Archive

Honey Comb Concrete

I have learnt today that this week that the term “Honey Combing” on a construction site has nothing to do with the thick sweet substance that Ryan pours on his porridge in the morning. Honey Combing is in fact the term given to poorly Lid concrete that results in voids in the finished surface of concrete.

Removing the form work during the excavation revealed a large area of steel rebar that the concrete had failed to cover. The cause was determined to be number of factors:

1. The operatives were instructed not to compact, vibrate and tamp the concrete excessively during the pour as the beam in question contained Geo Thermal pipes that were at risk of being damaged.

2. The concrete mix was not loose enough to allow it to flow around the steel to fill the void. In fact some of the slump test during the pour revelled stiffer then required concrete. The slump had been determined at an average diameter of 550mm and we had loads that varied between 650 and 400mm. The result was the expected dismissal of the concrete and a reshow for the concrete contractor it was a case of working the concrete a little harder. This was principally due to the fact that the concrete was already being pumped by the time a slump had been completed. Poor practice in my mind.

3. However ultimately I feel that pour steel fixing was the principal cause, although it is not a theory accepted among the entire site and principally not by the steel fixers. The pictures below clearly show that steel bars are packed too tightly and have prevented any concrete from passing between the bars to fill the void. The steel should in fact be lapped one bar on top of the other with the use of a cranked bar. In this case the bars were allowed to lie next to each other.

The upshot of all of this has been not and engineering problem more of a contractual problem. The making good of this void would seem fairly straight forward. The use of a fast setting cementitous mortar although it must reach the same strength or better then the surrounding concrete. My fag packet engineering behind why I feel this is a minor engineering issue is that the missing area of concrete is in fact only cover concrete and that the concrete within this region is concrete in tension with and in fact it is the steel that is carrying the load. Given that the beam is a rectangular section the area of concrete that could be removed would be half the depth of the concrete as all below the centroid would be in tension. The greater issue is that this section is typical in terms of steel across the site. A more worrying concern is that there may be more voids that can’t be seen. If a void is within the compressive section of the beam, typically here it would be the upper half of the beams, this would significantly reduce the load that could be carried across the beams. The quality control during the steel fixing was fairly stringent and while most of the team on site are confident that there would not be any further voids I looked into how one might determine if there were any further voids . The solution that I had come up with was the use of a ground penetrating radar. These appear to be fairly available for hire by many companies on line and are a very simple non invasive method of detection. Unfortunately the confidence of the team and the reluctance of the expense and delays to the programme means that we won’t be playing with any GPR systems and a non compliance report has been raised, once the making good has been completed the case will be closed.

New Children’s Hospital (NCH) Perth

Western Australia (WA) Wait Awhile!

The Project

The New Children’s Hospital Perth has been in construction since Jan 2012 and is the largest structural project JHG has undertaken at A$1.2Bn. This is the same project as Nik West but I will be looking at the services not concrete, however since Nik left the project it has changed quite a lot. They are still pouring concrete for a project which is due to be finished next summer! However the services are at full steam ahead. I am lucky enough to spend most of my hours in the basement, which the only benefit is its slightly cooler! I work with one other guy and we are responsible for all the services within the basement, we have split the basement in two, I have responsibility for one half which is East and West block which can be seen in the following picture as the blue and red areas.

As you can seen from the pic it includes two substations, LV and HV, one large Hydraulics room including reverse osmosis, grey water treatment room, pneumatic tube room, fire pump room, multiple air handling rooms and all the services which connect them to say the least. My initial challenges are getting a full understanding of everything in each room therefore I can actually ensure everything is done correctly. My role is Services Coordinator which basically means everyone asks us everything about the services!!

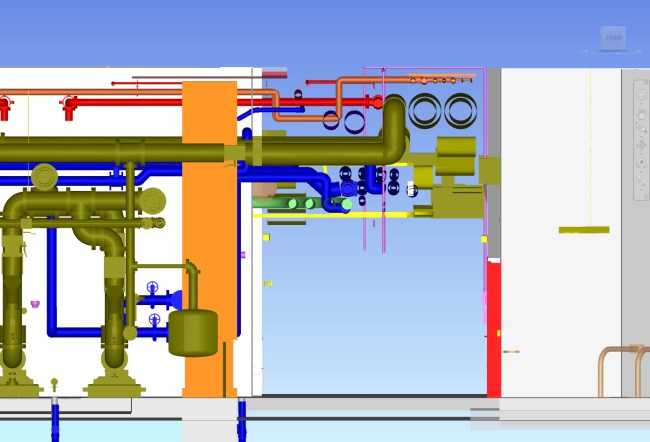

So after my chat with my boss he said “Ollie the corridor of death is 6 weeks behind this is your challenge” the following pic is the corridor it will probably be a small focus of most of my blog’s as its the main artery of all the services. This is how it looks now:

At present fairly sparse, with only wet fire (sprinkler system), fire main, Very Early Smoke Detection Alarm (VESDA) and some drainage. The hardest thing is the project is run using a BIM 3D model to ensure clash detection but not everyone one has bought into it, so we use the model but also have to do it by hand having discussion groups with the contractors and de-conflicting. I will go into more detail with the BIM modelling in the future. The following is a cross section of the corridor:

As you can see its busy and a lot to go in.

LIFE IN WA

Say no more…