Wood Street Police Station

At the risk of sounding like Jessy from the fast show (for those old enough to remember that): This week I have been mostly working on the redevelopment of the Wood Street Police station…

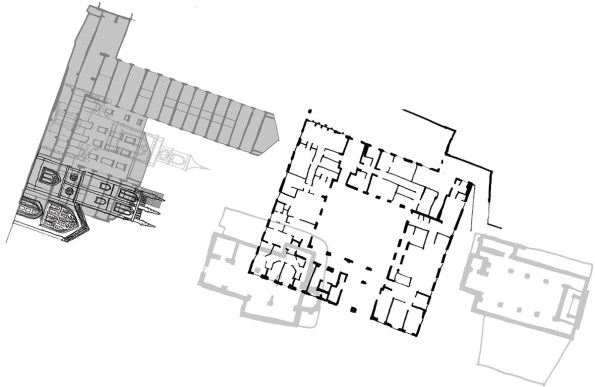

This is the headquarters of the City of London Police (CoLP). A sub-branch of the Met that look after the area around St Pauls and the financial district in the centre of London. The site was built between 1963-66 and sits within a compound containing buildings sat around a central courtyard, all on a two storey basement.

I can’t give you plans or internal pictures of this as I’m not allowed to download them from our secure server. Apparently they think me not trust worthy. What do they think I’m going to do? Upload them to a blog? How dare they?! SO all these photos are open source. And if you really a look inside you can watch this: http://www.bbc.co.uk/iplayer/episode/p01rrjbx/building-sights-series-4-5-wood-street-police-station

The plan is to put a 16 story tower in that courtyard adjacent to the existing tower. There are some problems with this…

Firstly the foundation design. The site is probably sat on London clay. I say probably because the CoLP won’t allow any sort of site investigation until planning has been granted since it would require a hole in the raft slab, and they don’t want one! It might have a couple of meters of gravel, but right now we don’t know. We also don’t know the ground water regime. We can guess it, and the best guess is that as soon as you cut through the raft slab water will come out. So currently the plan is to inject resin into the granular fill in order to drain the water within the working area. Gravel or not it will need piling, which leads to…

Access. The courtyard is entirely enclosed and access is via one of two vehicle “doors”. One leads into the courtyard itself and is both wide enough for a Range Rover type vehicle and tall enough for a dude on a horse. The problem with that door is that the slab that it leads onto will be removed in order to build the new building. So that doesn’t help. Behind door number two is the ramp that leads down into the basement. In order to get down to the second basement level you have to drive through the first level (that slab is coming out too) and down another ramp. You can get a low clearance piling rig, so you could drive one down. But it would be mega tricky. The better option looks like it’ll be to remove the slabs, ramps and all, and crane in the rig. There is the question of how you get the broken out slabs out. It’ll probably involve a skip, a crane and loads of pissed off people trying to get around the truck parked in the road…

There are other problems too. In order to properly assess the existing structures we went into the basement with a rebar meter. The results were a little confusing. Then we found some photos of the construction of the building and it looks like the members are steel, then encased in concrete for fire protection. Some of the transfer beams are about 2 meters deep, so breaking those out will be fun! We couldn’t get any more information as we’re not allowed to do any destructive testing until the budget has been confirmed. The budget can’t be confirmed until the planning pack has been submitted. In order to submit the planning pack we need to know what we’re doing. Which we don’t because we’re not allowed to drill a hole in the floor and find out what’s below it (among other reasons)… It’s the classic circular reference (to use an excel terminology – one for Damo).

All of this makes planning the cost of the project extremely difficult. For whatever reason WYG seem to be the only people running for this job. Maybe because it’s such a nightmare. But the in-house PM and blast analysis combination is definitely a bonus for CoLP since the new building will have to be designed to withstand an attack. That and planning this whole thing is a nightmare!

So while the structures team in Nottingham are wanting to get stuck into some Bentley action, they can’t, because if they do they might not get paid. First we have to work out what can be done, and how…

Guz,

My take. The issues you cite with access ring true so frequently but I think that is part of the ‘fun’.

Loading. I visited Grovensor Square which has to keep a listed façade meaning in some areas materials are quite literally being handballed. Not suggesting you do that, but use of a temporary gantry can help get some space for loading. Eg. Long reach excavator loads tippers timed to back into site as required.

Actions. 16 storeys – loading will probably not require hugely deep foundations. Therefore chances are a decent desk study would get a good feel for boundaries, properties of the soil horizons, groundwater levels and contamination. There will have been something done fairly close by. Presumably, some ground investigation could take place adjacent, rather than inside should everything else come up blank.

Circular reference – nice!

I think your last 2 paragraphs are the most interesting. Not wishing to see the tax payer out of money, but there is significant risk here for the client. Pricing that risk will be key. Has there been some risk analysis based on the amount of risk the client wants to transfer? Your last paragraph is interesting. Presumably the first step is to work out what it is you are to do, rather than what can be done/ I.e. define and agree your scope based on how much risk is to be transferred. Then you understand what it is you are to do and can then start considering the how. Out of interest are WYG to be employed as a client’s designer, or will it be more of a D&B contract, with WYG sub-contracted to a main contractor? Have you been asked to submit a tender? How are you getting paid for what you have done so far – what is your contract?

We know what they want, so the “what it is we are to do” bit is fairly well defined. The architects design is very pretty and the user requirement is well stated. But the “how do we magic a 16 story block into that hole?” bit is a little trickier.

You are dead right on the risk bit. And it’s a tricky one to quantify. I’ll have a think and get back to you…

There is a framework contract in place with CoLP, so all the hours so far are being billed to that account. One the feasibility study has been completed a separate contract specific to the project will be let to include WYG and the architect. One the design is more mature it is likely a D&B contract will be let to a main contractor and WYG will be novated under that contract.

Guz

This is an excellent example of ‘risk’ that John Moran would love. It seems that all you can do is make and state your assumptions

Kind regards

Neil

One the one hand: you’d be amazed what kit you can get where these days…. I am interested in what a designer might be able to do contractually if it were the case that the client would or could not grant sufficient access to permit full design?

At the moment we’re acting within the framework agreement in a concept design type capacity. As soon as they want us to provide something solid for planning purposes it becomes a lot more difficult. The design we intend to produce will be based on what we believe the most likely conditions are – straight into the clay, high ground water… – but will be heavily caveated against the most dangerous – lots of gravel and the like.

Then if the conditions are different, that can be addressed in the detailed design. Not an ideal situation, but what ever is?!

Guz, this sounds like the perfect preparation for upgrading the PSNI stations if that ever kicks off again. These are exactly the same issues that we had to deal with in the early 90’s when working in support of the RUC.