The Backfill Problem

My role within the NLE project has changed somewhat over the last week. After 4 months focusing on the construction and excavation of the Crossover Box I am now the package manager for our piling subcontractor. A great opportunity to sign off some key commercial ICE attributes.

But no less than a day in the chair and I was already trying to problem solve a potentially costly issue.

The Issue

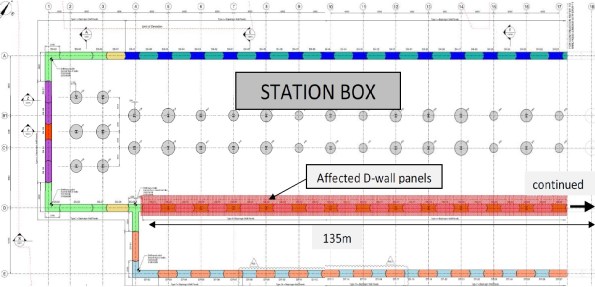

On one gridline, the diaphragm wall cut-off level is 10.4m below ground level. This wall lies between the escalator access and will form the ticket hall. It affects 135m of diaphragm wall. The question is, what do we backfill the excavation with once we have completed concreting?

D-wall panels with lower cut-off level

The usual practice would be to backfill the excavation to ground level by concreting above the cut-off level. However not only is this a large volume of concrete (can be expensive) but it will add untold days onto the programme in breaking out C50/60 (cube strengths have been achieving 80 N/mm2 @ 28 days a.k.a. rock solid) concrete. The situation is made slightly more complex as 16 of the 45 panels contain plunge columns.

The key issue is the stability of the piling platform, this needs to be maintained whilst backfilling with a solution that will self support, won’t be too difficult to remove and can be used throughout.

What are our options?

Gravel – This wouldn’t compact enough and apparently can induce a moment on the column whilst the concrete is still green.

Self compacting gravel (pea shingle) – Wouldn’t self support and would all flow out when the stop end was removed for the excavation of the adjacent panel.

Grout – Too expensive to be a viable solution, it would require 1685m3 (135m x 10.4m x 1.2m)

Soft mix (around C10) – An option but would still require breaking out.

The proposal 1

Considering that the difference in level requires a sacrificial cage that is used to hold the reinforcement at the right level we do have a framework to work on. The initial thought was if we could concrete just the end next to the stop end. This would need to be tied as once the stop end was removed there would be very little holding back this column of concrete.

The plan so far is to install a ‘sock’ or geotextile to the sacrificial cage. Self compacting gravel will then be filled inside and outside the sock. When the stop end is removed some of the gravel will fall into the excavation but the majority will be held by the sock.

The proposal 2

The addition to this option is to concrete the end. Some sort of loop or tie is then required to stop the column of concrete from toppling over or slipping out.

Options for Backfill Support.

These are just developing options which will hopefully lead to a trial before being implemented in August. If it fails we’ll revert to the concrete soft mix option. The amount of effort being put into this leads me to think we might be trying too hard to over engineer a solution and it might be better just committing to the soft concrete option.

Has anyone has come across an issue like this before?

On a different note

The progress in the crossover box has developed quite a bit. The first two props have been installed along with the monitoring measures (strain gauges and shape arrays) which has allowed us to start excavating.

Jonny

Just a little unclear

The backfill area is between GLs D&E and form GL2 towards 17?

The diaphragm on GL E is the lower – is this constructed form the lower level with the cage protruding? Maybe a longitudinal section?

Not too sure about the use of geotextile; to separate – demands no real thought other than will it withstand the application of the next soil layer

TO reinforce means that the geofabric must cut the shear failure line and be anchored beyond it; so what exactly is the wrap to achieve?

Apologies if it was confusing. The gridline in question is D, the slightly internal one. The backfill in question is inside the excavation (above concrete) rather than between differing d-walls. the excavation being 1.2m wide and as long as a panel (generally about 2.6m).

The plan for the ‘sock’ or geogrid was to line the cage with it so that we could backfill it and prevent the fill from flowing/ falling into the adjacent excavation when the d-wall stop end was removed. All this will happen under bentonite support.

Jonny,

The short answer to your question is No, I haven’t experienced something similar. But that isn’t going to stop me from offering my opinion.

Pouring a large volume of concrete and then having to remove it afterwards does seem like the easiest option in terms of design, but surely the cost of the concrete and then the cost and time associated with its removal would make it the least favourable. Creating a sacrificial cage (option 1) whilst proving a greater design challenge must surely be the correct approach. I would avoid option 2 simply because the phrase some sort of loop or tie” didn’t fill me with engineering confidence.