Archive

Entering the Morning Glory… but not quite as planned..

1. Temporary Works Design (TWD). The decision was made to disregard the original temporary works design for raising the morning glory spillway (MGS) as it was assessed to be unsafe and impractical. As such, a full redesign was required despite the project being two months in. A highly regarded, Sydney based, designer specialling in TWD was approached for assistance in the urgent matter. Upon his acceptance, a “short form consultant services agreement” contract was established. The designer quoted a ten week period in which they would complete the full design. Seven months later and the design remains unfinished.

2. Several mitigation measures were implemented in order to account for the significant TWD delays:

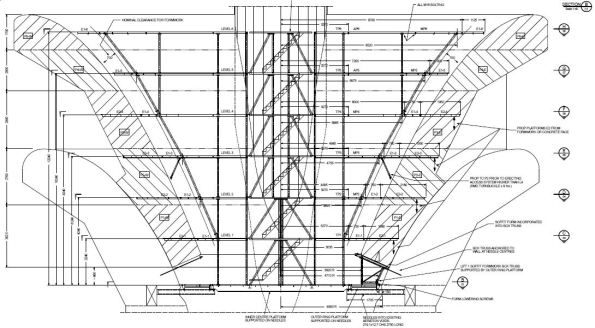

a. Construction sequence. Initially, it was planned that the MGS temporary works access structure was to be fully operational prior to any works commencing within. Due to the TWD delays the decision was made that once the primary supporting system(needle beams and steel mesh base) was in place, scaffolding was to be erected to allow access within. The new method made it possible to beginning locating and marking all existing steel reinforcement prior and the time consuming process of core drilling (1034 holes x 45Ømm x 850mm deep.

Delicate Lift Operation – 160T Crane inserting the primary, temporary works mesh base onto 34 x steel circular hollow needles within the MGS.

b. Fragmentation of works. In the initial tender it was stated that the MGS temporary access was to be fabricated by a single company. In the interest of time, the decision was made to break down the works into smaller sub works packages that would then be put to tender on an individual basis. Although this measure would facilitate concurrency in production, it would expose the task to compatibility issues in regards to final construction of the temporary works.

c. The remote location of Tamworth also influenced this decision to fragment the temporary works. Local fabrication companies flat refused to makes an offer on the total temporary works access structure due to the required production time. This was because of their limited workforce size, real estate and production facilities.

3. Lessons Learnt.

a. Contract Details. The importance of a thoroughly considered and reviewed contract has been clearly demonstrated in this instance. Although a provisional timeline was provided by the Design Company within the Short Form agreement, it was stated that an extension may be required. Additionally, the Completion Date was strangely specified as “Project Completion”, effectively saying that it’ll be done, when it’s done. Consequently, there is no financial penalty for the designer although they have over-run by five months.

b. Although the upgrade of Chaffey Dam is a State Water Project, funded by public money, John Holland are the private corporation delivering the project. As such, the federal requirement to go to tender on all on sub-contracts where public money is being spent, whilst good business practice, does not apply to John Holland. Following further investigation it was found that the design consultant selected is routinely employed by John Holland due to his impeccable track record and subject knowledge, despite the extended timelines!