Archive

Silver Spoon, Wooden Spoon

My design attachment has been very different from what I expected (I blogged about this a few weeks ago).

It seemed as though I had been given the silver spoon with the design manager job for the Calder Highway Overtaking Lanes (CHOTL). It doesn’t give me quite as much depth as I was hoping for, but the breadth is there in terms of attribute achievement. But it would seem that with my silver came a wooden one too…

I don’t have much else to focus on in the office (anything, in fact). Managing the CHOTL project has busy days and quiet days. As a Contractor seconded to GHD, I have to fill in a weekly timesheet that charges to whatever job I am working on. I was ‘sold’ to GHD by JHG, promising 40 hours per week for them to do with me what they will.

The issue I raised this end yesterday is that I am here until the middle/end of June. The estimate for the CHOTL project only allows 150 hours of my time (3.5 weeks full time). So the more time I invest in my project (or charge to it, at least), the greater my chance of going over budget. If I clock in fewer hours then GHD is ‘not getting their money’s worth’. Seems a little short sighted sticking me on a modest lump-sum agreement project with a 12 week timeline and when I can only apply myself for a third of it.

If I was GHD, I would be frantically trying to find a bigger project with a bigger Client to charge me to.

CPD/what I wish I’d known about the thesis

CPD/what I wish I’d known about the thesis

This is just a quick blog to follow on from the very useful blog by Rich Garthwaite on CPD and then talk a bit about the thesis.

ICE events.

There lots of presentations at One Great George Street which generally start at 18.30 so can be a good excuse for leaving site at a sensible time. There are a few annual talks which I have attended and thought were interesting for those in London or for those not, logging in online.

Joint Professional Meeting between the Royal Engineers and ICE, this year on 28 April 2016.

James Renie Medal – this is the top 3 successful CPR candidates from the previous year vying to demonstrate that they best reflect Renie’s principles.

ICE tour and history presentation. I did not hugely rate the presentation but having been to a few more things since, knowing a bit about the background to the creation of the ICE as well as seeing more of the institution’s home is only of benefit. The tour is by all accounts good.

Flemming Award, Smeaton lecture and John Mitchell lecture. These annual lectures which cover a geotechnics (and other topics) and two were recorded.

https://www.ice.org.uk/eventarchive/the-2015-fleming-award-competition

https://www.ice.org.uk/eventarchive/smeaton-lecture-2015

For those more geotechnically minded the Rankine lecture at Imperial College is pretty much the top end of geotechnical discussion and worth going along to hear about current themes in academia and industry. Next year (March) will be an overseas presenter. Don’t under estimate how popular it is!

These all help both towards CPD hours as well as attribute 9 in terms of participating in ICE events.

Thesis

The second point of this blog is just to point out some of the ‘what I wish I’d knowns’ regarding the thesis writing. Perhaps something others have found similar things, or not. I have got 4 points. Might be useful for Phase Twos now, albeit at preparation stage only.

Format. Slightly dull point but if anyone has resisted making use of the word styles, auto-format templates I would strongly encourage getting on board early. With 4 x TMRs, 5 x AERs and a thesis it will save hours on formatting if all of the lists of contents, figures, tables and most usefully references are all done for you. Also internal referencing within the document becomes easy as the document will self update. Highly recommended.

Timing. I found there was no time between TMRs, AERs and site work to start writing the thesis much before Christmas – clearly possible, you would just have to be more organised. Therefore the likelihood is you may choose a topic related to site and be writing it when not on site. However, it will help if you know what it is you are doing much before Christmas to allow primary data collection – as per the coursework timeline.

Primary data collection. For the reason above, if doing a site related thesis, collecting primary data from site is critical. If it’s tests on concrete or monitoring data or something else, I would advise deciding in sufficient time to get the information you need. You probably won’t manage to capture it all, so get all the details of people you might need to pull favours from afterwards.

Keeping a record. The biggest thing I am finding is not remembering quite what happened and when it happened. This is practically in terms of why some of the primary data is as it is (so I recommend keeping a site diary for sole thesis purpose of recording activities relating to the data). This is also cerebrally; trying to remember what you discussed or wrote on a notebook, 5 notebooks ago, did not work so well for me. I would have kept a better electronic record (text, photos,) of discussions, events and even thoughts to help remember everything when coming to put pen to paper a few months later.

Just my thoughts anyway.

Ground Improvement through Jet Grouting

Jet Grouting

Jet grouting is a construction process which employs a high kinetic energy jet of water to break down a soil formation into suspended particles and mixes the in-situ soil with cement grout. This process of hydrodynamic erosion of the soil and mixing forms a soil-cement mix which has improved properties. There are three distinct phases to the process (see Figure 1):

- Breakdown of soil formation using high-pressure jet. A borehole (90-150mm) is drilled to depth and fluid is pumped at a pressure >450bar to the base of the drilling rods to breakdown the soil formation.

- Introduction of grout. The rods are rotated slowly as they are extracted from the borehole and cement is pumped from the base of the rods simultaneously. This creates a column of soil-cement mix, evenly distributed through the treated volume. This phase of the process uses a computer to control to extraction speed, rotation, grout pressure and grout flow.

- Displacing of excess material. All excess soil-cement mix exits freely to the top of the borehole and removed. The pressure is stopped 500mm below ground level.

Figure 1 Jet Grouting Technique

Requirement at Australia 108

The scope of works for the Australia 108 project was to provide a jet grout plug from RL -7.0m to RL -8.0m to act as a strut against the core retaining wall and reduce estimated deflection during excavation. This would enable a 6m deep excavation from RL -1.0m to RL -7.0m without the requirement for walers and struts. It would also serve as a plug to reduce water ingress into the excavation. In total 106 jet grout plugs were placed varying in diameter from 1.4m to 2.2m, (see Figure 2). The ground conditions from RL 0m to RL – 17.0m is Coode Island Silt which is soft to very soft silty clay with high plasticity. The GWL sits at RL 0m. Menard Bachy secured the contract for these works.

Figure 2 Jet Grout Column Arrangement

Trial Works

The strength of the grout mix will be tested to confirm that 2MPa has been achieved at 28 days based on cubes sampled daily from the spoil return. It is possible to core the jet grout plug in situ and test but it is preferrable not to. Instead trial works were done prior to production of the core plug. The aim of the trial was to allow commissioning of the grout batching, pumping and drilling equipment and to ensure that the columns are consistent with the design assumptions.

Six jet grout columns were arranged as per Figure 3 to achieve overlaps of 400mm between 1.4m and 2.2m columns, and overlaps of 300mm between 2.0m and 2.2m columns. The trial columns were installed at the same depth approximately 10m away from the permanent location. The overlaps were cored and visually inspected to check for integrity prior to commencing the permanent works (photo of core sample at Figure 4). It was assessed that close to 100% of the Coode Island Silt had been replaced by grout and that the overlaps have been achieved.

Figure 3 Trial Column Arrangement

Figure 4 Photo of Trial Column Cores

Risks

The greatest risks with this method are as follows:

- Not achieving required depth.

- Not achieving column depth.

- Incorrect drill location resulting in insufficient overlap between columns.

- Damage to near-by structures and uplift due to the high pressure and flow rate.

To mitigate these risks, the jet grouters rely heavily on computer control and monitoring. The operators are given design parameters from the engineers and they ensure the equipment is calibrated and they adhere to these parameters; they provide a drilling record for every column as part of the QA process. They also drill approximately 100mm above and below the target depths to ensure there is a consistent band at the required depth. They also use GPS and surveyors to locate the boreholes pre drilling and provide an as built post drilling record. If a column is installed in the incorrect location or depth, the process can be repeated in the correct location as the pressure is sufficient to erode the soil-cement mix.

Method Statement and photographs

I have included below a simplified method statement to demonstrate the how the jet grout plug is installed prior to the core raft, as well as numerous photos so you can see how the actual construction process looks. In practice, it took a lot of co-ordination on site as the site set-up and trenches to remove the fluid spoil were a considerable laydown. Interestingly though, one thing I couldn’t capture well on photo was how much the ground bubbled due to the sub-surface pressures created by the process.

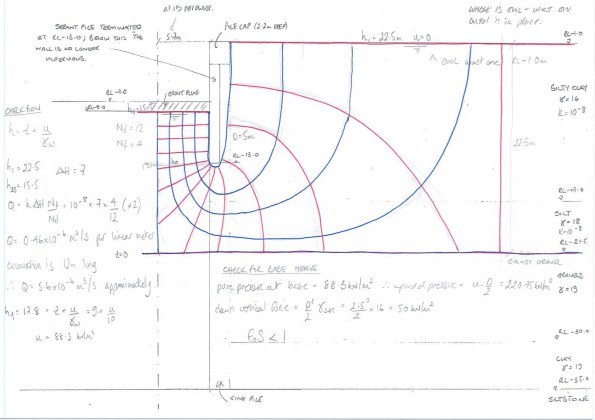

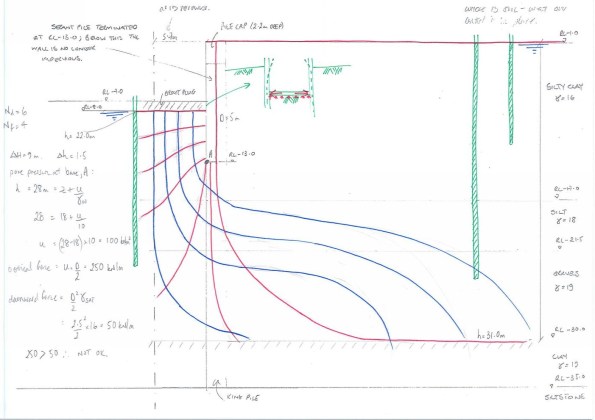

Flow Net

Flow Net Take 2