Archive

Second Week at the design office

After arriving last week, it has been none stop. Initially I found myself updating the drawings for Fisher Street (the Crossrail project).

However that only took a day, I was then tasked with doing a Cat 3 (external) check on some pile calculations. I was already worried about this task, then when I found out that the boundaries consisted of: 4 track line into Waterloo, Thames River and a 25 storey building. The most worrying of these boundaries was the railway line. The 4 tracks were positioned on a old brick viaduct, that had a 5mm capacity for settlement. Then I found out that the piles where for 3 x 30 storey buildings.

So I have now completed my calcs according to Eurocode 7. Initially I created the worst case scenario of the ground strata that would be encountered by the piles. From this I calculated both the shaft and the End bearing capacities of the piles. This was done by creating a spreadsheet (similar to the ones we did during phase 1) that has been setup, that all I have to do is input the dia of the shaft and the dead and live loads placed on the piles.I have then carried out a settlement calc using the Wallup software and the Tomlinson & Woodward approach. This has included both the long term and short term assessment. Both these conditions required differing inputs for the Clay and the stiffness of the wall (Secant Piles). I am now awaiting Skanska’s design to see if it comes anywhere near my cals. I hope they do!!!!!

The other big difference here is that each minute of the day has to be accounted for. That means that you have to submit a breakdown of the time you spend on each project. No more sending messages to Rich Phillips during the day, not if I want to keep the illusion of working.

Dickson Road Overbridge – Glenfield to Leppington Rail Line

Bridge complete….just about!

After coming back from a great holiday in NZ I pretty much expected a complete bridge and was quite surprised at how little had been done. The bridge is very close to complete but when I left on Fri evening there were still the throw screens to install and a fair amount of concrete surface work on the barriers especially where the slip formed barriers meet the sections that had to be hand formed. When I went on holiday there were four very small concrete pours to complete which and `i had arranged and booked everything in which would have only taken a week so I am not sure what they have been doing for the other 2 weeks. As a result I have still been on site a lot more than I anticipated in my final week rather than closing out all the QA paperwork and closing documents such as the ‘red line’ drawings and RATM’s. I have forgotten what RATM’s stands for now but it is simply a spreadsheet that documents all the contractual requirements where I had to write or file the relevant evidence that proves we have met the requirements such as a work lot number or particular photograph.

My last post showed one of the slip forming runs with a missing portion. Well, we did four separate runs of approximately 18-20m and that was run 3 which we did on the morning of the second day. That was simply a product of pour concrete supply by the concrete supplier. The concrete mix was a 10mm slump mix and as such they limit the transport load to 3m^3 per ruck. Throughout the two days even with constant phone calls we had a very poor service to the point where I requested that the project rep came out to visit site. The gap in the barrier was where we were waiting over an hour between loads to the point where the concrete would have gone off in the mould so we had no choice but to break out a section and start agin when the next load arrived. They accepted responsibility and I informed them that I would be putting in a claim to hand form that section which would be back charged to them. When I left for holiday I informed commercial about this but I get the impression it was ignored as the Commercial Manager doesn’t like to rock the boat so close to the end of the project. In my opinion no one especially the supplier wouldn’t have had a problem with this as they fully admitted liability especially when considering other issues we had with them. We were supplied the wrong concrete mix on the first day which was a kerb mix not a type F barrier mix which had 10mm stone rather than 20mm. After I sent it back I argued that this was their mistake and after they checked phone records of the order they apologised but the mix did not work well at first. The first run formed very poorly in the mould with most of the top section missing and having to be formed by hand with a 6 man crew training behind the mould. The subcontractor was blaming a lack of air entrainment within the mix but when I requested the air content of the mix (min of 4%) they said they had no capability to test the air content. The subsequent runs were much better so something changed within the mix. We had a further issue when the supervisor asked one of the excavator operators working nearby to remove some of the excess concrete that had been picked out at the end of run 1. This was now quite hard and as we had a 300mm foundation which had not been separated or saw cut it resulted in most of the barrier cracking along about 2/3 of its length. This meant we ended up breaking out most of run 1 and hand forming in on Dayworks which was expensive.

The roadworks seem to have been pretty slow but were complete when I left aside from street furniture and line marking so it looks like following the Road Safety Audit early next week the road should open next fri before xmas.

I start with SMEC on mon which I am not sure I am looking forward to as it is just going to mean more office work but I am hoping the hours will be more sensible. My commute is certainly a lot shorter so I should be able to bike to work a few days a week. At the moment I have had no official confirmation of how my rent will be paid and I have no car having given back the Ute on Fri. Hopefully I will be able to sort out the details at SMEC face to face with HR as JH certainly don’t seem to be keen to help – I find it ironic that being here to increase my contractual understanding I am with a company that has difficulty in honouring a simple agreement with the RE!

Last week of JHG, First Week of BG&E

It happened again!

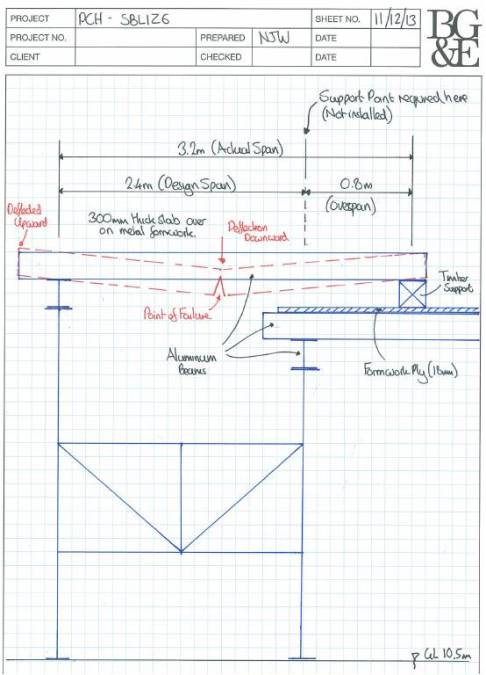

It has been a ridiculously busy end to Phase 2. The main reason has been another formwork incident in the South Block. During the pour of the last slab on level 1 the deck dropped by about 200mm. I wasn’t looking at the time but heard what sounded like a baking tray warping in the oven (Nicky still baking like a good wife should!), and immediately realised that it was the metal formwork buckling. I ordered all those still dopey enough to be standing on the deck to get off the slab, called the site manager and H&S officer. I then paused the concrete supply in line with the QA procedure implemented after the last settlement. What followed was the usual excitement involving the unions and subcontractors making the incident out to be bigger than it actually was (The ABC news channel quoted one of the concreters who had “seen his life pass before his eyes”).

On closer inspection it could be seen that the aluminium beam, on which the deck was bearing, had fractured causing the load to be transferred to the adjacent beams causing them to buckle. My first assessment was that it looked like a combination of over-loading and material failure. See image and calc sheet for sketch. The investigation found that the falsework was not constructed in accordance with design and the beam fractured because it had been overloaded due to an additional 800mm onto its design span. Though the falsework had been inspected by a 3rd party engineer, it would not have been possible for him to see the error in construction due to a ply sheet obscuring the view. The decision is yet to be made on the responsibility for the incident, but I think it is safe to say that the 3rd party engineer’s indemnity insurance and the formworkers are likely to take the hit.

What is interesting about this is the timeline surrounding the pour. The slab was originally planned for the Thursday, but was was delayed to the Friday due to a steel delivery issue, then further delayed to Saturday as the pour clashed with another large pour in the North block. It was then returned to the Thursday at 3pm on the Wednesday, resulting in an incredibly compressed timeline to complete of the slab (Steel was still being fixed in one corner of the pour as the concrete was flowing in the other). In my opinion this should never have happened, once a decision has been made it must be stuck to otherwise confusion reigns. The element being poured should always be ready the night before in order that quality and safety can be preserved (but maybe that is just my military head talking, as it seems to happen quite often here).

Though the incident would probably have occurred even if the pour had been on the extended timeline, it highlighted the lack of resources in the South Block and the pressure to perform to a demanding schedule. The advancing of the slab pour was dismissed as irrelevant in the investigation by the director who ordered it the acceleration – nothing more was said.

We are now left with this……..

Pretty much everything I feared would be the result of the original settled slab (SBUBZ3) is now hapening to SBL1Z6. Jackhammers have been going endlessly in a vain attempt to recover some of the lost time. Ironically to save 2 days we have almost certainly lost a week. The construction director still wants to complete level 2 by Christmas – lets hope Santas little helpers can break concrete out!

I have been a little more involved with the commercial department recently. Mainly running through the monthly claims and assessing their validity before forwarding to the Project Director for authorisation. PCH has not been the best for experience in this element of professional development due to the separation of the commercial teams from the site team. This has got better over the months but it is still a difficult beast to work with. I hope to gain more contractual experience with BG&E in phase 3.

In my time at PCH, I have been responsible for pouring 42% of the concrete in South block (over 5,000m3), this was mainly used in 14 suspended slabs, but also in 290 columns and various other walls and stairs. I am content that I know how to sequence and construct a building but painfully aware just how much detail is involved in just the smallest element of a structure. It is clear that the devil is in the detail and an engineer must know the structure inside out to ensure it is built correctly. This is a learning point that I will take to phase 3 as minimising the different details is key to simplifying construction and hence improving quality.

I have mixed emotions leaving the PCH project. Whilst excited to be starting the design attachment, I do feel that I am leaving the South block team even more under resourced. Though this has been raised at every team meeting, the PM has been unable to secure the hire of a replacement engineer. Whilst not the most effective engineer in the world, I think the reduction of 33% of the engineer coverage, which can only be a cost saving measure, takes no account of the wellbeing and workload of those who remain and is likely to have detrimental impact on the continuity within the team.

After a brief meeting with BG&E last week, I will be moving into the waterways and bridge department initially, but will be a kind of ‘floater’ with the ability to get involved in anything that takes my interest. I hope to get involved in the city’s new underground bus station design, some bridge maintenance/design and try to get up North to work on some of the mining infrastructure.

In other news, this is the first time in my life that I have not been issued clothes for work, Tesco’s, the Army, and JHG all issued me a uniform. Now going into a swanky city office environment I have had to buy new clothes. It was a little like back-to-school shopping with my mum, but I came away with the obligatory office attire of tight trousers, and pointy shoes. I am not sure how long this will last before I break out a couple of polo shirts and the chino’s!

First week in the design office.

The first week has been a gentle break into the design office life. It is clearly evident that consultancies are scratching around for work prior to Christmas, highlighted by 18 consultancies bidding for a potential A$100k upgrade of a culvert in the Perth Hills. If it is deemed that the structure is already adequate after the site investigation, the contract will only be work A$30k. If it is won by BG&E, it is likely that I will take charge of the ‘Bob’s Crossing’ project (I see it as a warmer in the bank). The tender response is due in prior to Christmas, and I will be reviewing it tomorrow. My thought currently is how to make the tender stand out from the others, which for a simple investigation is fairly difficult, however, a little research shows that the area is used by families for picnicking and kayaks for entry to the river, so potentially there may be an option to provide a simple jetty or slipway at minimal cost.

I am currently working in the waterways department, investigating the flood flows over 9 small bridges in the South of WA in an area called Denmark. The longest of these bridges is only 8m and barely 1.5m off the channel bed, but the flood index flows need to be calculated to design the crossings. My thoughts at the moment are that culverts would be the best solution for these rarely used tracks through the Jarrah forests. They will be quick and easy to install, have a good bearing capacity for large trucks to pass, and will be cheap to maintain. The contract is part of a panel contract with the Main Roads department of the WA government, so there is no competition for the job. It appears that the investigation is completed to size the crossing/barrels and then handed to the MRWA to do with as they wish. Pretty easy for the consultancy really, but done well and they will keep coming. As I understand there were issues with the last set of reports that BG&E submitted; different formats, different headings, elements missed. Most of this was due to splitting the jobs down to individuals and not checking effectively before issue. It appears that the directors have grasped this error and are leaning heavily on the QA and management of work packages within the teams. It seems like common sense to me but maybe I can bring a little coordination and admin (squaring away) to the party.

As suspected, I feel a little like a BeeGee walking around Perth CBD in pointy shoes and tight trousers, but everybody seems to be doing it, so maybe for once in my life I am in what they call ‘fashion’?

Oh dear!

Many of you will already have seen this photo on facebook but for the benefit of those who aren’t regularly bored by photos of my wife and children here’s your opportunity to laugh at my expense.

So Day 1 Ramboll UK geotechnics team: ‘We’ve got a couple of projects lined up for you to work on; one is the foundations for this bridge the concept that we’ve been given is pretty much unbuildable so I want to look at a sheet pile retaining wall option and the other one is a small domestic extension that requires a retaining wall design because the garden is on a slope. So here’s how to get into the road bridge file, here’s a programme called Wallap that we use for this, why don’t you see how you get on?’

Whilst that sounds rather flippant, this is exactly how it felt. Tonight I have been reading the Great Orator’s lesson notes in the vain hope of at least knowing the difference between drained and undrained parameters. I’m going to the sloping garden tomorrow with a ‘panda probe’ which is an electronic stick to hit the ground with, apparently one of the team did an entire MSc thesis on correlating hitting this thing and SPT values, I haven’t met him yet but I’m sure he’s hilarious.

That’s all for now, I needed to share my despair, this time I really will get found out.

Headache

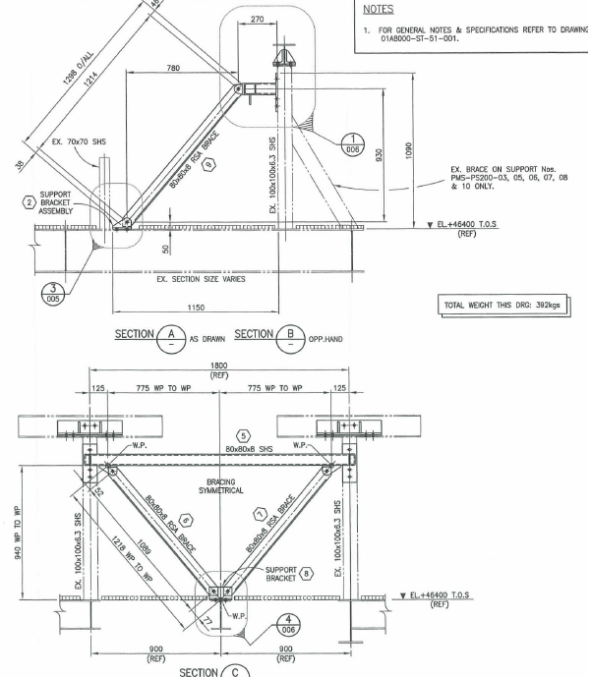

Clair Manifold Support Bracing

I have been trying to schedule this small piece of work for the last two months. I originally had it in the plan for December to execute during a well head maintenance period. Due to taking on the Clair coolers and the number of issues we saw at the close of that project, this one wasn’t ready for delivery.

Front End Loading

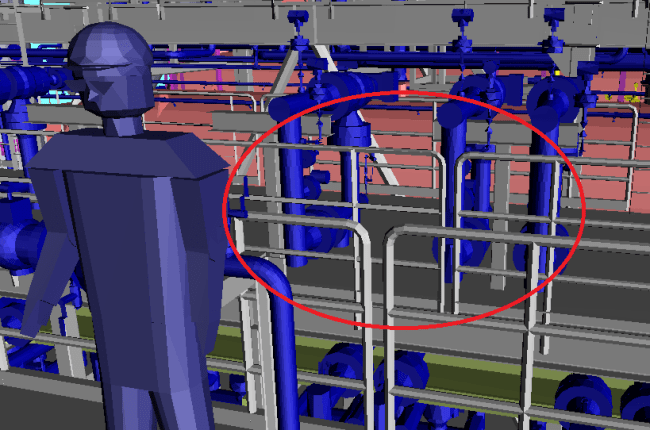

This particular job is the final part of a larger project to standardise the supports on the production manifold on Clair. Development of wells is such that this had been developed somewhat ad hoc, with each flowline or group thereof being a separate project and therefore subject to different design in the supports. In 2011 the standardisation piece was completed but a Project Change saw the development of additional cross bracing to reduce vibration resulting from the modifications. The vibrations are not so severe as to threaten integrity, but it is something that should really be address when considering preserving the long term integrity of the system.

(Above – T support on the production manifold)

(Below – Proposed new bracing to these T supports)

The bracing itself is not the issue, it does not breach containment and is affixed to the primary bracing. It is all drilled and bolted and therefore can be installed during normal production. However, the bracing results in a clash with the existing temperature sensors which requires for them to be removed and replaced with longer stems. The manifold cannot be flowed while these transmitters are removed. A simple probably £20-50k project is stalled because to run it in isolation would cost around a days production, 30,000 barrels at $100….

This part of the wider project was developed as a project change when it was identified that the new supports would not mitigate against vibration effects sufficiently. So the initial Define was not completed properly, that much is clear. This has been compounded because the project change has been developed with no thought to the schedule implications of replacing the transmitters. It is clear from the Workpacks and the WGPSN plan for the work, that an assumption was made that the transmitters could simply be replaced prior to installing the new bracing. I can find no evidence that any other solution was looked at for this problem. I would have thought that connecting the horizontal part of the T supports and diagonals down to the floor from there would avoid any clash and if can’t schedule this project into a planned outage, then I will be recommending that the project goes back into Define to better understand and develop a solution.

Time is Money

The hardest part of this process has been finding the right person to discuss the problem with to identify a way forward. The only planned outages generally fall into the category of TAR (Turn Around) or Wellhead Maintenance. There is no way that this work would get into a TAR, and if it did it would be the first to get thrown out again. The well head maint period is my best bet and they happen about twice a year with individual wells taken off-line for various workscopes to get completed. Clearly, no engineering manager is overly enamoured of the idea that I parachute some extra work into their plan and getting traction with the Wells team has been tricky. I now have the ear of the Wells team lead and I am hoping to get to a definite yes or no (expecting a no).

Bottom Line

This is probably the least important piece of work I have going on at the moment, but it is causing a disproportionately large headache. As an engineer, design should never take place in isolation, even if an SOR or other such mandate imposes project limitations, surely we must be professional enough to look beyond these boundaries for complications that the original author may not have foreseen?

End of the Chapter

I have just returned from my leaving breakfast having received a presentation piece from the whole office, a piece of a welded attenuator to help remind me of my experience!

In the last few weeks I have been winding down and handing over and have the following to report:

Commissioning – Pressure Integrity Testing – The animal holding rooms were checked for air tightness. These rooms are used to hold animals prior to and post testing so they need to be sealed inorder to prevent the ingress of contaminents or anything that may affect results. The testing is done by sealing the door with a vacuum pump so that the pressure becomes negative (pressure differential of 0.25 inches of water) then soapy water is sprayed on areas a leak is suspected of occuring. If there is a leak bubbles develop (see below).

Considering this was a retest it was disappointing that all 5 rooms failed. Most corners leaked, all the air tight plug sockets leaked and all the data points leaked. It has taken them 3 weeks to caulk these up so far…

Filter Installation – The sub attempted to install the pre filter (particulate), HEPA (High Efficiency Particulate Absorption) and HEGA (High Efficiency Gas Absorption – charcoal) in to all the lab filters. In the initial installation meeting the manufacturer stated silicon grease is need on the filter edges to stop them adhering to the housing. If not the filters stick and tear open releasing allsorts of nasties and creating a big clean up problem. This was agreed by all as essential until the actual event when the sub decided he could save money and get the job done quicker by not greasing. On investigation we found this was a recommendation and not specified in the contract so $14,000 later the sub is now greasing, on the grounds that this is a safety issue and should have been in the contract.

Sound Attenuators – I have now visited all 572 sound attenuators in the building and established all the parts of the change have been carried out – that one crew of 3 was used to change over 372 of them to the welded standard, that the bolted flanges with butyl gaskets above and below the floor (as opposed to the clamped sleeve fit originally installed) are installed and the rooms are all sealed between floors. This took 240 days which the Contractor is claiming as an extension to the contract time. Although I will miss the argument on why only one crew was used (a welder and 2 workers, not really technical) the time will be given because there is no physical way the project will be complete by Feb 14. This will take them over the current finish date of Jun 14 which I still think is optimistic. There is a reluctance to call for liquidated damages because the subs on this project are nearly all going bust (bad for the Government to be seen destroying business) and the project is too big to fail. However the cost is still negotiable as $12,000,000 seems excessive! This due to a number of overheads and the fact that relate to the change occuring in 8 parts. However our estimate is currently $3,000,000 for 100 days.

Vacuum pumps – Finally the designer gave me the calculations for the vacuum pump sizing. The issue boiled down to an error in the specification the designer added to the drawing. The pumps were listed at 104 ACFM at 28″ Hg each and should have been 330 ACFM at 28″Hg each. This meant the expected flow rate for 2 pumps running to support a diversity of 35% is 37.85 Standard Cubic Feet per Minute (SCFM). The filter is rated for 25 SCFM, so really is undersized. The parallel arrangement for the extra 25 SCFM filter was correct. We had a teleconference with the sub, designer and pump manufacturer who all agreed by the end that this would work with no back pressure issues for the extra resistance. Mission complete. The designer admitted fault and will do the revised drawing for free. The filter is still going to cost $5000 each to install, one in both B and C building.

Floor Drains – our cracked floor drain issue never really ended. On review we convinced the contractor that we needed to check the drains again. The first test is to run water in the drains to check they are not cracked too. We then requested that the drains be tested by pouring water into the drain to simulate the flood condition they are designed floor. This is because the drains were all installed in 2 parts. The recommendation is that plastic flashing is incorporated in the joint to so that water going between the drain body and concrete is directed to the weep holes.

The flashing should sit between the base piece and the plate below the strainer

However the spec did not call for flashing so we are now worried that the drains are going to get leaks round them when the concrete shrinks and cracks. As some of these drains are above the labs this could be disastrous. We have agreed to test 20% focusing on the accessible ones to minimise damage. However if over 10% leak we will need to consider remediation which looks like core drilling a hole around the drain an inch deep then filling the void with caulk! Testing starts next week.

Pump 17 – The sub organised a meeting for the designer, contractor team, USACE and the motor manufacturer to discuss the motor performance. As anticipated the manufacturer rep was a sales rep and had not understood the test results sent to him, paniced and promised a new motor! It arrived a week later but has not been fitted yet. We are still waiting to hear what the in rush currents should be. I suspect if this motor runs well enough the whole episode will be forgotten and we will continue with the oversized pumps, throttled to death and wasting money through inefficiency before burning out prematurley.

Whole Building Maintenance – the contractor was unable to produce the revised operation and Maintenance program for the building in time for me to assess it. The recent maintenance report is better but still needs tweaking so I leave the system in a better state with all parties talking amicably and my successor starting dealing with a nearly finished product.

Tomorrow I am giving a presentation on the Corps to my fellow officers before starting phase 3 on Monday.

And in other news:

We had another Staff Ride for the military guys to Gettysburg, this time all day with a lecturer from the War College to further explore leadership. There is always something new to learn here.

The Engineer Memorial at Gettysburg, ironic because there were no engineers at the battle!

The Ravens have won a few games now and are in the playoffs for the SUperbowl but their chances of a double are slim. We were invited by friends of mine in harrisburg to Thanksgiving. We ate turkey and ham until we couldn’t move then had pumpkin pie for dessert, great training for Christmas. The Black Friday sales were not too bad in Hunt Valley so I have done half the Christmas shopping and we took the kids to the Mummies (think egyptian) exhibition in Baltimore, stopping by the German Market on the way for a gluwein. We had back to New York this weekend to see the Christmas sites and neet Santa at Macy’s. Silly Season is well and truly here.