Archive

Spot the Obvious Mistake

Following on from my previous Blog Post: “A wheel wash – yes honestly the story of a wheel wash”. My exciting challenge to all bloggers is to spot the obvious error ( I hasten to add I am afraid this is not an interesting geotechnical issue).

Help – I am sorry I haven’t a clue

Pride cometh before a fall. I have been working on how to remove the temporary restraints from the secant pile wall for about a fortnight and now I am well and truly stuck. The waler and struts clash with 2 of the slabs. I have deduced 3 possible options, propping off the capping beam with hydraulic props, temporary propping from a lower basement (B3 to B2) and then cantilever the rest of the way, and the third is a hybrid of the two.

![IMG_2567[1]](https://pewpetblog.com/wp-content/uploads/2016/05/img_25671.jpg?w=595)

Some of the said struts and walers (they are 900 mm in diameter not including splice)

Time is of the essence here and the PM will not accept any loss of time. Which begs the question why didn’t he allow for their removal in the programme? I am naturally prejudiced against the cantilever option as because it slows the removal of the struts and walers by restricting access and I can’t help but ask why the didn’t do this before. The calculated delay to programme is 5 days. With LDs this works out to about $150,000 in lost time. The cost of hiring the temporary props is down to the sub-contractor so this isn’t much of a consideration. Risks – Removal of temp struts and the capacity of the capping beam is not yet known.

Option 2 (propping from B3-B2) is slightly quicker to remove the struts and walers with less temporary works but, it turns out both options require the pour 1 on B2 to be at strength before any struts can be removed so it still works out to a delay of 5 days. However, the wall is deformation is potentially worse and getting the necessary prestress into a diagonal prop can be very problematic.

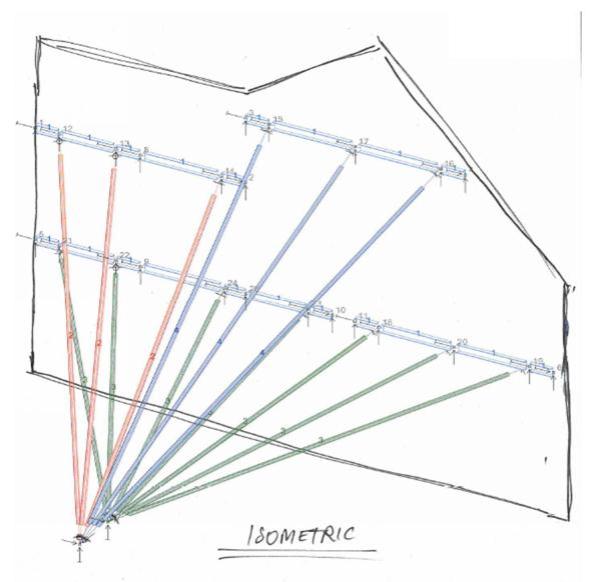

How the slabs work (numbers denote by pour a slab system is not locked until Pour 1 of the next basement level is at strength). The struts are located between B3 pour 4 and B2 pour 1.

Option 3 (Hybrid) has no delay to the programme but the most amount of temporary works (off critical path) – problem solved right? Wrong my PM has a ‘gut feeling’ and an inspirational idea. Just build over them! This might work if they were designed that way. While I and the Project Engineer were trying to argue for alternatives and pointing out how were we going to remove some of the members that are over 12 tonnes under ground in confined conditions without access to plant, I was being treated to a truly marvellous display of Oxford Union esque debating skills of “yeah I hear what you are saying but what my gut is telling me is if we build over it doesn’t cost me any time”. He then went on to show how we could encaste pulleys in the slab above (fiddling while Rome burned). I am starting to get an idea how this job was was so poorly priced and why it is so far behind programme.

To make matters worse he hasn’t paid Franki Pile who are the design authority for the wall and whose help we need to make this happen. As you can tell my meeting with Franki’s did not go well and I got my arse truly handed to me. While I need to man up and realise tomorrow is another day, other than quick strength concrete to gain the necessary 20 MPa quicker I am pretty much out of options or asking one of our drug dealer neighbours to bust a cap in the PM other than that I am pretty stuck. Do I swallow my pride, log everything and accept it will make a hell of a TMR?

More sketches to follow.

The nature of the problemthe struts cutting though pour 4 basement 2 (B2)and pour 1 basement 1 (B1).

The hashed areas are (temorary props option 2) the struts shown are the existing props. Option 1 would see them replaced by 2 props in each corner off the capping beam.

More heritage complications…

Consistent with my other blogs, this one also focuses on a heritage issue. Our structural design consultants have deemed the heritage building so unstable that much of it needs remediation before adjacent works can continue. Whilst there are many areas which require attention, this blog will focus on ‘The Southern Wall’. An elevation of the Southern Wall is shown in Figure 1. It is the wall without windows, half painted grey and it is a miracle the thing is still standing.

Figure 1.

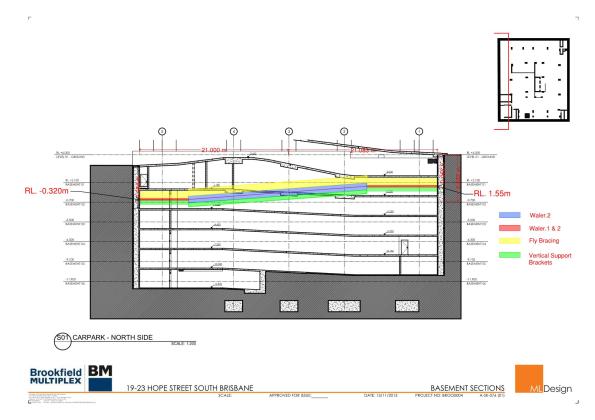

Several methods of reinstating the structural integrity of the building have been investigated but due to the time it takes to gain permission to do almost anything inside a heritage building, the level of internal instability between floors, contractual complexities and more – a temporary external fix has been selected. The solution involves three levels of walers being attached to the wall and then braced by a series of props. The solution is illustrated in Figure 2 and Figure 3.

Figure 2.

Figure 3.

This solution minimises the impact on the programme and allows works in the vicinity to continue, largely uninterrupted. The lower most waler is supported by the green props which all converge on to a single brace plate (BP1). The brace plat is bolted to the existing capping beam, but has had to be drilled to slot over the starter bars. The other two walers are braced by two separate groups of props, all of which converge to a second, separate brace plate (BP2). See Figure 4 for detail. Connection details are illustrated in Figure 5.

Figure 4.

Figure 5.

Not only does the steel provide support in elevation, they also prevent the road side elevation from falling into the adjacent street. It is difficult, but possible to see in Figure 1 that the western most 1.8m of the building (the left hand side) is almost entirely separate from the rest of the structure. Existing internal braces go some way to remediate this problem, but the proposed solution will help to prevent the matter from getting worse.

The long term solution is expected to be in the form of timber frames which will be sandwiched between the ceilings and floors of the building. Due to the issues highlighted at the start of this blog, this long term solution will be tackled in the distant future. This temporary solution is due to be constructed this week, I will post photos once complete.