Bridge Parapet Traffic Barrier Design

It has been a while since my last offering but now that my thesis is in and forgotten for the time being and I have finally started my CPR reports here is an update on life in the design office.

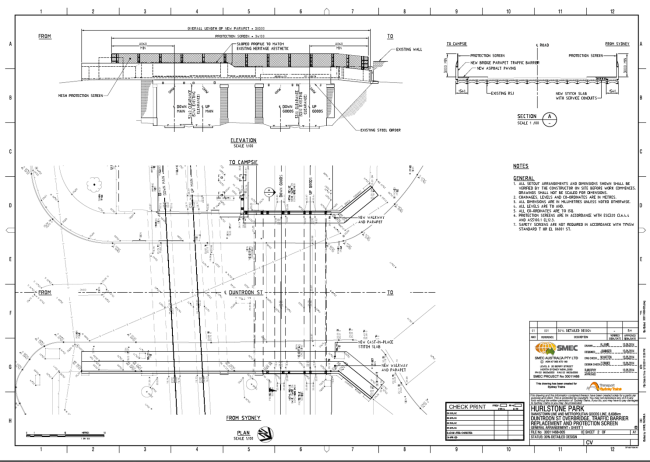

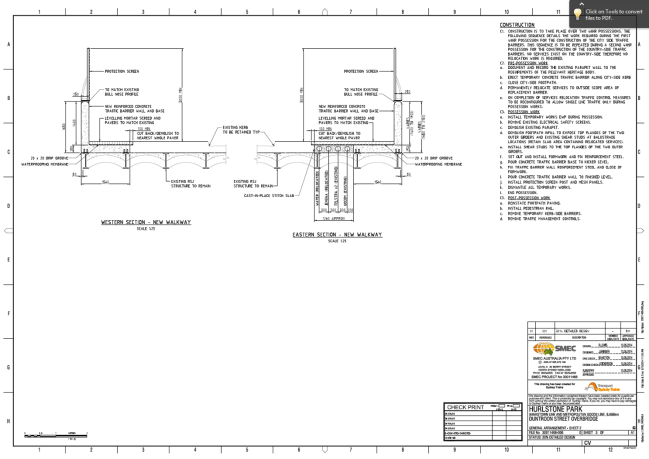

I seem to be the popular choice at the moment to compile and submit tenders, which doesn’t seem to be affected by the fact I have not won any yet because I have just received another one (no doubt my last) while also currently managing three design projects. Over this attachment I have been involved in nine projects (6 tenders and 3 design/PM). The one I have been working on intermittently over the last few months is the detailed design of a traffic barrier to replace an existing masonry parapet in order to comply with current standards. I have subsequently designed a cast in-situ barrier to be constructed on the outside of a 100 year old ‘jack arch’ rail overbridge. I have also modelled the bridge using Microstran to see if the existing structure can accommodate the traffic impact loads. A traffic assessment at the concept stage identified that an intermediate traffic barrier performance was required which stipulates an outward horizontal load of 180kN at 1.1m above road/footpath level, as well as a longitudinal load (to be applied simultaneously) and a vertical load (to be applied as a separate load case). The Australian Standard AS5100 (Bridges) does not explicitly provide a detailed analysis procedure for bridge barriers. As a result, current practice uses American Association of State Highway and Transportation Officials (AASHTO) design procedure based on yield line analysis. The design deliverables for the project are; Concept, 30% detailed, 70%, 100%, IFC. I have just finished getting the 30% DD drawings together to submit to the client (Sydney Trains) by the end of this week in a hope to have the 70% design complete and submitted by the time I leave. I have had to commission a Statement of Heritage Impact (SoHI) and I am now in the process of getting the environment team to produce a draft Review of Environmental Factors (REF) that may be affected by construction such as dust, noise, heritage, social and economic impact to the area. Because it is an overbridge that spans over two rail lines the work will impact rail services during two planned 48hr possessions as well as closing one lane and possible both to vehicle traffic during construction. The amount of work and consideration involved for all aspects of the project all stems from successfully identifying the stakeholders at the very start and you soon realise how many people, organisations and authorities are involved in successfully implementing a project. Below are the drawings at 30% design not showing reinforcement.

I have also been involved in ongoing managerial aspects with the maintenance centre column repair design as per previous posts and a fire protection upgrade design on a cable shaft at central station in the middle of Sydney CBD. I have not carried out any design for this but I have been given the job of PM to bring the project to completion. I also recently submitted a tender for a 1.7km cable route design which was valued at just under $300K with a rather vague scope of works. There was little time to clarify or ask for more detail on most of this – largely because of the fair tendering process every consultant must be informed if a question is asked and meanwhile you lose precious time which you may not have – so I compiled it based on the site inspection and project brief. The client (Sydney Trains) subsequently came back to all the consultants that submitted a bid and have changed the scope somewhat. It appears they put little thought into the original brief and this additional information contradicted previous information. I subsequently revised our originally fee to just under $400K having it reviewed by senior management. The whole episode made me view the client as very unprofessional and rather annoyed me. For instance one comment stated that all assumptions in our proposal should be deleted and the proposal should be based on factual information and the fee should account for the risk accordingly – what planet are these jokers on? It seems very odd – and the seasoned pro’s in the office viewed this in the same way – that the client expects to be entirely risk free. Especially if their own SoW is woolly at best. One of the first tenders I did had a 1000 page brief with various attachments and it was almost too much information, this was a 3 page brief with a rather ‘chip shop’ ppt presentation attached to it. When trying to compile a lump sum fee it very difficult to try and price a project when you haven’t got enough information but you want to be competitive. If the client is not clear on what he wants and asks the design consultant at tender that he is to tell them as part of the scope – which seems quite common in Australia – then surely the client must accept a certain level of risk because the supplier will have to make even more assumptions at the tender stage due to lack of clarity. I would be interested on everyone’s views on this and wonder if any of the other phase 3 lot have been involved in tenders and have had similarly clueless clients?

On other news, the family enjoyed a nice cruise up the eastern coat of Australia at the start of April up to Cairns and the Barrier Reef which was great. Ethan is like the energizer bunny and never stops. Being on a ship meant it was an easy way to travel as your hotel goes with you and by the end of the holiday everyone seemed to know Ethan by name having seen him run about the place for the past 2 weeks with me calling his name trying to keep track of him. It is hard to believe he was only 6 months old when we arrived in Australia and he is now fast approaching his 2nd birthday and Pip is now 5 months pregnant with no.2!

Jon, Great to hear from you again. Is the Sydney Trains work all traditional design contract followed by construction contract? Or is it preliminary design for cost and tendering followed by DBO?

The issue you raise about inexpert clients providing poor quality briefs leading to difficulties with cost certainty is not a new one and I hope you will get comment from others on this aspect. It was identified as a significant cause of inappropriate risk allocation and thence failure to obtain best value in public contracts in UK ultimately leading to the expert client concept (which, in my view, remains a struggle in most cases due to a lack of technical expertise in government and local authority employ) it’s a good discussion area at CPR if you want it to be – google construction procurment expert client and away you go!

Richard, the contracts do vary but the majority are traditional design followed by a separate construction contract. The column repair design is a good example of ‘contract creep’ because the original scope was for an investigation only into the causes of the corrosion but they subsequently asked for a repair reference design as the basis for D&B contract tender. What they asked for and paid for was more than a reference or prelim stage design because they were never sure on what they wanted. I was asked by the client to tell them what the scope change was and prepare the formal documents.

NSW is supposed to be the more developed of all the states/territories in terms of process, procedure, legislation and generally trying to do things right and as expected of a developed country. I hate to imagine how WA do business?