Archive

Oz NDY – Return Air Plenum Issues

Introduction

Prior to Christmas I was given an interim task to investigate complaints of doors being hard to close with loud whistling noises coming from the plantroom door on level 4. The project is a typical tenancy office fitout with construction complete and the office space occupied by Synergy staff.

I was given an initial steer by the project leader; his view being restricted Return Air (RA) flow to the AHU.

Background

The design of the floor (slab to slab) uses the ceiling void as a large RA plenum. The plantroom, containing the AHU, acts as a large mixing chamber mixing the RA (from the plenum) with the Outside Air (OA), which enters through louvers in the skin of the building. It incorporates a CO2 monitoring system that controls the motorised louvers to alter the amount of OA required to keep CO2 levels within permissible limits.

The main floor space is split up in to a number of offices (various sizes) and larger open plan areas. To reduce the chance of cross-talk between these areas full-height partition walls were constructed. Whilst this met the acoustic requirements it created a subsequent problem; the RA was being severely restricted in its attempt to get back to the AHU.

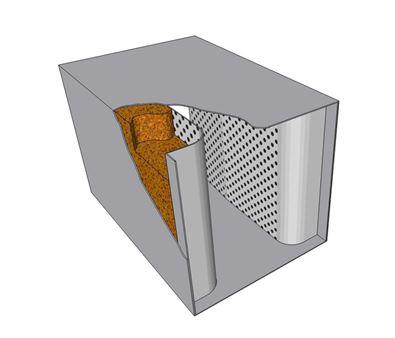

To resolve this, the design incorporated the use of Air Transfer Ducts (ATDs) installed through the partition wall. ATDs are essentially fitted into a rectangular cut-out in the wall and consists of standard metal ductwork lined with acoustic material. This allows both air flow through it and simultaneously reduces carried sound, as shown in figures 1 and 2.

Figure 1. Basic ATD with Acoustic Lining.

Figure 2. ATD in Use.

Identified Issue

A typical problem found in RA systems, that utilise a plenum rather than a ducted system, is not enough RA finding its way back to the AHU. In this case the number of installed ATDs is insufficient to allow the correct amount of return flow and is creating positive pressure build-up. Effectively, the mixing chamber (entire plantroom) is being starved of its required RA (under negative pressure) and the CO2 monitoring system, not seeing excessive CO2 levels, won’t allow any more OA in. Therefore, the only available air remaining is from outside the plantroom in the corridor (which is under positive pressure) and is now being sucked (willingly) into the plantroom and creating excessive whistling noises. Figure 3 shows a basic sketch I drew to aid in visualising the situation.

Figure 3. Situation Hand Sketch.

What’s possibly exacerbating the issue is the CO2 monitoring system. Because the RA is being restricted the CO2 monitor is most likely reading low CO2 levels, therefore signalling to reduce the OA intake as it’s not required to dilute the RA. This then creates increased negative pressure inside the plantroom and thus makes it easier to pull in air from the corridor due to the AHU fan demand. It then become a vicious circle as this extra air being pulled in from the corridor is most likely to come directly from the SA grilles, with little human traffic, meaning the CO2 levels will low.

Depending on how much the RA is restricted will determine the severity of the symptoms found.

During construction there were a number of design changes, doors being relocated and the like, which caused the air flows to change slightly. This however, is not deemed a significant reason for the symptoms being experienced.

Resolution

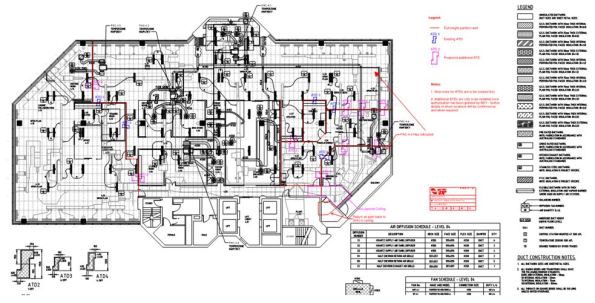

The resolution quite simply requires increasing the number of air passages through the full-height walls. As stated this had already been designed for and implemented through the use of 5 No. ATDs, however, clearly more are required. Figure 4 shows the drawing mark-up with existing ATDs (blue) and my proposed design for additional ATDs (pink).

Previous Resolution Attempts

The mech contractor had already attempted to solve the issue by cutting holes in certain locations within the full-height walls. While this may have helped to alleviate the issue, it has not solved it.

Figure 4. CAD Drawing Mark-up.

Design Calculations

I conducted some basic calculations to determine the number of ATDs required, allowing the same rate of return air flow as that being supplied to the floor space, resulting in a more favourable neutral pressure.

The calculations included splitting the floor space into sections, boundaries based on the full-height partitions, where I then added together the SA from each diffuser in that section. I then worked out the area required (using Q = A x V based on a 5 m/s air velocity) to get that flow rate through the wall to the next section. I continued the same calculations for the other sections, remembering to carry through the flow rate from the previous section as the RA from the entire plenum space is trying to get back to the same point (left to right when viewing the dwg).

In total I calculated an additional 9 No. ATD2’s (600mm x 400mm) were required. In truth it’s only the cut-out dimensions that are actually required to solve the air flow issue, not the ATDs per se.

Design Considerations

There are important factors in positioning ATDs within a plenum: availability of space between the upper floor slab and false ceiling, space between other services, and understanding the use of the rooms either side of the full-height wall to name the most important. All these were considered in my design. The last consideration, the use of rooms, is particularly important as this could determine the possibility of negating the need for ATDs in a particular location altogether. That is not to say there wouldn’t be a cut-out, just no ATD installed, so still allowing the required passage of RA.

COAs

Two COAs were considered, with time, cost and quality in mind. However, before the suggested COA is carried out a number of RFIs must be answered by the mech contractor, these are: confirmation of the location and size of previously made cut-outs, and an estimate on the availability of space to install the ATDs. The location and size of previous cut-outs is important as these could be utilised and potentially increased, based on the calculated sizes above, as suggested in the COAs below.

COA 1

This would be conducted in two stages, both during out of hours so as not to disrupt staff working:

Stage 1 – Make the cut-outs in the full-height partition walls as indicated on the mark-up drawings. This should solve the issue, however may lead to excessive cross-talk. If the room pressures have been restored, the symptoms disappeared and there is no detection of cross-talk, or it is at an acceptable level, then the works will be complete.

Stage 2 – Assess the level of cross-talk, if it is not acceptable then conduct stage 3.

Stage 3 – Install the ATDs in the designated cut-outs, thus solving the cross-talk issue.

Pros and Cons

The main pro is: If stage 1 is sufficient there will be a substantial cost saving on negating the need for possibly all or at least some of the ATDs; each approx $1000 a piece depending on size.

The con is: If stage 2 is required then there would be extra labour costs due to the mech sub-contractors having to go back a second time to install ATDs.

COA 2

Do as COA 1 but all stages in one go.

Pros and Cons

The main pros are: Reduced labour costs for the mech sub-contractor and all the work being done in one go means minimal disruption.

The con is: The ATDs may be superfluous in solving the issue and therefore present an unnecessary cost.

Noise Level Consultation

I discussed the issue with our acoustic engineer and am confident that the overall cheapest option, that still achieves the required acoustic quality levels, is COA 1. This is based on not all the positions identified requiring ATDs. The exact number cannot be confirmed until a further assessment is conducted post stage 1 of COA 1.

Recommended Solution

The recommend solution is COA 1 but I envisage having to discuss these actions with the mech contractor, as alluded to, to get answers to my RFIs. This may also involve going on site to discuss further.

Update

During the preparation of this blog I learnt, through a third party, that the mech contractor indicated it wouldn’t be possible to fit the ATDs as proposed due to lack of space in the partition wall around the plantroom. There were some other suggestions mentioned, such as, installing a large transfer grille in the corridor/plantroom wall but this would need to be quite large to solve the issue and would likely look pretty rubbish not to mention noisy. It would then require an attenuator on the plantroom side to attenuate the plant noise. I think the next step is to meet with the mech contractor to discuss options.

What did I learn?

A key observation, which extends to all projects, has been that no matter who you ask for advice, you will always get a slightly different answer. The key principles will be the same but individual engineers’ will be basing their ideas on their accrued experience. I suppose this highlights the meaning of engineering, derived from the Latin ingenium, meaning ‘cleverness’ and ingeniare, meaning ‘to contrive or devise’, and just goes to show there is more than one way to skin a cat. The challenging part is to learn how and why these little design nuances can aid in delivering a more technically, sustainable and economical solution and therefore aid in refining your design skills. The technical solution also needs to be balanced with any political considerations, especially when wishing to win any future work with the same client.

I also learnt about the disadvantages of plenum based return air systems and found this article helpful in understanding:

In Other News

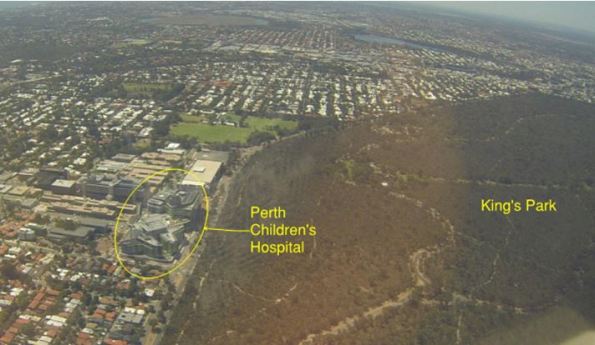

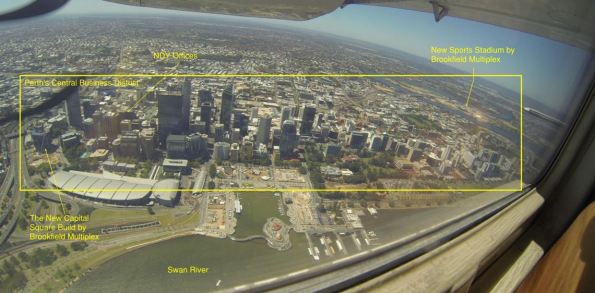

I organised a surprise birthday present for the wife; a great view of Perth from 1500ft. It included a shot of JHG’s PCH project and the new sports stadium, managing contractor being Brookfield Multiplex (new alternate Ph2 attachment). I’ve also included a few other snaps…

Perth Children’s Hospital.

Perth’s New Sports Stadium – Still in the structural build stage.

Perth’s Central Business District.

WA Coast Line.

Happy Wife Happy Life!