Bruce C16 Caisson Swage Repair

If the title of this blog makes absolutely no sense to you then you’re at the same starting point that I was when this project was handed to me! This project is currently the top structural integrity concern in the BP North Sea portfolio but is actually relatively simple once you get your head around what’s involved. The project pretty much covers all the core competencies, focussing mainly on contractor management and project management, with a good dose of health and safety due to the nature of the offshore industry and some complex lifts which are required.

If the title of this blog makes absolutely no sense to you then you’re at the same starting point that I was when this project was handed to me! This project is currently the top structural integrity concern in the BP North Sea portfolio but is actually relatively simple once you get your head around what’s involved. The project pretty much covers all the core competencies, focussing mainly on contractor management and project management, with a good dose of health and safety due to the nature of the offshore industry and some complex lifts which are required.

Background

A caisson is effectively a big pipe which extends from the deck of an offshore platform down to below sea level. Its purpose is to minimise the effect of waves on seawater lift pumps (seawater being the obvious choice offshore for cooling, processing and fire fighting).

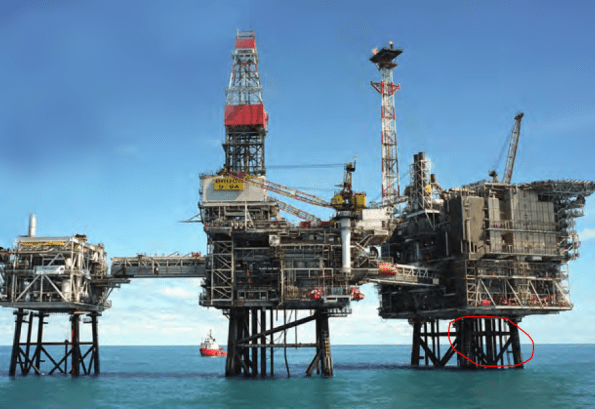

The BP Bruce asset, comprising of separate drilling (D) and process, utility, quarters (PUQ) platforms is located some 200 miles East of Aberdeen and was built in the early 1990s. The PUQ platform has a number of caissons which are shown in the images below and right (circled in the photo and labelled with hexagons on the drawing). The dashed lines in the drawing are the jacket (support legs and bracing) of the platform. The caissons are attached to the second horizontal brace down. Sea level is approximately at the midpoint of the top set of cross bracing.

BP Bruce Asset (Seawater Lift Caissons Highlighted) & Jacket

Due to a combination of the age of the asset, climatic conditions and the corrosive nature of seawater, structural integrity is a constant challenge. The point where the caissons on Bruce are attached to the platform is the point of greatest stress and corrosion and caissons C12-C17 have suffered major cracking (example shown below in photo). Why this is such an issue is due to the ‘dropped object’ risk. If the caisson were to break at the crack then 30 m of 1 m diameter steel pipe would plummet towards the seabed. There is a risk if this happens of damaging nearby caissons (and therefore the ability to fight fires), the jacket (therefore putting platform integrity at risk) or equipment on the sea bed (therefore putting production and hydrocarbon containment at risk).

Bruce Caisson Crack

Options

In order to address this risk BP considered 2 options:

Option 1 – Replacement. This is something that Imran was working on several years ago and was cancelled due to cost. Replacement would involve procuring a new caisson and all the related deconstruction, transport and construction works. This represents a significant investment; whatever you think it will cost, add 3 zeros in cost and triple your time estimate for offshore! In the current economic climate costs are being minimised and so this option is unlikely to be funded. Equally the life of the new caisson would far exceed the expected life of the platform and greatly reduce any return on investment.

Swaging Tool and Liner

Option 2 – Swage Repair. This is the option chosen and the one which I will be responsible for executing offshore. First the caisson is internally cleaned using a tool which utilises a high pressure jet of water to remove marine growth and corrosion. An internal liner is then lowered down over the crack before the swaging tool is inserted (see image). The tool is pressurised to expand the liner beyond its elastic limit whilst remaining within the elastic limit of the caisson itself. The liner is thus held permanently in place and seals exactly to the shape of the caisson. The process is illustrated in this handy video.

The Project

The main contractor for the project will be BP’s engineering partner, Wood Group PSN (WG PSN). Two specialist sub-contractors (known as ‘vendors’ due to BP’s global nature) will be involved. Sparrows are an offshore lifting contractor and will be responsible for the lift plans, rigging and executing the lifts (example shown in image below). Oil States, an offshore engineering specialist, own and operate the swaging tool and have fabricated the liner. I recently attended the 6 week constructability review where, as the client, I approved WG PSN actions thus far and the offshore execution schedule. Additionally I have carried out the project risk assessment in line with BP’s risk matrix and HSE guidance. This led me to identify the risks associated with the lifting and I have raised these with Sparrows. As this is the third project in a series of 4, the remainder of the risk assessment related to on-going risks and those identified previously.

Example of Complex Lift Procedure

The C14 caisson on Bruce underwent a similar repair in September 2015 and the procurement for the project included that which was required for C16 and C15 (I will likely take on C15 as a project once the C16 repair is complete). The liner and additional fabrications required are currently in storage and I am assured they will be inspected and re-certified prior to project mobilisation. Mike has blogged previously about some of the issues with materials going missing offshore so this is an area of concern for me. Other than a substandard bill of materials I was handed in the 6 week review I have had no issues so far.

Other concerns relate to the site itself. The laydown area outside the pump room where the swage repair will take place is fairly tight for space (see image below). I am competing for time in the asset schedule with another project which also requires the use of this laydown area. This, combined with the fact that the crane needed to lift my containers onto the laydown area is out of action until 4th July is already causing project delay to creep in. I will shortly be having a meeting with the other project team and the asset engineering team to de-conflict the projects and discuss the crane issue. The meeting may also see the scope of my project expand to include the C15 repair immediately after C16.

Bruce Laydown Area

Finally there is one fairly show stopping problem with this project in that the very expensive, vendor owned swaging tool might just get stuck in the pipe! Luckily Oil States have a procedure for this and the tool has a number of shear pins which can be broken by using an over pull tension in the lifting cable. Unfortunately the overhead gantry crane in the pump room is not rated for this. Fortunately a ‘strong back’ frame was fabricated for the C14 repair, which combined with some big jacks can be used to produce the required tension. Unfortunately the deck plates on the floor of the pump room aren’t robust enough to support the strong back frame. Fortunately some large steel plates were fabricated for the C14 repair which can be placed on the deck to spread the load. Suddenly it can be seen where the extra cost and time comes in for offshore projects!

Summary

So yes, that’s it, after months of the PET course and highly technical study, I have been placed in charge of a project to put a pipe inside another pipe! There is a lot of de-confliction which needs to happen to get the project mobilised but I have taken over at a time where the onshore execute phase is all but complete. Next month I should be offshore during the swaging process and will report back on the offshore execution.

Sam, this looks like an interesting project. Since the internal liner and caisson will be made of different materials and have different thermal properties, what consideration has been made to how this new composite section will react to environmental changes?

Could the different expansion rates of the materials causing crack at extreme temperatures?).

Also what measures are being taken to prevent or reduce the galvanic corrosion between the liner and the caisson?

Hi Gary,

As the caissons are carrying seawater only, their temperature should remain fairly constant so no real risk of differing expansion rates.

In terms of corrosion I’m not sure. I am meeting the WG PSN engineer tomorrow and will discuss it with him. Given the life of the asset the risk is again probably quite low. Projects such as this one are designed to extend the life of the older assets by 5-10 years maximum. The North Sea fields are predicted to remain productive until around 2030 so even to that timescale the expected life of the repair is significantly less than that of a new caisson. I will report back when I know more.

Sam an interesting project, and it seems you will be getting plenty of relevant experience. The question that Gary has asked is quite searching looking forward to your reply.

Hi John,

Thanks for the vote of confidence! It’s been a long few weeks of completing training and waiting for projects to be allocated so good to finally have something to get my teeth into.

Looks interesting Sam. I like the fact that the emergency removal method for the very expensive piece of equipment is essentially pull really hard and hope we break the thing we want to break.

I notice on the video that the sleeve is profiled giving the liner something to mechanically attach to. Is your cassion profiled or are you just squeezing against a smooth surface? If so what parameters will be used to determine that the swager has done it’s job; just diameter?

Hi Henry,

My caisson is a straight profile, as for smooth, probably not after so long sat in the North Sea! I should be able to get some photos from the inspection to confirm.

You may have noticed a P-V graph in the video. The Oil States guys who operate the tool will take pressure and volume readings during the swage and it is these readings that determine when the process is complete. The deformation characteristics of the two materials is what holds the liner in place rather than mechanical profile.

An update on some of the questions raised in response to my blog:

1. Materials (Gary). The liner is fabricated from a similar structural steel to the caisson. There is therefore minimal risk of galvanic corrosion.

2. Process (Henry). Observing the P-V graph (at around the 2:00 mark in the video) there are effectively two curves, one after the other, separated approximately where the line goes form blue to purple. Between A and B the liner is expanding within its elastic limit until it touches the caisson. From B to C it is expanding plastically and begins to expand the caisson elastically. At point C the caisson reaches its elastic limit and it is the following ‘kick’ upwards on the graph that the tool operators use to determine that the swaging is complete.

Hi Sam,

How did you find out about the equipment and processes associated with C14 that you’ll utilise on C16? Do BP document their lessons learnt well or was it a case of corporate knowledge and you were speaking to the people who did C14? What’s your role going to be when you’re out on the asset?

Hi Rich,

It’s not so much lessons learned although a defined BP process does exist for that. For this project it’s a combination of information management and the corporate knowledge of the project engineers in the team.

Both BP and WG PSN have file stores with all the previous project documents in them, along with document controllers (people who can actually find stuff for you!). BP also documents all changes to plant, processes and ways of working in an online system. This system provides a lot of checks and balances in terms of risk management as well as recording the changes themselves.

I’ve taken over C16 from the guy who did C14 so I have pestered him with questions in order to fill in my knowledge gaps and steer me in the right direction. He attended the initial Oil States trial of this repair method and is very knowledgable on the subject.

Out on the asset I will carry on the project management role. If there are any issues during the repair the foreman will no doubt be looking in my direction to sort it, which is slightly daunting at this stage!