Archive

Friday Night in Harrisburg

All new buildings are required to complete an Air Barrier Test (ABT) and the Defense Logistics Agency (DLA) HQ is no exception. The leakage rate is important because it indicates how much conditioned air is being lost to the outside environment. It costs money and energy to condition the air inside the building and so it is wasteful to allow it to leak out. More specifically, as the client USACE specifies an allowable leakage rate and if the building fails then the issue must be resolved. Given that the leakage rate is determined by the construction method of the building and this building is very much in the stage of finishes being applied there would be no quick fixes if it fails; so it’s important.

The test was completed on a Friday evening a couple of weeks ago with a provision for a test early on Saturday if required in order to avoid interfering with other trades as the building had to be sealed for the test. Dusk is generally considered the best conditions for testing as the dT between the building and outside is the greatest to be able to detect leak causes using thermal imagery. Sadly, as you will see below this doesn’t necessarily make for the best photographic conditions.

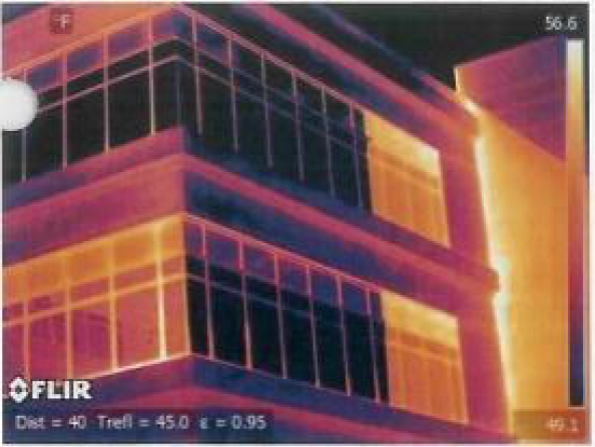

The test consisted of sealing up all ‘intentional’ openings, sealing a number of fans into one of the doorways and pressurising the building. The test was completed twice, first subjecting the building to a negative pressure and second subjecting it to a positive pressure. After a short while to allow the building to reach steady state it (where the pressure is not rising/falling) it could be assumed that the air leaking through the building’s skin was equal to the air the fans were blowing into, or out of, the building. The later was measured through a range of differential pressures to give the leakage rate. Whilst the an operator recorded these measurements for the first test, depressurising the building, the air tester and I walked around the building with the thermal imaging camera, and the less technical back of the hand, to identify any significant leaks. Any cold spots in the building skin or cool air blowing into the building were subject to investigation. For the second, pressurisation test, we walked around the outside to do similar but given the scale of the building this was less effective.

Fan bank 1. A second bank of 3 was put in a nearby doorway to provide sufficient flow rate to achieve steady state.

The system needs to read the same pressure at both fan banks. As the right hand bank has twice the number of fans of the left one it has twice the flow rate.

The standard.

The USACE standard is 0.25 CFM/75 sq ft enclosure, meaning cubic feet per minute per square foot of envelope at 75 Pa differential pressure. This, peculiarly for the USA is a single standard whereas in the UK we have a variety of rates to choose from depending on building usage. The units of measure in the UK are m3/hr50/m2, which is m3 per hour, per m2 of building floor area at 50Pa differential pressure. 2 m3/hr50/m2 is the UK standard for a low energy air conditioned office which is about 0.14 CFM/75 sq ft.

In an office building most of the floor area falls into this however, broadly speaking, unconditioned spaces are exempted; meaning that they have to be sealed off from the main building. Large complex buildings such as skyscrapers or buildings with significant restrictions to airflow, such as a single door separating two halves may be split into zones. The DLA HQ can be treated as one zone as there are large open plan areas and multiple stairwells and lift shafts. The building envelope is usually calculated by the Designer of Record (DOR) but in this case was calculated by the contractor, after a year of asking the DOR. The building is 309,240 sq ft, therefore:

0.25 x 309,240 = 77,310CFM is allowable for this building.

The leakage rate is tested at a differential pressure (between outside and inside) of 75Pa, which compares to 50Pa in the UK.

The practicalities of the test.

The sealing of ‘Intentional’ openings refers to closing all of the doors within the doorframes as well as any HVAC vents, kitchen flues and the waste vents. To ensure optimal pressure equlaisation within the building a few measures had to be taken:

- For every 500 sq ft of suspended ceiling at least 4 sq ft of ceiling tiles must be removed to promote pressure equalisation.

- All internal doors had to be wedged open; fortunately many aren’t fitted yet.

- The doors to the lift shaft had to be wedged open to ensure equalisation to the rooftop mechanical room.

The biggest issue was doors blowing open on the tests destabilising the pressure. The prime contractor had let all of their guys go, for the day, to ensure good running of the test having people, with some form of comms, ready to chase down open doors would have made the whole process a lot simpler. Having plenty of guys on standby would be something I imagine the RE would have got right!

Six of the nine fans used drew a maximum of 3kW. Each of the 230V circuits (the building has 110 and 230V circuits) had a 15A breaker meaning that it could only support one of these fans, or two of the smaller 1.5kW fans. This resulted in about 30 minutes of getting out electrical drawings, resetting breakers and moving extension leads around. The master electrician could have planned this prior to the test.

Results.

In the end the building passed with ease however there were still some interesting elements. The biggest loss areas are:

- Doors. Being freely moving there is always going to be a level of leakage through these. If the building had failed by a small amount then upgrading the seals would have been a way of marginally improving performance.

- Although none of the windows open, as they are penetrations into the buildings skin they act as a potential break and pathway. One window had a good breeze blowing through it that could have been sealed with a bit of mastic if required.

- Sockets and fittings, both internal and external. Again a penetration into the building’s internal skin where air can finally leak through.

- Architectural Interfaces. This would have been the main problem at the DLA HQ. Where differing building methods meet the interface can cause an issue if it is not properly sealed. An example is the auditorium on the DLA HQ which is essentially another building tacked onto the side of the main building. It was built using prefabricated panels, whereas the main building was cast in place. This had been identified as a risk in construction and was mitigated by the liberal application of spray foam.

A doorway. This is taken on the depressurisation test therefore the dark section is showing cold air blowing through the door seal.

The normal picture comparison was black. This shows an architectural interface between a precast structure and a clockwork construction with facade. As this is taken from the outside the bright yellow is showing warm air escaping.

The results came in last week showing that the building had leakages of 0.143 and 0.132 CFM/ft2 for pressurisation and depressurisation respectively. So it passed with ease in the USA, but might have only scraped through the UK equivalent test because of its complex architectural features.