A change of scenery

It is not quite a tropical heaven but it is a change of scenery.

The declining oil price has had a detrimental impact on the Projects and Modifications (P&M) budget. Unfortunately, one of my major projects has been suspended until the cash flow problems improve and the other projects are starting to culminate. As such, I decided that I fancied a change of scenery where I would be able to get the most out of my remaining two and a half months. Consequently, I am now sitting in the discipline engineer (DE) team, as a mechanical engineer.

The way I see it is that P&M is the interface with approved engineering design contractors and ensures that the contractors deliver what it is the client is after. The role of the DE team is when a project flies close to the limit of the Engineering Technical Practices (BP equivalent of BS), and the contractor’s won’t touch it, then the DE team can conduct detailed calculations and assess the risk and make a judgement call.

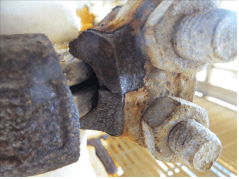

I have been sat here for a little under a week and I am already getting stuck into some calculations; Mark would bloody love this place. I’ve used Bernoulli’s equation, D’Arcy Weisbach, I’ve downloaded some pressure vessel calculation software (yes downloaded only because I’m still scarred from Hevacomp I daren’t attempt it yet). I might need a crate of Stella Artois before I attempt to wrestle with a software programme. Obviously for those of you who know my drinking ability, by crate of Stella I mean a can. I am looking at materials failure of a particular weldless joint offshore and I will probably write a method statement for checking other existing clamps. There are some other bits and pieces to going on and I expect to receive a steady stream of work until I leave.

I am writing this post for two reasons; the first is to illustrate how versatile the BP PLC placement is. Even though a PET officer has been on attachment here for the last four years there are still a lot of people who don’t know we are here and what we can offer. The current attachment works very well and I don’t think I needed to make the move to DE but BP were more than happy to accommodate my request. Future incumbents may be able to explore options for trying to work in different parts of BP although bear in mind that 16 months is not that long to get settled and stuck in. I have discussed this with Brendan and we will continue the info ops campaign prior to leaving to ensure the profile of PET officers is lifted once again. (This is doubly important during a time of redundancies in the North Sea because there will be a large turnover of personnel in key appointments).

The second is to highlight that I expect to be able to add to my A and B competencies prior to taking CPR.

Nick

Good to see that you are spreading the net to get the most of your attachment. Its interesting to see the range that you are getting involved in which can only go to complement your UKSPEC competences for PRI. Fortuneately for you a lot of the PRI reviewers have a good understanfing of the O&G industry and there are always enough applications from Aberdeen in the pipeline (no pun intended!) for comparison of roles.

The joint looks like it has failed over a period of time – what are your first thoughts? Presumably you’re asking are we looking at a material failure or a systemic failure? Where does the buck stop? What will the method statement be telling peope to check/do? What happens after everything has been checked? Will everything have to be checked?

It’d be interesting to understand how you are approaching this, not only for comment from others but also to get you thinking about this as a possible talking point at your PRI; a problem such as this will demonstrate a lot of the attributes expected of you and it’s good to have examples such as this ready to roll out if you need.

Mark

Mark, there has already been an investigation and the conclusion is that the failure was a result of hydrogen induced stress corrosion cracking (HISCC). This occurred on only a small portion of the clamps though. The investigation then looked at why this was and it turned out that the manufacturer had a faulty process whereby there was no quality control and it was possible for some of the clamps that had not been tempered yet to get mixed in with the ones that had been tempered. Hence, there were clamps sold that were too hard and susceptible to HISCC.

I have been reading up on the different methods of doing hardness testing and I’ve narrowed it down to those that are suitable for portable testing. My next step is to speak to some materials experts and some offshore construction engineers. I want to pick the test that requires the least preparation to try and make it as easy as possible to identify faulty clamps. If I was dealing with soldiers I would say I’m making it idiot proof. Once I’ve decided on the type of test, I will complete a generic risk assessment to consider if the clamps are in love lines, water lines, hydrocarbon lines etc. This will make it easier for the assets to embrace the testing. I also want to make recommendations about whether to do this as a campaign ( a team that go from asset to asset) or in house with resident asset engineers. There will be pros and cons of each but I want to add some science to it. I’ll include whether to buy the testing equipment or hire it by the end. At some point I will write a preparation and testing procedure but this will likely just be copying something that exists.

Thanks for the comment Mark.

I meant live lines. And having just read my reply I meant that I would be able to explain it to soldiers as idiot proof. BP would not appreciate it being called this but it would be beneficial to be idiot proof for the sake of consistent results.