Archive

Oh dear!

Many of you will already have seen this photo on facebook but for the benefit of those who aren’t regularly bored by photos of my wife and children here’s your opportunity to laugh at my expense.

So Day 1 Ramboll UK geotechnics team: ‘We’ve got a couple of projects lined up for you to work on; one is the foundations for this bridge the concept that we’ve been given is pretty much unbuildable so I want to look at a sheet pile retaining wall option and the other one is a small domestic extension that requires a retaining wall design because the garden is on a slope. So here’s how to get into the road bridge file, here’s a programme called Wallap that we use for this, why don’t you see how you get on?’

Whilst that sounds rather flippant, this is exactly how it felt. Tonight I have been reading the Great Orator’s lesson notes in the vain hope of at least knowing the difference between drained and undrained parameters. I’m going to the sloping garden tomorrow with a ‘panda probe’ which is an electronic stick to hit the ground with, apparently one of the team did an entire MSc thesis on correlating hitting this thing and SPT values, I haven’t met him yet but I’m sure he’s hilarious.

That’s all for now, I needed to share my despair, this time I really will get found out.

Headache

Clair Manifold Support Bracing

I have been trying to schedule this small piece of work for the last two months. I originally had it in the plan for December to execute during a well head maintenance period. Due to taking on the Clair coolers and the number of issues we saw at the close of that project, this one wasn’t ready for delivery.

Front End Loading

This particular job is the final part of a larger project to standardise the supports on the production manifold on Clair. Development of wells is such that this had been developed somewhat ad hoc, with each flowline or group thereof being a separate project and therefore subject to different design in the supports. In 2011 the standardisation piece was completed but a Project Change saw the development of additional cross bracing to reduce vibration resulting from the modifications. The vibrations are not so severe as to threaten integrity, but it is something that should really be address when considering preserving the long term integrity of the system.

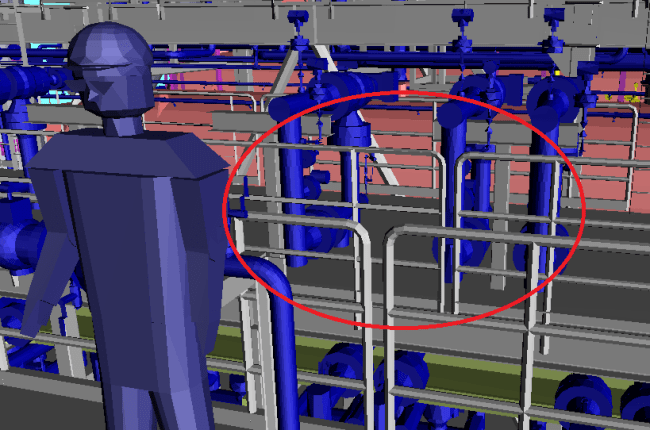

(Above – T support on the production manifold)

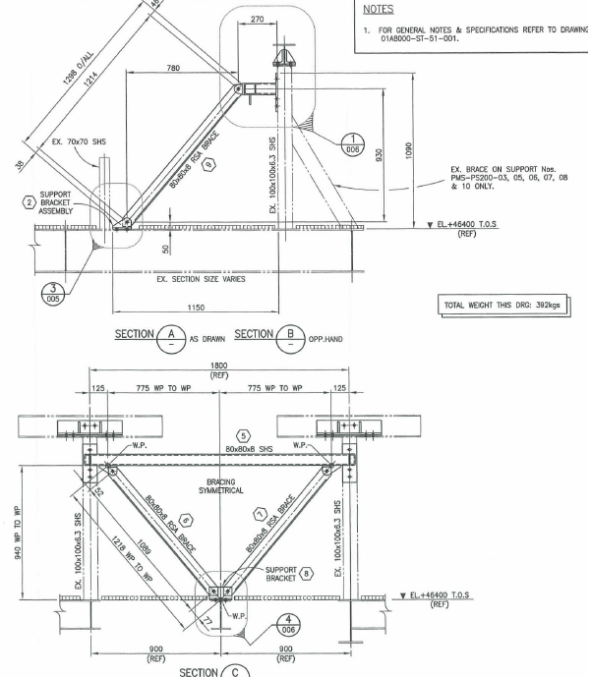

(Below – Proposed new bracing to these T supports)

The bracing itself is not the issue, it does not breach containment and is affixed to the primary bracing. It is all drilled and bolted and therefore can be installed during normal production. However, the bracing results in a clash with the existing temperature sensors which requires for them to be removed and replaced with longer stems. The manifold cannot be flowed while these transmitters are removed. A simple probably £20-50k project is stalled because to run it in isolation would cost around a days production, 30,000 barrels at $100….

This part of the wider project was developed as a project change when it was identified that the new supports would not mitigate against vibration effects sufficiently. So the initial Define was not completed properly, that much is clear. This has been compounded because the project change has been developed with no thought to the schedule implications of replacing the transmitters. It is clear from the Workpacks and the WGPSN plan for the work, that an assumption was made that the transmitters could simply be replaced prior to installing the new bracing. I can find no evidence that any other solution was looked at for this problem. I would have thought that connecting the horizontal part of the T supports and diagonals down to the floor from there would avoid any clash and if can’t schedule this project into a planned outage, then I will be recommending that the project goes back into Define to better understand and develop a solution.

Time is Money

The hardest part of this process has been finding the right person to discuss the problem with to identify a way forward. The only planned outages generally fall into the category of TAR (Turn Around) or Wellhead Maintenance. There is no way that this work would get into a TAR, and if it did it would be the first to get thrown out again. The well head maint period is my best bet and they happen about twice a year with individual wells taken off-line for various workscopes to get completed. Clearly, no engineering manager is overly enamoured of the idea that I parachute some extra work into their plan and getting traction with the Wells team has been tricky. I now have the ear of the Wells team lead and I am hoping to get to a definite yes or no (expecting a no).

Bottom Line

This is probably the least important piece of work I have going on at the moment, but it is causing a disproportionately large headache. As an engineer, design should never take place in isolation, even if an SOR or other such mandate imposes project limitations, surely we must be professional enough to look beyond these boundaries for complications that the original author may not have foreseen?