Oz NDY – Vetwest Animal Hospital.

Introduction

Introduced previously is my current short-term project; designing a fitout for a Vetwest animal hospital. This is my first project as a Project Leader (PL), essentially project managing from start to finish. Before leave I/we submitted a concept design solution for review by our client, the managing contractor, Perth Citi Fitout (PCF) and their client, the building occupier, Vetwest. This blog discusses the on-going project and challenges.

Concept Solution Review

Reading my first client email correspondence, with reference to the concept design, I am already sensing the commercial challenges of the client facing side of design consultancy. PCF are concerned about changes we have made from their initial thoughts, particularly referring to the mechanical design of the air-conditioning (A/C) system. This is because we have included additional equipment which will increase their costs and eat into their profit margin. Without seeing the contract between Vetwest and PCF it’s hard to know if PCF are on a fixed price contract or not. I think they are as indicated by the technical data sheets they supplied us for the air conditioning units, which included a supplier quote of AUD $55k for 3 x Daikin split DX Variable Refrigerant Volume/Variable Refrigerant Flow (VRV/VRF) units.

Our concept design suggested 4 x packaged units costing circa AUD $70 – 100k. This was based on the layout split into four zones and included a dedicated unit for the HEPA filter in the surgery room. Packaged units aid in mitigating operational interruptions for maintenance as they will all be roof mounted. But PCF’s proposed split DX units would mean the indoor unit being located in the ceiling void which would disrupt operational use, including treatment/surgical operations. There are also other benefits of using packaged units but PCF, with confirmation from Vetwest, want to keep the costs down. That’s absolutely their prerogative but our view is split DX units are more suited to domestic buildings rather than commercial.

Although not our contractual duty, we feel we must look out for the interests of Vetwest and provide a design solution to their requirements, especially as they are seeking Australian Veterinary Association (AVA) hospital accreditation. This will indirectly aid PCF because if they fail to deliver the scope of works in accordance with Vetwest’s specification then they will become liable for variation charges.

How to manage this…

In order to tackle this I set about highlighting the benefits, via justification, of our design. Annoyingly, this information had already been submitted, written into a Consultants Advice Note (CAN). But, not wanting to simply reiterate this information, I set about giving the problem its due diligence by providing additional information which I gained from further research. This gave me the opportunity to review our design myself and pick-up on a couple of improvements that could be made. For example, the specific requirements of the Accreditation Scheme for the AVA (ASAVA) referring to the prohibition of any Air Transfer Grilles (ATG) and requiring a dedicated exhaust fan to outside the facility for the isolation room. This also included a dedicated exhaust fan and a motorised volume control damper connected up-stream of the supply air (SA) grille. This ensures the design’s ability to maintain negative pressure and if the exhaust fan should fail the SA damper can be completely closed to avoid positive pressure build-up.

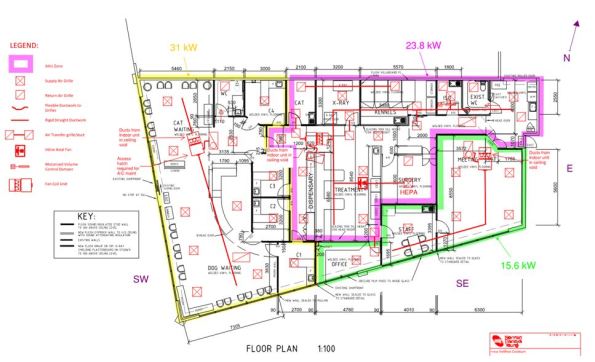

Talking this through with the Project Director (PD) we came up with a compromise and amended the concept design, see figure 1. We reduced the number of A/C units to three, utilising the split DX units PCF proposed to keep costs down, by combining the surgery room with the rooms in the purple zone. The surgery room would therefore require its own SA leg of ductwork and a dedicated inline booster fan to overcome pressure losses from the HEPA filter unit. It would also still require a dedicated exhaust fan as air from the surgery room cannot be returned to the main A/C unit.

Other changes were: combining exhausting air from the cat and kennel rooms, via linked ducting, which reduced the number of exhaust fans by one; reducing rigid ducting and replacing with flexible ducting where possible, but still in accordance with BCA guidelines where maximum lengths of flexi duct must not exceed 6m; and; designing in two options for drainage, one using bucket and floor waste traps, the other a grease trap. This was TBC by Vetwest as to the outcome of their application to Water Corp for a trade waste permit. Ideally this should have been done before so we knew the exact requirements for which we are being asked to design to rather than us having to suggest multiple solutions.

I also drew-up three hydraulic concept designs for: hot and cold water, oxygen and suction, and drainage.

Figure 1. Revised Mech Concept Design.

Next steps

These changes were submitted to PCF and Vetwest for review and I am awaiting their feedback. Vetwest physically gain access to the building on the 1 Feb so is the earliest any on-site works can commence. Therefore, once the concept design has been approved and frozen (hopefully in the next two days) we have said we can complete final detailed design two weeks from then. So hopefully ready by the 1 Feb. In the mean time I am cracking on with software based heat load calculations so I can size the A/C units for the supplier to order in and stay inside lead times.

Heat load calculations

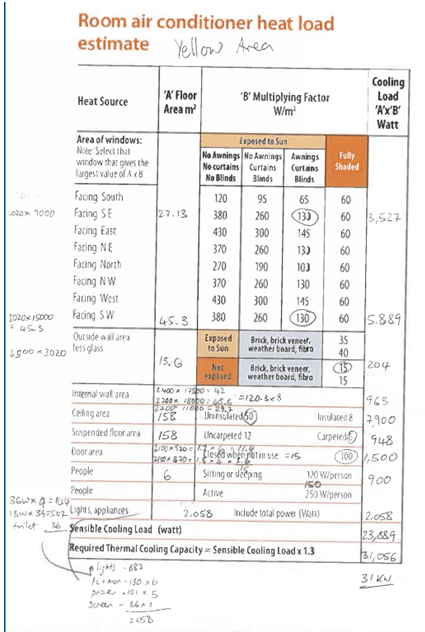

Figure 2 shows an example of my initial estimated heat load calculations – using the Australian Institute of Refrigeration, Air Conditioning and Heating (AIRAH) template.

Figure 2. Estimated Heat Load Calculations for the yellow Zone.

For detailed design NDY currently use a software package called TRACE to calculate heating and cooling loads in order to aid sizing of key plant, such as, A/C units, boilers, etc. It is shortly to be superseded by an advanced programme called CAMEL; I vaguely remember Ben Foster making a pun about it when comparing it to Hevacomp. CAMEL has the added bonus of integrating its building details and input data with another software package called BEAVER. BEAVER is a building energy simulation programme which is used by the majority of building owners/occupiers to estimate: heating, cooling, fan, equipment and lighting energy consumption. However, for this project I will be using TRACE.

What did I learn?

In summary, so far – a lot! It really is just like conducting one of the projects from Phase 1, so in that respect that was perfect training. The only real difference is the standards being Australian – but then they are very similar and searching for them is the same.

Stakeholder engagement is key. We had an initial project meeting before Christmas and followed it up with a site recce. Getting stuck into the detail this past week has highlighted a number of areas that needed clarification. Therefore a number of RFIs, directed at both Vetwest and PCF, were sent, all to aid project management. The good old fashioned telephone being the preferred method, with all communications followed up in writing, be it by email or CAN.

Thanks Fran,

Great to be seeing a job from start to finish, esecially engaging with the client side on design principles. A little surprise that you, rather than a technician, are crunching numbers for heat load calcs unless it’s proof of concept thumb nail stuff but I guess that’s the E&M way of things

Richard,

It is good to get involved with the client but also extending the stakeholder engagement to Vetwest direct; for clarification of certain aspects but more importantly expectation management.

In terms of crunching numbers, it is very much rule of thumb concept stuff but important to go through and understand none-the-less. I see it akin to playing the role of Sect Comd on exercise whilst at Sandhurst; everybody wants to be the Pl or Coy Comd but you have to learn and understand the basics first, what your men/women (technicians) have to go through.

Additionally, the design office is structured such that even Project Leaders (PL) help out with concept design. For me personally it also helps, having never worked in a consultancy before and jumping straight in as a PL means there’s potentially a level of technical stuff I’m not fully up to scratch with.

Fran

Good to see the projects come in handy, even the time spent in hevacomp gives an appreciation of what needs to go in at the early stages to get any sensible answers out to a client.

A good example for PRI in the making here, and a bonus to see a project all the way though.

Mark,

Absolutely. Although using TRACE heat load software feels like deja vu of using Hevacomp, including all the frustrations experienced!

Fran

For me the majority of the building looks straightforward, good exposure for PRI but straightforward. For me the clinical areas would be the focus. Have you identified any specific areas of concern? I’m thinking low level extracts, transfer grilles and pressure relief to maintain sterile conditions mainly but there will be other issues undoubtedbly. I appreciate this is a Vet site so I’m interested in the parallels between this and hospitals.

I’m still intrigued with respect to the medical gases being supplied to the OR. If this is a fully functioning theatre which would be suggested by the need for a clean air unit then how is the requirement for anaesthesia being met? Coupled with anaesthetics there would also be a requirement for AGSS which is something better thought about early. I’m also surprised not to see compressed air supplies too. Oxygen and vacuum seems like a small provision, even in the veterinary world.

Mark,

Areas of concern I have are:

Drainage – I’m awaiting Water Corp’s specific requirements for any pre-treatment before entering the wastewater system. This will come in the form of a trade waste permit. There was talk initially of needing a grease trap (although no food preparation on-site) but we want to value engineer this out and use localised bucket and floor waste traps.

Air-Cleanliness – Was initially a concern but I now have confirmation that our HEPA filter design in the surgery is following ‘best practice’ guidelines. Using an inline fan to overcome pressure losses from the filter and a dedicated exhaust to outside. Similarly for the isolation room where we have a dedicated exhaust to outside and the supply air will have a motorised damper so in case of exhaust failure we can reduce the air flow rate to maintain negative pressure. These two points massively help Vetwest in gaining the AVA’s Hospital accreditation.

I actually talked through these design principles with the veterinary doctor who reviews the accreditation scheme applications; he liked what I was suggesting and even asked for company details so he could pass on our expertise to potential clinics/hospitals seeking consultant advice/work.

Mech design – Trying to get the three FCUs positioned so that, where possible, we solely use flexible ducting to keep costs down. The BCA stipulates a max 6m length between hard fixings; I think I have managed it but the detailed design will confirm this.

Availability of space – Although not technical but a very real practical concern. Vetwest have asked that the suction compressor and oxy cylinder supply along with the following all go in the back of house area (3.5 x 4m): heating water unit (25 ltr), freezer, W/M, dryer, wash sink, switchboard and fire hose reel. This will be tight enough and now I have heard from the MC that the currently locked down roller shutter door, due to an existing cylinder store the other side belonging to another business, is to be utilised as rear entry. Something I am eager to confirm and that they neglected to inform us of earlier.

In terms of medical gases – The only requirement from Vetwest is for oxy and suction. I am therefore assuming they provide anaesthesia via injection then maintain via a separate anaesthesia machine (cylinders) mixed in at point-of-use with the oxygen. Therefore negating the need for a AGSS, although this could be coupled with the venturi suction sys.

Oxy – is using cylinders reticulated from the back of house room and they also produce their own in-house oxygen with a portion supplied from BOC.

Suction – As they already have a compressor and wish to utilise it I am thinking of designing a venturi suction system rather than using a suction pump. The AS states free-flow rates not less than 40 L/min and suction not less than – 60 KPa gauge pressure.

No compressed air supplies due to not using medical air and so probably why they don’t require reticulated nitrogen for powering surgical tools. This may be being supplied at point of use direct from cylinders?

Overall I think there are parallels between this and hospitals but maybe not quite to the extent you think. This is a very small set-up and I don’t have the figures for no. of operations per year but a quick Google search came up with the majority being for cosmetic reasons at the owners’ convenience, such as, debarking and tail docking. Western Australia has 341,000 dogs and 303,000 cats with Australia having the highest incidence of pet ownership in the world at 66% of homes. By comparison the US has 65% and UK 51% (Petcare information and advisory service).

Fran,

On the commercial front do you have any direct communications with the client or does it all go through the MC? Curious as the later would obviously muzzle your potential to be able to highlight issues to the client if they were going to end up with a compromised design as a result of the MC trying to maximise their profit margin.

Also debarking! I thought it was a spelling mistake until I googled it. I’m no animal rights activist but I’m pretty sure I have an issue with that.

Henry,

You are correct, and that is why I sought permission from the MC in order to discuss matter directly with the client.

In addition to what I originally wrote, having spoken more frequently with the MC, I actually believe that although they are concerned about their profit margins, they also want to see that the design meets the client’s requirements; something that could otherwise end up biting the MC in the backside.

Ditto reference the debarking; it’s a bit like buying a goldfish and then being annoyed that it swims.