Home

> Uncategorized > Spot the mistake

Spot the mistake

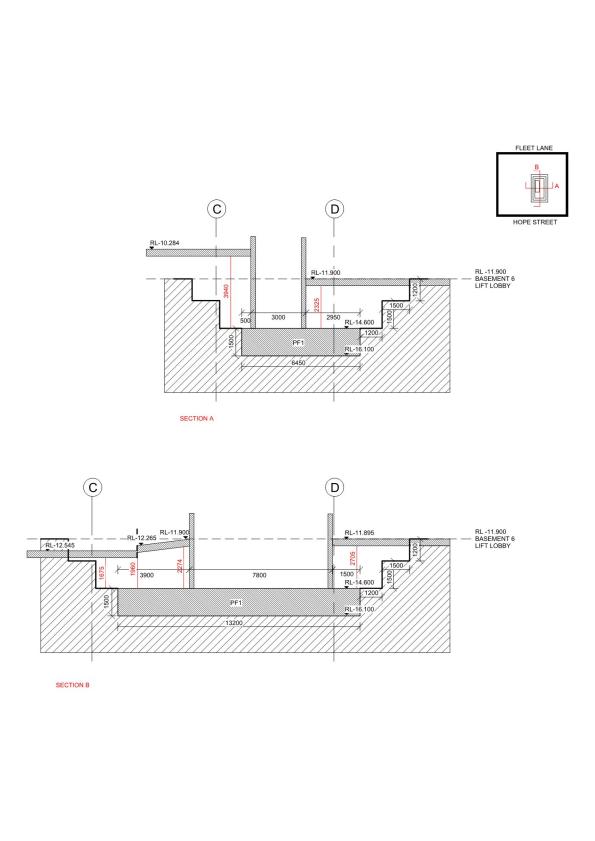

The sub-contractor wants to backfill the core (big hole in the picture) with spoil from on site to support the slab on ground that will be locked into the lift core. The core is currently open with 1.5 m benches down the base footing and the backfill will be approximately 3 m deep.

The material is crushed phyllite which has ended up like brown clayey GRAVEL. I needed a CBR of 15 the CBR rating indicates 20, what did I miss. CBR link.

I was talking to the Geotechnical Engineer when I discovered that I am idiot (we already know that my subbie is an idiot). Hint the core is likely to be wet.

Categories: Uncategorized

That looks safe! The sensible ladder access is my favourite element of that photo, closely followed by the three heavy machines all piled up next to the hole. The excavation doesnt look retained though I could be wrong. I’m struggling to understand what you intend to acheive with the backfilling? Are you not constructing the pile cap with reinforced concrete? Assuming you are I would expect your pile cap will take some time to construct, given its likely to incorporate a fair amount of Re-bar fixing. You’ll therefore have a decent number of subbies sat in an unretained hole fixing re-bar for a period of time? Is that right? We have a similar task in london clay but have just started sheet piling before commencing excavation of the core cap.

Tom

PS: And are you only supposed to have one layer of props on the main excavation?

PPS: Is there any edge protection around that hole?

Nope but good stab from what you can see, the concrete barriers are over 2 metres away and so is the orange mesh fencing and in an excavation zone (northern half of site). The ladders are fixed at the top and bottom so while it’s not ideal, it’s safe. The benches have been geotech approved and are at standard 1.5 m benches so effectively a 45 degree slope (see diagram) and fall from height is mitigated. The machines are parked over 5 m from the excavation so will not impact upon the steel workers.

The core is being filled by a pad footing so you are right, there will be plenty of steelies but the site has some prep to do before the are let in. There is blinder and hydraulic sealant that still needs to be added first.

Hint the slabs tying into the core, are not suspended they are slab on ground so need to rest on something. That is where the fill comes in.look at the CBR.

Your putting a clay-gravel material into the void and casting a slab on top which is locked into the lift core. The soil will swell when it is wet – very likely – where as the core is likely to settle due to the axial loading. The fact the slab is locked in and not suspended means it wants to move down when the core settles but it is on top of expanding soil trying to push it up?

Spot on Jo, I would say top of the class but you are. The clay will swell by approximately 20 mm and exceed the limitations of the slab. The swell is not excessive in UK terms but they haven’t heard of clayboards out here. So what other options are there?

http://www.parchem.com.au/construction/product/foundation-formwork-systems/eccovoid/i/175/

I assume the slab will be structurally sound to supports it’s own weight without the soil underneath in the long term. Can you not fill to within a tolerance then use something like this product to support the concrete during curing? We have a similar issue in that the core and stability columns are likely to settle to a greater degree than the podium columns due to the huge axial loads. Our design incorporates suspended slabs on corbels rather than locking them into the main stability structure.

My back up plan was use stabilised sand the. Fill the remainder crushed phyllite. This is a commercial shit storm and may make another good TMR. We don’t want them to use the phyllite at all. It’s due to rain here and it turns to crap. Laying it down and compacting takes a long time so it’s a game of chicken with the subby. there LDs are $15k a day ours are now $36k. so we are paying for stabilised sand and pea gravel to speed it up. I was in with the regional director today discussing options. The stabiles sand and gravel will cost ‘$60k and save us probably 4 days on critical path. Our LDs are at $1.5M at the moment so we are fighting to get time back.

Oh and I wouldn’t bet on anything at the moment. I may have to build over and bury some anchors.