Archive

And now for my next project……

Like my colleagues, the blog has been on hold whilst I finish my thesis. Since then it has been hi tempo in the office too, as we complete (mostly) the Marine Terminal HVAC design and start on a UAV hangar design in upstate New York. As rather a lot has happened in the last few weeks I shall try and make this bite size.

Quantico: My invitation from the USMC meant I was able to sit in on a 1 star R&D briefing on the latest energy saving measures to be implemented. This included not only changes in policy but a whole host of kit that can either harvest or generate energy to supplement current needs. This includes boots that can charge your radio batteries as well using waste generator heat to wam up shower water. A very ineresting experience particularly as the USMC seems to have less money than we do and is getting industry to do the research for them rather than doing it themselves for the sake of those lucrative government contracts. Needless to say some of this experience ended up in my thesis.

Caven Point: As with all design project coming to an end, this has been a period of mind changing and total redesign. This including swapping ouot VRF for VAV systems, totally removing VRF from workshop areas and changing all the asociated air handlers, make up air units, louvres, fans etc accordingly. Then at the 90% we received requests for additional items including, extra partition walls in large office areas (total recalculation for the room(s) and equipment resizing), changing A/C to just ventilation in three warehouse rooms (more equipment redesign), Air Curtains over all roller doors (to stop flies and heat loss – a ‘helpful suggestion’ to the end user from one of my team) and all this with a week to do just after the thesis deadline. The lack of communication between the design team has beenthe biggest frustration in this period. It still happened that every day I log on and there is a change on the drawing that affects me considerably or the user has realised that something is not quite as they remember asking for and needs changing. Part of the game I know but the inability to stick to the design requirements set out at the beginning of the project has added delays. The whole process is so rushed that any Contractor taking this on stands to make a fortune in changes due to design issues. At least I won’t be around when that happens……..

Fort Belvoir VCC: I attended the project kick off meeting in early April which turned out to be a classic case of ‘You can lead a horse to water…’ with some of the shareholders. To recap, this is a visitors control centre which processes people attending mostly retirement functions who are not DoD employees. A glorified guard room in short. However this facility must also be a 24hr facility, blast protected and strategically placed, just in case the worst ahppens. Located after the turn in to base but before the main gate, it is still a design that needs refining hence the meeting. What started off as formality eventually ended in a 3 hour contradictory argument. But to explain this I need pictures:

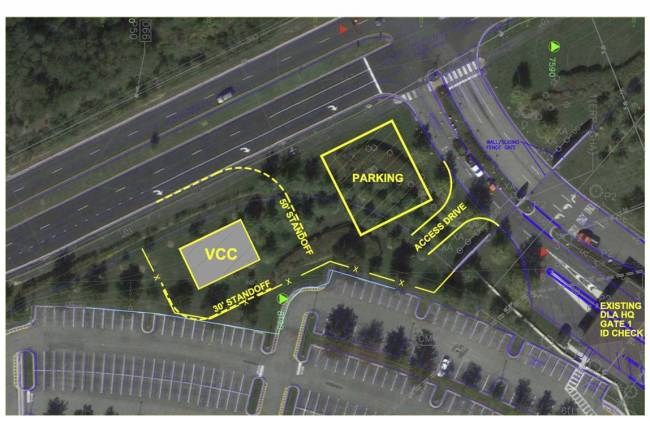

Option 1 the Garrison Teams favourite optioin

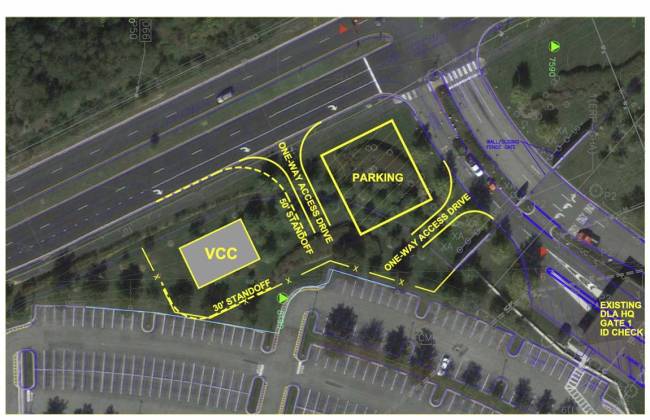

Option 2 Everyone elses favourite

From the start the Garrison maintenance team said option 1 was the only choice. We questioned this because it clearly interferes with traffic going in to the main gate, causing a potential bottleneck which stop entry to the post or could easily be missed in which case the only way to get back to it is to go on to camp, turn around and go back on the highway. We were politely told this would not happen because the only people using this facility were going to be going to retirement parties normally held mid morning, coming infrequently and that people turning around behind the gate is just what happens (I should add that this is the most heavily guarded gate I have seen in the US!). When we pointed out option 2 offered a far less likely chance of causing obstruction because it could be accessed off the main highway and if we made this road 2 way and no one would ever need to go through the gate in order to turn round, thus improving security. We were told that this choice would obstruct the rush hour traffic on the highway because up to 100 people could need passes all at the same time, any time of day (probably rush hour) and that the gate guards were quite happy waving people through to turn round! There was still no resolution after 3 hours so it was left to an admiral to make the call. I think he diplomatically chose a design that was a compromise. From the mechanical point of view, one of the staff was keen to get renewable energy in to the building. They wanted solar water heating and a geothermal heat pump. We presented the case that solar water heating was not financially viable for a single toilet sink and that a geothermal heat pump would be $40,000 more than air source heat pump and would take over 30 years to pay back. The customer went away unconvinced that money should be a barrier to green technology!

Fort Drum UAV hangar: Because the VCC was so small I was given the chance to put my radiant floor heating research to the test with my next project. This is $30 million UAV hangar in Northern New York State where the minimum temperature is around -30 degrees and 35 degrees in the summer. Most of the building is a standard design but the loads for the location need to be recalculated. However the hangar floor (25,000 sq ft) is going to require full underfloor radiant heating and no one in my department has any experience so I get first go! We have no design software for this so it is back to hand calcs to work out all the losses etc for sizing. Still no idea how I will draw this system either. And a 65% design is due in 2 weeks!

A UAV hangar

OPD: In the USACE Officer Professional Development course we are given the chance to get an insight in to the responsibilites of the District from the eyes of the Commander which means seeing some pretty interesting stuff in the local area. We started with an American PFT complete with 2 mile run, which we all passed, before heading off to the debris vessels. These are used to keep the water ways clear of logs and other debris as well s scooping the bodies out when aircraft land in the Potomac. Next was the Springfield site where a specialist team was clearing mustard gas and UXO from a former university house basement using equipment that would not look aout of place at USAMRICD. This required great tact from the team in dealing with the public who are understandably twitchy about having UXO in theback yard! We visited the Washington Aquaduct to see how USACE produces most of the water for the DC area before a visit to the new Intelligence Community Campus Building. The current buildings are being ripped out, including the fascade, then are being rebuilt as lecture facilites to meet modern code as they were nearly all built in the 50’s and 60’s. This propject had encountered numerous problems with the public, who did not want to see any new building and were against all construction (even if it is in the National interest). This resulted in delays and a reduction in height of the multi storey carpark so that it is below tree top height. Our next day started with a VIP trip to the Pentagon. This building is absolutely enormous (2.4 times the floor space of the Empire State Building) and was modernised recently to be a little town with every single type of shop so no one ever needs to leave. We were given a brief on the role USACE plays in the DoD and then saw the site of the 9/11 impact where a Chapel of Reflection commemorating those who died, is located. After a hasty lunch we tool the metro to the Capitol Building where were given a guided tour which included showing us the few areas the British did not burn down in the War of 1812. We are able to see the Senate debating but this was not that exciting with only 2 senators in the chamber. The final part of the experience was a trip to Arlington National Cemetary which is managed by USACE too and is still Army property. The plot size is enormous and they are having to expand to meet the projected demand until 2050 (barring no more major wars obviously). The most impressive part was seeing the guard change at the Tomb of the Unknown soldier. If you think you can do rifle drill, google this and find out how it should be done!

And in other news:

The weather has been a little unpredictable recently, with a retaining wall collapsing that took half a street with it in central Baltimore. The rivers rose 6ft in 12 hours and we are getting the same again tonight. Wildfire season has started in California which only mention because the USMC base I was invited to in order to see the demo of the equipment mentioned at the briefing has just been evacuated!

I was able to volunteer for a STEM evening at a local Elementary school where the kids learned how to build bridges using toothpicks and marshmallows. This was optional for the kids but amazingly we had 3 full classes and a merry time was had by all.

And on the home front Warrick is really enjoying baseball and develping a good swing, Ava has now turned 4 and we are making the most of the last few months by day tripping to New York, Philadelphia and Amish country with a break in Ocean City due in 2 weeks. So much to do so little time……

Bridge Parapet Traffic Barrier Design

It has been a while since my last offering but now that my thesis is in and forgotten for the time being and I have finally started my CPR reports here is an update on life in the design office.

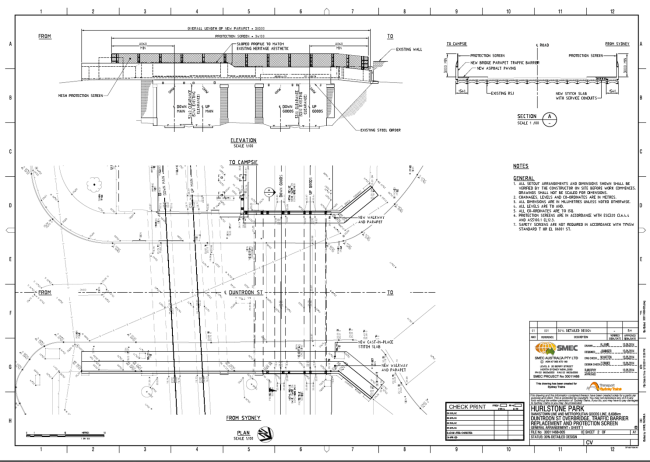

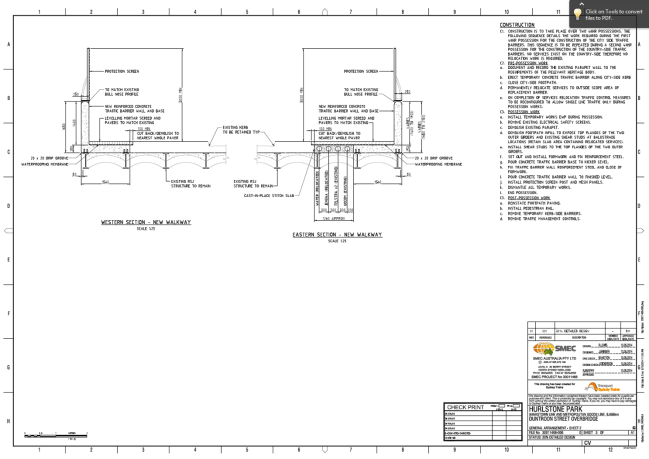

I seem to be the popular choice at the moment to compile and submit tenders, which doesn’t seem to be affected by the fact I have not won any yet because I have just received another one (no doubt my last) while also currently managing three design projects. Over this attachment I have been involved in nine projects (6 tenders and 3 design/PM). The one I have been working on intermittently over the last few months is the detailed design of a traffic barrier to replace an existing masonry parapet in order to comply with current standards. I have subsequently designed a cast in-situ barrier to be constructed on the outside of a 100 year old ‘jack arch’ rail overbridge. I have also modelled the bridge using Microstran to see if the existing structure can accommodate the traffic impact loads. A traffic assessment at the concept stage identified that an intermediate traffic barrier performance was required which stipulates an outward horizontal load of 180kN at 1.1m above road/footpath level, as well as a longitudinal load (to be applied simultaneously) and a vertical load (to be applied as a separate load case). The Australian Standard AS5100 (Bridges) does not explicitly provide a detailed analysis procedure for bridge barriers. As a result, current practice uses American Association of State Highway and Transportation Officials (AASHTO) design procedure based on yield line analysis. The design deliverables for the project are; Concept, 30% detailed, 70%, 100%, IFC. I have just finished getting the 30% DD drawings together to submit to the client (Sydney Trains) by the end of this week in a hope to have the 70% design complete and submitted by the time I leave. I have had to commission a Statement of Heritage Impact (SoHI) and I am now in the process of getting the environment team to produce a draft Review of Environmental Factors (REF) that may be affected by construction such as dust, noise, heritage, social and economic impact to the area. Because it is an overbridge that spans over two rail lines the work will impact rail services during two planned 48hr possessions as well as closing one lane and possible both to vehicle traffic during construction. The amount of work and consideration involved for all aspects of the project all stems from successfully identifying the stakeholders at the very start and you soon realise how many people, organisations and authorities are involved in successfully implementing a project. Below are the drawings at 30% design not showing reinforcement.

I have also been involved in ongoing managerial aspects with the maintenance centre column repair design as per previous posts and a fire protection upgrade design on a cable shaft at central station in the middle of Sydney CBD. I have not carried out any design for this but I have been given the job of PM to bring the project to completion. I also recently submitted a tender for a 1.7km cable route design which was valued at just under $300K with a rather vague scope of works. There was little time to clarify or ask for more detail on most of this – largely because of the fair tendering process every consultant must be informed if a question is asked and meanwhile you lose precious time which you may not have – so I compiled it based on the site inspection and project brief. The client (Sydney Trains) subsequently came back to all the consultants that submitted a bid and have changed the scope somewhat. It appears they put little thought into the original brief and this additional information contradicted previous information. I subsequently revised our originally fee to just under $400K having it reviewed by senior management. The whole episode made me view the client as very unprofessional and rather annoyed me. For instance one comment stated that all assumptions in our proposal should be deleted and the proposal should be based on factual information and the fee should account for the risk accordingly – what planet are these jokers on? It seems very odd – and the seasoned pro’s in the office viewed this in the same way – that the client expects to be entirely risk free. Especially if their own SoW is woolly at best. One of the first tenders I did had a 1000 page brief with various attachments and it was almost too much information, this was a 3 page brief with a rather ‘chip shop’ ppt presentation attached to it. When trying to compile a lump sum fee it very difficult to try and price a project when you haven’t got enough information but you want to be competitive. If the client is not clear on what he wants and asks the design consultant at tender that he is to tell them as part of the scope – which seems quite common in Australia – then surely the client must accept a certain level of risk because the supplier will have to make even more assumptions at the tender stage due to lack of clarity. I would be interested on everyone’s views on this and wonder if any of the other phase 3 lot have been involved in tenders and have had similarly clueless clients?

On other news, the family enjoyed a nice cruise up the eastern coat of Australia at the start of April up to Cairns and the Barrier Reef which was great. Ethan is like the energizer bunny and never stops. Being on a ship meant it was an easy way to travel as your hotel goes with you and by the end of the holiday everyone seemed to know Ethan by name having seen him run about the place for the past 2 weeks with me calling his name trying to keep track of him. It is hard to believe he was only 6 months old when we arrived in Australia and he is now fast approaching his 2nd birthday and Pip is now 5 months pregnant with no.2!