Archive

London School of Hygiene and Tropical Medicine Update

As previously mentioned one of the projects I am involved with at Bryden Wood Limited (BWL) is the replacement of steam plant at the London School of Hygiene and Tropical Medicine (LSHTM). This blog is a long overdue update on the project, which aims to give background information and highlight what I’ve been doing.

The project

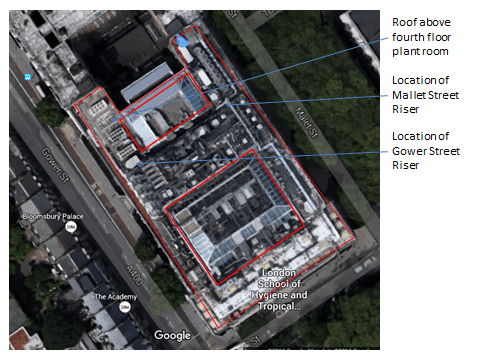

The LSHTM currently has two steam generators that are sized to produce 1300kg /hr of steam at 10 Bar g (g denotes gauge pressure). Steam within the building is mainly used for autoclaves (units you put kit in for sterilisation) and a couple of air handling units (AHUs) although the current generators are also linked to a district heating system and provide redundancy for an element of the school’s heating system. The generators are located in a sub-basement and distribute steam up two risers to serve the loads in the building. The LSHTM was originally shaped like a capital A. Extensions to the building have seen the two hollow sections within the building filled in. This is leading to insufficient ventilation reaching the plant room where the steam generators are, resulting in the building overheating. Analysis of the use of steam within the building has identified that it is no longer required to supply the district heating system and will only be used as a back-up heating supply in extremis. Therefore maximum steam demand is 520 kg /hr.

Aerial view of LSHTM. The red line demotes the outline of the building which used to form a capital A shape. The two hollow sections of the building have now been filled in.

The client, LSHTM, therefore wishes to install two new, appropriately sized boilers at fourth floor level and take steam back down the building to serve various loads. The existing system will stay in use and only be stripped out once the new system is fully online. This will require a period of gradual handover from systems as individual loads are brought online. The project is valued at £1M and the consultancy fee is a fairly small £50K.

The BWL team looking at this project is 3 strong; a director who effectively brought the job to BWL when he moved company, myself as the mechanical lead and an electrical engineer. The project is mainly mechanical in nature and the director is keen to take a hands-off approach, so I’ve essentially got a huge degree of responsibility and autonomy on the project which is great.

Steam

Before I go any further it’s probably worth explaining a bit about steam, although I won’t fully explain all the concepts this will end up like War & Peace. The following link is very useful and informative if you get involved with steam design at all or want more information:

http://www.spiraxsarco.com/Resources/Pages/steam-engineering-tutorials.aspx

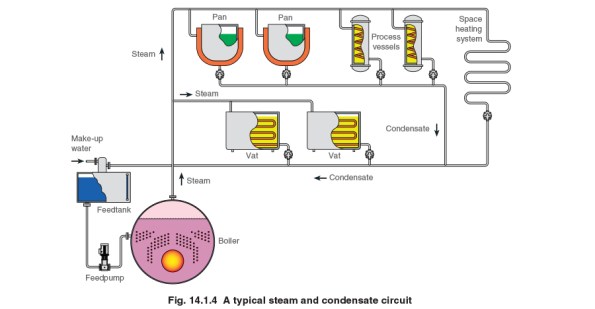

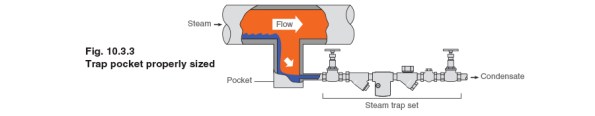

In normal mechanical systems it is usual to see a flow and return pipe. This is the case when dealing with steam except that the flow pipe contains your steam, which is dry saturated steam (steam that has had energy added to it so that it is completely dry) and the return contains something called condensate. Condensate is generated when the dry steam is subject to a change that allows it to change state to a wet steam of liquid. This change in state can either be caused by a drop in pressure or temperature. The change in state can be deliberate – the steam is being used in a processs e.g. through a heat exchanger or unwanted, e.g steam running along a pipe cools and condensate is generated due to the loss in energy. What we don’t want to happen is for condensate to build up in steam lines (impacts the performance of heat exchanges, is corrosive and can lead to water hammer damage), therefore condensate is removed using something called a steam trap. We also don’t want to waster condensate if possible as it still has energy within it which we can reuse at the boiler / generator and is valuable in that water going into a boiler needs to be treated. Reducing the amount of new water required by recirculating condensate reduces costs massively.

What have I done to date?

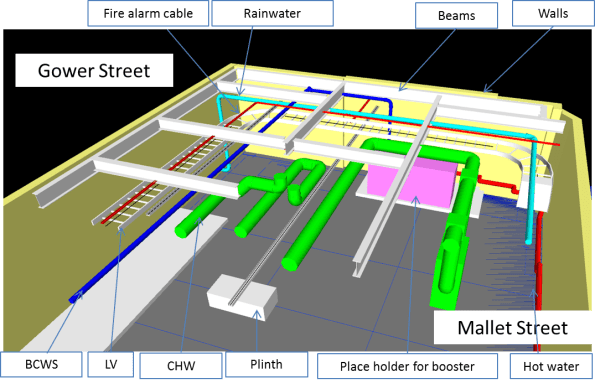

I’ve surveyed the site and produced a basic REVIT model of the plant room that we need to put the new boilers. In conducting my surveys I’ve also identified that one of the AHUs being served by steam isn’t utilising the steam (valves isolated and pipes cold), I’ve since spoken to the facilities manager who has confirmed this has been the case for two years. This has allowed me to removed the AHUs from the steam load profile a saving that allows me to drop down a model size on the boiler and save the project up to £50k – not bad for just having a walk around. I’ve just pulled together and submitted a Pre-Qualification Questionnaire and mini-tender document for the purchase of the steam boilers which goes a long way to filling the short falls in my C competencies from phase 2. Next stage is to move onto a bit more detailed design and start sizing pipes.

Basic REVIT model exported to NAVISWORKS to show the constraints within the fourth floor plant room.

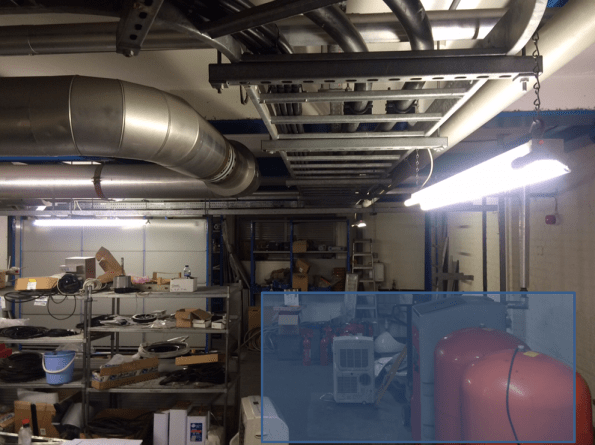

View within the fourth floor plant room where the new steam plant will go (denoted by the blue square).

View within one of the existing risers. This is the better set out of the two, the other looks like someone has just thrown pipes and wires in. There appears to have been plenty of expansion over the years but not stripping out. There are also no as built drawings or schematics, which when services are incorrectly labelled makes coming up with a plan interesting.