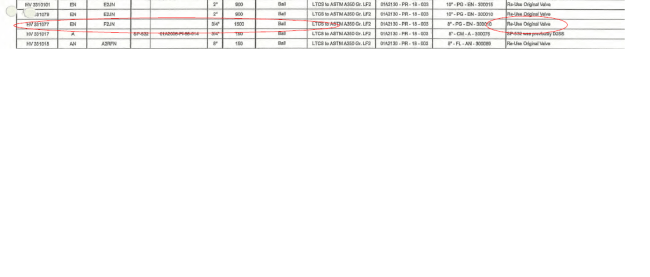

Because someone thought we were keeping the old one and re-using it as per this construction valve schedule:

So what happened?

A lot of attention was paid to the removal and construction of the big heavy coolers, the pipework and all of the supporting steel. All of the big and expensive items were analysed, as they should, to ensure they would operate safely and that they were moved around deck safely. However no-one thought to write a destruct valve schedule, check off the valves for re-conditioning and re-use as and when the lines were destructed. No one thought to check the construct valve schedule against the destruct ISOs and do a sense check. Bottom line is, WGPSN have cocked up and now we are chasing a very real deadline.

Several hours later…

Resolutions

I’ve spent much of the day chasing down options with the WGPSN JRE, Stewart Russell. He was away yesterday and making any kind of progress was like wading through treacle. Everyone I spoke to just seemed to want to stick their heed in the sand and believe that the easiest options would work out. In the end they kind of are, but there is a lot of work required to get them across the finish line. This has been an excellent opportunity to see how the SPA / JRE relationship is supposed to work and I have spent most of the day coordinating BP and placating the TAR team while Stewart has been chivvying WGPSN along to produce their deliverables.

So…

Option 1: We have an untagged valve of mostly the same specification off-shore that is not required for any other i.e. buckshee. The problem is that the valve stem is rolled and not forged which means a deviation is required to get it authorised for service. On top of that, for the deviation to comply with BP technical practices it must be supplied with certification of the mills fabrication techniques to provide QA. However as the valve is untagged it has taken a while to track down the correct certification and this won’t be complete until morning. I have agreement in principle from the BP mechanical TA that this deviation will fly, especially as it is a deviation that has been accepted before as the standard fabrication technique is to roll and not to forge valve stems. Trust BP to do it the hard way. I am confident that with this approach we can have the valve in place by CoP tomorrow.

Option 2: I identified 48 valves currently held in the BP inventory that possibly fit the bill and WGPSN has narrowed this down to 19 hopefuls. By the morning we may actually have a winner, but there is no guarantee that we could get it to Clair before Option 1 could bear fruit. In support of this option would be the fleet of EC225 Superpuma sitting on the airfield at the moment…

Option 3: Buy a new valve of the correct spec. Ironically this is not really an option due to the lead time.

We also considered blanking of the flange where the valve should sit as this valve is a dead leg on the system. However the valve is probably there for a reason and I am waiting to hear back from ops whether this would be a viable solution. And anyway I would still have to do a bunch of paperwork to get a modification like that passed.

So, as it stands the mechanical window which was due to close in about 53 minutes is wide open and my (Projects and Mods) arse is hanging well and truly out of it. Lets see what we can get done tomorrow!

Sounds like fun. This could make for an interesting fly-on-the-wall style documentary – inside the real BP!