Modules Anyone?

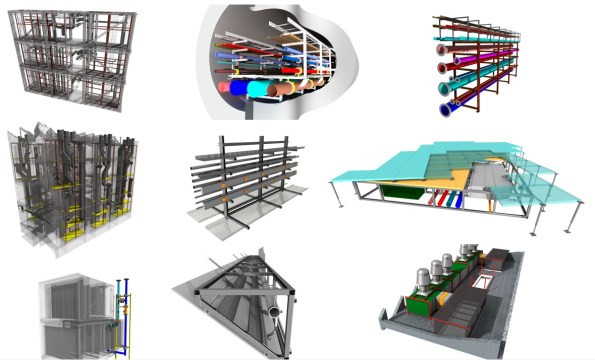

The project I am working on is making extensive use of pre-fabricated modules and so I thought it might be of interest to the other E&Ms. Here is a diagram showing the major module units that have been designed for the two buildings and tunnel being constructed as part of the project.

Figure 1 – BIM Model of 9 of the module units

Description

Top Left – Energy Centre Rises that connect to the tunnel modules

Top Centre – Tunnel Modules (3.5m Wide, 6m long and coupled together with a centre walkway)

Top Right – R&D Building Services Ring

Middle Left – R&D Risers (3 risers in total)

Middle Centre – Lab spine (medical gases, domestic services and 3 phase-busbars that can be tapped off anywhere in the labs)

Middle Right – Underfloor modules

Bottom Left – Cooling/heating Coils.

Bottom Centre – Sprinkler modules (600 of them concealed in the saw-tooth roof of the R&D centre)

Bottom Right – AHUs

Lab Spines

Of these modules, I think the lab spine modules may be of particular interest to the military engineer as recent operations have proven the necessity of rapidly deployable and easy to construct medical services. These modules would support this requirement very well and could provide a variety of services from medical gases and domestic services to power and data distribution.

Figure 2 – Showing the variety of medical services included

In order to install this spine system, each module is elevated and suspended from the ceiling and then the modules are braised together which also means that the level of craftsmanship required for installation is very low.

Figure 3 – The Lab Spine layout showing the tap-offs and outlets

This system is incredibly versatile and acts as a universal busbar where a tap-off can be placed anyway along the spine and the user can draw off 3-phase power, hot water, cold water, medical gases and compressed air.

Figure 4 – View of the medical gas outlets

In addition to providing services, the spine also acts as an open air cable tray, providing a tidy solution for internal wiring and data cabling.

Figure 5 – Electrical services are located at the rear with a busbar at the bottom and cable trays above

These modules are not due to be installed until April next year and so sadly I will not be involved in their installation and commissioning but I hope to be involved in the tendering and final specification as part of my phase two attachment.

Hi Gary,

Flip side of having an installation that can utilise a lower skill set is that you get someone with a lower skill set who is still able to happily stuff up the work. I saw this particularly with fusion welded pipework and push fit joints.

Not sure if I agree with your comments about the med gas modules being highly suitable for the military. Are you talking about having something pre-fabricated in the UK and sat on the shelf? Every project will potentially have different requirements so you could end up with an expensive module that covers all bases. Additionally they’re bulky once constructed which doesn’t make them ideal to fly around the world.

Rich, yes I think having them sat in the UK would be good option but I do take your point that they are bulky to transport but with the type of applications we are talking about, there is likely to be a substantial logistics chain available.

They are very flexible units as they have almost everything you would require in a medical facility and so should be able to support a wide range of requirements. In terms or loads, I cannot comment on the maximum supply rates of the various gases and domestic serves nor the rating of the cables.

Another option could be for a module to be used as a standardised design with a standardised schedule and drawing (or a series of standards based on room size or load requirements). In this case the fabrication works can be sub-contracted out locally with an STRE providing quality assurance. The installation could be also be sub-contracted locally or using an MCF that could train on identical modules back in the UK as part of PDT.

Funny you mention fusion welded pipework as I will be inspecting some next week………

Interesting to see the two ends of opinion with regard to prefabrication :-). I would suggest that a middle ground whereby you might locally manufacture in theatre to a set pattern modules for installation elsewhere within theatre i.e. off site construction. Whether this might be local labour with an option on participation in the QA/QM or not is another interesting angle.