Archive

To PC or not to PC…. That is the question.

Sorry about the title. This blog is about the issues surrounding working on someone else’s site; something it seems that M&E engineers have to put up with a lot.

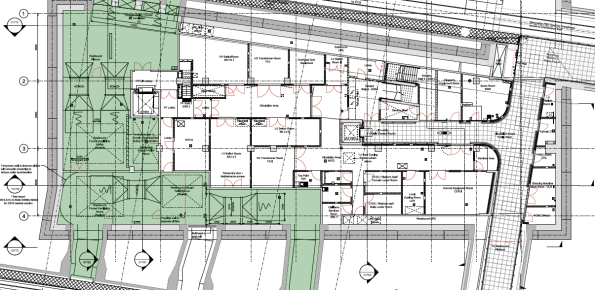

The work being carried out by my employer (ATC joint venture or ATCjv) involves installing a long term temporary ventilation system to replace a slightly cobbled together short term system – please see earlier blog. This involves fitting out most of the bottom floor of the station (level -4) with four ventilation fans, ducting and associated attenuators and dampers. See image below:

Temporary Ventilation Fan Installation

Co-ordinating the installation process has occupied most of my time for the past month. It involves threading the equipment through the existing ticket hall structure, most of which is still an active building site. As you can imagine this creates a nest of interfacing problems with the main site civils contractor, Costain-Skanska Joint Venture (CSjv).

The CSjv site is running to its own schedule and is unwilling to give up an inch of it to allow the tunnel ventilation works to go in. They have taken the step of insisting that ATCjv take Prime Contractor or ‘PC’ responsibility of our work area; leaving the unusual situation of a ‘Russian doll’ arrangement where we own and run a site four stories underground inside another separate site. The extents of the ATC site are shown below:

The ATC site shown in green (four floors underground in the CSjv basement)

The process of setting up the PC area was not smooth. Any readers who have yet to undertake the SMSTS course may be in the dark as to the requirements of holding PC of a site. The full requirements are on the HSE website here:

http://www.hse.gov.uk/construction/cdm/2015/principal-contractors.htm

Keeping it as brief as possible the PC is the ‘duty holder’ of legal responsibility of the site; they are required to produce and assure the health and safety of the workforce, compliance with environment and noise regulations, secure the site and provide welfare. The end result is a substantial pile of paperwork that no-one will ever look at unless an accident happens.

PC Paperwork. It’s what I joined up for.

I found it interesting to consider the depth and detail of site paperwork compared to that I remember being in place on RE construction sites.

The idea that ATCjv can setup and run a complete site in the middle of another fully functioning site is a bit silly. When that site is underground it is very silly. However, ATCjv have been instructed by Crossrail to do so: his brings around an odd situation that to use their welfare facility the workforce has to walk 1.1km along a tunnel and then climb to the surface to use the toilet (in reality they just find a dark corner of the tunnel!)

The Site Welfare Facilities

Digging slightly deeper (excuse the pun) it seems this arrangement has come about because the first work group to enter the site from ATCjv were roundly regarded as “cowboys” and managed to get a Crossrail H&S warning raised against them. The CSjv site basically looked for any way to transfer the perceived H&S risk over to ATCjv; this has then caused nearly two years of paperwork hassle for ATCjv to run and administer a completely separate underground site.

It seems that in construction first impressions are everything.

Well, the weather outside is frightful..

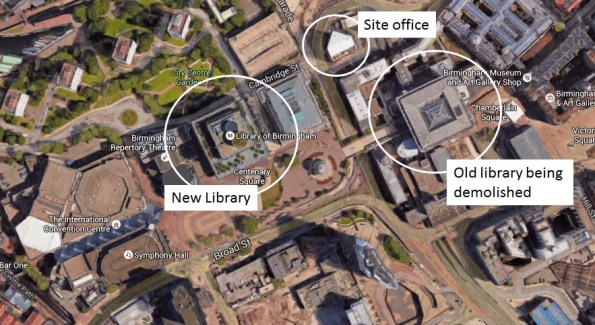

Defects – On our phase 2 placements we rarely get a chance to get involved with any maintenance or defect periods. This week however I have been lucky enough to be involved with a previous Carillion site that was finished in 2013, it helps that it is next to my current site, see Fig 1. The Library of Birmingham is the most visited tourist attraction outside of London, and it leaks like a sieve.

With the storm rains that we have been having, a defect has been identified where rain water is getting under the curtain walling on 2 floors with a terrace level. This is most likely through the service exclusions (sorry E&Ms but you do like to mess up a good impermeable box). I do not know the contract obligations that exist with this previous project, however Carillion have sent a team to control the ingress of water. The plan included puddle pumps, sandbags and cat litter, seriously, cat litter, enough for a pride of lions.

The issues that have arisen now include:

- What is the plan to stop water ingress during future storms?

- What was the design storm used and how did it compare to the weather experienced?

- Is it a design flaw or is there a construction issue?

- What are Carillion doing using a separate project team to fix the issue?

This immediate reaction has bought some favour with the library (Q4), but there will undoubtedly be a redesign and some work completed in the coming months. Watch this space and I will explain the contract obligations and where liability for the works and defects lie.

Breaking Bad Brisbane Style

So its been a hell of week here at Brisbane Casino Towers. The local residents have been high as kites, from throwing objects out of their balconies, jumping on to mobile cranes, breaking into our sub-contractors offices and stealing their laptops and now finally they have been busted for running a meth lab!

Brisbane’s finest displaying an interesting cordon.

Brisbane’s finest displaying an interesting cordon.

In my last post I mentioned that I have been placed in charge of removing the temporary struts and ground anchors. Believe it or not we don’t have any software for 3 D mapping and given that the problem is a three dimensional one I produced this for my meeting:

Its all hi-tech at Brisbane Casino Towers. (The numbers relate to order of pours and it’s used to explain the load path of the slabs).

The removal of the supports is a nightmare and sums up the project really. The props are designed by ADG, the anchors by QPS, the permanent slabs by BGE and the wall by Franki Pile (now known as the WALLAPs for their worship of the false god WALLAP). For me it is a great opportunity that has drawn the attention of the Regional Director but I can’t help but, feel that they gave it to me because it is something of a mission impossible and they would probably have to sack someone if it goes wrong – (Neil/John TMR2 coming your way). Anyway the meeting went well, I ran it entirely and the 3 chartered engineers were pretty complementary. I will go into more detail later but, this is only the start of it.

Oh on a positive note the we all went to see Australia v England at the Suncorp  I’m sure Izzy is concerned about the English defence and not that I have confiscated the Haribo!

I’m sure Izzy is concerned about the English defence and not that I have confiscated the Haribo!

It’s not all about the bike…

I’m currently reflecting on the last 15 months living and working in Oz whilst exploring the vast bush of WA.

I’m about to start day three of a 10 day epic trail ride from Albany back to Perth following the infamous 1000km Munda Biddi trail.

So far the terrain is akin to the UK’s green rolling countryside complete with similar weather – very wet and windy!

En route I have come across the more obscure Aussie road signs and Sappers Bridge.

220km down with a couple of easier days ahead before the epic 167km day 5!

What’s that Skippy? Someone’s trapped down a well?

Well, well, well… I have often found myself taking one step forward and two back as a direct result of working alongside a heritage building. Several issues have arisen but this blog will focus on one – a 19th Century water well.

Given that we are working on an old brewery site, some distance from the nearest river, the existence of wells is to be expected. What is most frustrating with this recent issue however is its location, see Figure 1.

Figure 1.

Figure 2 is an image of the well, after being ‘carefully discovered’ by an excavator. The well is approx 1.4m in diameter, the A3 clip board in the image gives an indication of the scale.

Figure 2.

Unfortunately, not only did the well caused me to cease works whilst the Archeologists investigate its historical importance, but it is located exactly where a tie back beam is designed to sit and almost exactly where a pile was designed to sit.

Fortunately the well issue has now been resolved. The Archeologists have conducted their assessment and have allowed us to continue and the clash with the beam and pile has been avoided. The well can be excavated to a reduced level sufficient enough to allow the tie back beam to bridge across it. The pile was required as part of a temporary piling bridge allowing us to use a 30t piling rig alongside the shoring wall. As a result of a separate issue, we have redesigned the foundation piles in this area, allowing a 20t rig to be used. The surcharge load resulting from the 20t rig can be resisted by the shoring wall without the assistance of a temporary piling bridge. The bridge and its piles are therefore no longer required – catastrophe avoided.

Project Update: A Relentless Pursuit for Cost, Quality and Time

Now TMR1 and Thesis Form A’s are out the way I thought I’d provide an update on placement progress and a few of the issues we have encountered along the way. As my title suggests many of these are occuring because of the relentless pressure on the construction team to deliver the project as quickly, cheaply and to uncompromisingly high quality . As we know from phase 1 something probably should be prioritised, unfortunately that doesn’t appear to be a well received strategy on site.

As you may recall (probably not) from my first blog we are using a top down methodology on the main Tower structure. Underneath the large Ground Floor (GF)slab we have unleashed the earth work contractors to crack on with the bulk excavation, taking our basement level from 9.0m OD to around 2.0m OD at its greatest point. This is a twelve week programme based on a target of moving 100 spoil vehicles away from site each day. The largest obstacle to this operation is not the digging or site movement of spoil, it is actually getting enough vehicles to and from site despite the constant challenge of breaking through London traffic. As such much of the earth is moved away at night which is probably proving a delight to our few local residents. To the sub-contractors credit they are doing well; they have their own exclusion zone so everyone else is able to keep out the way, which is useful considering the large number of excavators and dump trucks rattling around below our feet. Now they are underway tempo is impressively frenetic and as a result the ‘Bat Cave’ is taking shape nicely.

![IMG_0246[1]](https://pewpetblog.com/wp-content/uploads/2016/06/img_02461.jpg?w=595)

![IMG_0241[1]](https://pewpetblog.com/wp-content/uploads/2016/06/img_02411.jpg?w=595) The challenge of starting this process did throw up a nice on site leadership issue. After four weeks of hard work thrashing themselves to get the basement ready for commencement of this excavation , which they achieved, the junior construction team got a harsh email from a senior manager criticising quite a few trivial things on site. This inspired a near mutiny and, for a few days, a very inharmonious working environment. It was remedied by an honest, open conversation between various levels of management. One of the junior managers (not me I should add) fluctuated between near tears and incandescent rage when explaining his disapproval of the heavy criticism the on-site construction team was consistently receiving from, in his words, ‘Office bound desk jockeys’. Add a few favourite Aussie expletives in there behind the word jockey and you get the gist of his point. Everyone is now friends again, for the moment, but the unrelenting pressure applied by the project management team is starting to take its toll on morale. We shall see how long the current truce lasts.

The challenge of starting this process did throw up a nice on site leadership issue. After four weeks of hard work thrashing themselves to get the basement ready for commencement of this excavation , which they achieved, the junior construction team got a harsh email from a senior manager criticising quite a few trivial things on site. This inspired a near mutiny and, for a few days, a very inharmonious working environment. It was remedied by an honest, open conversation between various levels of management. One of the junior managers (not me I should add) fluctuated between near tears and incandescent rage when explaining his disapproval of the heavy criticism the on-site construction team was consistently receiving from, in his words, ‘Office bound desk jockeys’. Add a few favourite Aussie expletives in there behind the word jockey and you get the gist of his point. Everyone is now friends again, for the moment, but the unrelenting pressure applied by the project management team is starting to take its toll on morale. We shall see how long the current truce lasts.

Above the GF slab we have commenced structural steelwork on the main Tower, another key milestone. On Saturday six 20 Tonne steel columns were erected with a mobile crane. This was all going well until they realised that the lifting plates, temporary steel lifting connections attached to the head of each column, were fabricated in the wrong orientation. Fortunately, with use of a heavy duty steel drill and an extra few hours the issue got fixed and the columns were placed upright in the correct position. Drilling extra holes into precision fabricated steel elements on site isn’t an elegant solution but it worked. Now the columns are in place steel beams are starting to fly in (not literally of course) and the skeleton of the ground floor structure is rapidly taking shape. The steel erection is surprisingly quick and they are clearly a well-rehearsed team. Floor one will hopefully be complete in a few weeks, at which point we will have only 39 more storeys to go!

Above the steelwork the east slip form rig of the large central concrete core has begun to rise once again. Its currently at floor 8 and will pause at a pre-determined hold point on floor 10, allowing the western component of this core to catch up. We will not be able to progress the core beyond floor 10 until the pile cap is constructed in the basement. This controls the vertical load through the exposed plunge columns in the basement, primarily required to prevent them buckling which is obviously bad when you have 10 storey’s of reinforced concrete suspended on them. Once the pile cap is constructed the effective length of these columns is gradually reduced which allows us to increase the axial loads and continue the progress of the slip form.

We have also increased the Tower Cranes on site from 1 to 3. To make things more challenging we selected self-climbing cranes, one suspended inside each core. These effectively hang off the walls of the cores and climb up the lift shafts behind the slip form rig. Unfortunately this is reasonably new technology in the UK and nobody really understands the process for each climb or how long it will take. We really are making much of it up as we go along. What we do know is that if we don’t figure it out soon then the slip form rig will catch up with and hit the crane. This is problematic. The other excellent news is that our three cranes are all pretty much aligned on the same axis and therefore clash frequently. Trying to figure out which crane can do which task without impeding other works is like a giant Crystal Maze puzzle with no solution. This problem has an impressive number of intelligent people very confused for most hours of the day.

And in final news we had a very serious accident on site. A scaffold contractor fell roughly seven metres through a hole in the GF slab and into the basement excavation. I’m told that’s far enough to know you are falling before hitting the ground, which is obviously a long way. The investigation is ongoing so I can’t really add anything else other than that his injuries are, luckily, fairly minor considering the distance he fell. He landed on soft, loose soil which was very fortunate indeed. Had he hit the large item of plant located close by it probably would have been a different outcome. Without going into the details it looks like a freak accident, that said it proves the point that if something can go wrong, give it enough time and it probably will. Be careful out there folks!

In summary, tempo is relentless in order to maintain programme, quality cannot be compromised and the cost must be controlled. This all adds up to a very challenging construction project with lots at stake. More to follow once the excavation hits the pile cap OD.

Phase 3 Concluding Blog

My time on phase 3 is drawing to a close (3 weeks to go) and phase 2 have now been on site for a while and are possibly starting to consider their options for phase 3. I thought it might be worthwhile blogging about finding a phase 3 placement.

I’ve been attached at a company called Bryden Wood Limited. Bryden Wood is a small consultancy with approximately 80 employees split across four offices (London, St Albans, St Petersberg and Singapore).

How did I find my placement?

I used contacts I made whilst on phase 2. Carillion’s M&E design manager at Battersea had worked in consultancies previously and used his contacts to get me an interview / informal chat at BWL. That chat was pretty pain free and was as much about me confirming that BWL could for fill my requirements. Other options that were open to me but that I didn’t follow up were working for Carillion’s consultants. I didn’t pursue that option as I felt there would be too much risk of being sucked into working on design associated with Battersea.

Advantages of working at Bryden Wood:

The advantage of working for a small company like Bryden Wood is that I don’t feel like a small cog in a huge unwieldly beast (which was often the case at Battersea). The projects I’ve been involved in have been relatively small in size, which means I’ve had a great deal of autonomy on them, which has been very useful for gaining experience. The company also doesn’t feel particularly corporate and has a family feel to it, which makes it a nice environment to work in.

Downside / Risk of working at Bryden Wood:

The main downside of working for a small company like Bryden Wood is that there is a bit more risk in terms of the amount of work available. We’ve had a few projects put on hold, which has led to contractors and permanent staff being laid off. This has led to the number of projects I could get involved with being reduced, that being said I’ve never been without work; although for my last two weeks it looks like I’ll be doing some pretty mundane CAD work.

Potential Opportunities

In summary I think my attachment at BWL has worked well. Although I’ve not covered as many projects as I thought I would do at the start of phase 3 I think I’ve covered enough – the proof will come in a few weeks at CPR. I still stand by my decision to go for a smallish firm. I’d recommend BWL to any M&Es looking for a placement in London or Hertfordshire. I’d be more than happy to make introductions if anyone wanted look at them for a possible phase 3 attachment.

I want problems not solutions!

Not much to report on my site due to construction delays resulting in no on-site E&M activity and so my days are currently spent reviewing tender bids and checking designs. So instead of blogging about something interesting happening on site I thought I would write about a little ‘wrist slap’ I got the other day which for me highlighted a key difference of how we as Army Officers sometimes ‘do business’ compared to Engineers and Project Managers in industry. I hope this may serve as a warning to others or the Phase 1s.

Last week I was reviewing the mountings for three 11T chillers and calculated that they had a uniformly distributed load of 14kN/m^2 which exceeds the slabs design load of 9kN/m^2. Also these chillers are mounted in the centre of the slab and exert a maximum point load of 31kN which again exceeds the specified design loads.

Since we are under a management-only contact, the responsibility for the design of steelwork mounts or slab reinforcement lies firmly with the Principle Designers, in this case BDP. So I wrote an email to BDP explaining the problem and in good Army Officer fashion, I didn’t just point out an issue but also suggested 3 possible solutions that we in the office had been discussing based on the specification of the selected chillers which up to now the designer had no visibility of. So, a job well done thinks I and I move onto another task until the designer replies with a developed course of action.

Anyway, within a few hours I received an email back from a member of the project working for Skanska instructing me to not ‘suggest’ potential solutions in future correspondence to the designers. This is because the designer (who is getting a reputation for cutting corners and doing as little work as is possible within the confines of the contract) will likely read the email and just choose one of my suggested solutions without investigating it further or developing a detailed design as I had hoped. Furthermore the designer would likely list Skanska as being responsible for this design change which would ultimately result in Skanska unknowingly accepting a significant design risk. Oopps!

So from this I have learnt that although some of the methods we have developed in the Military are generally very useful and well received in industry, we still need to be careful as they may not always be the most appropriate and we cannot always assume that those around us will also act in a similar ‘good ole military fashion’.

Who turned off the power?

Situation

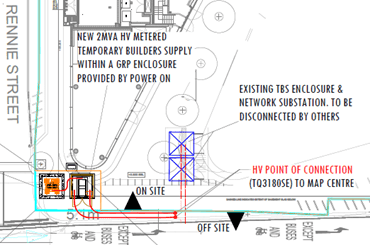

Laing O’Rourke (LOR) originally constructed the original substructure (75% of the 3 floor Basements) and installed the Temporary Building Supply (TBS) consisting of an enclosure and network substation. It was positioned in an area that would not conflict with the original substructure works but it would need to be moved before LOR returned to site to complete the substructure.

Reflection

Brookfield inherited the site from LOR and have been entirely focused on the construction of the tower. In the process they have neglected to carry out sufficient analysis regarding the temporary power and realising the potential impact. The TBS and RMU should have been moved earlier in the programme or the temporary power layout should have considered the future move.

Instead the project has progressed and increased the impact of the pending change by having more steel wire armoured (SWA) cables installed directly from the Ring Main Unit (RMU) to the large plant, cranes and hoists, wet riser system and welfare facilities.

Issue

Power On (HV specialist) and UK Power Networks (District Network Operator) were required to do the majority of the works to install the new TBS (1x 2MVA transformer). In order to switch the HV connection from the old TBS all the power to the site needed to be isolated.

Mitigation

In order to reduce the impact of the power outage the option of hiring 2x 500kVA generators was taken. The problem of siting 2x generators on a construction site was finding 6m2 of flat ground with enough strength from the concrete slab. The area North of the new TBS was identified, Aggreko (generator sub-contractor) visited the site, agreed to install the generators with extra fuel capacity by conducting the lift from Rennie Street.

When Aggreko delivered the generators, the Crane Op was unable to place the generators from Rennie Street. Therefore the decision was taken to conduct the lift from the pit lane and site one generator. It caused problems for the deliveries on that day but ultimately prevented a larger problem from unfolding.

Environmental

This was raised and checked by the Environmental specialist on site:-

From 1st September 2015 construction projects within the Greater London Area are required comply with the London Low Emission Zone Non-Road Mobile Machinery (NRMM) requirements. All NRMM with an engine net power between 37kW and 560kW must meet minimum standards in terms of exhaust of Nitrogen Oxides and Particulate Matter. All qualifying plant must be recorded in an online register and those that do not meet the require standard have to be replaced.

Anyone else experienced any emissions restrictions?

Oz PCH – Subbies not getting paid…never!

I saw this in this week’s The Western Australian and thought it worth a share…

If the print is too small to read is summaries that JHG are submitting false statutory payment declarations to the State Government of WA (the client). This particular subbie is owed $335k for works completed and there are others who also claim they are owed for work but are reluctant to speak out while they hope their disputes can still be resolved.

There is also talk about the façade subbie, Yuanda who are reported to be owed $12 million. However, this is due to a dispute over a number of faulty/damaged panels. I think JHG are worried that the cost involved of replacing so many panels is not worth what Yuanda would stem to lose and so fear they would just walk away and not bother – hence JHG withholding payment – which we all know, to use Australian slang, is just not cricket.

The devil will be in the detail and the report goes on to say that the Auditor-General’s review found JHG had presented “reasonable” grounds why amounts claimed by subcontractors had not been paid.