Archive

Round Up

This is the post that was going to be written on Friday, basically a round up of my portfolio, since I haven’t done that in a while…

Clair Coolers

Leak testing completed last Wednesday which means that commissioning is pretty much there and with start up scheduled for Thursday, all fingers are crossed that the new coolers and pipework do what they are supposed to. It has been a manic month and a half getting this project finished, but worth it. We are just over £1m over budget and about 5 days late, but the TAR is off by 2 weeks and none of that is our fault, so we are looking good. The budget bust was probably a given based on the emergent nature of the work, but I have secured the necessary expansion to the financial note and at the end of the day the partners did not really have a choice.

The next 90 days will be spent completing the technical and financial close out and I am intent that this is completed on time. We shall see.

Clair Minox B Blower

This is my next biggy with off shore execute scheduled for Feb 2014. This is a scope that has been engineered and is awaiting the slot to execute. It probably deserves a post in its own right to explain the ins and outs (of which there are several), but it is offering me a couple of interesting opportunities. Not in the least the issue of a safety critical interlock arrangement on the modification which has been identified as not being necessary. I think that it has potential to satisfy my B competencies as I am planning on writing a draft technical note to cover the issue and support a decision to proceed without it being implemented. Time is tight, so this is high on my to do list.

There is a fair amount of schedule and planning work to be done on the project as a whole to make sure it goes off without a hitch. This Thursday I will be flying down to Stroud to visit the firm who are reconditioning the blower of my post from last week.

Clair HP Cooler

I’ve still got to find the time to write the SOR for this project. It is halfway there and I am getting increasing pressure to get it over the line to support the design estimate that is just beginning. Yes, I know, how can the estimate go ahead when the SOR is not written. Well, this is the fourth leg of the Clair coolers saga that was dropped from the 2013 TAR due to increasing complexity threatening the execution schedule of the other three coolers. It has been estimated before so this is really just a revision to include the cost that were not picked up in the original estimate, the SOR is more of an update that a brand new document. This is due for 2015 execution and therefore almost certainly going to fall one of the two new secondees.

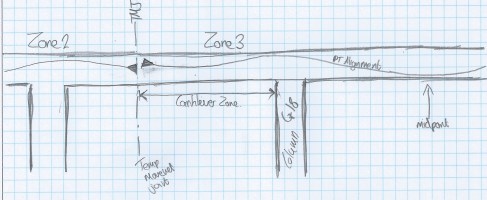

Bruce P60 Bridge

Yes, this is still going on. I now have all of the deliverables for this project in Define and will be writing a project sanction DSP over the next 2 weeks. This one has snuck under the radar a little bit and I need to create a document that presents the engineering challenge vs the financial benefit to the asset so that they can decide to go or no go. With the Rhum field now definitely coming back on line there is potential for a change in atmosphere on this issue what with the extension of life of field by a fair few years. This is my personal mission to get some kind of resolution on the project.

Bruce Caissons

C13 is chuntering along in the background and I won’t really be doing any work on it until the new year. Suffice it to say that bringing Rhum back on line may have a significant effect on this project. When Rhum starts up the asset will have no redundancy in sea water lift unless this caisson comes back on line. We shall see if it changes any, my guess is not in the next 12 months but it is likely to be a priority for 2015 installation.

Clair Flowline Support Mods

Not much to say here. I’ve bumped the execute into May 15 because there is no appetite from the asset to give me information while the TAR is ongoing. I will keep plugging away at it, but I am not overly optimistic.

In other news:

Hugo has started walking so, being Swiss, he should be skiing by Christmas. I have started home brewing, my first batch is homebrew version of St Austells Tribute. It is merrily bubbling away in the spare room and hopefully in a few weeks should be a decent pint. The home made heat exchanger (single pass immersion coil) and aerator (car pump + aeration stone) worked very well. I will post some pics at some point. There is a striking correlation, Hugo finds his legs just a few week before his dad loses his!

Repetitive Issues

As JM always said the biggest risk in construction is the ground conditions, and hopefully that is firmly behind the South Team now (though the basement team will have to deal with the slab-on-ground down there). The Upper Basement and Ground floor are finally complete, meaning we no longer need to backprop the slabs to the foundation making construction a much cleaner and less risky business. The issues with concrete continue though.

Not only is the level 1 slab a much more intricate beast in profile and finish it also uses a combination of concrete mixes to accommodate external areas that require additional waterproofing. Fig 1 shows the structural drawing detailing what concrete mix is required.

The white background denotes a 32MPa mix, the green hatching denotes that it should have a shrinkage reducing additive included to restrict shrinkage to 450micons/m (Eclipse) and the red hatching that there should be a waterproofing additive included (Xypex). From the figure it is now clear what the shape of the building will be for the subsequent floors. There are several awkward aspects of this:

1. A close control of the concrete entering the pump is required, and also skill in ensuring that the correct mix ends up in the correct location, in short competent concrete placing subcontractors (something we are lacking – see later).

2. The external areas all require falls to drainage points. As I have discussed in previous blogs, JHG design team, against delivery team advice, have decided to pour falls integrally with the slabs. In my opinion this is a money and time saving initiative that due to poor placement skill will ultimately cost more money and take more time to rectify.

The following images are examples of poor concrete placement on the last pour:

Fig 2, shows where the concrete placement subcontractor has placed a height marker to indicate the ridge line of the top of the slab falls – a good idea, as long as you remember to remove it. Fig 3. Shows a cutting disc that has been lovingly placed into the top of the slab and pushed in for good measure. These are just 2 of the many issues I have found with the finish of this slab. The others:

- Surface finish not steel trowel float to allow follow on trades to waterproof

- Set-down levels not adhered to and concrete poured too high resulting in edge gullies in what is meant to be a flat drainage channel.

- Concrete poured above the height required (no excuse as they use a laser height monitor.

- Footprints in set-downs (claimed to be formworkers returning to remove stakes used to hold in set-down forms)

Whatever the issues, whether it be poor concreting or trades walking over a finished slab, it states in the concrete placement subcontractors contract that they are responsible for the concrete finish, and for protecting their work. NCR’s are going to rain, especially a separate concrete contractor has now been contracted for the basement and is producing an incredibly better finish. The client even made a joke in the pre-pour meeting about it.

We have started forming up level 1; it is taking twice as long as expected though for 2 reasons.

- The formwork contractor has run out of competent carpenters to do the intricate angles and curves

- The formwork contractor no has no incentive to perform as he is now on a costs + contract where JHG are paying the invoices + a percentage.

All that said the formwork is looking quite good. It is nice to see some curves after 7months of straight edges. What the image also shows is the cast in Halfen channels that the precast walls lock into. The locations of the channels had to be estimated by the delivery team as the shop drawings from the precast panels had not been produced due to a delay in procurement. This may turn out to be another problem to fix down the line if the channels do not allow enough flexibility to accommodate the panel brackets.

The current issue that I have found with Level 1 is that the structural design has not effectively checked the design of the reinforcement, cast ins, services or PT for clashes. It is causing many issues on site that are not helped by the individual subcontractors inability to liaise with each other. It is actually in their contract to liaise with other trades but none appear capable of doing so and resort to just complaining to any JHG employee who is available. It really is very petty. The issue shown in Fig 5 however is purely the structural engineers issue of not deconflicting PT and reinforcement. The issue is not in the alignment of the ducts or placement of the anchors but in allowing in the design of the reinforcement for the placement of the pans that allow the stressing of the cables to take place. As it stands the pans (400mm wide) do not fit side by side as designed between the vertical links, spaced at 600mm across the beam. My proposal was to stagger the PT ducts to allow them to fit between the links. This is only possible at this point at the PT is effectively being used to create a cantilever over a column to increase the capacity of the adjacent beam (See fig 6). It occurs to me that many of these issues could have been avoided by using a single BIM system and good communication.

Fig 5: Clash between PT pans and Reinforcement. Lack of understanding of how the structure is constructed.

In other news, I went on a site visit to Perth City Link (the project Rob Ridley worked on), which is nearing completion, 6months ahead of schedule and on budget – I am sure it has everything to do with Rob’s input. It was good to spend a bit of time with engineers from other projects to share experiences.

The PCH project has decided not to replace me when I leave in Dec. Not bigging myself up at all, but I think this is a decision based purely on cost and not thinking about the repercussions on the remainder of the team. Even a grad engineer would be a bonus, especially when a Grad engineer costs approx $75k a year and the value of liquidated damages in $180k/day. The maths is simple. The ongoing joke(?) is that i don’t do anything anyway – funny!

It was good to get across to see the Bainger’s in Sydney, if only for a little while. While the girls and little ones took in the sun and café culture, Jon and I went out to his site for a wander around. It was good to see how things are done on the East side of the country, and to be honest a little scary how different some of the procedure are at the PCH. I even caught Jon working when away from playing solitaire at his desk. David, I think this is a contender for the new prospectus!

It was also good to catch up with a few ex-RE’s to take part in the Tough Mudder event. As it turns out the ‘Wrestler’ fancy dress resembled more of a gay 80’s fitness instructor, but it held up well and nobody got broken. This weekend was the Perth Tough Mudder event with chicks, so a slightly fast pace than that with ex-Army lads who have embraced the civvy-spread.

Time for a little break now, so off to NZ next week to gather seismic research for my thesis, and may take some time off to spend with Nicky for our anniversary too.

Cracking the whip.

The reality is that the bridge would be complete by now if the initial backfill had been completed within the programmed 6 days and not drawn out to 6 weeks by the Civil Team but as it stands we are on course to complete before xmas. I realise I haven’t blogged for nearly 4 weeks and I am not sure where that time has gone, I did have good intentions during the week but with a TMR to write and trying to push productivity on site before I know it its 7 in the evening and with an hour commute I should be getting home if I want to remain married. The last 2-3 weeks have been extremely exhausting if I’m honest, I go on holiday in 3 weeks’ time and I am trying to push for the bridge works to be complete by then which if I can achieve will be 12 days ahead of programme. To the credit of the subby they have bought into my vision and stepped their game up and we have now completed all abutment retaining walls, both approach slabs and will start installing the pre-cast parapet sections next week. I feel like I am constantly badgering (persuading) people to work that little bit faster or smarter and feel like I actually own this bridge and want to see it come to fruition before I leave. As a result I have at times lost complete confidence in the supervisor as he has no interest in working at the same capacity as I currently am and I have found I have taken on more of his responsibilities in order to keep momentum when I should be gradually giving him more responsibility. Most of the supervisors from what I hear have a fairly poor work ethic and rarely supervise anything at times, this has been an immense cause of frustration for me coming from a background where a SNCO is generally highly competent and can be left alone to manage quite complex tasks to having a supervisor who can barely spell and will spend 2 hours at lunch shopping. The main issue is how JH trains his people, which is adhoc at times but largely non-existent. The supervisor I have for instance is a really nice guy and we do get on very well but his work effort is sporadic at best, he has good weeks and then it seems he needs a bit of a rest before he gets another wind. I have often had chats with him about how to improve how he operates and to his credit he takes it on board and he has improved as a supervisor over the last 8 months. This is largely due to the fact he received no training to be a supervisor in the first place and received a field promotion form leading hand to foreman as there was a slot to fill. The majority both supervisors and engineers seem to be on contract for this project only and so have no job security and most have been applying for the next employment over the last 2 months since all contract staff will be gone by xmas. The constant message from JH is that there is no work probably until the end of next year and by the way your all off the project by the end of Nov but will try to find you work if we can – this has not had a good effect on morale and most importantly productivity.

Well, slight rant over I’ll get back to the bridge. At present we are about 4 days ahead of programme with a key activity coming up which is installing the parapets. In reality we should be able to install the 24 panels at a rate of 6 a day but that is only if we get the prep work right. Each panel weighs 3T and is held in place by three L shape brackets that fix onto the deck/wingwalls/retaining walls. The fixing anchor as you can see from the diagram has been cast into the appropriate element and there is a levelling screw at the back edge that can be adjusted and sits on a steel plate that is epoxy glued on to the concrete. This has the potential to take a long time if the prep is not right as the tolerance is only mm between each panel. Once the panels are in the traffic barriers are formed over the bracket which tie in the panels and form the parapet barriers along the length of the bridge. On Eastwood Bridge we had one of these panels move out when we poured the barrier which gave us issues when we installed the metal traffic railings and throw screens which sit on top. I think this was due to the anchor fixing slipping as the bolt sits through a slotted hole and I think the additional force generated from wet concrete caused the bracket to slip which tilted the panel outwards as opposed to the bracket actually failing. To remedy this I intend to weld all the nuts and reinforce the brackets with straight bar diagonals welded on once all the panels are installed and we are ready to pour the barriers.

Other issues last week were with the approach slabs where the steel was wrongly fixed. I went out to check the steel 2 hours before we were meant to pour as I couldn’t get out earlier due to end of month cost reports due that day and the Project Verifier was already there who also spotted the mistake which I didn’t think looked good. The supervisor should really have spotted this when they started but it seems no one decided to look at the drawings beforehand. The chief steel fixer is a grumpy git but extremely good at its job and it has been very rare that he has got something wrong although I have picked up a few things recently. I can only assume he thought the steel was the same arrangement as the RW bases which have the larger dia steel bars at the top of the slab due to the increased tensile stress at the top generated from the wall resisting the backfill. The approach sabs have the larger dia bars at the bottom and so at the 11th hour we had to strip both approach slabs which lost us a day which is quite crucial at this stage. It also means I lose a day on the parapet installation as I need to be able to traffic the slab early in order to get on the deck to install the deck parapets. Looking at previous concrete strength we have achieved 80% strength which is required for loads over 15T at around 5 days. As a result I requested an extra cylinder to be tested at 5 days as well as the usual 7 and 28 days which will be tested on Wed next week and I can make a call as to whether we can traffic the deck or wait until 7 days.

The remaining work on Dickson following the parapet installation will be the traffic barriers, walkway (including services installation), traffic railing and throw screens and the type F traffic barriers that extend out from the parapet barriers for a further 25m on both sides and abutments. I am still negotiating with a slipforming subcontractor to do the type F barriers in 2 weeks’ time so I can see it done before I go on holiday as I have done a lot of leg work (plus a TMR on it) and would really like to see the process in action.

Aerial photograph taken of Dickson Rd Overbridge for the recent edition of the project newsletter

Aerial photograph taken of Dickson Rd Overbridge for the recent edition of the project newsletter

As for work on any of the other bridges it is all on hold at the moment and I don’t intend to get side tracked from Dickson to carry out any further defect work. I have been told that will fall to someone else once I have left but I am still costing 9 out of the 14 bridges on the project. Luckily I have just done that for the last time last week although I only managed 6 within the 24hrs we were given to get the forecasts in. The only major movements of money on the bridges are primarily Dickson Rd but this should also start to slow as the major structural work is now complete.

In other news little Ethan is just about walking and is enjoying his new found freedom. We went to the international fleet review at the start of the month and managed to get a prime view of the fireworks display (which was apparently bigger than new year’s) right in front of the opera house and harbour bridge. Ethan managed to stay awake until the last big fireworks crescendo which you would think would wake him up a bit. The bush fires in the Blue Mountains have been pretty horrific with the air full of smoke at times even in the city centre. The project is not that far from some of them and coming into work last mon you could taste it in the back of your throat. It also affected visibility around the local roads. One of the girls in the commercial team lost her house after leaving in the morning to take her daughter to a hospital appointment she returned and it had gone but her neighbours 2 houses down were untouched. Apparently the embers can travel for up to 50km and still burn your house down.

Pump It

Just a quick post today, more on friday is the plan…

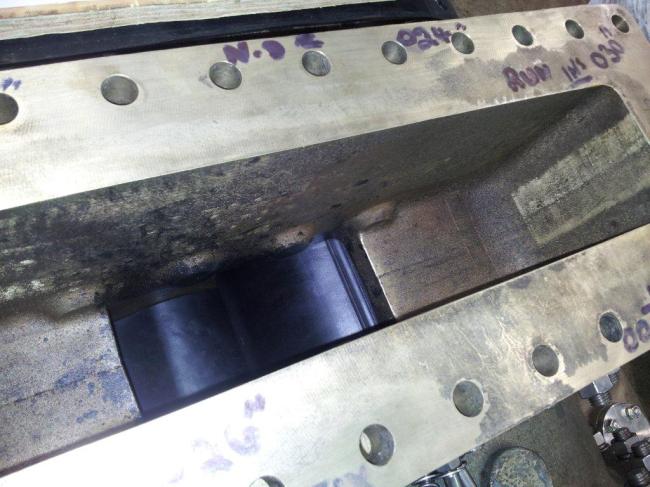

Now that Clair Coolers is winding down, Clair Minox Blower B is starting to wind up for off shore execute on 2 Feb. That gives me 19 days to the 12 week gate and while we are mostly there, there is a fair bit of work to get us through. The Minox system uses nitrogen to strip oxygen from sea water for use in re-pressurising wells to increase extraction rates. Removing the oxygen presumably reduces the compressibility of the injected water which protects the plant and pipes used to do so (water hammer?), but I have a little more reading to do on that front. Either way we are upgrading the ‘B’ blower on Clair to increase water injection capacity.

The project itself is another fixer that has been attempted previously but not completed. To that end the equipment below has been sitting out in the elements (at a cost of £20k a month) rather than in a covered hanger being regularly inspected and turned over. QA issues with the storage company. It is now down for re-conditioning / testing with the manufacturer, the photos below are proof from them that it is actually in a better condition than I first thought. My question to you is, from the information below, what kind of pump is it? It is a blower and it sends nitrogen around a closed system.

Mark, if you read this, I can send you the photos and GA for one of your pump lessons…

The Drinker from the Poison Chalice

Ironically the office has got a more positive vibe now that our commissioning engineer has been “moved on to Baltimore”. Since I arrived she has been a source of frustration for both the contractor and us, regularly winding the subbies up by telling them they are incompetent (which is true) but not offering any constructive comments. This has caused such bad blood that she is number 3 on the Client’s Representative Top Ten List of Things He Hates (the Contractor is not even on this list!). So after much wrangling the boss has moved her on (which was a mutual decision) before the project goes backwards. On her leaving we sorted through the stuff she had left and found items dating back to February that were months over due which even the contractor had forgotten about.

Over the last months I have taken it upon my self to try and resolve issues that have been dragging on a while because no one else can get a result (the poisoned chalice). For my avid followers this has so far amounted to the floor drain and the faulty pump 17 (more on that later). Now I have picked up another topic which is Temporary Building Maintenance during construction. I gathered together the customer reps and we thrashed out the issues concerning maintenance. Aside from the equipment that is due commissioning there is no record of maintenance on anything else including the fire pumps. There is also concern that what maintenance there is happening is not good enough especially when water from the boiler has 10x too much iron in it and cooling towers have excessive bacterial growth. I took the time to review Operation and Maintenance Manuals for all the big items (boilers, chillers, cooling towers etc) and then tried to check what the non commissioning items only to discover that the submission for theses items has never been sent to us. Armed with some good facts and examples I had a meeting with the contractor who was very receptive (they like dealing with Army guys more) who admitted the document was missing and that they could improve by changing procedures and including more details. As I suspected there was no way they were not doing the maintenance but they were not always including the details because this document had not been written to tie it all in. So months of whinging dealt with in a 2 hour meeting. I have now got to go through the building equipment list and identify every item that needs maintenance. Should take me 6 weeks! We also have over 2000 QA issues to address. So many of these are legacy from guys who have left the project that they are just sitting there with no one taking ownership. I will be sorting them out next week and apportioning responsibility where necessary. Some of these are over 2 years old and have been dealt with but are still not signed off.

I also visited the steam generation plant on site to see how it compared to our boiler setup. This is pretty big facility providing steam for all other buildings on site. Our interest comes form the fact that the plant has a continuous analysis system that checks the water quality constantly and can notify the engineer by phone or wifi if an issue occurs that the machine cannot sort or even order more chemicals. The equipment is all provided free by the vendor (although the installation isn’t) who set this up and enhance boiler lifetime considerably.

Above. Where the magic happens

Below. One of four big boilers

Our current boiler system relies on little old men taking readings every hour for 8 hours, chucking in a coffee can of chemicals when ever he thinks things are out of kilter. This seems very old fashioned and imprecise and the water test result imply it doesn’t work. However this is what the customer wants! I will have to change their minds.

Pump 17 continues to delay the commissioning of the cooling system so I used this as the basis for my TMR to try and get resolution. As mentioned previously the pumps are too big and need better control through VFDs but without analysing the situation it is difficult to get any support. It turns out the motors are nearly 200% oversize even including the need for expansion. We have referred the matter back to the design team in Baltimore because the designer is not conceding on this. Interestingly the Design firm recently acquired the firm that employs all our QA guys…….We still have no answer on whether fire dampers should be tested with the system running. We have gone to the engineer at Ft Dettrick to find out what they did and why. Rain last Friday managed to flood the sump with the fuel return tank in it. This is inside the generator building and is meant to be dry so it was a bit of a shock to see the watering pouring in through the pipe line from the flooded sump in the fuel storage area. Even more of a shock for the King Snake stuck down there! It turns out a bung to block this pipe had been left off because no one thought the other sump would flood but it did because the lid was badly fitted. QA issue 2001…..

In Harrisburg the fun and games continue. The Contractor still has no idea how the steel beams are going to be moved on the roof. The most recent idea has been to cut all the beams in to 3 pieces so that they can fit on the quad bike trailer. This will cost them even more money and slow down the job even more. On that note we have still not received an updated schedule due 1 July. Office engineering are drafting a letter saying that as no schedule has been received it is obvious that the contractor considers the project is running on time so there will be no come back if the project runs over time. This might get there attention especially as they are running 9 months late. That said even after a directed letter was sent, telling them to employ a new Safety and Health Officer in 2 weeks, it has been stiffly ignored for 6 weeks. When challenged the response was that they were having trouble hiring someone. It turns out that they were trying to poach the SHO off the HQ project next door but he would rather eat his own hands than work for these clowns! The High Bay Drain Fiasco continues. There are actually serious discussions as to whether there is a need for the over flows especially as we had 9 inches fall last Friday and there were no problems.

The HQ building is coming on well and they are starting to pour the floors. I enclose a photo of this possible project for my successors (C and E&M).

The steel will all be up by next May but there will be plenty going on especially as that is when the Mechanical equipment will start going in.

And in other news….

It is a bad time to be depressed in DC with a shooting and self immolation not to mention furloughs. The furloughs did not impact us because our funds come from last years budget but we had guys from the district drafted in to keep them employed on our budget.

The Orioles finished 3rd in the League so did not qualify for the wild card place in the finals, the Ravens have had a pretty ropey season winning 3 and losing 3 with not much hope of another Super Bowl this year but the State College Terrapins (Terps) Football team is doing well with 4 wins and one spanking by Florida State 63-0. This equals the biggest loss in the history of the college competition but that is what happens when your quarterbacks are all injured in the game.

Halloween is rapidly approaching and the amount people spend over here is staggering. They really go to town and where we are is so popular for trick or treating, people bus in from around the county. We have bough 4kg of stickys already but we have been warned that might not be enough!

We also took part in another great US tradition of going to visit a time share at an outdoor pursuit centre. These places are very well set up for doing nearly everything both winter and summer so we were nearly tempted to stump up $10,000 for 2 weeks a year for life (transferable to resorts all round the world). However when we declined and they asked if $5,000 was OK we decided that was too necky and collected our voucher for a free 3 day holiday and left.

Warrick also found a car for me.

Growing Frustration

I am exceptionally pleased that I only have 6 weeks left on site, the last 3 weeks have proved to be incredibly frustrating for me and keeping my opinions to myself is proving difficult. Those of you that I have talked to in person will be aware of how annoyed I have been at various points during my attachment but here are some of the highlights from the recent past:

- Yesterday I witnessed an incident with 2 of the tower cranes which could only have been described as dangerous. On bringing it to the attention of the project managers I was told to go and get the sub contractor to fill out the near miss report and after some discussion instruct them to remove the crane driver at fault; a message I duly delivered. This decision was reversed by the PMs after shortly thereafter, doing nothing for the company credibility nor mine.

- Last week I have having serious issues with the council highways dept and couldn’t get the desired answer back, so I asked the PM for his help in dealing with it, request ignored, Monday morning we receive instructions from an irate highways supervisor to return the road closure to 2 way traffic immediately 4 days earlier than planned, at the point at which they looked for someone to blame, I walked out.

- I chair the sub-contractors coord meeting on a weekly basis, which means I receive the sub-cons concerns and plans for the next week do my best to deconflict at the meeting and take the points that can’t be fixed then and there to people who can work on them in slow time. Often I have requests for more storage space on site, which doesn’t really exist but that is a story for another time, AER 3 probably. There had been some safety concerns raised over the over head working where we have formwork being struck above mast climbers or people working below, there was a suggestion of a daily briefing that would deconflict space and time for overhead activities. I included in the minutes and put it to the PMs who seemed underwhelmed and at that time more interested in patresses (a subject which has dominated conversation over the last 2 weeks at the highest level of the project) nobody else seemed that bothered, I tried again, ignored again. Last Thursday we had a RIDDOR reportable accident when some plywood being struck from a slab fell on a cladder in a mast climber and broke his shoulder blade, suddenly interest appeared in deconflicting people woking overhead.

A complete whinge today, sorry, but my only real sounding board on site was an agency site manager who they’ve got rid of in order to bring in their own websters blokes.

Hot salty fluids

As previously mentioned I have been supervising bringing the utilities onto site, so far it has gone fairly well I had to decide to abort the BT ducting as there simply wasn’t going to be enough space for the work to go on, this will be revisited in the future as the disruption will only impact on site activities rather than the public. I had to deal with a complaint from the Southern BBC Engineering and Operations Manager which was quite an uncomfortable phonecall, it felt a little like OPTAG where the SIMPRESS are sticking a camera in your face and trying to trip you up with questions.

The geothermal element of the installation is quite interesting, what I didn’t realise is that the Southampton geothermal borehole is the only functioning one in the UK. The original project was started as part of a Dept of Energy experiment in the late 70s, the DoE decided that it wasn’t a viable option but Southampton City Council decided to pursue it and went into partnership with private enterprise and started the Southampton Geothermal Heating Company, there are some other complex company arrangements that involve Cofely GDF Suez that I still don’t truly understand but it’s just minor details. Because the City Council are still involved in the scheme it seems that connection to the scheme is often a planning condition, bribery by another name.

Anyway the scheme works something along these lines (see Rich aged 5 sketch).

The borehole is 1700m deep and taps into a geothermal aquifer containing ‘ancient’ brine at 76 degrees Celsius (the bit I can’t quite get is why it needs to be ancient and if it is it must take a while to recharge) a pump at 600m deep draws the water to the surface it arrives at about 70 ish degrees. At this point it goes through a heat exchanger to with fresh water and the cooler brine is discharged into Southampton Water. The fresh water temperature is now topped up to 80 degrees using some combination of Combined Heating and Power plants (CHPs) conventional boilers and biomass boilers. Once the desired temperature is reached it is them pumped around the distribution network that runs under Southampton. In key buildings such as the Civic Centre there are additional boilers that maintain the temperature of the network.

A building that is using the system has a flow and return pipe plumbed into a metering rig. Crucially the metering rig allows the provider to measure energy used, by monitoring temp in, flow through and temp out the clever computer works out how many MWh of energy have been used, I guess this has something to do with specific heat capacity and other such stuff that GCSE physics mentioned. The demand is controlled by the BMS which decides to raise or lower flow as required. There is a limit on the return temp and the contract specifically states that it must be around the 55 degree mark.

The flow pipe can flow in both directions (not simultaneously for the confused Civils amongst us, I stopped short of asking the stupid question of how that works, instead choosing to nod sagely) depending on demand. So if a sudden demand occurs near the civic centre CHP and pump it will be fed from there and the CHPs and pumps are the other extremes of the network pump water inwards to fill the ‘gap’.

Once inside the building I think ( though need to check) I think it goes through a big heat exchanger in the plant room which pumps it around what I suppose could be described as a ring main and then on everything third floor smaller heat exchangers steal heat away for the DHW and heating systems.

All the connection has been made onto a live system in what they refer to as a ‘hot tap’ the provider have been banging on about it for weeks now and made it sound really exciting. It wasn’t, just a couple of blokes all the way from Scunthorpe with a drill, no steam, no blowback nothing.

What a big shaft. Note all the services running through the same small area of road way, at least half of the ones seen behind the guying drilling shouldn’t have been there.

M’s I prepare for the questions I can’t answer.

Mark, in all seriousness if you’re excited by this they’d be more than happy to have you come and look at all the engines and other stuff that moves.

The Devil is in the Detail – Closure

Well, not quite.

When presented to the Technical Authorities, one of them noticed that on the valve plate it stipulates a maximum design temperature of 90 DegC, not ideal on a line that can see 175 DegC. This was missed at every step along the way and set our meeting off to a bad start. Luckily Woodgroup were able to offer up a ringer that was suitable for service up to and beyond 175 DegC. However this new valve had had the valve stem changed out, but there were no certificates to QA the material used. As a work around I got agreement that the valve could be fitted for leak testing, thus allowing MC1 on 28 Sept, but to be used in hydrocarbon service it would need to Positive Material Identification (PMI). PMI would have required for a trained person to be mobilised with the equipment (think speed gun), so I gave the Asset a choice, PMI the in place valve or we fly out a ringer with certs complete. They went for the second option and so this valve is now fitted and I am left with the glamorous business of ensuring the deviation is recorded in the change management system – queue much chasing after people, bullying and coercion.

If you are interested, here is what the most expensive valve in the world (gram for gram) looks like…

The real drama didn’t start until close of play last week and luckily I’ve not had to get too involved. On Thursday the ACE Engineer responsible for developing the commissioning plan highlighted the fact that the test pressure stated on the piping isometrics was some 30 bar lower than that required by the piping specifications. Following some calculations by BP it appeared that the incorrect temperature factor had been applied to the design pressure to calculate the test pressure (1.5 instead of 1.75) resulting in this discrepancy. This quickly blew up into quite a large issue between BP and WGPSN, with WGPSN spending the weekend checking all of the pipe work in the Coolers project, then all of the pipework in the Clair TAR and then all of the Pipework in the Magnus TAR. A considerable expenditure on Wood Groups part to ensure that, while the pipe work did indeed fall short of the required standard, it was more than suitable for service. Part of the issue lies in the way that BP specifies pipework on assets which is flawed in that it is a massive over estimation in most cases. Ultimately the situation has been justified and there will be no requirement to replace the pipework, which is a massive relief, and the hullabaloo that it caused nicely distracted everyone from the valve issue and I have managed to get it sorted in the back ground.

In hindsight, I should have spent more time when the valve issue was flagged up restraining WGPSN to ensure that we had the right solution. I allowed us to go forward and present a completely inappropriate valve to the TAs and it was only luck that we had a second, more suitable, option to present to them. I am now in the process of trying to implement these tactics to the new issue, Independent verification.

OSCR Regulation 19 mandates that IVB is carried out as a check calc for the project to ensure that disasters like Piper Alpha and Deepwater Horizon don’t happen in the North Sea. There are 20 days until the system is due to go live and I just got handed 23 pages of comments that require response from WGPSN. The clock is ticking once again.

In the background I have also re-written the project Approval For Expenditure to make sure that I don’t run over budget. I like the philosophy of moving the goal posts and in this case it was agreed. My request was for a cool million and it should be approved shortly, unfortunately they BP won’t be giving me the 10% commission I requested.

All in all, good stuff for CPR methinks.

Time is tight.

It has been a few weeks since my last post and lot of has happened since. The bridge deck has been poured on the 22nd on possible the worst day. No rain, still, but it was well over 30deg and the wind was right on the limit for operating a boom pump. The wind on the deck which is 9m high gave us curing issues as the surface started to dry and crack very quickly. As part of the pour plan I had worked out roughly what the rate of evaporation would be in accordance with the spec and with the wind gusting over 60km/h we had to constantly apply alcohol in a fine spray as soon as a portion of deck had been screeded. A bit of woeful mismanagement by the supervisor meant that we didn’t have hessian, plastic sheeting and the water hose ready to start curing the deck as soon as we should have and by the time we got it all covered there was a lot of cracking on the initially poured section. We have moved swiftly since as we stripped the scaffold on both sides over the next few days so we could start the backfill to the first Abutment RW levels. As a result we havn’t been up on the deck for the last couple of weeks so I have yet to see how bad the crazy paving effect may be. We backfilled both sides by 1.35m and poured the four base slabs for the first RW’s swiftly followed by the stem walls the week after and this week we have started the next stage of backfill for the next RW which will take us under 2m below the top of deck. I should have insisted on wet curing for the lower RW’s as all four bases had a fair amount of surface cracking on yet another windy day which means I didn’t learn my lesson the first time but more truthfully means I just couldn’t give the pour the required time or more accurately the planning time it required relying more on the subcontractor to do the right thing. I have found this has been the case on a number of occasions, when I was purely a site engineer at the start of the attchment I had the time to comprehensively plan a concrete pour and direct it but with multiple sites and a crippling amount of paperwork to produce I have to rely more on the supervisor and the subcontractor. It has often reminded me of what Richard and John would say regarding knowledge of those you work with and to never assume they know what they are doing. I have frequently been surprised at how little knowledge of concrete the FRP company demonstrates who now frequently ask me what or how they should do something which 7 months ago would have been laughable. My supervisor is similar but tends to know what he should do but hasn’t a clue why – I felt exactly the same in JM lectures except I didn’t even know what I should do!

Abutment A wingwall shutters

Abutment A wingwall shutters

Backfill to next RW’s on abutment A

Backfill to next RW’s on abutment A

The aim is to open the bridge before xmas which is achievable as per the programme rewrite the other month but means I have practically zero tolerance for inclement weather or unforeseen problems. Having really pushed the subcontractor over the past few weeks we are a few days ahead in the programme but the critical piece will be the next backfill stage this week. We have a public holiday coming up which means no trades on site this weekend or mon, tue next week so we need to finish the next stage by this fri. This has already been compromised as the general superintendent ordered all machines to stop and knock off for the day over concerns of the dust levels which has meant we have lost a half day. The rail systems continue to be installed and all track has now been laid. The earthworks on the northern approach are now complete and the southern approach is probably only a week away from getting up to level. All this activity has meant it has been very difficult to build a bridge, it is almost likely other teams view the bridge as a hindrance and not the actual reason they are working in the area in the first place. The earthworks team seem to think they are special – which they are but not in the way they think! We did have a crossing point for plant over the tracks which got ripped out yesterday without any communication whatsoever which means to get from one abutment to another we now have to drive round onto the public road over Eastwood bridge and through the opposite gate which is a slight embuggerance. The sooner we get the backfill up to level and are able to traffic the bridge the better.

I still have responsibility for the eight other bridges along the alignment but as I have no more resources this has been mainly confined to administrative work regarding NCR’s and RFI’s. We have completed the substation work with the exception of two LV pits along an access road. Conduit issues still continue although the issues at Scalabrini and Kemps Creek have been resolved. I managed to cut the conduits cleanly enough for the HV cables to be pulled through today. The problem had been the limited space (40-70mm gap) to get any cutting equipment as deep as 700mm to cut the lower conduits. In the end we encased the conduits in mortar and got a concrete cutting subcontractor to come in to wire saw flush to each walkway slab face. This was fine for one side but when trying to cut the other side only 70mm away the wire saw tended to find its way back to the original cut so we ended up using 50mm core drill to stitch cut the other side which made a little messier but we were able to tidy up any buring and sharp edges to the clients satisfaction. Cowpasture Rd viaduct has now experienced the same issue as when an attempt to pull the cables through was made an obstruction was found. CCTV cameras showed some form of blockage so we a subcontractor has been employed to break out the conduits in the walkway to investigate. Having done this with the top conduits we haven’t found any blockage so far – could be a waste of money!

![IMG_2179[1]](https://pewpetblog.com/wp-content/uploads/2013/10/img_21791.jpg?w=225&h=300) Cowpasture Rd viaduct Combined Services Route (CSR) walkway

Cowpasture Rd viaduct Combined Services Route (CSR) walkway

Having spoken with John Reddie last week and again today I think we are close to finally confirming my design attachment with SMEC. SMEC have designed all the bridge structures on this project and I am hopefully heading to the bridge design team but SKM is a back up company which could be an option.

In other news, our little man managed to take 3 unaided steps last week which I managed to witness having come back from work an hour earlier than normal. He has done bugger all since so I don’t think he is in a rush to walk and quite frankly he can take his time as its hard enough keeping track of him in quadrupedal mode. My wife organised a group 1 year old birthday party for her baby group at the weekend on the park at Coogee beach which was great fun with about 60 people turning up unfortunately I had to take Ethan and myself home early after he projectile vomited over me 3 times for good measure – it was not a good look! Also finally got caught speeding the other week having missed my usual turning on the motorway (half asleep) I failed to see a cop car parked behind a forest as you do who clocked me at 90km/h in a 70km/h in the middle of nowhere on a straight road. He took pity on me fortunately as I explained I was a tourist in an unfamiliar area which took the fine down from $450 to $250 which is still scandalous, he looked genuinely disappointed when he realised I had a UK license and so he wouldn’t be able to award me any points. Having been here for 7 months and only just been caught speeding considering that is the only offence the NSW police enforce is not too bad but maybe they should focus on reducing the amount of shootings that go on here.