Repetitive Issues

As JM always said the biggest risk in construction is the ground conditions, and hopefully that is firmly behind the South Team now (though the basement team will have to deal with the slab-on-ground down there). The Upper Basement and Ground floor are finally complete, meaning we no longer need to backprop the slabs to the foundation making construction a much cleaner and less risky business. The issues with concrete continue though.

Not only is the level 1 slab a much more intricate beast in profile and finish it also uses a combination of concrete mixes to accommodate external areas that require additional waterproofing. Fig 1 shows the structural drawing detailing what concrete mix is required.

The white background denotes a 32MPa mix, the green hatching denotes that it should have a shrinkage reducing additive included to restrict shrinkage to 450micons/m (Eclipse) and the red hatching that there should be a waterproofing additive included (Xypex). From the figure it is now clear what the shape of the building will be for the subsequent floors. There are several awkward aspects of this:

1. A close control of the concrete entering the pump is required, and also skill in ensuring that the correct mix ends up in the correct location, in short competent concrete placing subcontractors (something we are lacking – see later).

2. The external areas all require falls to drainage points. As I have discussed in previous blogs, JHG design team, against delivery team advice, have decided to pour falls integrally with the slabs. In my opinion this is a money and time saving initiative that due to poor placement skill will ultimately cost more money and take more time to rectify.

The following images are examples of poor concrete placement on the last pour:

Fig 2, shows where the concrete placement subcontractor has placed a height marker to indicate the ridge line of the top of the slab falls – a good idea, as long as you remember to remove it. Fig 3. Shows a cutting disc that has been lovingly placed into the top of the slab and pushed in for good measure. These are just 2 of the many issues I have found with the finish of this slab. The others:

- Surface finish not steel trowel float to allow follow on trades to waterproof

- Set-down levels not adhered to and concrete poured too high resulting in edge gullies in what is meant to be a flat drainage channel.

- Concrete poured above the height required (no excuse as they use a laser height monitor.

- Footprints in set-downs (claimed to be formworkers returning to remove stakes used to hold in set-down forms)

Whatever the issues, whether it be poor concreting or trades walking over a finished slab, it states in the concrete placement subcontractors contract that they are responsible for the concrete finish, and for protecting their work. NCR’s are going to rain, especially a separate concrete contractor has now been contracted for the basement and is producing an incredibly better finish. The client even made a joke in the pre-pour meeting about it.

We have started forming up level 1; it is taking twice as long as expected though for 2 reasons.

- The formwork contractor has run out of competent carpenters to do the intricate angles and curves

- The formwork contractor no has no incentive to perform as he is now on a costs + contract where JHG are paying the invoices + a percentage.

All that said the formwork is looking quite good. It is nice to see some curves after 7months of straight edges. What the image also shows is the cast in Halfen channels that the precast walls lock into. The locations of the channels had to be estimated by the delivery team as the shop drawings from the precast panels had not been produced due to a delay in procurement. This may turn out to be another problem to fix down the line if the channels do not allow enough flexibility to accommodate the panel brackets.

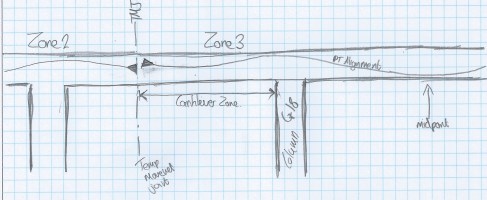

The current issue that I have found with Level 1 is that the structural design has not effectively checked the design of the reinforcement, cast ins, services or PT for clashes. It is causing many issues on site that are not helped by the individual subcontractors inability to liaise with each other. It is actually in their contract to liaise with other trades but none appear capable of doing so and resort to just complaining to any JHG employee who is available. It really is very petty. The issue shown in Fig 5 however is purely the structural engineers issue of not deconflicting PT and reinforcement. The issue is not in the alignment of the ducts or placement of the anchors but in allowing in the design of the reinforcement for the placement of the pans that allow the stressing of the cables to take place. As it stands the pans (400mm wide) do not fit side by side as designed between the vertical links, spaced at 600mm across the beam. My proposal was to stagger the PT ducts to allow them to fit between the links. This is only possible at this point at the PT is effectively being used to create a cantilever over a column to increase the capacity of the adjacent beam (See fig 6). It occurs to me that many of these issues could have been avoided by using a single BIM system and good communication.

Fig 5: Clash between PT pans and Reinforcement. Lack of understanding of how the structure is constructed.

In other news, I went on a site visit to Perth City Link (the project Rob Ridley worked on), which is nearing completion, 6months ahead of schedule and on budget – I am sure it has everything to do with Rob’s input. It was good to spend a bit of time with engineers from other projects to share experiences.

The PCH project has decided not to replace me when I leave in Dec. Not bigging myself up at all, but I think this is a decision based purely on cost and not thinking about the repercussions on the remainder of the team. Even a grad engineer would be a bonus, especially when a Grad engineer costs approx $75k a year and the value of liquidated damages in $180k/day. The maths is simple. The ongoing joke(?) is that i don’t do anything anyway – funny!

It was good to get across to see the Bainger’s in Sydney, if only for a little while. While the girls and little ones took in the sun and café culture, Jon and I went out to his site for a wander around. It was good to see how things are done on the East side of the country, and to be honest a little scary how different some of the procedure are at the PCH. I even caught Jon working when away from playing solitaire at his desk. David, I think this is a contender for the new prospectus!

It was also good to catch up with a few ex-RE’s to take part in the Tough Mudder event. As it turns out the ‘Wrestler’ fancy dress resembled more of a gay 80’s fitness instructor, but it held up well and nobody got broken. This weekend was the Perth Tough Mudder event with chicks, so a slightly fast pace than that with ex-Army lads who have embraced the civvy-spread.

Time for a little break now, so off to NZ next week to gather seismic research for my thesis, and may take some time off to spend with Nicky for our anniversary too.

Nik,

Sounds like there’s some PM work to be done on co-ordination meetings and risk registers/register reviews. Intresting issues with the PT tensioning trays, please take photos and copies of drawings – I might have a use for them… I’m not suprised you found JB working, I think he’s on a bridge on the river Kwai mission.