Who turned off the power?

Situation

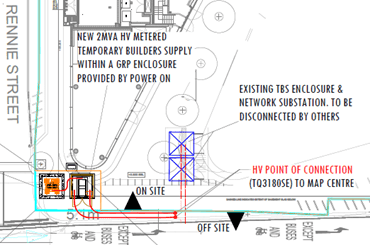

Laing O’Rourke (LOR) originally constructed the original substructure (75% of the 3 floor Basements) and installed the Temporary Building Supply (TBS) consisting of an enclosure and network substation. It was positioned in an area that would not conflict with the original substructure works but it would need to be moved before LOR returned to site to complete the substructure.

Reflection

Brookfield inherited the site from LOR and have been entirely focused on the construction of the tower. In the process they have neglected to carry out sufficient analysis regarding the temporary power and realising the potential impact. The TBS and RMU should have been moved earlier in the programme or the temporary power layout should have considered the future move.

Instead the project has progressed and increased the impact of the pending change by having more steel wire armoured (SWA) cables installed directly from the Ring Main Unit (RMU) to the large plant, cranes and hoists, wet riser system and welfare facilities.

Issue

Power On (HV specialist) and UK Power Networks (District Network Operator) were required to do the majority of the works to install the new TBS (1x 2MVA transformer). In order to switch the HV connection from the old TBS all the power to the site needed to be isolated.

Mitigation

In order to reduce the impact of the power outage the option of hiring 2x 500kVA generators was taken. The problem of siting 2x generators on a construction site was finding 6m2 of flat ground with enough strength from the concrete slab. The area North of the new TBS was identified, Aggreko (generator sub-contractor) visited the site, agreed to install the generators with extra fuel capacity by conducting the lift from Rennie Street.

When Aggreko delivered the generators, the Crane Op was unable to place the generators from Rennie Street. Therefore the decision was taken to conduct the lift from the pit lane and site one generator. It caused problems for the deliveries on that day but ultimately prevented a larger problem from unfolding.

Environmental

This was raised and checked by the Environmental specialist on site:-

From 1st September 2015 construction projects within the Greater London Area are required comply with the London Low Emission Zone Non-Road Mobile Machinery (NRMM) requirements. All NRMM with an engine net power between 37kW and 560kW must meet minimum standards in terms of exhaust of Nitrogen Oxides and Particulate Matter. All qualifying plant must be recorded in an online register and those that do not meet the require standard have to be replaced.

Anyone else experienced any emissions restrictions?

Alex, lots of interesting points here. It reminds me a bit of posts about temporary works items during the phases at Battersea. People only seem to think of things when problems arise and it always tends to be someone else’s issue. As it happens at my site we had to have temporary power using a temporary substation. The temp substation did not have enough power for the tower cranes so a temporary generator was also needed. Finding a place for it was a challenge, not just space but loading considerations too.

The NRMM came in while I was on site. A bit of an admin burden to get going but then every time a new piece on plant is used (within the bounds you state) it has to be added to the database.

Lots of our plant and equipment was ‘crossrail compliant’ so met the regulations as I think it is more of a formalising of common sense than a radical change. Having looked into some of the noise emission issues on construction sites I think the idea behind the regulations is well founded. If plant is already above the lowest exposure limits it means additional PPE is required. That does not suit anyone so if a generator (for example) must be more fuel efficient, have low emissions and be quieter to be on an inner city site (or elsewhere) I think that is good.

Why could you not position the items? Was there a lift plan? Why do tower cranes need so much power compared to a building?

Alex, any thoughts as to why there is an upper limit on power within the regulations?

Jim

Alex, are you using BIM on site as I am surprised the issue of crane access or suitable locations for the generators was not highlighted earlier using a BIM model. With the issues of space and lifting, were smaller generators (say 4x 250kVA) not suggested?

Alex,

All sounds very familiar, I had great fun (not) getting a temporary substation sited. I take it getting the transformer out at the end has been considered? I know that one of the temporary transformers installed at Battersea was probably going to have to be cut up to get it out (I wasn’t involved in the decision to locate it); what was even more impressive was that nobody seemed to be particularly bothered about it.

Damian

I agree, it seems to be a lack of planning and belief that it isn’t their problem. Yes the loading on the slab had to be checked and then confirmed by the Site Engineer. The noise emission was an issue raised by the local residents and resulted in soundproofing surrounding the canopy of the generator. The introduction of the regulations certainly makes sense when considering the continuous operation.

The distance of the lift from Rennie Street and the weight of the generators put the HIAB beyond the safe working limit. The lift plan was conducted in advance by Aggreko but they didn’t consider the extra distance caused by the outriggers of the HIAB. It is the amount and size of current required to power the necessary plant for the Tower Cranes compared to the small load from lighting, computers and power tools.

Jim

I haven’t been able to find a definitive reason but I would suggest it would be because of a lack of machinery above 560kW that meets the standard. Within the regulations there are certain exemptions such as 30 days on site and unavailability of compliant machinery.

Gary

There is no BIM for the site – whether that is a blessing or a curse depends on your viewpoint. There are certainly some examples where BIM could have avoided problems such as a clash between the brackets on external cladding and soil vent pipe (SVP). The 2x 500kVA was decided on the initial site visit by Aggreko and were delivered a few days later. The decision was taken to install the 1x 500kVa generator because it was on site; using smaller generators was not considered at the time it would have worked but with additional costs.

Rich

The hotel which is starting to be constructed will overhang the TBS and this will creates its own difficulties and problems. The difficulty of removing the TBS was considered and it lead to other potential sites being identified but this was the only solution that would work.