Shear and UPL

Shear and UPL

This is not what I am doing but a technical problem has popped up on a site one of the members of my team oversees and I thought it was interesting.

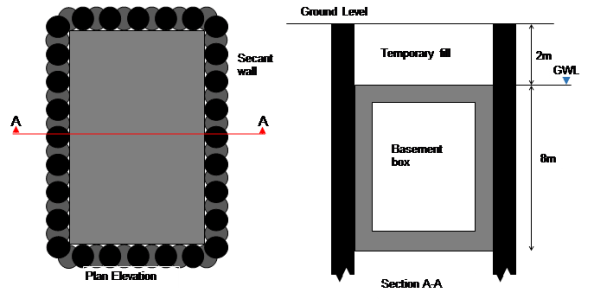

Imagine a secant wall in a rectangular formation with an in situ basement box to be poured inside it – see below.

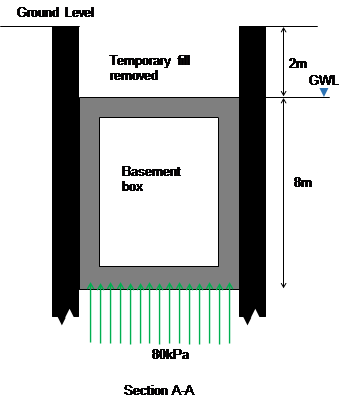

The base of the box is at 10m below ground level and the water level is at 2m below ground level. Over time as water pressures return this creates an uplift stress of 80kpa. Assuming the base and walls have a downward stress of about 60kPa this leaves a remaining 20kPa downwards stress needed. When the fill is placed above the box this results in a net downwards pressure (bulk weight of soil (20kPa multiplied by 2m gives sufficient resistance). However, let us assume that the fill gets removed for a subsequent development (as is planned).

The risk is uplift failure (UPL), I.e. the box tries to move to the surface because of the buoyancy effects.

The solution.

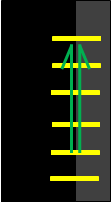

Dowel bars (yellow) between the male secant piles and the internal box provide shear resistance (green arrows) to stop the box lifting up.

Dowel bars fixed between piles (black) and inner box (grey)

The problem

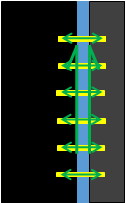

Suppose over time water is able to get between the secant wall and new basement box. Over a bit more time the gap between the secant wall and box might increase a bit more. So the dowel bars now act in tension between the secant wall and hydrostatic head (blue) pushing the box inwards. Over more time still and the dowel bars act in tension due to the lateral force (horizontal green arrows) applied by the hydrostatic head which makes them strain, or elongate, and therefore have a slightly reduced shear capacity.

Tension in dowel bars created by hydrostatic head, dowel bars strain (extend).

An 8m depth of water implies 80kPa or 80kN if the dowel bar resists one metre square (for simplicity). E=(F/A)/(ext/original length). Ext/orig=(80/pi d2/4)/E, E (210GPa), d =40mm, implies 0.2mm/600mm multiplied by E (210GPa) equals 70MPa axial stress.

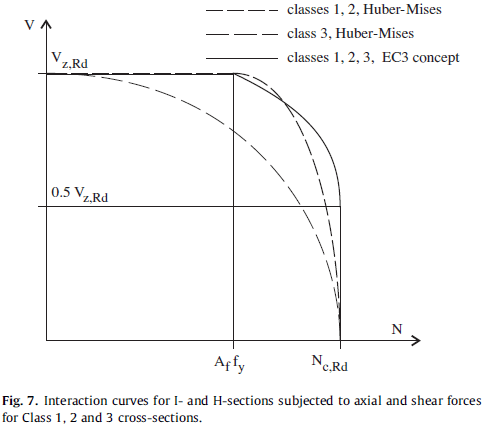

Remembering back to EC3 days or Von Mises, as axial force increases, shear decreases. Therefore this increase in stress in axial force (N) may reduce shear (V) to below the design capacity – Vz Rd reduces as axial force increases.

The question is why does the reinforcement bar extend by 0.2mm? The design specified a plain bar, the contractor installed a normal ribbed reinforcement bar into the secant wall which would generate tension between the secant wall and inner box as the hydrostatic head builds. A smooth bar would also lateral movement without reduction in shear capacity.

The problem is worsened when uplift occurs because the rebar it put into bending and therefore undergoes further reduction in capacity. See the 3D graph below where moment reduces capacity even more.

The solution (2)

Install a sleeve over the rebar thus removing the interlock effect of the ribs on the inner wall. This allows lateral movement of the dowel bars to avoid any axial force. Uplift is ten resisted by the dowel bars as planned in the design!

Summary

Clearly there are a number of assumptions and simplifications in this blog (basement box would also resist some lateral force reducing movement, soil type ignored, move to drained approach). I thought this issue was seemingly minor, but with an accumulation of risks (tri-axial forces) the consequences could be high. I would argue the likelihood of the risk arising is low but having specified a design solution to a complex problem, Arup was not going to reverse its view (with full finite element analysis to back up assertions) just to hurry the job along.

If I take a free body diagram of half the box and turn is on its side: I’m le ft with a concrete table; the (hydostatic action on top of the table varies from 0 to 80kPa linearly) Also on the ‘top’ of the table are a set of (tensile) spings( if the dowles are ribbed). I would suggest that if you modelled this in StaAdPRO You midght find theat the box wall thickness limited the (tensile) load in the spings, with a preferential load path to the base and top ( the legs of my table) . Let’s say then, the unavailablity of stiffness in the dowels limits the imlied load. This is turn limits the extension of the ‘dowel springs’ . If there were a basal uplift which dowels would accept the (potentially moment inducing actions) A) eat max extension and therefore min flexural rigidity OR B) those of minimum extension and greatest flexural rigidity?

Answers on a postcard please

Bloody clever these Arup types!

John, you have not lost the ability to ask difficult questions where the question in itself is complicated!

If I understand your question, I would go for B because with minimum extension those dowels have not strained as much and therefore have more capacity to carry moment inducing actions. If modelling with StaadPro are you putting the supports on top of the concrete table so the table is in theory hanging off spring supports or are the feet of the table on supports? I assume you place a triangular UDL load (0-80kPa) on the table top, then on one table leg apply a constant UDL of 80kPa (base of structure/vertically up the table leg)? The question being do the dowels which extend carry less moment (i.e. dowels towards the 80kPa loading carry less moment).

I’d agree

Yes you have it correct ‘srings resisting the pressure (sort of hanging in my model)

Triangular pressure distribution with the base ressure as you have it

The dowels with the greatest extension have a ‘felxural rigidity (EI/L ) where the L is the extension becuse otherwise the uplift is resisted in pure shear

Presumably you can’t inspect the dowels to confirm corrosion etc so there’s a time dependent risk in relying on them in future. Any reason why the basement couldn’t be internally ballasted during removal of overburden and construction? fill it with water and then pump out…

Hi Richard – I am not sure if the dowel section size took account of corrosion but I suspect it did for the design life required. A waterproofing membrane (painted) was also applied to the dowels so that is likely to help the corrosion risk for a period, although as you say this will be unchecked.

The basement is going to be full of plant equipment. The design was required to mitigate the risk, i.e. a post construction action is/was not planned.