Spot the mistake No 2

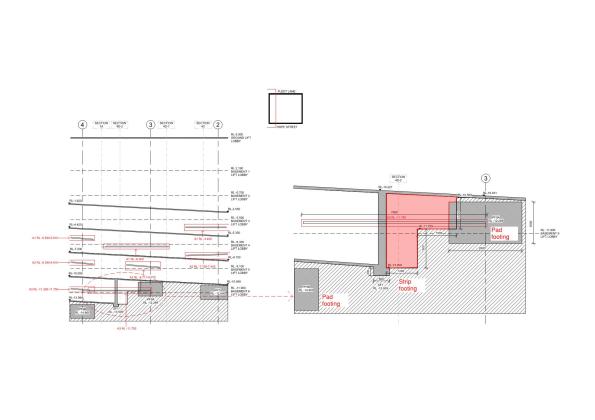

I am beginning to dread Monday mornings!We are just about to backfill the core and are in the middle of a commercial minefield. We have 50% of the footings complete and 30 % of the slab on ground, with the southern half of the site still bare rock and some more excavation to get down to bulk.

I am dealing with the restraint of the secant pile retaining wall on my site and I was asked to look at a build sequence to remove the anchor waler, that is going through the strip retaining wall. The very helpful wall designers then told me that I had to build the slab above then remove waler. Now this is designed as a slab on ground and the area in red needs to be backfilled. So I challenged that I only had to backfill to the bottom of the waler with compacted fill- They conceded.

Hurrah – smug for no reason, I go about my business until one of my cadets asks me how the wall is tied into the central core as there are no details of the connections. Now I am not in charge of this wall as it belongs to the ‘lone ranger’ but, he wasn’t interested in what cadet had to say (the cadet is exceptionally bright). I also know this wall is 18 m long and nearly 3 m deep and cannot be supported by the lift core and the secant pile wall. So how is it supported?

Smelling a rat -I check with the Project Engineer who tells me it doesn’t need to tie into the core as it is supported by the slab on top and bottom. What did they miss and how should I solve the problem? I look forward to hearing your suggestions.

Plan view here S-CD-10-001_3-Markup Retention wall

I’m afraid I am struggling to understand the question Doug, let alone suggest answers.

I can have a stab: one bag of sand, two bags of gravel, half a bag of cement?

In seriousness look at what the forces are then ask during construction how are these resolved?

I’d love to Doug, but do not understand the terminology.

How does the wall stand up when you are lobbing in soil and compacting on one side and the slabs are not built?

Doug – That question makes it clear. Interesting problem. For some reason resolution of the image is poor. I now see the right hand one is a blown up version. You are missing some stiffness, or supports during backfilling.

Have you done a sort of gravity retaining wall to check that the wall will actually not be stable? Has the wall been cast – if not a greater embedment will help.

I assume you have looked at temporary props (raking or level)? What about geogrid on the inside of the core to increase shear resistance of backfill material?

I will see what I can do about the image – it looked ok on my Ipad but I have just seen it on my computer.

The strip footing is 600 mm wide and the wall is 3 m high – so it is not an effective retaining wall in its present design. The bench is 1200 mm away to allow for the formworkers and before you ask they don’t do single side formwork in Queendland. Otherwise we could have single formed and poured it up.

Greater embedment will mean a dramatic change in design and methodology and potentially risk undermining the secant piles in a really sensitive location (14 storey building 2.5 metres away).

Geogrid – would you not need to compact and would there still be a lateral load of some sort on the wall. A risky option?

Things not mentioned. Extending the pad footing towards the bench to make an L type retaining wall. I initially looked at this this back filling but it would need to go back 2/3 of the height so 2 m so not a low cost option.

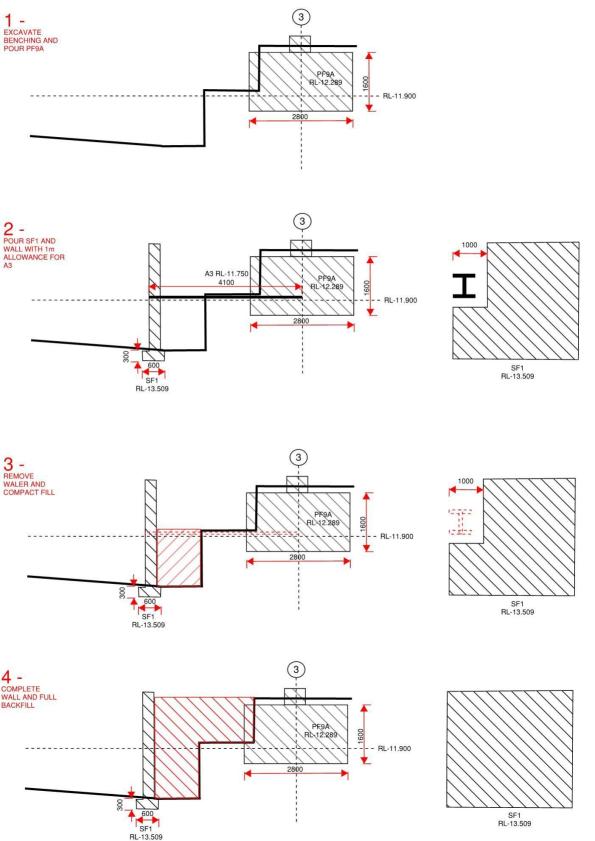

Raked props – this is where we are going once we have removed the formwork. The key thing is that this needs to be deigned for and up until the cadet asked a question about a connection noone knew this was a risk.

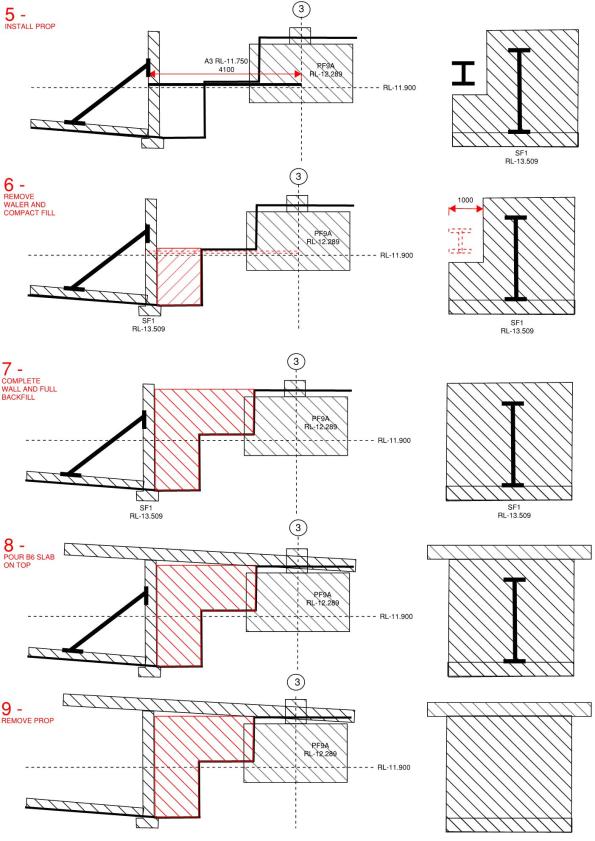

I have added the build sequence for backfilling that should be clearer. That may highlighlight the issue.

Doug, thanks i will have a look at the sequence. it will be interesting to see how this gets formed. A good example of needing to know how the thing is to be built. Were there any CDM (or equivalent) things mentioned about this in the specification / on drawings? I would have thought this was a residual design risk.

You would think so wouldn’t you?

As I said not my responsibility but as the site troubleshooter it now is.

Doug

I am afraid I may not fully understand the issue – was the original design intention to complete the left slab first before backfilling to the right of the wall and then completing the right side slab?

I don’t think there was that much thought put in. The Lone Ranger didn’t consider the waler for the ground anchors that cuts through the wall or how it retains itself during construction. But I believe he thought this was a suspended slab.

Doug

I cannot expand you photos and so I find it hard to follow

Kind regards

Neil

I have made the PDFs into JPEGs the first build sequence was what was originally proposed and the second is the new updated builld sequence with a suspended slab initially built on the backfill to remove the need for formwork and time consumming backfill. The backfill will consolidate over time and leave the slab suspended.