The importantance of off-site inspections

Nothing significant to report on my site as we haven’t started the installation yet and so we are still in the process of procuring and reviewing RAMS. Personally I have a plant movement package out to tender with the supply chain and I am in the process of reviewing tender returns for AHUs, and procuring some steelwork for some chillers and cooling towers as well procuring a temporary ventilation system for a tunnel – which is turning into a bit a nightmare as the current design does not sit well with the insurers (yes this will become a future blog……..).

Anyway I thought I could post another blog about off-site manufacture and modularisation focusing this time of the importance of off-site inspections.

Yesterday I visited Skanska Fabrications in Slough where 22 pre-fabricated tunnel modules are being manufactured. These modules will be used to for chilled water, high grade hot water, low grade hot water, domestic water, low voltage, high voltage, data and fire alarms. Each module is 3.2m wide and 6m long and weighs 4000kg and to give an idea of the scale of these goliaths, the picture below shows one module and the lower large orange-capped pipes are 400mm in diameter – so not small!!

![IMG_0382[1].JPG](https://pewpetblog.com/wp-content/uploads/2016/06/img_03821.jpg?w=595)

The first tunnel module nearing completion

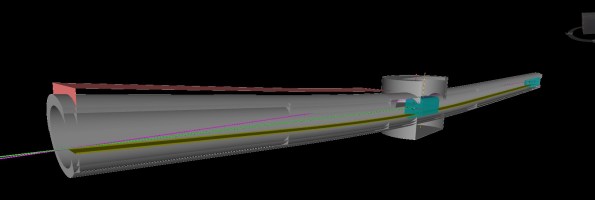

The BIM Model used to develop the installation method (note the centre shaft, winch cable lines and differing inclines)

These modules were designed using BIM and BIM also was used to simulate the modules being moved by a winch to ensure there was enough clearance in the tunnel for the winch cable and also to calculate the size of the walkway to ensure the winch cable could be ran through the centre of the installed modules in the latter stages of the installation. A picture of the BIM model showing the winch cable analysis is above. Since the modules were designed using BIM, every part of each module has its own asset code and a QR code sticker is placed on every pipe section, tray, bracket etc. These QR codes can be read by our iPads on site and they are linked to the BIM model using Naviswork BIM360 Field meaning that if I required any information about a component during installation all I have to do is scan the QR code with my iPad and I will be provided with design data, flow rates, mass, supplier and several other data sets. I have been very impressed with this system so far.

It is my responsibility to install these modules in the 132m, 4m wide tunnel and so I am regularly visiting the factory to check the quality of the finished product and identify any issues so changes can be made prior to delivery to site. One of the first issues that stood out to me was the lack of lifting points and winching points and so the fabricator is going to develop a suitable design solution and I will arrange a factory visit for the lifting Sub-Contractor to check the design and final fabrication.

The tunnel nearing completion

The second fabrication issue that became apparent during my visit was the use of corrugated kick-plates which prevent the floor panels from being lifted out, significantly hindering future maintenance. Again the fabricators are going to redesign these and opt for a flat kick-plate.

Another issue is whether or not the modules will slide down the 0.537 deg slope under their own weight. The Project Manager responsible for this design was adamant that they would slide as PTFE slip pads are used between the modules and the rails but I was confident that they will not and this debate has been going on for several weeks. Anyway rather than guessing I decided to use some GCSE physics to calculate whether or not it would slide. My calculation was that it would not and in fact it would need a 1.7kN force to get it moving. This for me was one of those moral courage moments as I did not want to blatantly challenge a senior PM but if it didn’t move, it would be my problem to resolve on site and the requirement to push or winch the first modules would fall outside of the package scope and would incur additional cost. So I was keen to mitigate this risk early to reduce costs and avoid any unnecessary delays.

So this short visit has confirmed to me the importance of off-site inspections and inspecting a physical product rather than purely relying on a BIM model.

I thought this post may induce some debate over the benefits of this pre-fab approach. The client and senior leadership team seem very happy with it but I am not convinced. The main issue with this design is that we have to wait until the tunnel is completed before installing the modules where as if we were using a traditional installation, we could be mounting brackets, trays and pipes directly behind the slip formwork as it moves along the tunnel, casting the secondary lining. Plus looking at sustainable development, these modules will be a challenge to remove when the product reaches the end of its life as the centre access shaft will be capped and backfilled. Also I think the module frames will make maintenance much more difficult. Thoughts?

On a personal note, I have got my aircraft flying again and so I am once again terrorising the skies above Essex and Hertfordshire. I would therefore recommend avoiding flights out of Stansted or Luton for the foreseeable future.

![IMG_0200[1] IMG_0200[1]](https://i0.wp.com/pewpetblog.com/wp-content/uploads/2016/06/img_020012.jpg?w=294&h=220&ssl=1)

![IMG_0358[1] IMG_0358[1]](https://i0.wp.com/pewpetblog.com/wp-content/uploads/2016/06/img_03581.jpg?w=293&h=220&ssl=1)

Gary,

Nice pipes. Pre-fab definitely has its pros and cons, but on the whole I think it’s the way forward. How many onsite man hours are you saving by prefabricating? One of the greatest threats at Battersea was the supply of manpower, by prefabricating SRW halved their labour histogram, which was one of the main reasons that they won the job. One of the biggest downsides in my opinion is the lack of flexibility; those things are huge. If you start running behind on the construction programme you’re going to rapidly run out of space at the Slough factory and have to start paying for storage. Again harking back to Battersea, but I think Carillion ended up paying in excess of 500k for additional storage. Will you be competing for crane time with anyone else when it comes to lowering them into the tunnel? If you loose the crane have you got anywhere to store the modules on the surface. Again at Battersea site was constrained and if we lost the crane there was a very real threat that the modules would have to be returned to Slough.

Rich, to answer your questions:

In terms of labour, I will check the histograms and see how much time has been saved.

A crane is being brought on site for the sole purpose of lifting these modules at a rate of two a day but if required we have enough space to store about 6 modules on site.

However it should not come to this as the modules will be supplied at a rate of two per day, meaning that in the event of delays, modules will simply be held at Slough. As part of the contract, Slough are contracted to store 15 modules on site. But yes, space is tight on site in Slough which is why we are unlikely to use them for the large riser modules and in the future may share work between the Slough and Doncaster fabs.

It seems that a lack of storage is a problem for most sites. At site we have almost no space, so the services subbies can only bring in a few cages to store on the floors they are fitting out – and that’s only if there is crane time.

On the subject of off site vs on site, I think that latter wins on the sole reason of continuity of work. It allows the manufacture time to be completely de-coupled from the structures. This allows for more accurate planning for man power and deliverables. On site the service installation is being delayed by the slow stripping of the form works. At present there is only one full level that has been stripped and 3 half levels. The subbies are not going to throw manpower at this project until they get clear runs as they don’t want to waste money on underemployed labour.

I’m with James on the vote for off site. The issue of storage in case of delays could be put to bad contract writing, or contract writing whilst thinking too wishfully, to a degree. Delays must be expected. Another big winner is quality, it is far easier to make a quality product in a purpose built factory environment than it is out in a muddy hole in Essex.