Like for like, but not quite…

The pace of life in Aberdeen is picking up and people are actually starting to ask my opinion and give me more responsibility. In the last couple of weeks there are two jobs that have taken up a significant portion of my time; the modification of lifeboats to increase their capacity and the modification of 34 cabins on the Clair asset. Both of these projects combined will go most of the way of increasing the capacity of the platform from 120 to 154, which is the key enabler for the turnaround next summer. The cabin upgrade is going okay so I’ll only cover the lifeboats in this blog.

The Lifeboats

The lifeboats task has been rushed through a little bit and was supposed to be in two phases, with the first phase being like for like. Things have not turned out like that at all. Phase 1 is the recertification of a davit A frame used to lower the freefall boats into the water using a hydraulic pump unit (HPU); it is now definitely not like for like. Despite going through several levels of technical checks it turns out that the original 17kW motor has been changed for a 26.4 kW motor by the vendor and they failed to inform BP. At first it was assumed that the increase was because there must be a bigger pump in the HPU. However, this is not the case and it appears it was just the vendor standardising their HPUs. From their point of view it makes perfect business sense to standardise their units but it is criminal to not inform the client on what was supposed to be a like for like swap. As result of the change in motor there is now a problem with cabling. The current installed cabling is 6mm2 three core cable rated to 36A. Since time is very tight with when the job should go offshore the vendor is saying they cannot swap back to the 17kW motor and that the best solution is to de-rate the motor to 22 kW and change the protection device to accommodate the slightly larger motor. The calculation below is why this won’t work and why we are left with two options: 1) increase the motor and change the cabling or 2) leave the cabling and go back to a 17kW motor. What I have put below will be confirmed (probably more accurately) by WGPSN next week but this is what I think:

The old motor is rated for 17kW, with Ifl = 28 A

The new motor is 26.4 kW

In is the nominal current of the protective device.

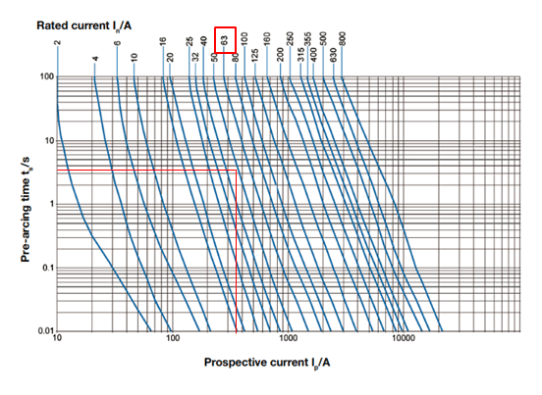

The protective device is selected from a time – current characteristic curve where Istart up is 8 x IFL (for a motor) = 8 x 44.5 = 356A

Should the cable need to be replaced then the job may not go offshore because it will involve someone from operations risk assessing the work because there are other live cables in the pillar that feeds the HPUs. The asset may not be happy with this.

Risk Assessment

The other phases of the lifeboats are pretty much on track but there has been a great deal of risk assessment done regarding the construction because there is overboard work, scaffolding, hydraulic fluid and new technology involved. The whole process is very meticulous but occasionally there is a lapse.

When asked what was the mitigation for hydraulic fluid falling into the sea the response was to use big Norwegian thumbs to plug the hole or do it at night so nobody can see!! That sounds more like a Sapper’s approach to risk assessment.

I must stress, this was a not what was captured as the mitigation.

I will keep you up to date with this task because it is due to go offshore for the scaffolding in Jun.

Other news

I have been sampling the delights of Scottish cuisine and have come across a strange soup and a deep fried Mars bar. I’ve not tried the soup, I’ll save that for Joe Wood when he comes to visit, but the Mars bar was actually quite nice.

mmmmmm…Cock Soup.

Nick what is the starting method of the motor, I would be suprised if it was direct on line.

Well be surprised John, it is a DOL motor.