Archive

Do they REALLY mean it?

As of next week I have to start conducting site inductions. So I’ve started getting my head into McAlpine’s Health and Safety policy.

Obviously they induct everyone on their first day, insist on CSCS cards and SMSTS trained supervisors. That’s the norm. But McAlpine are attempting to go further…

McAlpine have the” Work Safe, Home Safe” tag line, and claim to be attempting to change the culture of construction by pushing Health and Safety to the fore. They conduct workforce engagement session each week and everyone who works on site must attend one within two weeks of starting.

But do they follow it through? Do they really mean it?

How much does all this cost? There’s the cost of the materials, facilities and training courses. And there’s the lost hours which impacts on the program. And program = money. Particularly when the subcontractor is currently 3 weeks behind. McAlpine must think it’s worth it in the long run. So where are they making that money back?

A couple of weeks ago I posted this photo and learnt the lesson of “It’s all about money”.

That happened because a tipper was driving onto a pile of spoil to dump more material onto in. The pile hadn’t been compacted and there were no stop blocks or banksmen to stop him. He drove onto a loose area, it gave way, dumper at funky angle. But prior to the last trip, he must have driven onto the pile 5 or 6 times.

In my mind each of those trips was a near miss. It was an unsafe practice that could have resulted in injury – proved by the later incident. So what did McAlpine do? Did they report the incident internally as an accident? Did they scorn the sub-contractor? No. They recorded the incident as a near miss and cracked on.

Prior to any work being conducted on site risk assessments and method statements must be completed by the sub-contractor. John and Harry would hate them. They’re full of stuff about slips, trips and falls and make no consideration to how the tasks relate to each other. They don’t require a real consideration to the risks involved or what the safest way to conduct that activity is. There is one method statement for steel fixing and another for drainage. Nothing on how they interact though. Which led to this:

In case you’re wondering a large non-return valve should fit on that pipe. A lot of rebar had to be cut to get it in. And for each bit of rebar they cut, they have to put an additional area of steel back in, including a full anchor length. So they’re really not helping themselves.

So I ask again: Do they REALLY mean it?

I sense a TMR coming on…

Site Two Fifty One – Uncertainty in Ground Conditions

On Wednesday, the first ground bearing CFA pile was drilled. The stratum is made of 7m of river terrace deposits (sand and gravel) then 19m of London Clay. The auger was drilled to a depth of 24m and on extraction the nozzle at the base of the auger was found to have been blocked (reasons are extensive – poorly primed hoses, gravel getting stuck within the bottom of the auger, but not the focus of attention here).

On removal of the auger the gravel began to “flight” which is where the size of the hole increases in relation to the bore diameter. This is a particularly prevalent problem in sands and gravels. Add in a water table at about 1m depth and that compounds the problem.

Pleasingly my pile mattress was doing a good job at holding the pile rig up. Less pleasingly was the undermining occurring below it potentially causing diffemderential settlement and risk of the rig turning over.

Take 2. The next ground bearing pile was approached in the same way. Auger goes in, no blockage, concrete comes out and auger extracted. Nice vertical concrete pile. Then the reinforcement cage was added then it was pushed into the pile with an 8.5m column to sit the cage at the right cut-off level. This was in order to avoid breaking down the pile with reinforcement in. Everything great.

Take 3. Auger is drilled in and at about 20m embedment the extracted material from the pile drops into the ground. The foot at the bottom of the pile rig mast was starting to get undermined and so the drilling was stopped and the auger retrieved.

With John Moran’s prompting, he directed me to the ICE Specification for Piling. There is a section on CFA piling in ground with a loose section overlaying a stiff clay layer – see below in Option 1.

Solutions

Option 1.

Reduce the auger rotation in relation to penetration. I.e. reduce the auger turning speed or increase the rate of penetration. There must be some flighting (or extraction of material) to avoid corkscrewing the auger into the ground which would then be impossible to retrieve.

The specification says where there is high ground water there is higher risk of over fighting and so casing the piles should be considered.

Option 2.

We have just reconfigured the pile rig from cased rotary bored to CFA because it enables the deeper piles to be installed in the Lambeth Group below the London clay. So changing back to Cased is not likely to happen. Additionally the combined case and CFA rig that Laing O’Rourke own only drills to 17m.

Option 3 – chosen option.

Surcharge the loose ground around the auger with dry material. This should then stop any displacement of material around the pile mast. Turns out this is pretty effective! 4 piles done on Thursday and 4 on Friday.

Why does this work? I will attempt to speak in effective stress language. I think this is nothing more than a case of the quick condition, recently spoken about by Guz. As the auger penetrates through the Gravel it unloads the ground (simply by extraction of material by the auger). With the high water table, and the reduction in total stress, the augering results in the effective stress (Terzaghi : σ’ = σ – u) reducing to zero, i.e. piping. Hence, this causes the ground around the hole to fall inwards. So by adding additional total stress (surcharge) it maintains a positive effective stress and stops the ground from collapsing. So now piling can continue.

Not a calc sheet in sight

Here are a selection of some of the issues that have arisen over the last week,

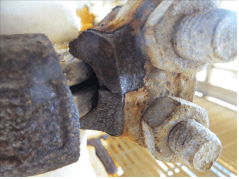

1 – My spanner doesn’t fit – The standard ‘you must be able to construct what you design’ comes to the forefront with my first point. The fabricators constructed the middle waling for the cofferdam, which consists of double UB’s welded together with plates. The problem is that the ends are bolted together and someone decided it was a great idea to position bolts inside of the facing web openings (see photo below).

Solution – Ignore the bolts and weld instead.

Cofferdam middle waling

Close-up of restricted bolts

2 – Answers on a postcard please – Our sheet and CHS piling gang have done a good job, however, they are really starting to drag their heels. The commercial team who draw up the contracts have dropped a clanger and employed them on an hourly rate, which has been fine up until the last couple of weeks. They are now well aware of the last safe moment for the cofferdam to be finished and are doing everything possible to ensure they don’t finish a minute sooner. The question now is how do you speed up someone who has the upper hand and technically isn’t doing anything wrong, frankly neither the carrot nor the stick will work this time!

Solution – …?

3 – The chalk turned to toothpaste – The majority of the fill being brought to site is chalk. This is causing no end of issue given the current weather. If it’s in a dry-ish state and well compacted it forms a sound and stable base for the abutments and road surface to be built on, however, it is not so dry at the moment and yet we are continuing to receive 600 tonnes a day. The lads were told to stockpile it so that it could be distributed at a later date in the 200mm layers with 4 passes from a 3.75 tonne vibrating roller as per MCHW. BUT…what they actually did was cover the whole site with over 1000T and after a night of rain they rolled it. Watching the roller move would be like watching Jabba The Hut on a water bed!

Solution – A nuclear density and plate bearing pressure test will take place tomorrow to assess the situation. Any areas that require remedial work will be stripped back and sorted. The danger is that if the logistics are not managed correctly then areas could get missed and become soft spots. To add to the issue chalk continues to be imported to site and stockpiled correctly.

4 – My window won’t stay open – In order to monitor the settlement of the site, steel plates have been placed in the ground with vertical dywidag bars fixed to them. As the ground settles, the plates move down and this can then be recorded through surveying. The problem is what do you do when the window of your roller keeps sliding shut? Well, if you work here then you use a gas axe to cut 90-100mm of dywidag off that annoying rod that sticks out of the ground that you have to drive round, so you can make a window wedge!

Solution – Use average settlement data from the other 17 rods on the site to predict the settlement at that point and then offset all future results. Add a note on the site induction that all bars are not to be tampered with and brief all current staff at the following morning brief.

Another settlement rod who had a near miss with the same roller, good job it was protected.

5 – Who ordered the piles? – The first batch of cofferdam piles arrived this morning (AZ 20) but unfortunately the clutches had not been crimped. Before the batch was accepted the order was checked and it turns out it was our fault. The cost involved in sending them back to be altered was not the issue, in this instance it was time.

Solution – Level three precast concrete slabs left over from a design alteration on the crane jetty to create a welding bed. Tomorrow the center clutches will be welded together.

If only the piles had used crimpers instead of straighteners on their centre parting!

Our make shift welding yard

And finally – I saw our crane driver carrying what looked like a bottle of water, he must think I was born yesterday….my money is on gin or vodka!

Technology merging with health and safety.

Site Two Fifty One

Technology merging with health and safety.

This week I attended the Laing O’Rourke “Mission Zero – Ask the Question” workshop. This is the Laing O’Rourke mandatory health and safety briefing which aims to get their staff to work safely on projects. It is a pretty decent attempt at raising awareness of health and safety in the workplace and potential pitfalls when working on projects. Impressively, Laing O’Rourke has produced a short film illustrating an accident on one of their sites (early removal of back-propping causing a slab collapse). The film is relevant and applicable to many sites, raising multiple issues and creates an excellent scenario for discussion. The real focus of the workshop was not to teach employees about health and safety, but simply get people asking the question to ensure activities are done safely.

Later in the week I attended Priority 1 training. Perhaps familiar to some, but likely not all, this is an online tool to enable snagging, permits, tasks and observations to be recorded electronically and geographically. The software aims to “improve the way that information is collected, managed and reported within live construction projects”. The example I will cite is based on the Health, Safety and Environment Supervisors’ check I do weekly. One of the items I check is edge protection. If I find a missing toe board, I then raise an action. I take a photo, fill out a short form and assign a date and organisation to resolve the problem. You might say what is wrong with a paper form and telling the site foreman to sort it. That method works but it fails to record trends and give the project leader timely feedback on issues that have arisen. Moreover, the snagging tool allows tasks to be assigned to a variety of sub-contractors which can then be monitored for their progress and have records kept with the photograph/location data acting as evidence of performance. It’s a good tool and probably has lots of other useful functions which I expect will become apparent soon (issuing of permits for example).

This week, a PowerPoint brief was issued for delivery on-site to highlight recent issues across multiple Laing O’Rourke sites. Good information sharing and method of learning from others’ mistakes. Especially applicable as we do all of these activities!

Tipper wagon overturned due to unsuitable ground conditions – wagon should not have gone onto area in question.

The area being rolled was sloping to the left. This should have been levelled out prior to and during the backfilling operation.

Military – Civilian Processes

I thought I would look at a few checks/processes in the world of construction I think the military do well at based on my experience of the civil industry. The people/checks/processes are all present/done on civilian construction sites and it really has reinforced the good old Troop Commanders’ checks being vital to keep a project running. Not just with counting spanners but the checks to ensure the equipment is serviceable (PA test in date and item functions).

QM in charge of materials and logistics

SQMS to make the logistical chain

G1098 storeman

Lifting tackle register

Tp Comd monthly checks

Equipment Care Inspections

Complete tool boxes for tradesmen

SHEF statements

Section composition (section comd and 2ic with tradesmen)

First parade checks

Whole Fleet Management

Risk registers

Fire NCOs

Tool box talks

Orders process

My site is at an early stage and so effectively lacks a bit of section comd leadership. It has some good quality tradesmen but a lack leadership skills are to be found on-site. I know on more advanced projects lots of these things (G4, material requisition, health and safety provision) just happen but in my case, I (we) are establishing the safe systems of work. I would like to say it is a bit of a pain, but actually I am learning a lot from it and think I will learn more from a maturing system, rather than a mature system.

Back to Battersea

Well this week escaped the sleepy hollows of the New Forest to head back to the Powerstation to host a group of RE Senior and Junior NCOs on a H&S site visit. They are deploying to the Falkland Islands to construct a concrete pad foundation for a radar station being constructed by 39 ER. This was part of their pre-deployment training and an opportunity to see the H&S principals learnt in the classroom at Chatham in practice. I took the group round with my old mentor Richard and the ex-Grenadier Guards H&S guy who had started working at Battersea just before I left. I was pleased to say that they had actually made progress since I left and it was interesting to stand on the 8th floor overlooking the river.

As the group will be mostly working on construction of a large concrete slab, I concentrated the tour on the concrete pouring aspect of work. I showed them the area where Byrne Bros were preparing the re-bar for a large floor slab pour and I took the time to highlight the quality control aspects such as checking cover, bar diameter, spacing, formwork, etc. Later in the afternoon we were able to see the team pouring the slab and the group were able to take away a number of points to bring up with their chain of command. They noticed that the thick work gloves that they had been issued would not be suitable for the intricate task of wiring together rebar and that paper suits would be essential for concrete pouring even though the QMs department has deemed it too expensive.

The group would also be installing drainage so I explained the Carillion policies on permits to disturb the ground and safety in excavations. I took them to view the final processes of the infamous micro-boring that has finally connected the foul drainage to the Thames Water trunk main. As I left Battersea they had just uncovered that the trunk main was too close to the Battersea Park Road bridge for them to retrieve the microboring machine. The team from Barhale ended up having to recover it from the Network Rail arch that runs underneath road. They constructed a steel girder gantry (see picture) over the reception pit to recover the machine and push it out of the arch using a miner’s railway track. Thames Water would not allow them to tunnel directly into the old Victorian sewer using the machine so the last few meters were completed using a traditional timber heading with soil grouting and de-watering. The total cost of the operation is now likely to exceed over £1m and is almost 4 months later than the planned completion date.

I think the day has been an extremely worthwhile trip and I felt that the H&S tour was a good opportunity for me to remind myself how much I have experienced and learnt on the placement. The guys were astounded by the scale of the project and they have taken away some good ideas to include within their pre-deployment training. I think we should encourage more trips like this for the artisan trades back in units to learn more about industry standards and large scale engineering projects.

Back at the ranch in Poole I have been plodding on with some breakwater design analysis of the super port in Morocco and I have also been given a smaller task of the Cat 3 design checks on a small boats marina in Gibraltar. John will be impressed that I have done some hand calcs for bearing capacity and settlement all by myself but it hurt my brain! I also had an escape from the office for a trip with the Army XC MTB to Cyprus for our training camp and to compete in the (not so) Cyprus Sunshine Cup, the first UCI stage race of the year. There we were competing against Olympic medallists and World Champions in a 4 day stage race including 2 days covering 50km each in the mountains. The final day was just 2 laps and a start loop on the XCO course that looked more like a Chamonix black downhill course but you had to ride up the back of the rocky drops in lycra! The race started pretty badly when I was wiped out 20m from the start by my fellow Sapper teammate Maj Charlie Batty. I think thought the photo evidence proves that I had overtaken him though!

Life on the Western Front

I’ve now been on the Peters Village project with BamNuttall for a couple of weeks and am slowly working out what is going on…we’re building a bridge!

The Peters Village project is a new community consisting of 1000 houses, schools, shops and so on. It is expected that in time it will grow to 5000 houses and as a result the local area infrastructure requires a large uplift. BamNuttall are responsible for the local area infrastructure but not the housing development.

The project office sits on the East side of the river, however the bridge section of the project is run from the West. Currently the site resembles a complex obstacle plan and is covered in a foot of mud making it look more like the Somme than a building site.

Project Overview

The project can be neatly split into a series of sections each with a dedicated team:

On Site Roads – These will feed the new built community and incorporate some ground preparation for the village.

Off Site Roads – 3km of road network to link the village to the surrounding area.

Medway Valley Crossing MVC – 150m pre-stressed, post-tensioned, cast in place river bridge

– 30m pre-stressed, pre-tensioned bridge over a live rail line

– 500m road and deep drainage linking the two

Kent council scheme proposal

Thankfully I am in the team responsible for the MVC, which will expose me to a much broader range of tasks and engineering issues. The river bridge sits on the critical path for the MVC section of work and that is the main focus of attention at this stage. The Rail Bridge has, and continues to, slip further behind regarding the start date, however, it has so much float in the schedule that there is no immediate concern.

Currently there are two key areas where efforts are being focussed, these are:

- The False Work Jetty

There is a requirement to maintain a 20m navigable channel open at all times. In order to achieve this a jetty will span out of each bank parallel to the main bridge; these will support the cranes required for construction. Directly below the main bridge a second jetty will be constructed to support the bridge false work. At present we have the west side crane jetty complete and are halfway through piling the west side false work jetty. Finally, two cofferdams will be constructed (the first started today) in order to provide access to construct the main bridge piers. Below are a couple of images that will hopefully add clarity to my poor explanation.

Crane jetty’s, false work Jetty’s, cofferdams and bridge piers

Late stages of construction, false work removed

View from the end of the west crane jetty. The closest four piles

Mark the corners of the cofferdam. Taken at high tide.

- Consolidation of Existing Ground

The ground profile across the site is clay over laying chalk with a thickening alluvial layer as you near the river. Currently the site slopes towards the river and is anywhere from 4-8m below the required formation level. Chalk is currently being imported from the cross rail tunnels to build up the level of the site and also to surcharge the clay and consolidate it. In order to increase the speed of consolidation band drains have been used. It is predicted that it will take at least six months to reach the required level of consolidation and a number of techniques are being used to monitor it. I will expand on this in detail in future blogs.

In Other News

Remember that moment on Ex Cofferdam when you messed up your calcs at 0200hrs on Wednesday morning and you can’t understand why no pump in existence is capable of emptying your hole…no…maybe that was just me, but fear not because we have a little blue pump on site that could not only deal with Ex Cofferdam but is actually callable of pumping out a rising tide on the Medway!!!!!!!!!

Thankfully a concrete plug now seals the end of the sheet pile wall and we’re not wasting diesel trying to fight nature any longer! I’m not sure if the poor lad monitoring the pump had been told to do it as a wind-up or not but as it was my third day on site I just smiled!

And Finally…

In case you were wondering, yes it is possible to eat an entire Soreen loaf, Mars Bar and drink close to a litre of Coke in the time it takes to drive an 18m pile into the ground. Should anyone wish to marvel at the evolutionary wonder that is our 110T crane driver please feel free to get in touch to arrange a private viewing.

The invention of talking

ICE attribute E3 (I am sure E&Ms will have something similar) requires us to “Demonstrate sound judgement on statutory, contractual and commercial issues in relation to your area of responsibility.”

On completion of AER 1 I was naïve enough to believe I understood enough and could crack on with “doing stuff”. It turns out I was wrong (Neil – one for you).

There is loads of other, seemingly small, stuff that you need to understand to really appreciate the commercial implications of what happens on site.

On my site we’re just 6 weeks in and our sub-contractor (PCH) is over 2 weeks behind schedule. According to their recovery schedule they should be pouring the first section of the basement raft slab on Monday. That won’t happen. Primarily because they still haven’t ordered the top rebar, let alone had it delivered or fixed it. PCH is staring down the barrel of a non-conformance report which looks very bad for the company. So naturally they’re looking everywhere to find someone else to blame. Therefore we (the main contractor) must ensure we’re whiter than white. We cannot be made to look responsible for their lateness. Therefore there is a huge push to ensure that all the RFIs are answered, designs approved, drainage and water-proofing inspected and tested, etc…

This has come to the fore thanks to a problem with the lightning protection. The installer struggled to reach the required resistivity (one for the E&Ms) and as a result had to come back and redo some work. This isn’t the end of the world; they can do the remedial work around the steel that has been laid. The problem that was highlighted is that the lightning protection package manager hadn’t told anyone there was a problem. So the construction manager asked the question “what else don’t I know?!”

The problem is communication. We all sit in an open plan office in a large porta-cabin (like TFH HQ for anyone that ever saw it) and no one talks to each other (like TFH HQ). But this lack of communication could have led to a “get out of jail free” card being given to PCH. So we’ve implemented a severe measure: each day at 1700 the engineers and the site supervisors get together and talk about what happened that day, what should happen the next day and thrash out any problems. It’s not new, it’s not clever, it’s not quite an O Group but it’s not far off.

In summary: There is nothing discrete, everything that happens on site carries a commercial implication. Therefore it’s key that I keep in mind how all the parts are interconnected as any delay could cost someone loads of money!

Slightly early this week and a bit dry, so here is a gratuitous digger shot:

AIRBORNE!

UPDATE: It turns out PCH (the sub-contractor) were having some cash-flow problems. So McAlpine (the main contractor) have bought the steel direct on their behalf and will deduct the sale amount from their payment. This should speed up the process and we’ve managed to secure a better rate! It’ll start to arrive on Wednesday. Guess which lucky individual gets to count it all when it arrives…!

A change of scenery

It is not quite a tropical heaven but it is a change of scenery.

The declining oil price has had a detrimental impact on the Projects and Modifications (P&M) budget. Unfortunately, one of my major projects has been suspended until the cash flow problems improve and the other projects are starting to culminate. As such, I decided that I fancied a change of scenery where I would be able to get the most out of my remaining two and a half months. Consequently, I am now sitting in the discipline engineer (DE) team, as a mechanical engineer.

The way I see it is that P&M is the interface with approved engineering design contractors and ensures that the contractors deliver what it is the client is after. The role of the DE team is when a project flies close to the limit of the Engineering Technical Practices (BP equivalent of BS), and the contractor’s won’t touch it, then the DE team can conduct detailed calculations and assess the risk and make a judgement call.

I have been sat here for a little under a week and I am already getting stuck into some calculations; Mark would bloody love this place. I’ve used Bernoulli’s equation, D’Arcy Weisbach, I’ve downloaded some pressure vessel calculation software (yes downloaded only because I’m still scarred from Hevacomp I daren’t attempt it yet). I might need a crate of Stella Artois before I attempt to wrestle with a software programme. Obviously for those of you who know my drinking ability, by crate of Stella I mean a can. I am looking at materials failure of a particular weldless joint offshore and I will probably write a method statement for checking other existing clamps. There are some other bits and pieces to going on and I expect to receive a steady stream of work until I leave.

I am writing this post for two reasons; the first is to illustrate how versatile the BP PLC placement is. Even though a PET officer has been on attachment here for the last four years there are still a lot of people who don’t know we are here and what we can offer. The current attachment works very well and I don’t think I needed to make the move to DE but BP were more than happy to accommodate my request. Future incumbents may be able to explore options for trying to work in different parts of BP although bear in mind that 16 months is not that long to get settled and stuck in. I have discussed this with Brendan and we will continue the info ops campaign prior to leaving to ensure the profile of PET officers is lifted once again. (This is doubly important during a time of redundancies in the North Sea because there will be a large turnover of personnel in key appointments).

The second is to highlight that I expect to be able to add to my A and B competencies prior to taking CPR.

The Good, the Bad and the Ugly.

It’s been a while so it’s time for another blog.

There has been a bit of a shift within the team as 2 of the Assistant Structural Engineers handed their notices in and left rather quickly resulting in a team of 4, under the Senior Structural Engineer, being reduced to me and one other. This has clearly increased my work load but frustratingly not entirely in productive areas.

The Good.

So the subject of my previous blog was an independent foundation design for a standalone gantry crane that I initially completed by hand as practice before inputting into the computer analysis software Masterseries. I completed this design and sent it to the client with my recommendations as their proposed orientation could not be accommodated due to the foundation size required and the existing building geometry. This has since been returned with a slight amendment and is sat in my in tray to look at their new proposal and make the design amendments accordingly.

This process led onto my largest design responsibility to date. I was required to design the foundations for a second 4 bay 7.0m x 35.0m extension to an existing portal frame building. The original building and first extension were completed by CRP so much of the design input was already available.

The first stage was to take the existing building footprint and set out the new nodal positions and detail appropriate section sizes based on the original frame as the steel section design information was unavailable. I had however received the loads from the steel designers, as nodal loads, (which made life easier) and allocated those to the frame accordingly. I made an adjustment to the surcharge load from the original due to a different slab requirement and dug out the original site investigation report to ascertain the ground conditions and safe bearing pressure of 225kN/m3. This indicated a layer of chalk at 1.5m from the underside of the slab and I decided that this would set the depth of my foundations. Once these parameters were established I individually designed the 16 foundations required before economising the design for ease of construction by reducing this to 5 different sizes. Partly due to the specified depth, I was able to negate the use of steel in the design and recommend the bases were constructed from mass concrete, thus reducing the cost. Once complete I submitted the design to the Senior Structural Engineer for a few tweaks before detailing the drawing in AutoCAD and sending to the client for discussion and approval.

I have also managed to get involved in a number of other areas of work that the consultancy cover.

I have worked on the preparation of a number of tenders in particular the drafting of remedial work specifications for small domestic and commercial projects. I have also been appointed Assistant Project Manager for a couple of local refurbishment projects. The first a £120,00 upgrade of a Day Centre, the second a £1m upgrade of a existing steel portal frame warehouse. Both of these jobs came about from my discussions with the MD to complete DO C5 (Managing Contractual Issues). I wanted to work on small scale, local projects that I could possibly see through during phase 3 and would allow me interaction on site. Whilst I was initially reluctant to be involved in the projects, as I did not perceive them to be engineering heavy, I have subsequently realised that they fulfill the requirements for the DO more than adequately. My work across both projects has included; feasibility studies and work specifications for tender, contractor hosting on site, return tender assessment, prestart meetings, liaison and coordination between the clients and the contractors during works, quality management and assurance on site (C4) and a host of other smaller tasks. All of which have contributed to finalising a number of outstanding DO’s.

The Bad.

Due to the 50% reduction in engineering staff in the office I have had to take on some additional drafting responsibilities. Whilst not hugely significant much of the design I am currently conducting I subsequently have to detail in AutoCAD. The 2 Engineers that left used to do much of the detailing to assist the CAD technicians (who are also undermanned) and hence the task has fallen to myself and the other Assistant Structural Engineer. I have voiced my opinion on this but equally understand that it partly comes with the territory and responsibility of working in a small, very busy consultancy. The issue will shortly be resolved however as 2 new CAD technicians start next week, one of whom is an ex RE draughtsman. I hope he brings his own sandbag for my war dits as they’re just not appreciated by civilian engineers.

And the Ugly.

It is something I realised on phase 2, but even more so with the projects I am working on during phase 3, there are plenty of opportunities to complete the DO’s, even in areas that are not immediately obvious if you push for them with your placement mentors. I am gaining a wide range of experiences on phase 3 and although I am not churning out impressive designs for half of London like Richard, or Riyadh Metro like Steven, I feel I am getting a rounded consultancy experience, akin to the type of activities we may be conducting when back in the green. I have continually sought to shape the direction of my placements, guided by the DO’s, by being outright and robust with the various MD’s and PM’s who I have found are generally receptive to my requirements. I would recommended this to the current phase 2’s as it is easy to become stove piped by companies as you show competence for the conduct of particular engineering activities and you suddenly become the ‘piling go-to guy’ and that’s all you experience in phase 2/3.

That’ll do!

After a week off last week the learning curve had ramped up again this week.

Two tower cranes up, three to go. We’ve cast the ducts for the power cables to the tower cranes into channels under the blinding. This keeps them out the way and protected. The ducts continue across the site and spit out of the edge of where the building ends.

Ducting emerges… …from under the (still wet) concrete

Adjacent to this is the berm holding back the sheet piles (in that area they’re just there for water control really, less so for soil retaining. In order to install the cables it was asked if the berm could be locally removed in the corner to allow the cables to come straight down the pile wall and into the ducts.

The berm in question

So I broke out the cofferdam notes and off I went. I discovered that although the piles would still stand, it seemed likely the top would see a deflection of up to 40mm.

5 meters behind the wall is a public road complete with services under it. I then estimated the services would probably see a localised deflection of up to 20mm. Well beyond the acceptable 10mm. So it needs bracing.

So I broke out the Cofferdam spread sheet and off I went. I estimated the wailing load, and thus the prop load. I selected a propriety system that could accommodate and made a recommendation. My CEng took one look at it, halved the section size said “that’ll do”.

It’s due to get installed next week.

I really hope it holds!

![WP_20150327_08_29_51_Pro[1]](https://pewpetblog.com/wp-content/uploads/2015/03/wp_20150327_08_29_51_pro1.jpg?w=300&h=169)

![WP_20150327_12_43_39_Pro[1]](https://pewpetblog.com/wp-content/uploads/2015/03/wp_20150327_12_43_39_pro1.jpg?w=300&h=169)

![WP_20150317_13_18_20_Pro[1]](https://pewpetblog.com/wp-content/uploads/2015/03/wp_20150317_13_18_20_pro1.jpg?w=300&h=169)

![WP_20150313_08_58_31_Pro[1]](https://pewpetblog.com/wp-content/uploads/2015/03/wp_20150313_08_58_31_pro1.jpg?w=276&h=160)

![WP_20150313_08_58_41_Pro[1]](https://pewpetblog.com/wp-content/uploads/2015/03/wp_20150313_08_58_41_pro1.jpg?w=271&h=157)

![WP_20150313_08_59_02_Pro[1]](https://pewpetblog.com/wp-content/uploads/2015/03/wp_20150313_08_59_02_pro1.jpg?w=300&h=169)