Leaky Pipes

The main fun last week was that the boilers in FtIG shutdown unexpectedly. The contractor has left site temporarily making things more difficult. The issue is not yet resolved so I will blog it when further progressed. In lieu of that excitement here is a thought on sustainability/serviceability.

After the shutdowns of the dual temperature distribution piping from my mechanical room in FtIG we noticed that significant quantities of make up water are required to return the system to pressure; this means that there is a leak somewhere. To do my bit for sustainability I mentioned this to the client and was met by little in the way of enthusiasm.

Replacing the pipe work had initially been part of the scope of the project but as there was no cost benefit attached to it this element was removed to improve the pay back period of the project. This is because the project was funded based on energy conservancy it had to have a 10 year pay back period. The client that the pipes were leaking however didn’t attach a cost to this.

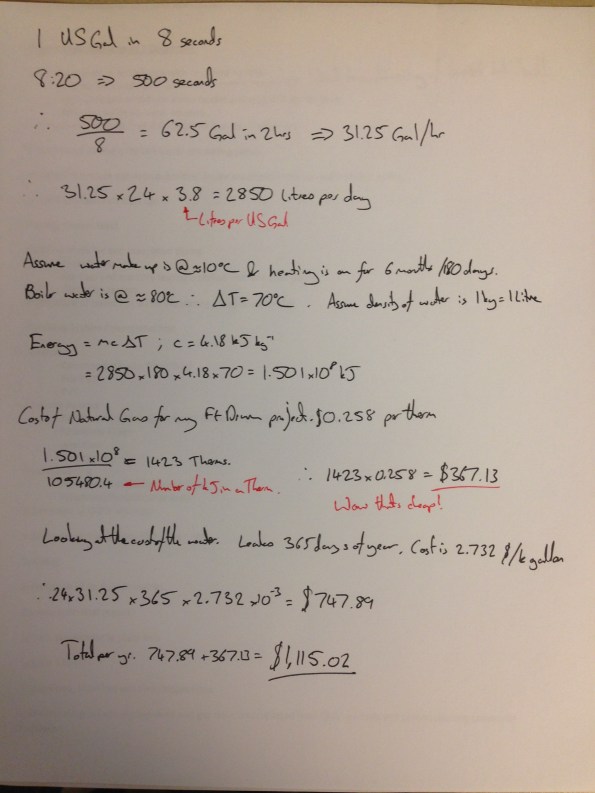

The cost is inconsequential now but for the opportunity to exercise my calculator I have had a stab at it. I conducted a test on site to work out the leakage rate before plunging into a heat loss calculation.

I shut off the pumps and make up water valve and left the system to rest. The static pressure was initially 10psi. To get a representative flow rate for the make up water I used the local tap off to fill a 1 gallon jug, this took on average 8 seconds.

After 2 hours I opened the make up water valve again and timed how long it took to refill the system. By now there was plenty of air in the system from the leaks and so once the valve stopped gushing I restarted the pumps to cycle the system through the air separator with the make up water valve closed to remove the air and ensure the pressure rebuilt to 10 psi. I repeated this process 3 further times until the system balanced. The time on the stopwatch for the make up water valve being open was 8:20. So

This method is clearly riddled with errors, for a start:

- Water leaking whilst I was refilling the system.

- Stop watch error.

- A static condition is not the same as when the system is operating.

- How representative the local tap flow rate test was to the flow rate of the system when nearing 10psi.

- The exact cost of energy and water; I used some figures from Ft Drum. I did an initial calculation using my electricity cost, this came out at $5,400 a year!

However the discussion has to start somewhere and some data, even with a large error value, is better than none.

Either way, had this test been done a few years ago it might have added $11,000 to the budget (or $12,500 if accounting for 2.5% inflation), which might have brought the system within the payback period. I have tried chasing down some of the early paperwork but to no avail.

More pressingly, we are due to treat the system with chemical to preserve the inside of the pipework. The contract calls for testing and topping up the system every month At 31.25 gal/hr the lost water rate is 31.25 x 24 x 30 = 22,500 gallons a month. I don’t know the exact size of the system but assuming 2000′ of 4″ pipework it would be 1300 gallons, which is about 2 days work for our leak. Therefore the contractor will be paying to completely re treat the system each month, significant quantities of chemical will be released into the ground and the treatment of the system will be totally ineffective in preventing corrosion.

I continue to beat my head against the proverbial brick wall on this one…

Henry,

How did you notice initially that significant amounts of make up water are required? Are you noticing leaks around the building yet or do you think it’s just weeps leaking into the lagging. Excuse my ignorance but is FtIG your big warehouse? If so are there concerns about equipment being damaged yet?

Good question, that I probably should have covered. Because the system being replaced has to be keept on line rather than being stripped out and refitted it has meant a lot of short outages while elements are fitted or tested. When restarting the system the contractor noticed he could hear pump cavitation meaning there was air in the system indicating one or more leaks. Anecdotal evidence of some leakage is that there are a couple of areas that don’t accumulate any snow during the winter as the ground is nice and warm; this could also be as a result of no/poor insulation on that piece of pipe.

FtIG is not the big warehouse, its another site. As far as the direct effects of water the dual water lines service 4 buildings and therefore run underground. The water leakage is therefore underground somewhere so will not damage equipment.

Is the client keen to attempt to fix the problem? Could there be pressure from an environmental aspect to have to do something?

If you are able to narrow down the problem locations through snow melt analysis could the costs of repairs be reduced?

So far the client hasn’t been keen to fix the problem. Rather than snow melt analysis I have been told by our sub contractor that the client has a thermal imaging camera and know where the leaks are! As far as the environmental aspect goes the chemical treatment isn’t that bad, by that I mean it isn’t illegal to discharge it, so I didn’t think it was the best argument to pursue. I got hold of the O&M manual for the boiler and I think it would invalidate the warranty so that is my primary tack at the moment. Ultimately though it is their decision which, I suppose, is the dilemma we are left in as engineers sometimes with respect to sustainability. We can state a sound case but if it is a little more expensive, or someone up the client chain isn’t interested the momentum stops there.