Oz PCH – Fire & Smoke Management Cause & Effect: Technical and Commercial Issues.

Introduction

This blog highlights the commercial impact of a technical issue that can spread across many levels and affect multiple subcontractors/parties.

This could be yet another contracts management exam question.

It also covers next steps in fire cause and effect design development and testing and commissioning.

Issue

Reviewing the fire and smoke management cause and effect matrix highlighted some potential issues for the mechanical equipment; namely fans and dampers. Centigrade, mechanical fit-out subcontractor, had to install 72 x additional smoke dampers (electronically controlled) in various fire zones across the project. 10 x original dampers have been removed so the actual delta is 62. This was due to the initial design drawings by NDY, design consultancy, not reflecting departmental design changes.

Schneider, controls subcontractor, didn’t know about the additional dampers which now presents a serious technical issue; the ability to connect each new damper to a controls board. This throws up lots of detail like; have all the walls and ceilings in those areas been closed? Where is the connection point for the cables? Etc, etc.

Why didn’t Schneider know? Whose responsibility was it to inform them of the design change? From a technical stand point Centigrade has to have their new smoke damper design approved by NDY. Whether design consultants like to officially approve a third parties’ design is another matter; usually they don’t and won’t in case things go belly-up. However, they should at least review and comment on it. This design review information is then sufficient for them to either pass on to those who need to know about it; in this case Schneider, or at least inform the managing contractor, JHG; or ideally do both. So what actually happened? Nothing! This has led us, the commissioning team, to get involved in design – which clearly isn’t/shouldn’t be our remit. This situation reinforces NDY’s alternate acronym; Not Done Yet.

This type of ‘interface verification’ to use the commissioning vernacular for a scope gap between two or more subcontractor’s works meeting, seems to be a recurring issue in a number of areas across the project.

Solution

In order to find a technical/operational solution, to get the system working and to a commissionable state, we must now conduct a desktop study and understand exactly how many, including the exact location of the additional dampers, require wiring into Schneider control panels. Figure 1 was used to help explain how to go about this; splitting project areas into fire zones and then annotating drawing schematics with additional dampers to then understand the best possible wiring route to Schneider’s control panels. Figure 2 shows the cause and effect matrix as intended by NDY. It requires cross referencing against updated fire and smoke zones according to as-built architectural drawings. The trade contractors can then work through the detailed design of their individual dampers (smoke, fire, and smoke-fire). This then all needs to be reviewed and approved by NDY; which JHG will be insisting they sign-off on.

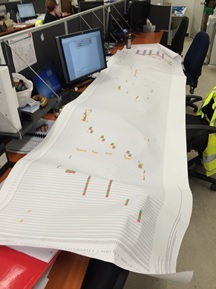

Figure 3 is the printed version which you can see is a pretty big beast. This is only the mechanical equipment with similar sized spreadsheets for miscellaneous equipment interfaces such as; hydraulics, lifts, medical gas, AGVs, security doors and PA alert system.

Commercial Implications

Commercially, this will open a can of worms; Centigrade will be putting in a variation order for their additional smoke damper design work; and Schneider will follow suit for their additional controls cable to said dampers. JHG will then no-doubt pass these straight to NDY as it was their inadequate design that caused the issue.

Playing devil’s advocate; NDY will most likely say the reason additional smoke dampers were required was because Fredon, plantroom mechanical fit-out subcontractor, changed the layout of some of their AHUs in the plantrooms. And here’s the irony; why do you think Fredon had to change the layout? Correct; because NDY also poorly designed that area too.

In terms of project contractual relationships; JHG being the managing contractor have a very ‘thin’ level of management that sits above the subcontractors and consultants (see figure 3). This means that issues of communication, as in this example and many others where subcontractors need to talk to each other, have to be managed carefully – which unfortunately on this project, due to the ‘thin’ level of management, isn’t all that great.

Design Development

The issue discussed above should have been solved months ago. Remembering we are in the testing and commissioning phase and our remit is to conduct just that, but we have found ourselves having to develop the design first. We have had to set up a workshop to ‘war game’ a few example areas to; a) prove NDY’s Cause and Effect Matrix, b) add in any additional dampers as a result of fire and smoke zonal changes and c) ensure these additional dampers get the required power/controls to operate. Once the subcontractors understand how to develop the design (which still lies with NDY), NDY will then review and approve.

Testing & Commissioning

This will involve using the revised cause and effect matrix to test each and every fire and smoke zone across all levels; a pretty mammoth task. Without going into too much detail, the detailed fire engineer design report stipulates test methodology and what pressures we need to be within. As outlined in the report and from AS 1668.1:1998 The use of ventilation and air-conditioning in buildings – Part 1: Fire and smoke control in multi-compartment building; it states “positive pressure not less than 20 Pa and not greater than 100 Pa shall be developed in all non-fire-affected zones above the pressure in the fire-affected zone…”

The air-conditioning system and controls interface aims to achieve this pressure gradient by a combination of; stopping the supply air and ramping the extract/return air in the fire-affected zone (to create negative pressure) and then ramp the supply air and stop the extract/return air in the adjacent non-fire-affected zones (creating positive pressure). The 100 Pa maximum is stipulated to ensure doors can be physically opened by escaping occupants. Figure 4 shows an example of the fire and smoke zone drawings being used in conjunction with the subcontractor’s shop drawings to identify the location and type of damper in place and establishing, using the cause and effect matrix, if the actual as-built layout can achieve the design intent. This was a dry run of how we intend to run our workshop.

Potential Issues

A number of issues can arise from the testing which I will blog about separately if and when encountered; if I’m not already on Phase 3 and here to witness them that is. Generally they will be things likes; can we achieve the 20 Pa min pressure drop across the fire zone doors? Can we rely on extract/exhaust alone to create the pressure gradient? This could be a requirement due to the outcome of integrated scenario testing where an electrical power failure has occurred, simultaneously with a fire starting. The back-up generator and UPS system will only provide power to essential and critical-essential supplies and not non-essential. Unfortunately, a number of the AHU supply fans are powered on the non-essential supply and so if lost to a power outage cannot play their part in zonal pressurisation. There will be other potential issues concerning building fabric air-tightness throughout the building but particularly regarding smoke walls that dissect a fire zone. These will have motorised smoke dampers but still require adequate sealing to avoid smoke spill. There will also no-doubt be other potential issues specific to certain areas of the building like staircase pressurisation and the like.

Fran,

Interesting stuff I presume your AHU’s that aren’t on the back-up generator and UPS can’t be considered when considering meeting the minimum requirement of pressure difference. But will they still be utilised if there is power available? What do you have in terms of an evacuation alarm / public address system? We don’t have anything other than individual smoke detectors and alarms in each room. The philosophy being that each apartment is fire rated compartment and therefore the best place to be in the event of a fire is inside your apartment.

Rich,

Correct. Those AHUs on non-essential power will contribute to pressure gradient but in the scenario of a simultaneous fire and power outage they won’t. This was a major concern of ours and I did an initial study a few months back to determine how many AHUs would be in this boat. The concern was asked if NDY and they have assured us the return/extract air will be enough to create the minimum 20 Pa; but when you add in potentially poor fabric air tightness I think it may be difficult to achieve.

In terms of evacuation and alarm, the design is for horizontal evacuation only. Each fire zone is fire-rated to 2hrs with some areas like central risers and Comms rooms are 4hrs. The idea, specific to hospital evacuation, is achieved by zone. The idea being you can’t evacuate everyone at once and some, those in intensive care or isolation wards, will take much longer. The initial alarm is via a sophisticated system that has a silent alert in zones on the same level so as not to panic occupants and allows staff to stage evacuation under control.

Interesting that you talk about approval by NDY. We ‘accept’ everything rather than ‘approve’ it in order to avoid being liable.

I assume the bills for this could be quite high if there are insufficient spare I/Os in the relevant controls boards!

Henry,

Interesting…Usually they would try and steer clear of ‘approval’ as I mentioned in the blog. If something does go wrong then it’ll be their IP that we go after. However, as the cause and effect is NDY’s initial design and what ever the subcontractor’s need to do to complete it is predicated on that initial design, therefore, we must get NDY to approve it. This is a major concern of the subbies; they are frightened of being held liable for when the system doesn’t work because we can’t achieve pressure gradients. But, the reassurance for them is, as long as they have followed the initial NDY design and NDY have commented and approved the design then they will be off the hook.

It’ll be interesting to see if NDY try and avoid approval but thier IP is already under jeopardy from many previous mistakes so we’ll see…

Henry,

Typo in the above reply, it should say PI – Professional Indemnity.

Fran, looks like a slam dunk against NDY that they will find it very difficult to wriggle out of if JHG really push the claim. However, the directors’ old boy club may yet come into play and a deal will probably be done on a golf course somewhere. Our take on this at Gatwick was trust no one outside of the business and sanity check everything provided by third parties. Unfortunately to do this you need to be an intelligent Client, something that is a lot easier to claim to be than to achieve. Ironically, this is exactly the sort of issue that BIM is supposed to prevent. If I were JHG, I would be looking closely at why it didn’t.

With regard to the fire mode for the AHU, as long as the supply is shut down in the affected area and the extract in the protected space, the fans will eventually achieve the required delta P, the only variable will be the time taken to do this and this will be determined by the flow rates of the respective fans and the leakiness of the building. I hope that it is inconceivable that a modern building is so leaky that the desired pressure can never be reached, but it is feasible that it may take so long as to be an almost pointless activity.

Jim,

Just came out of a lengthy meeting discussing this and the situation now seems to be more confusing than before we went in! Centigrade have potentially installed Fire Dampers in a number of Smoke Walls mistakenly thinking they were purely Fire Walls; this has happened as they confused the 1 hr fire rating of what is actually also a smoke wall. NDY are asking the fire engineer of the impact whilst Centigrade are investigating the extent of the problem. If the answer is they must be smoke – fire dampers then this will have serious commercial implications for Centigrade as the areas we investigated in the mtg have had ceilings completely closed.

A number of RFIs have been answered by NDY and it has been confirmed that the zones supplied by AHUs on non-essential power will be able to achieve a pressure gradient of min 20 Pa from the extract alone. Therefore, we will test and commission with any AHU on non-essential power supply switched off and only run the extract fans. However, we will then still need to test the pressure gradient achieved with the supply fans running to ensure we don’t create more then the 100 Pa max; to ensure the doors can be opened. This then allows us to ramp down the supply fans individually to programme the controls accordingly.

Clearly the proof will be in the pudding whilst testing and hopefully we can avoid having to employ mastic murphy!